Lithium ion battery anode material and lithium ion battery prepared therefrom

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of increased battery temperature and internal pressure, irreversible changes in the structure of positive active materials, explosions, and combustion, etc., to improve durability The effect of overcharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

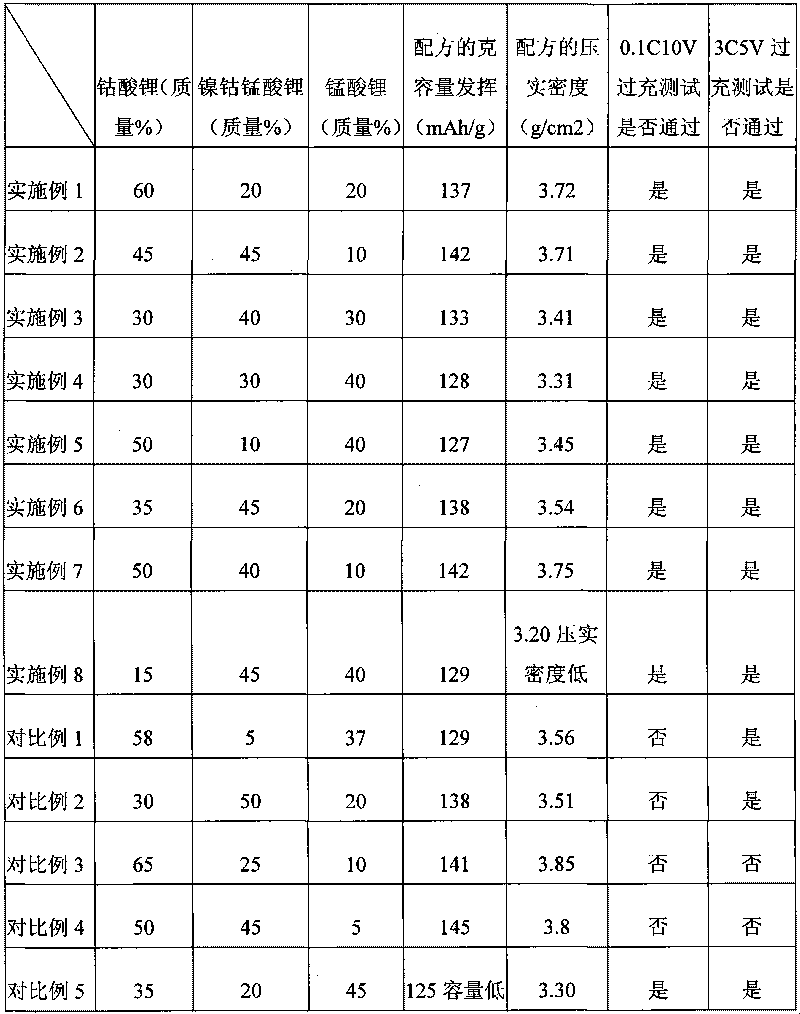

Examples

Embodiment 1

[0025] According to parts by mass, 6 parts of lithium cobalt oxide, 2 parts of nickel cobalt lithium manganate, 2 parts of spinel lithium manganate, 0.4 part of conductive carbon black and 0.4 part of polyvinylidene fluoride, N-methylpyrrolidone was used as a solvent, prepared into a slurry, coated on 16um aluminum foil and dried. The molecular formula of the lithium nickel cobalt manganese oxide that this embodiment adopts is LiNi 0.5 mn 0.3 co 0.2 o 2 , wherein the particle size D50 = 4.526um.

[0026] The pole piece is continuously rolled, cut, and super-welded aluminum strip to make the positive pole piece.

[0027] The negative electrode sheet used is graphite negative electrode.

[0028] The electrolyte solvent system used is a multicomponent mixture of ethylene carbonate (EC), ethyl methyl carbonate (EMC), and dimethyl carbonate (DMC), and its mass ratio is EC:EMC:DMC=1:1:1 , the electrolyte adopts LiF 6 PO 4 .

[0029] Wind the positive electrode sheet, negati...

Embodiment 2

[0035] This example differs from Example 1 in that the mass parts of lithium cobalt oxide, lithium nickel cobalt manganate and lithium manganate are 4.5 parts, 4.5 parts, and 1 part respectively, and the rest are the same as in Example 1. The experimental results are shown in Table 1.

Embodiment 3

[0037] The difference between this example and Example 1 is that the mass parts of lithium cobalt oxide, lithium nickel cobalt manganese oxide, lithium manganate, conductive carbon black, and polyvinylidene fluoride are 3 parts, 4 parts, 3 parts, and 0.35 parts respectively. Parts, 0.35 parts, the molecular formula of lithium nickel cobalt manganese oxide is LiNi 0.8 mn 0.05 co 0.15 o 2 , wherein particle diameter D50=3.540um, all the other are with embodiment 1. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com