Patents

Literature

64results about How to "No reduction in capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

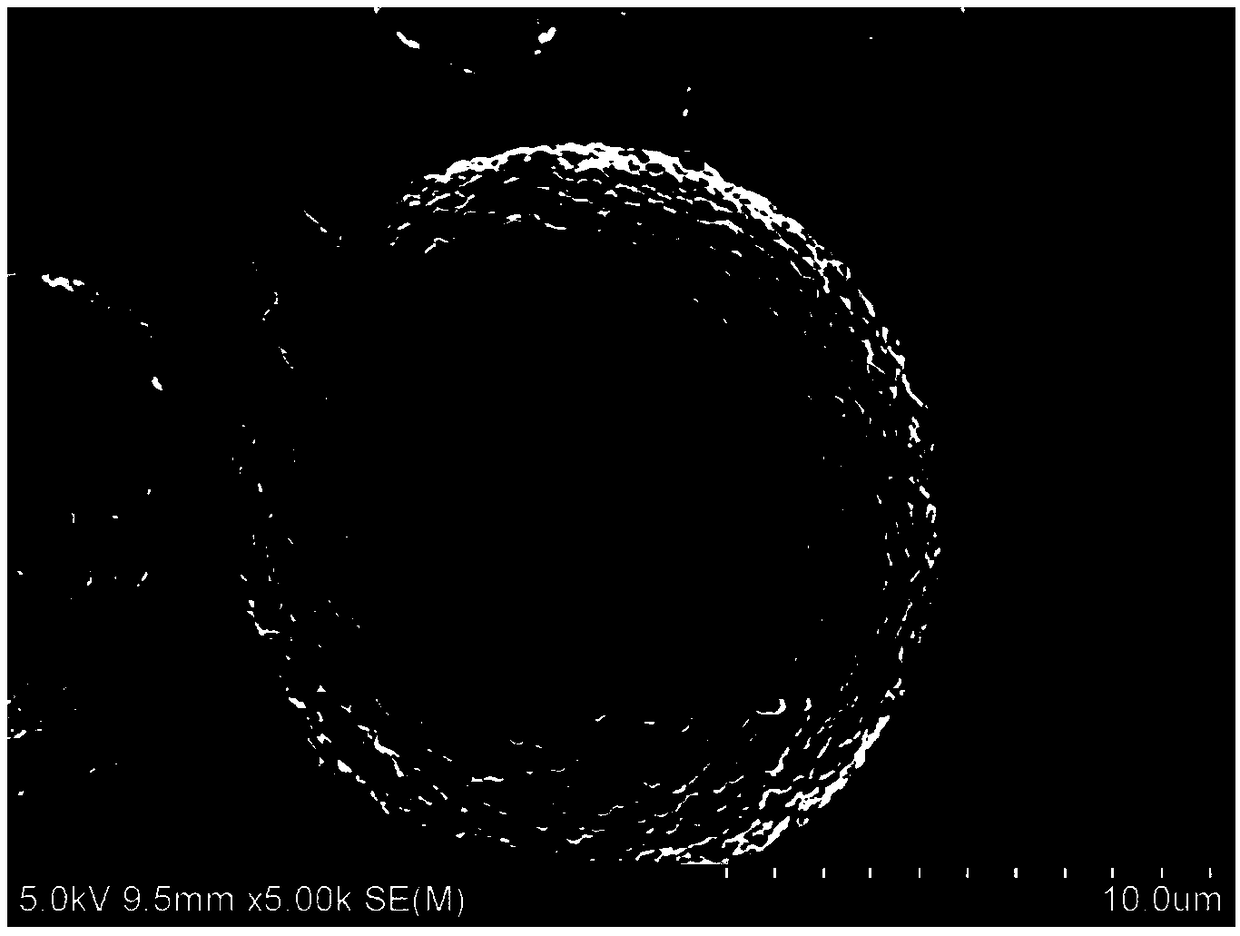

Lithium titanate composite electrode material with surface coating layer

InactiveCN101764209AChange physical propertiesChange chemical propertiesCell electrodesMagnesium phosphateMagnesium orthophosphate

The invention relates to a battery electrode material, in particular to a lithium titanate composite electrode material with surface coating layer; in the lithium titanate composite electrode material with surface coating layer, the electrode material is composed of lithium titanate particles and a coating layer coated with the surface of the lithium titanate particles; the particle size of the lithium titanate particles is 100nm-95mum, the average thickness of the surface coating layer is 0.2nm-5m, and the particle diameter of the composite electrode material is 0.1-100mum; the material of the surface coating layer is one or mixture of more than one kind of insulation oxide, insulation composite oxide, aluminium phosphate, magnesium phosphate, lithium fluoride, lithium phosphate or LiMPO4, wherein M is magnesium, ferrum, cobalt, nickel, chromium, titanium or vanadium; in the invention, by carrying out surface coating treatment to the surfaces of the existing lithium titanate particles, a layer of protective film is formed on the surface, so as to change the physical and chemical characteristics of the surface of the lithium titanate active material, the surface can not be reacted with electrolyte even if under overpotential condition, so as to avoid ballooning and ensure the capacity and the circularity of the battery not to be reduced.

Owner:SUZHOU PHYLION BATTERY

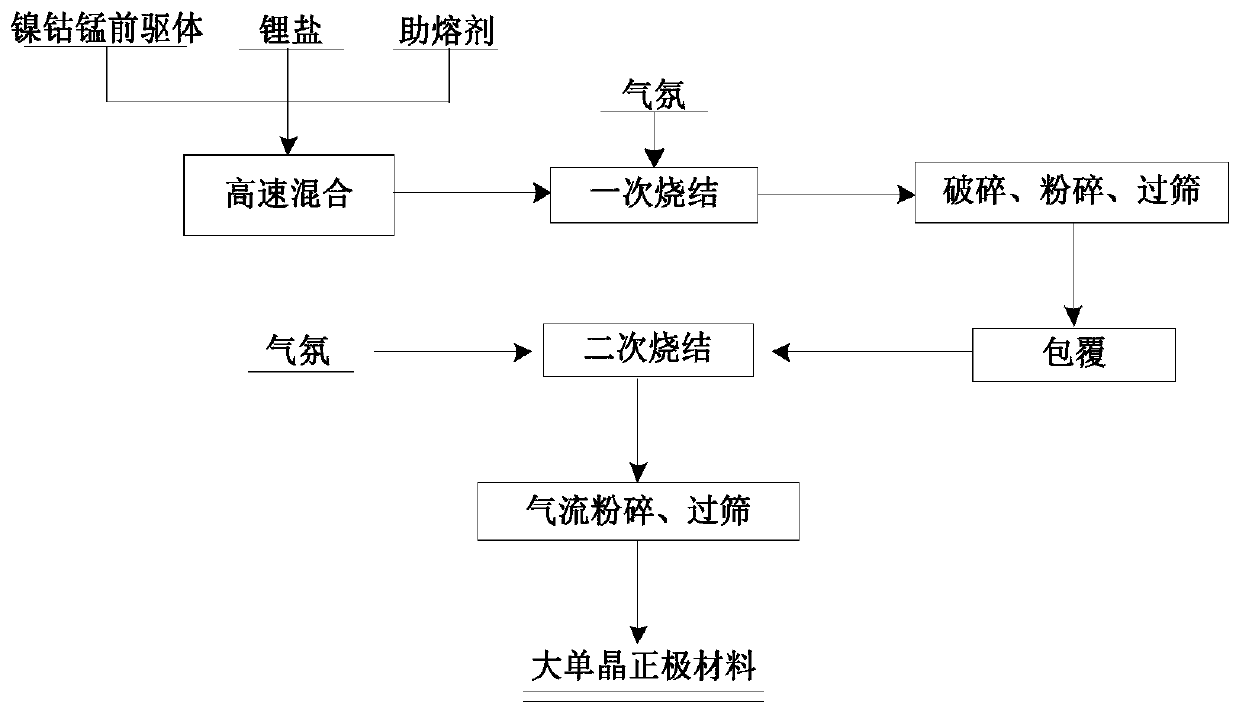

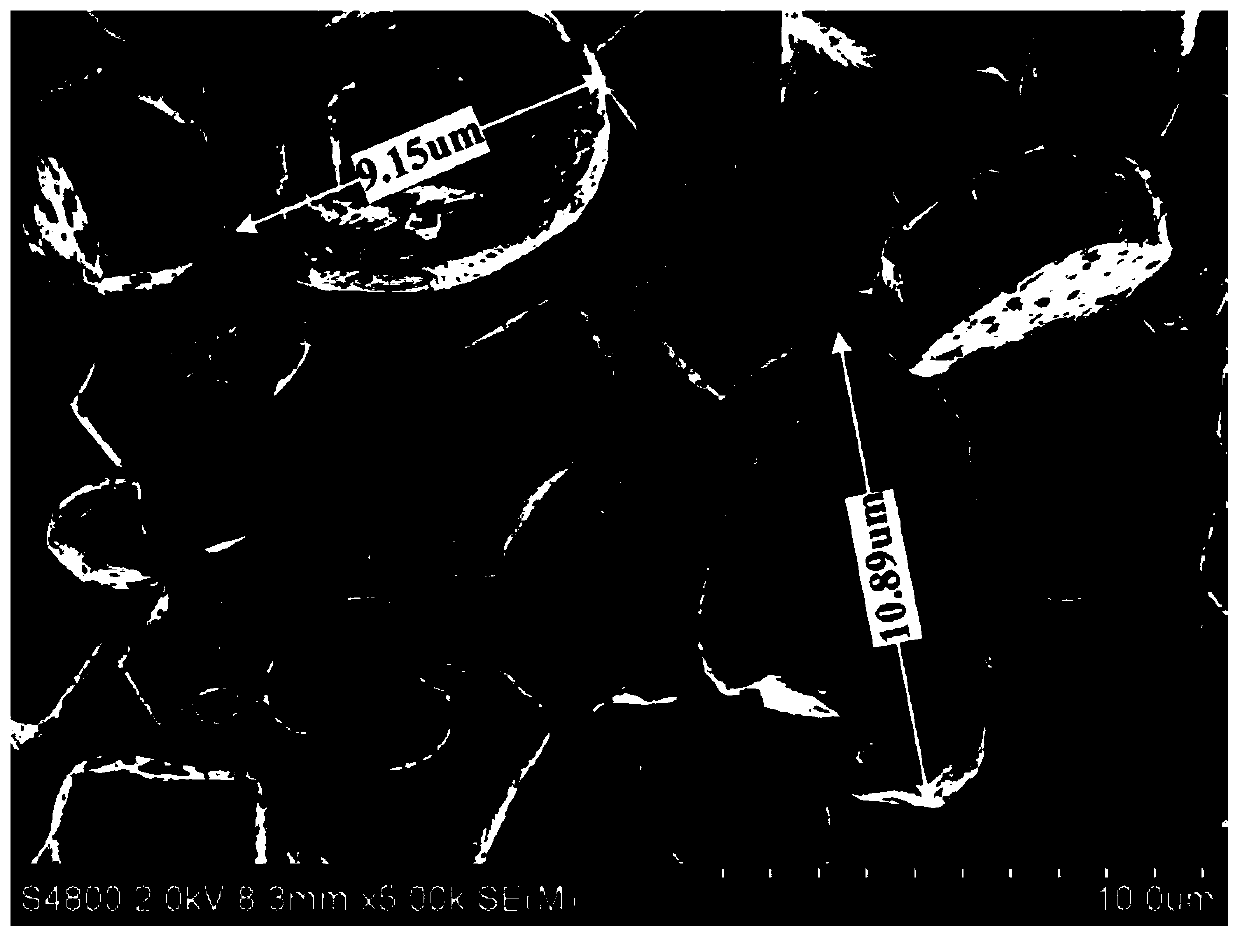

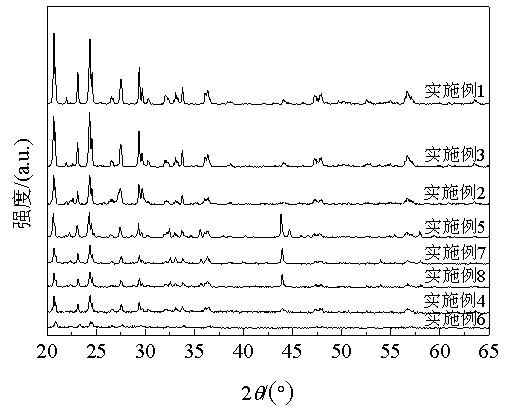

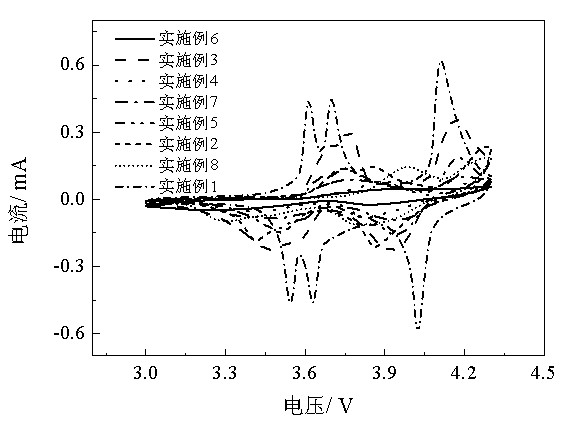

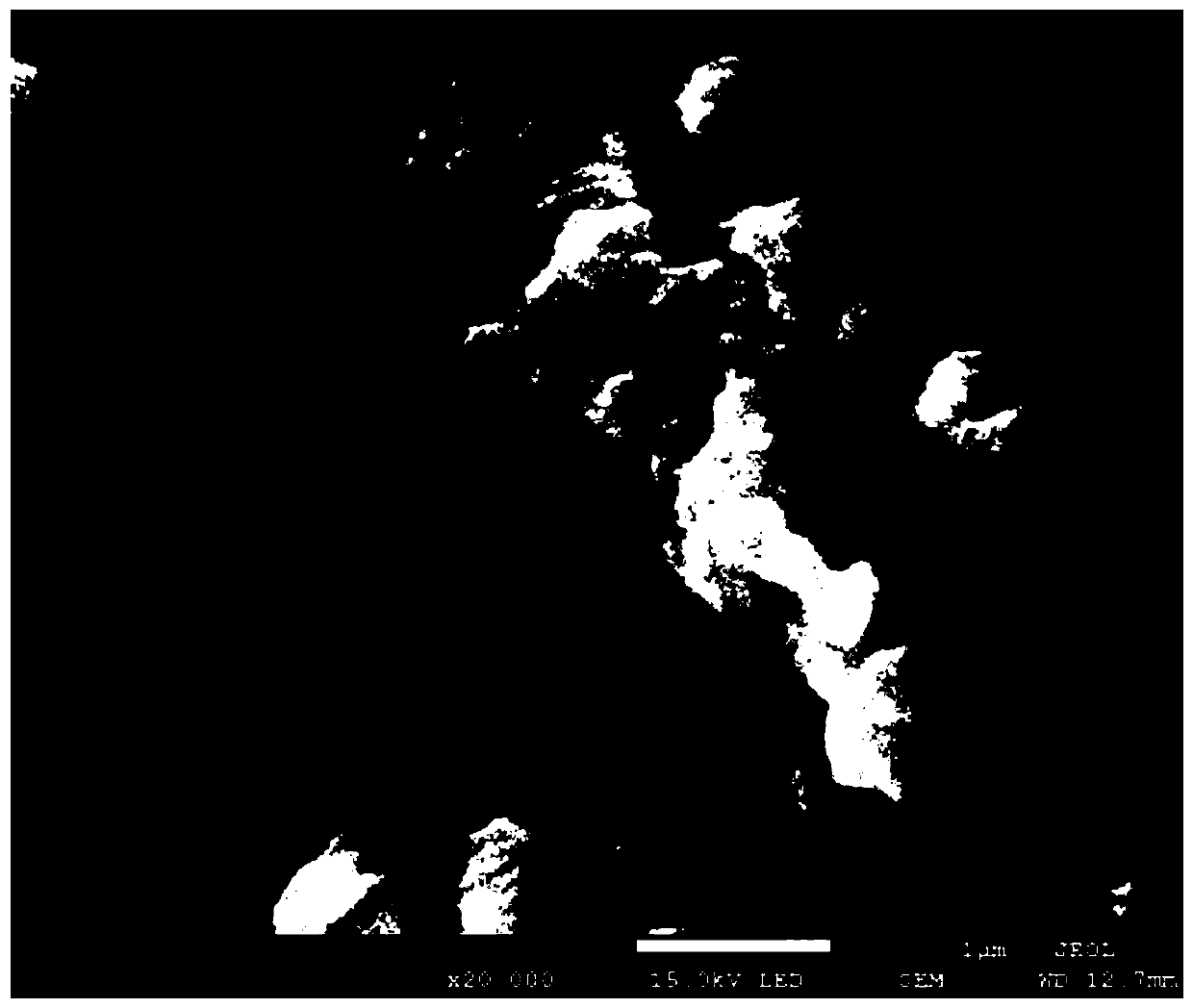

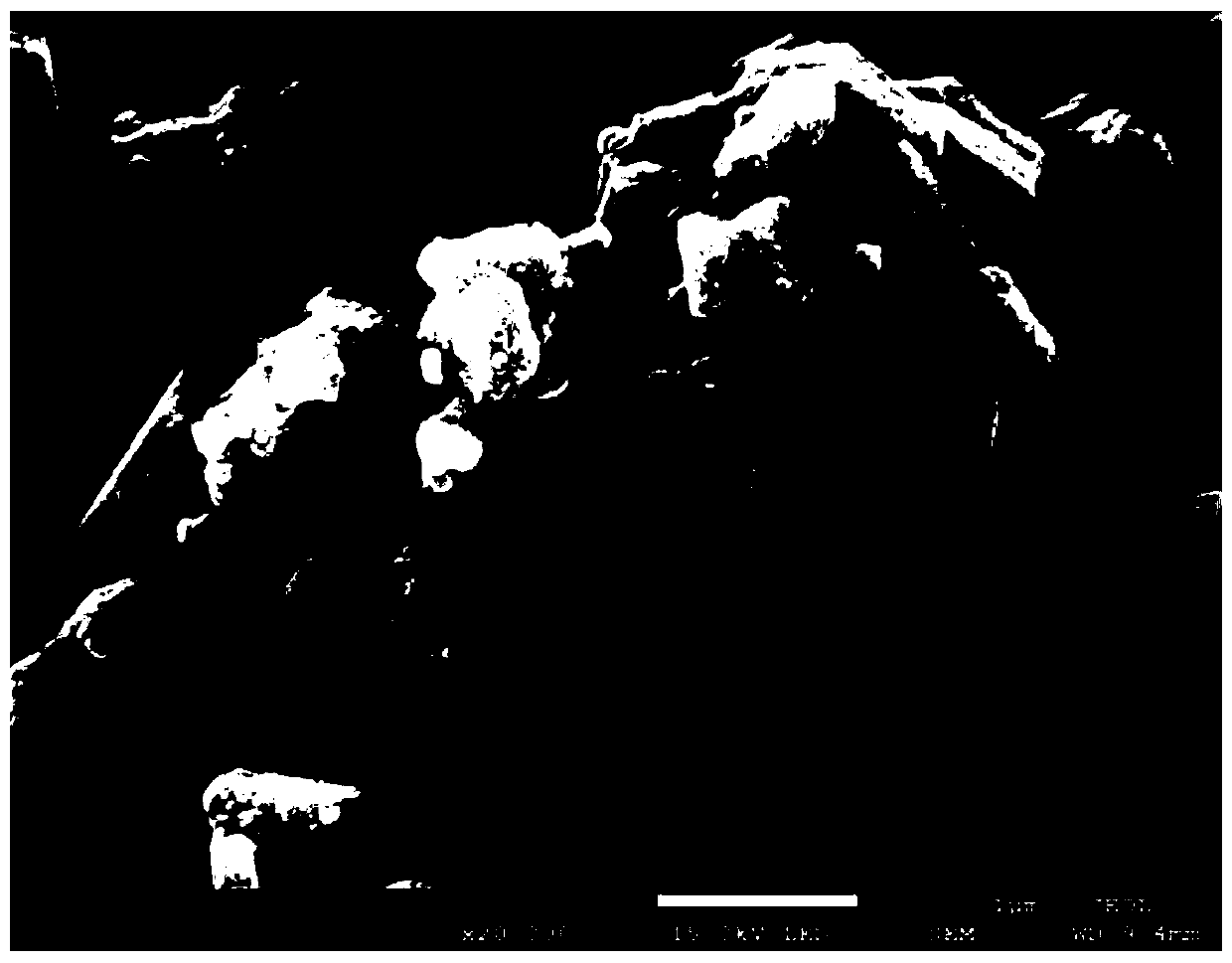

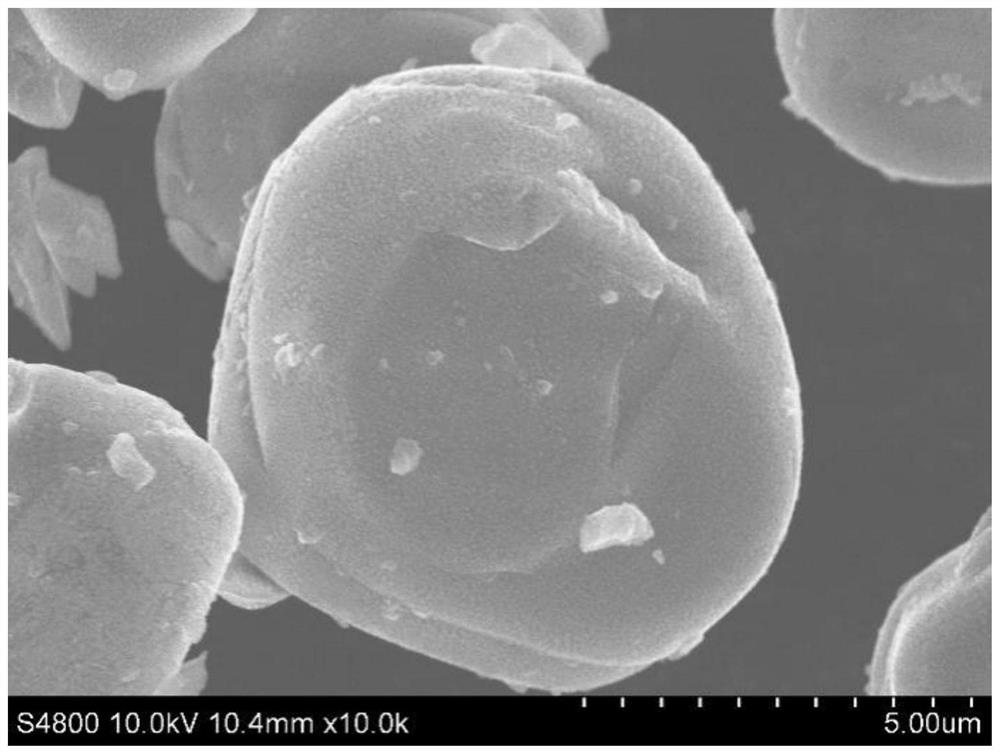

Preparation method of large single crystal lithium ion battery nickel cobalt lithium manganate cathode material

InactiveCN110534733AUniform thicknessHigh crystallinitySecondary cellsPositive electrodesDispersityManganate

The invention relates to a preparation method of a single crystal lithium ion battery nickel cobalt lithium manganate cathode material. The method comprises the following steps of: (1) taking a small-grain crystal spherical NCM ternary precursor, a lithium salt and an A element-containing nano fluxing agent as raw materials, uniformly mixing the raw materials by adopting a dry-method high-speed mixing mode, and performing primary sintering under an oxygen-enriched atmosphere condition; (2) subjecting the sintered material to jaw breaking, roller pairing, crushing and sieving so as to obtain asingle-crystal once-sintered base material; and (3) mixing the primary sintering base material with a B element-containing nano coating agent, sintering again under an oxygen-enriched atmosphere condition, and then performing jaw breaking, roller pairing, crushing and sieving to obtain the large single crystal lithium nickel cobalt manganate cathode material. The cathode material prepared by the invention has the characteristics of the large particle size, the good dispersity, the moderate specific surface area, the high compaction density, the high voltage, the good high-temperature cycle performance and the like.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

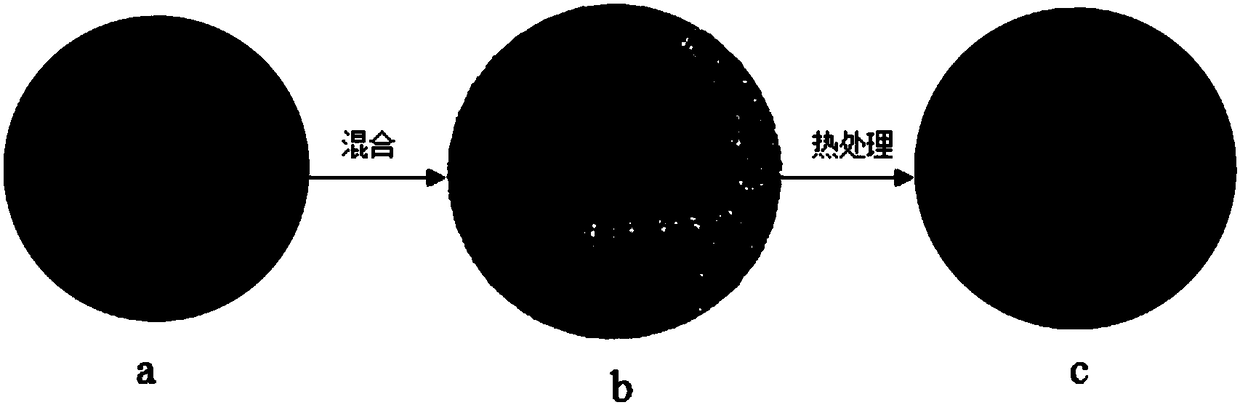

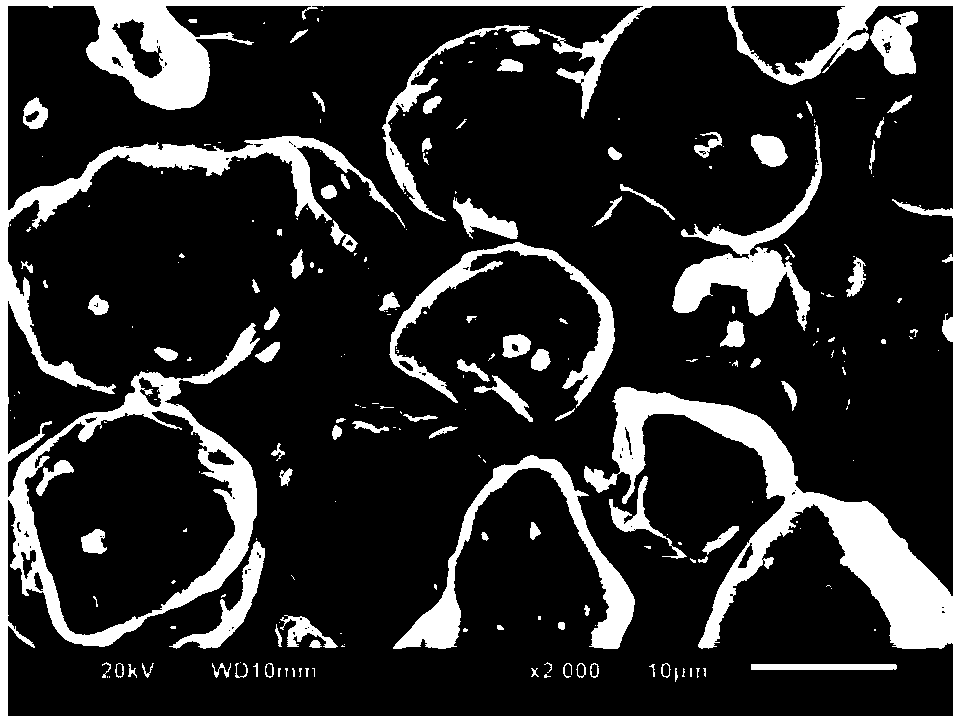

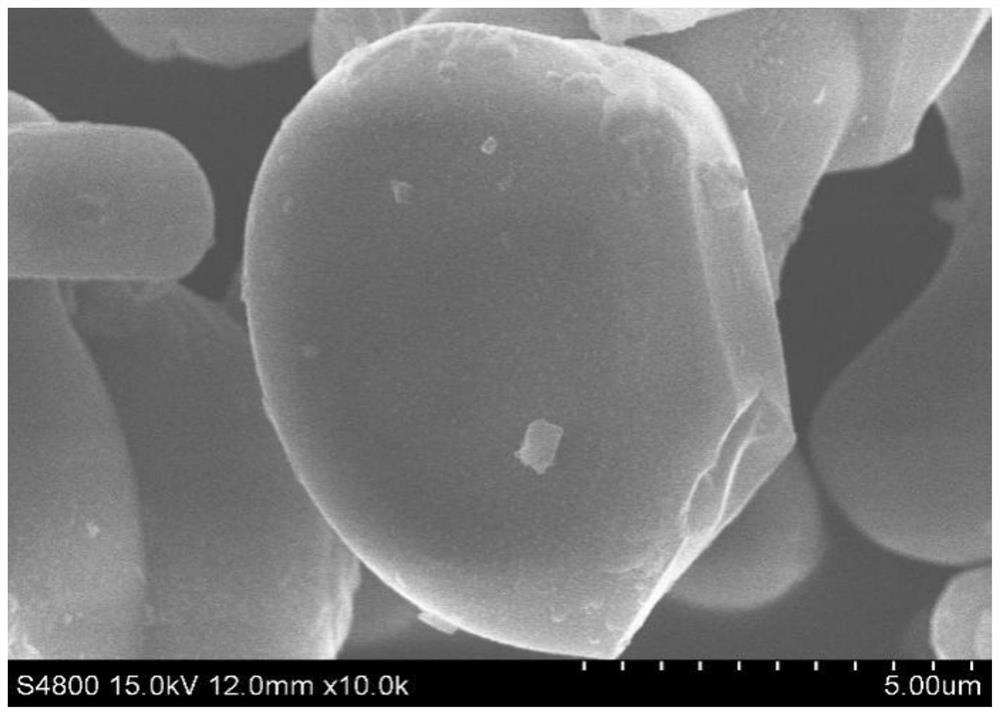

Lithium cobalt oxide material of core-shell structure and preparation method of lithium cobalt oxide material

InactiveCN108232127ANovel structureNo reduction in capacityCell electrodesSecondary cellsLithiumCore shell

The invention discloses a lithium cobalt oxide material of a core-shell structure and a preparation method of the lithium cobalt oxide material. According to the lithium cobalt oxide material, both the core and the shell of the material are made of lithium cobalt oxides as substrates, the core is optionally doped with a doping element A, the shell is doped with a doping element X, and the weight percentage of the doping element X in the shell is greater than that of the doping element A in the core. The preparation method comprises the following steps: 1, mixing a lithium source, a cobalt source and a doping substance A', and performing calcining, crushing and screening in sequence, so as to obtain a core substrate material; 2, mixing the lithium source, the cobalt source and a doping substance X' so as to obtain a shell precursor; 3, mixing the shell precursor with the core base material, and performing thermal treatment, thereby obtaining the lithium cobalt oxide material of the core-shell structure. The lithium cobalt oxide material of the core-shell structure is novel in structure, the core and the shell are made of same substrate materials with slight doping amount differences, the core and the shell can be very well transitioned and fused together, and situations such as cracking or powdering can be avoided in the charge and discharge process; the lithium cobalt oxide material is simple in preparation and easy in industrial production.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

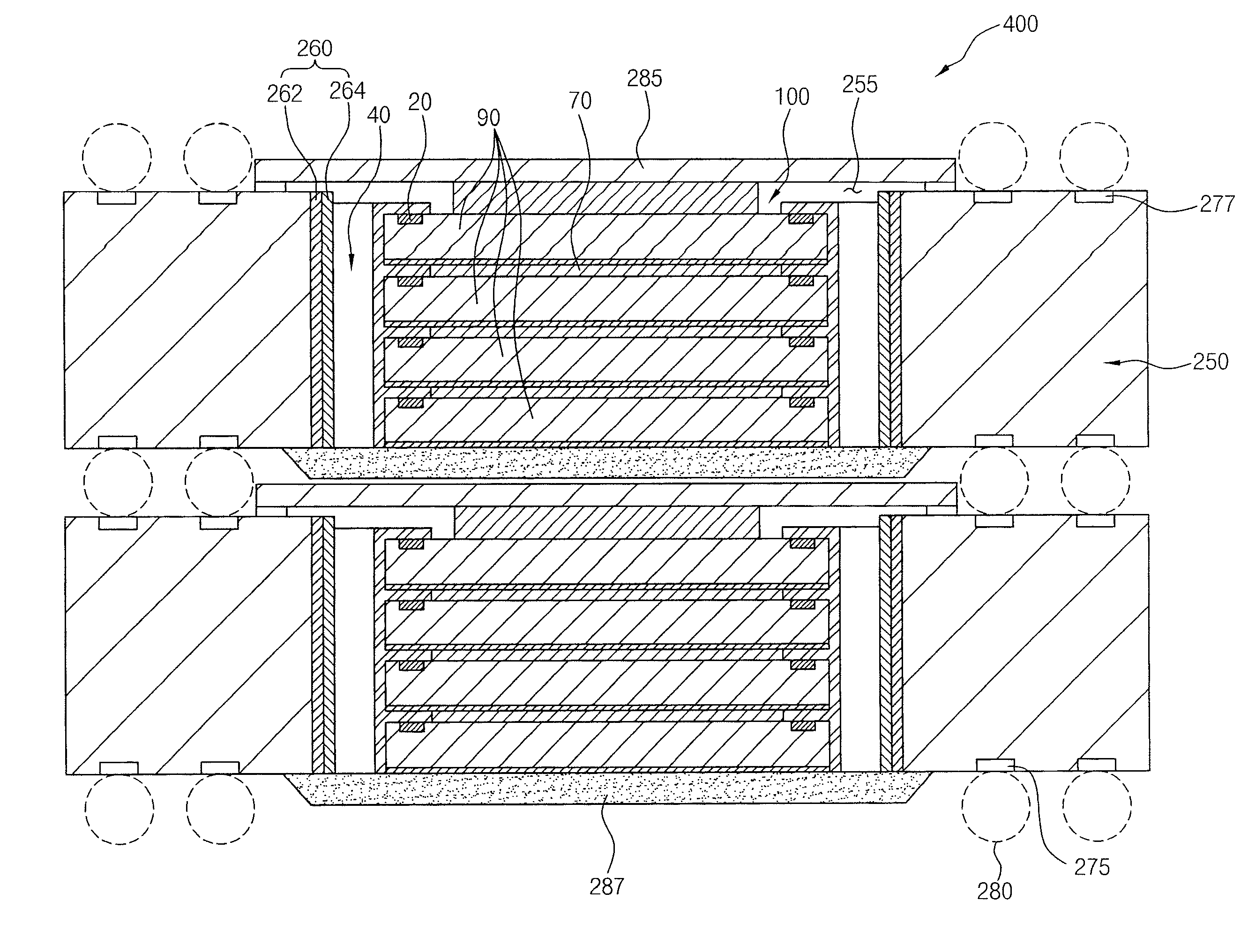

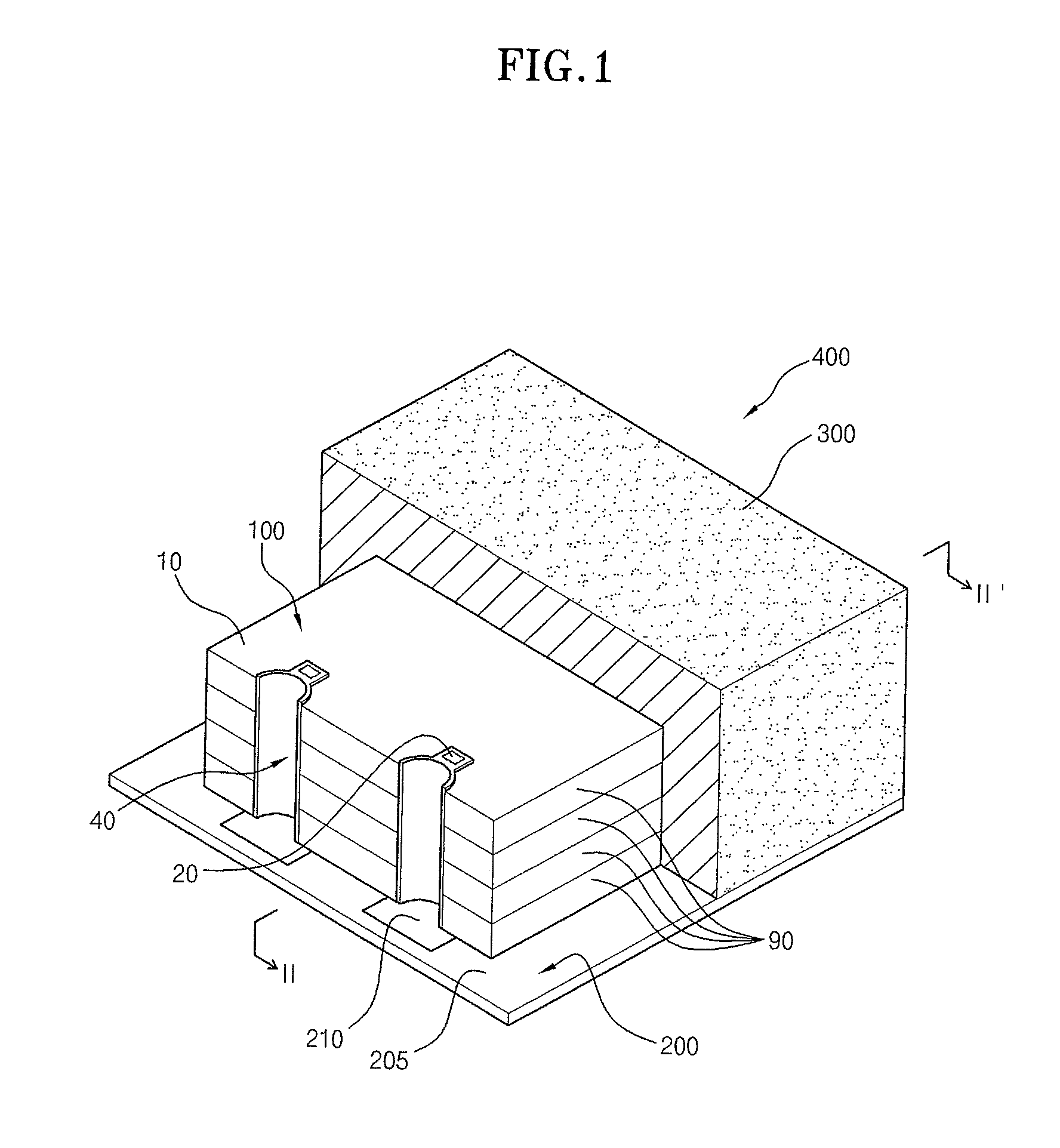

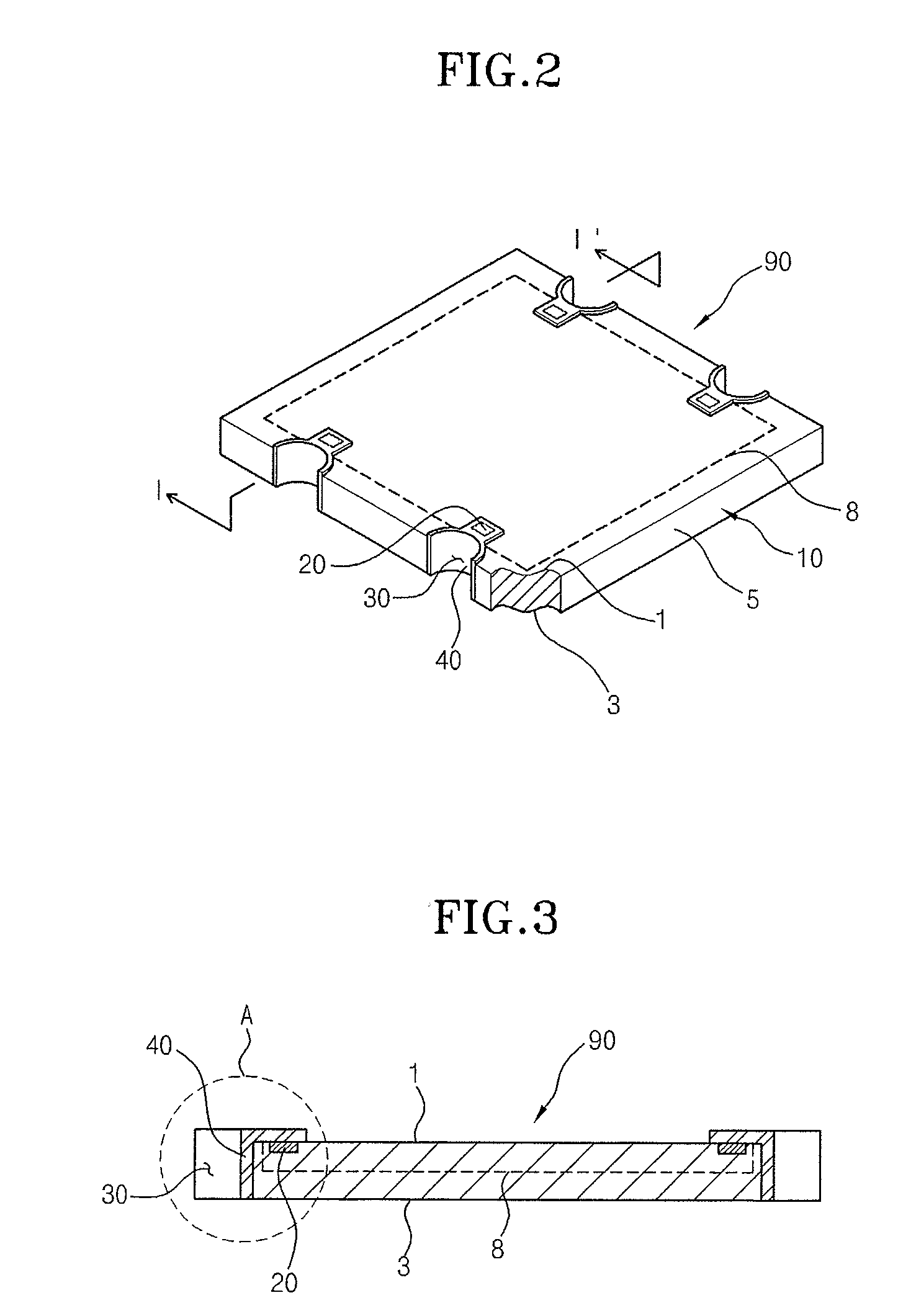

Stacked semiconductor package without reduction in stata storage capacity and method for manufacturing the same

InactiveUS20090096076A1No reduction in capacityImprove structureSemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

A stacked semiconductor package includes a semiconductor chip module including at least two semiconductor chips with a semiconductor chip body having an upper surface, a lower surface, side surfaces coupling the upper surface and the lower surface, and a circuit part. The semiconductor chips include pads coupled to the circuit part and disposed at an edge of the upper surface. A recess parts are concavely formed in the side surfaces corresponding to each pad. Conductive connection patterns cover the recess parts, and each conductive connection pattern is electrically connected to a corresponding bonding pad. The semiconductor chip module is disposed on a substrate, and the contact pads of the semiconductor substrate are electrically connected to the conductive connection patterns. The stacked semiconductor package provides an improved structure that can contain a plurality of stacked semiconductor chips with no reduction in data storage capacity.

Owner:SK HYNIX INC

High specific capacity secondary lithium ion cell

InactiveCN1688063AHigh affinityImprove transmission efficiencySecondary cellsActive material electrodesLithiumMean diameter

A high-specific capacity secondary Li ionic battery includes a shell containing an electrolyte bag, a positive, a membrane and a negative, among which, the positive is composed of a positive collector and Li compound oxide attached to its surface, the negative is composed of a negative collector and adsorption and de-adsorption Li ionic substance containing inactive oxide fast ions adhered on its surface, thickness of the active substance adhered on the negative surface is 0.03-0.30mm, the weight ratio of the inactive oxide fast ions playing the role of a conductor and the negative active substance is 0.01-1.0:100, the mean diameter of the ions is 10-300nm. When using as active material to fill in a thick electrode with high density, an inorganic oxide fast ionic conductor is applied to the negative to improve the Li ionic transmission efficiency from the active substance to the negative surface.

Owner:EVE HYPERPOWER BATTERIES INC

Method for charging and discharging lithium secondary battery, and system for charging and discharging lithium secondary battery

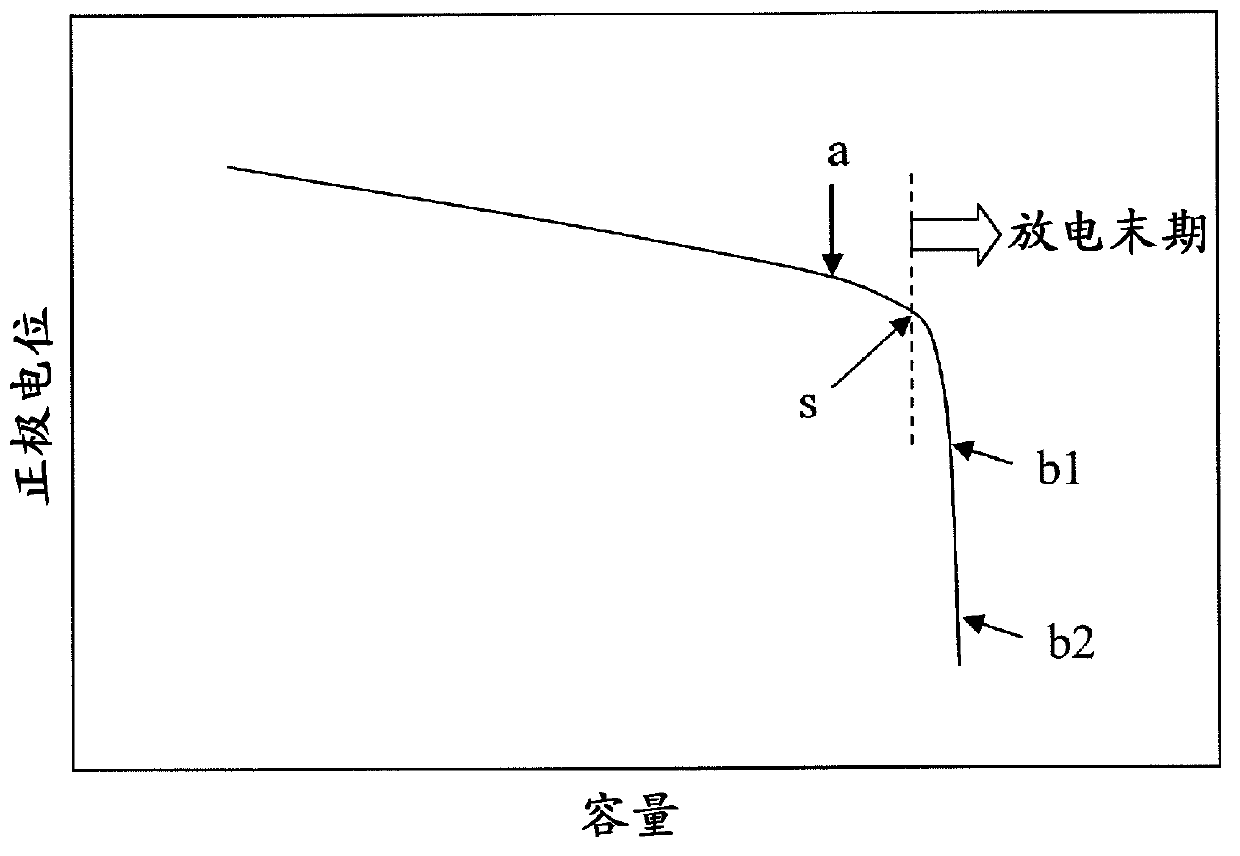

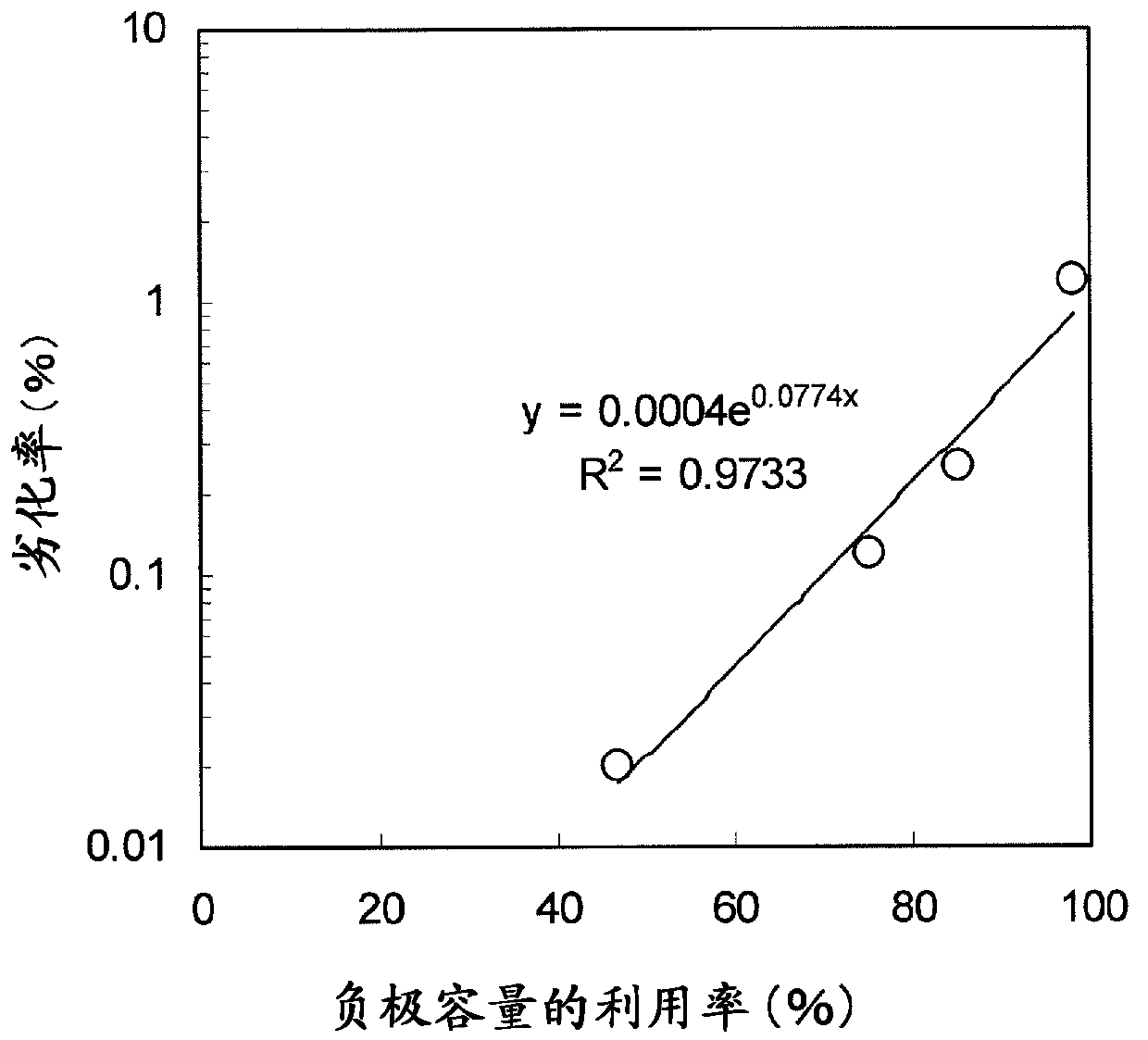

InactiveCN103283083AReduce capacityNo reduction in capacityCell electrodesSecondary cells charging/dischargingLithium metalEngineering

A method for charging and discharging a lithium secondary battery which comprises a positive electrode having a positive electrode active material that is capable of absorbing and desorbing lithium ions, a negative electrode having a negative electrode active material that is capable of absorbing and desorbing lithium ions, a separator that is arranged between the positive electrode and the negative electrode, and a lithium ion-conducting electrolyte. The positive electrode active material contains a lithium-containing transition metal oxide, and the reversible capacity of the negative electrode is larger than the usable capacity of the positive electrode. In this method, a first charge and discharge, wherein the charged positive electrode is discharged to a first potential VDp1 which is lower than 2.7 V based on lithium metal and at which the discharge is terminated, is performed.

Owner:PANASONIC CORP

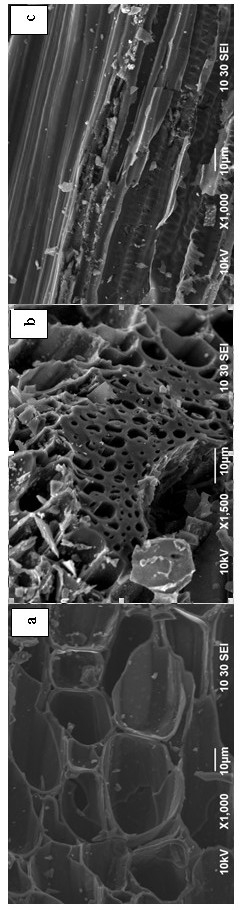

Preparation method for novel lithium vanadium phosphate/bamboo charcoal composite cathode material

The invention discloses a preparation method for a novel lithium vanadium phosphate / bamboo charcoal composite cathode material. The preparation method comprises the following steps of: uniformly mixing vanadium pentoxide, lithium hydroxide or lithium fluoride or lithium carbonate or lithium acetate, ammonium dihydrogen phosphate or phosphoric acid, salicylic acid or citric acid or ascorbic acid or tartaric acid or sucrose, and bamboo charcoal in proportion; evaporating water in a 50-80 DEG C water bath to form a sol; drying the sol in a vacuum drying oven for 8 hours at 120 DEG C to obtain a lithium vanadium phosphate precursor; cooling the lithium vanadium phosphate precursor to room temperature, grinding the precursor and putting the ground precursor into a die to prepare a cake under a certain pressure; putting the cake into a porcelain boat, and covering conductive carbon black (SP) powder on the cake; heating the cake in a microwave oven for a certain period of time; cooling the cake to room temperature; and taking the cake out, and grinding the cake to obtain a bamboo charcoal coated lithium vanadium phosphate / bamboo charcoal composite material sample, thus forming a bamboo charcoal connected conductive network. When used as a cathode material of a lithium ion power battery, the novel lithium vanadium phosphate / bamboo charcoal composite cathode material has the advantages of high capacity and magnification, long service life, low price and environmental friendliness.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

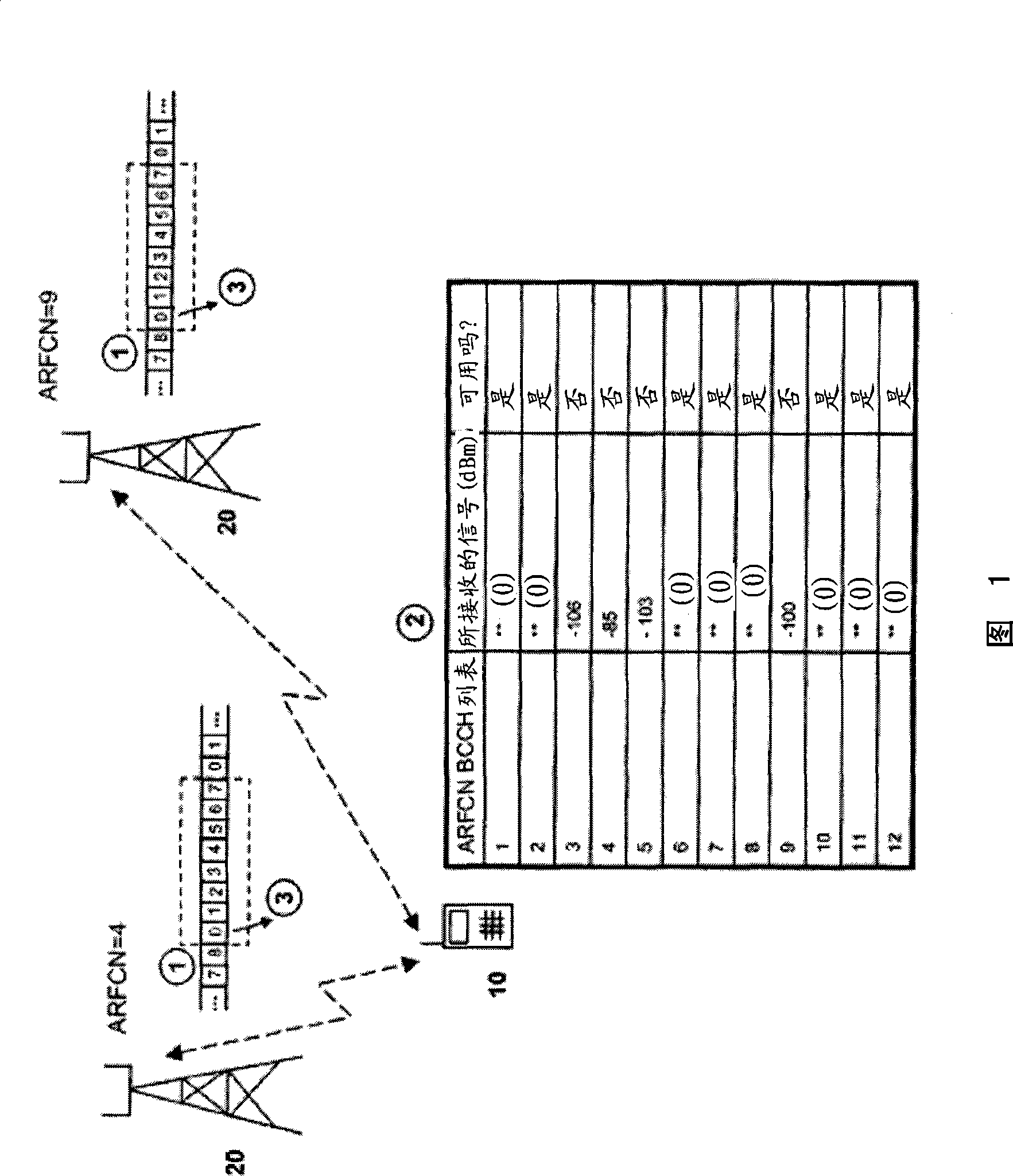

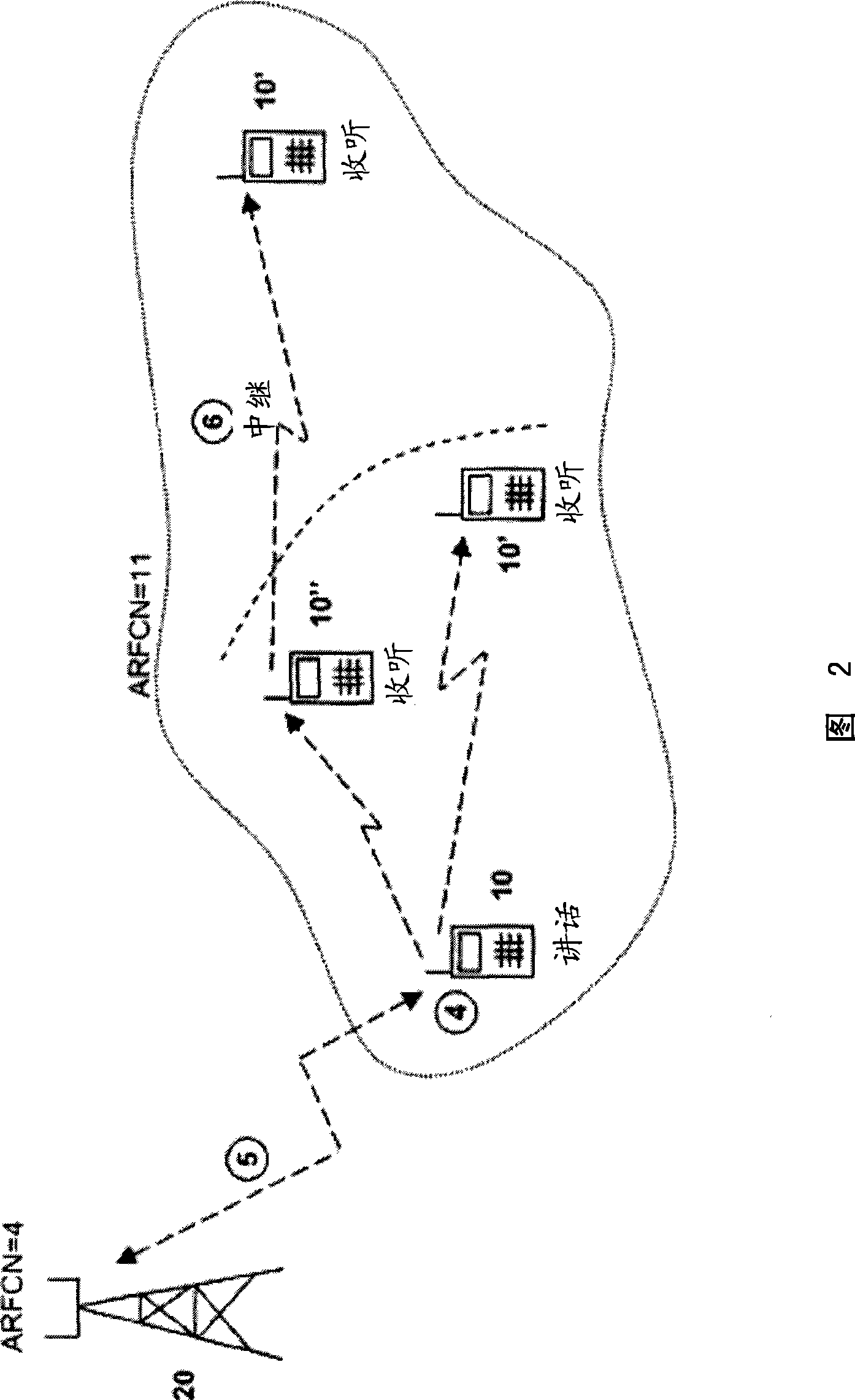

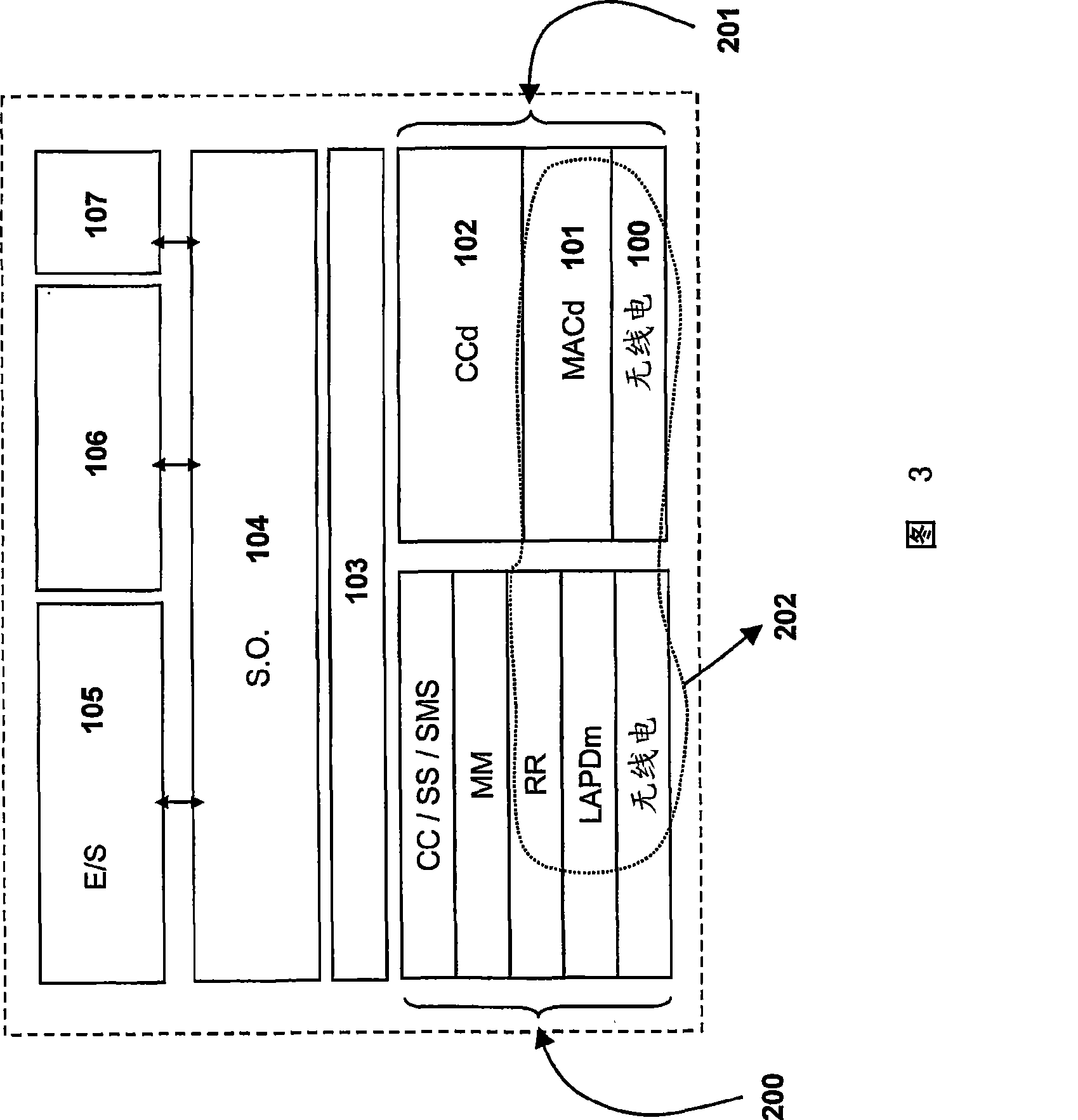

Method and system for establishing a direct radio communication between two or more user devices in a cellular mobile communication system

InactiveCN101438605ANo reduction in capacityConnection managementBroadcast service distributionTelecommunicationsFrequency spectrum

The invention relates to a process for setting up direct radio communication between two or more user devices within a mobile cellular communications system, said users subscribing to the same operator, comprising: - using a cognitive radio technique to detect spectrum resources available for radio communications in a certain area within which said at least two user devices are located, characterized in that the process further comprises: - selecting at least one resource from among the available resources, said resource being a resource of the operator common to said two or more user devices, and - setting up a direct radio link between said two users using said detected free resource of the operator. The invention also relates to a system for setting up direct radio communication between two or more user devices within a mobile cellular communications system.

Owner:VODAFONE GRP PLC

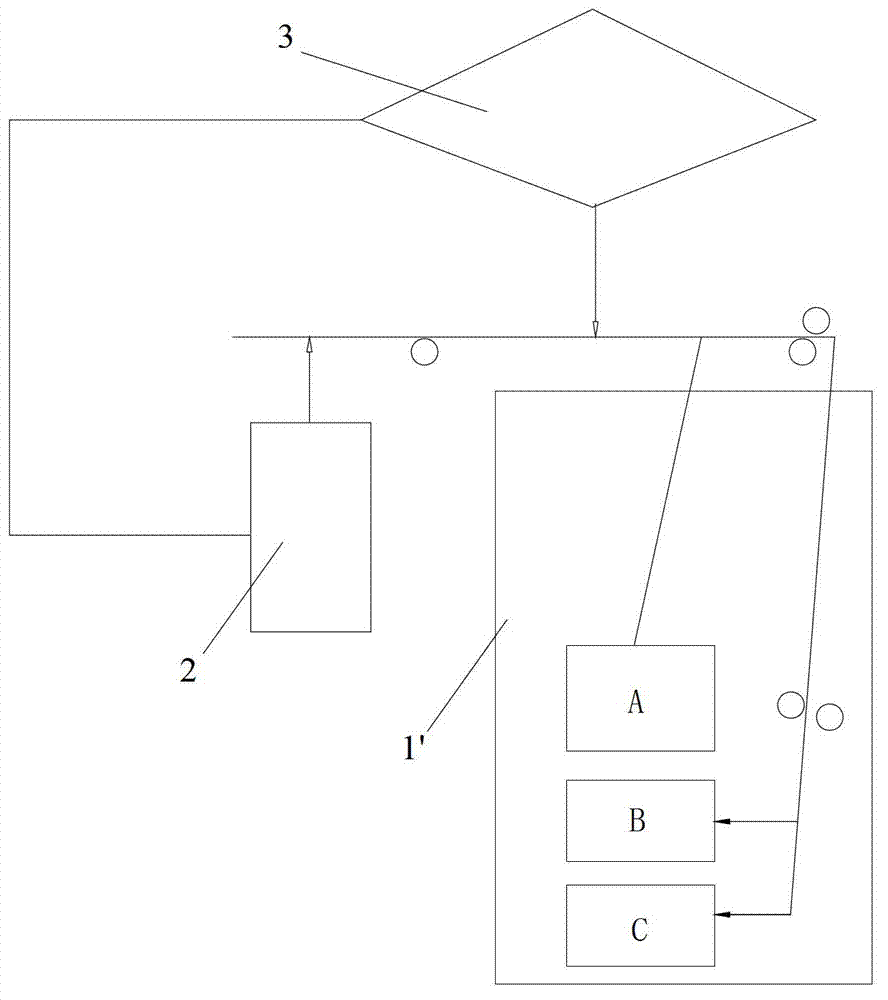

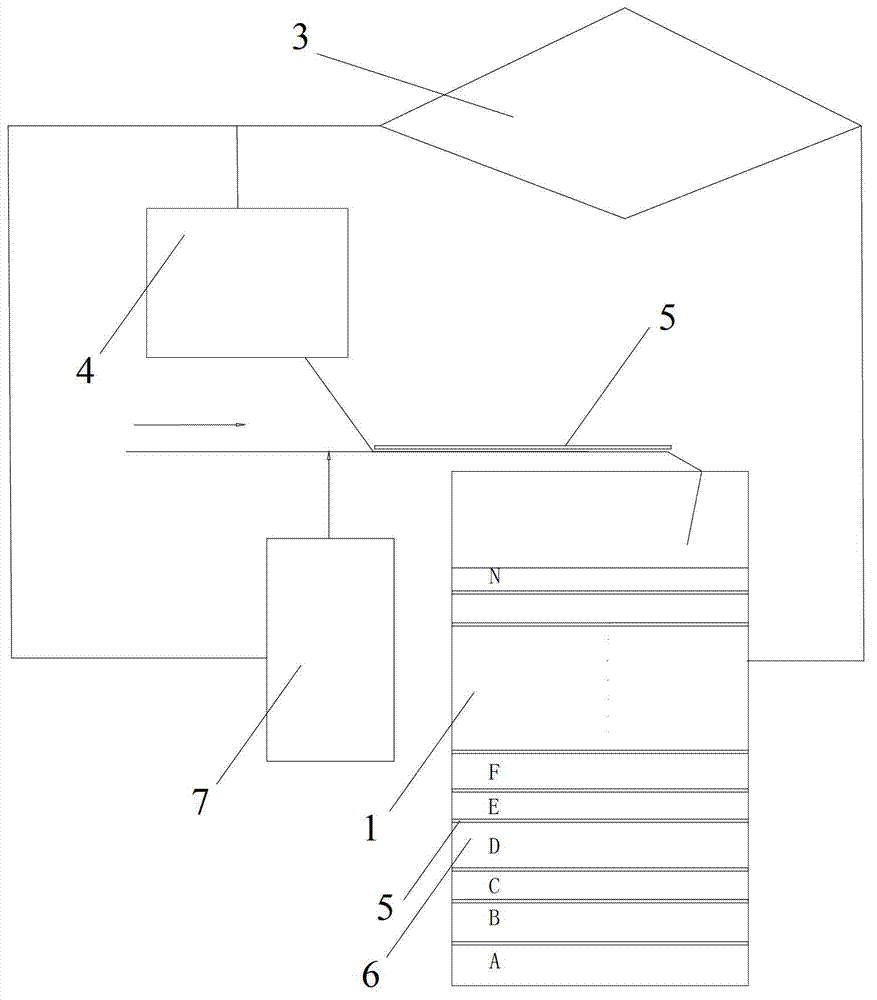

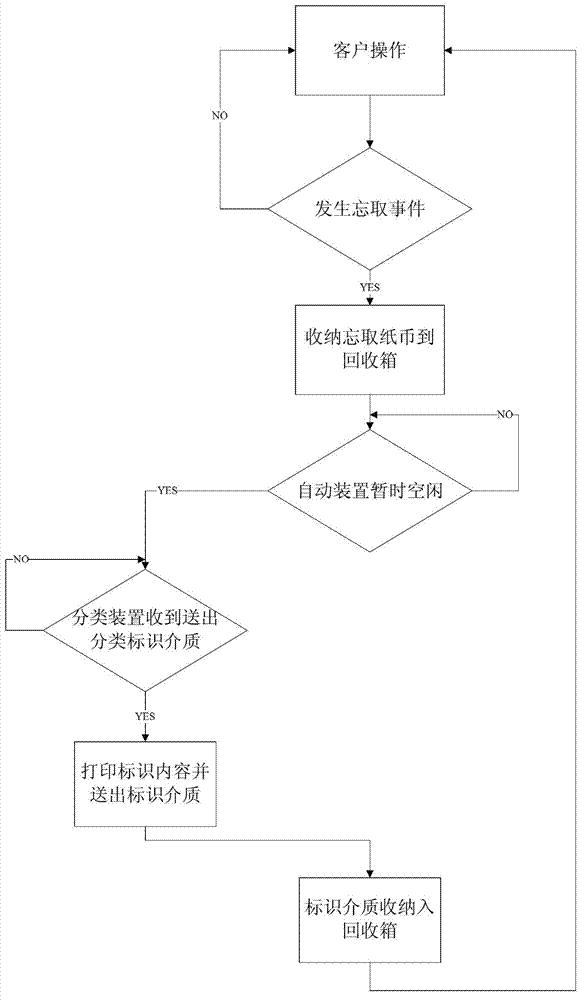

Paper currency recovery method and paper currency recovery device

InactiveCN103198557ANo reduction in capacityNo weight lossCoin/currency accepting devicesATM depositingRecovery methodPulp and paper industry

The invention discloses a paper currency recovery method and a paper currency recovery device. After a recovery box of an automatic transaction device recycles each sum of paper currency, a sorter is used for printing recorded information corresponding to the sum of paper currency on an identification medium, and storing the identification medium to the recovery box and placing the identification medium on the sum of recovery paper currency. An independent mechanism with the functions of printing, storing and distinguishing the identification medium is additionally arranged, if distinction is required, the identification medium with identification information is stored in the recovery box after each sum of paper currency is recycled, detailed information corresponding to the sum of recovery paper currency can be printed on the identification medium, so that the recovery box can meet the requirement of multiple classifications without partitions. The capacity of the recovery is not reduced, the weight of the recovery box is not increased, and meanwhile the phenomena of out of service due to the fact that multiple sums of recovery paper currency with same categories can not be distinguished, and therefore a service rate of the automatic transaction device is greatly improved.

Owner:GRG BAKING EQUIP CO LTD

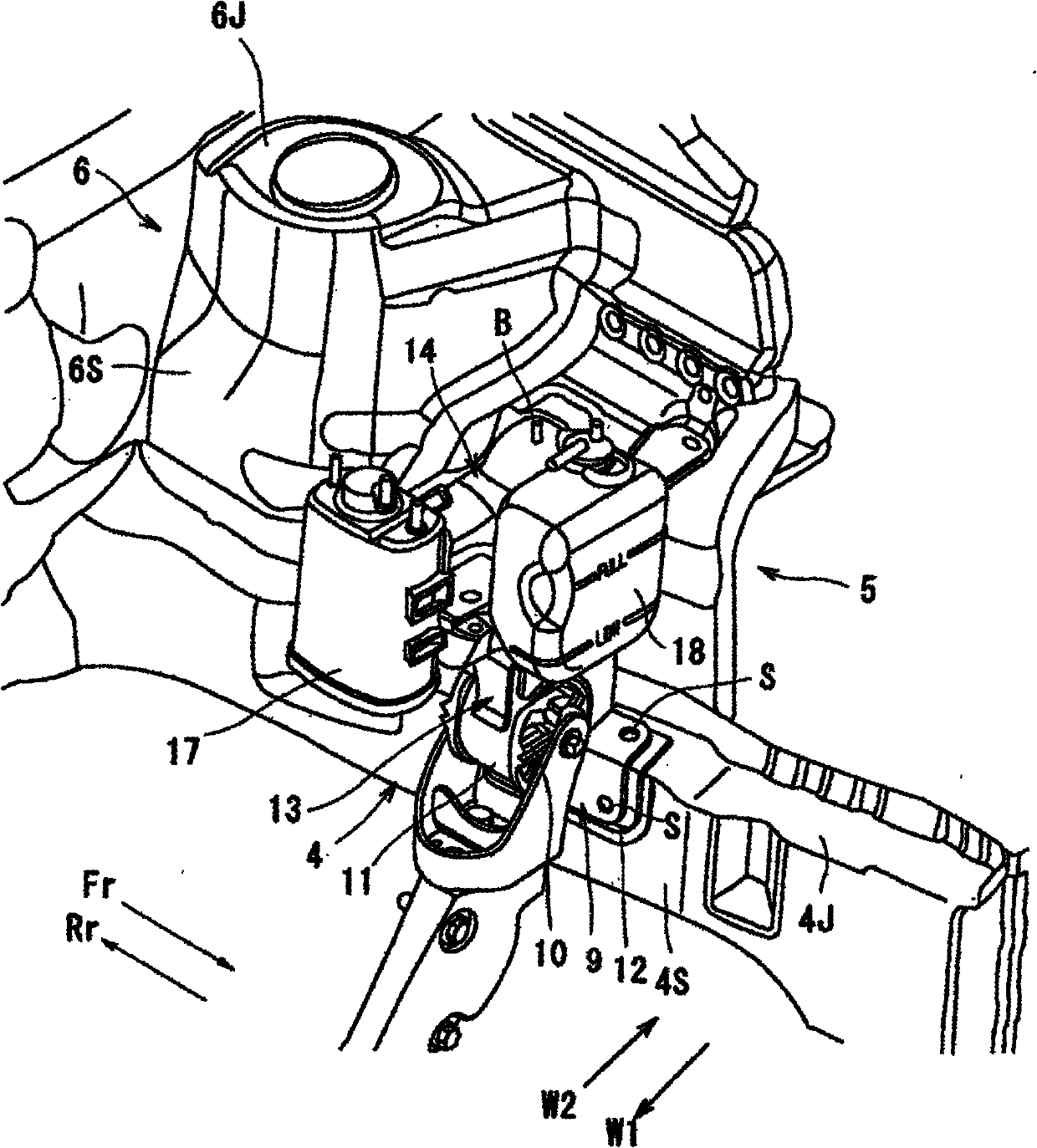

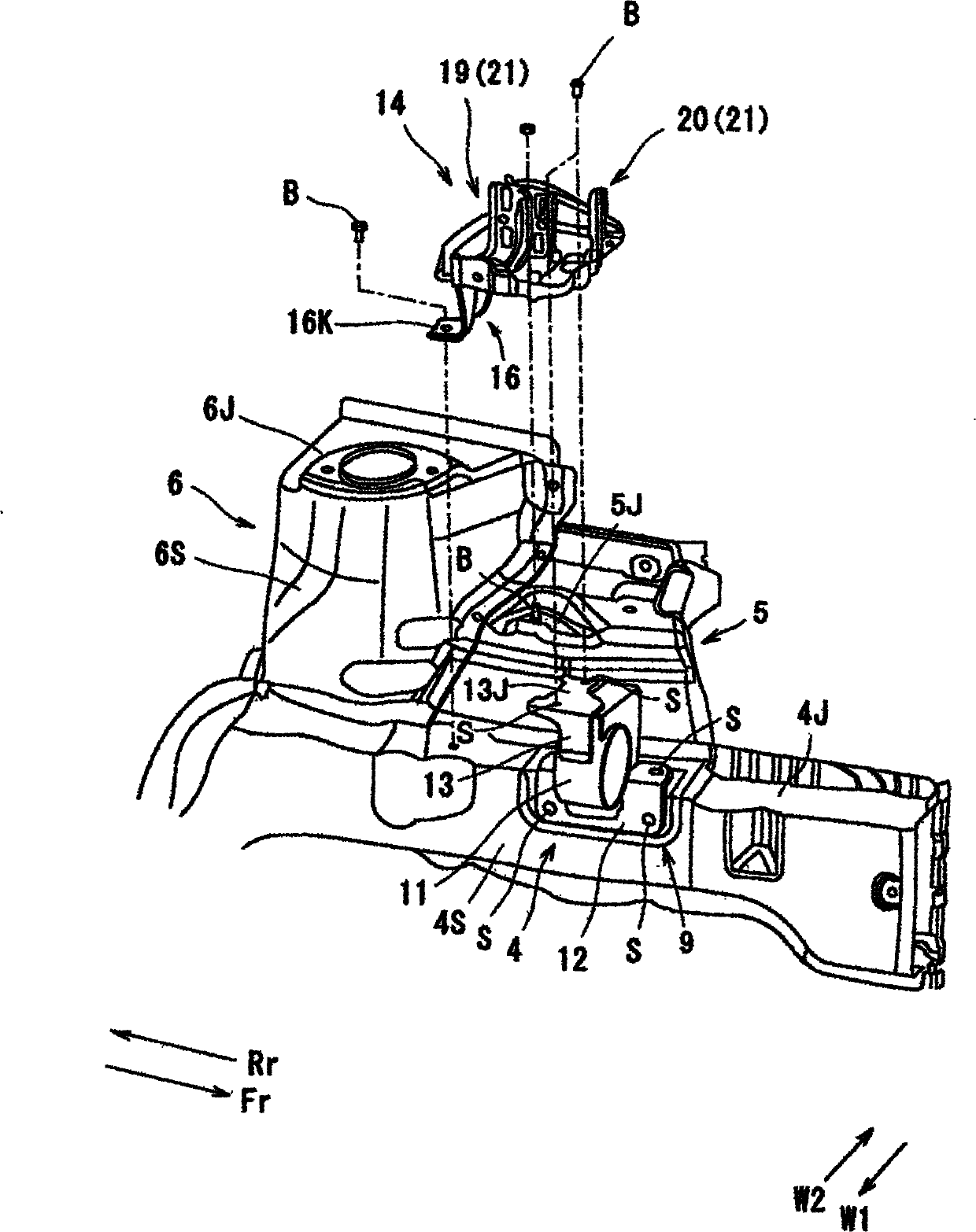

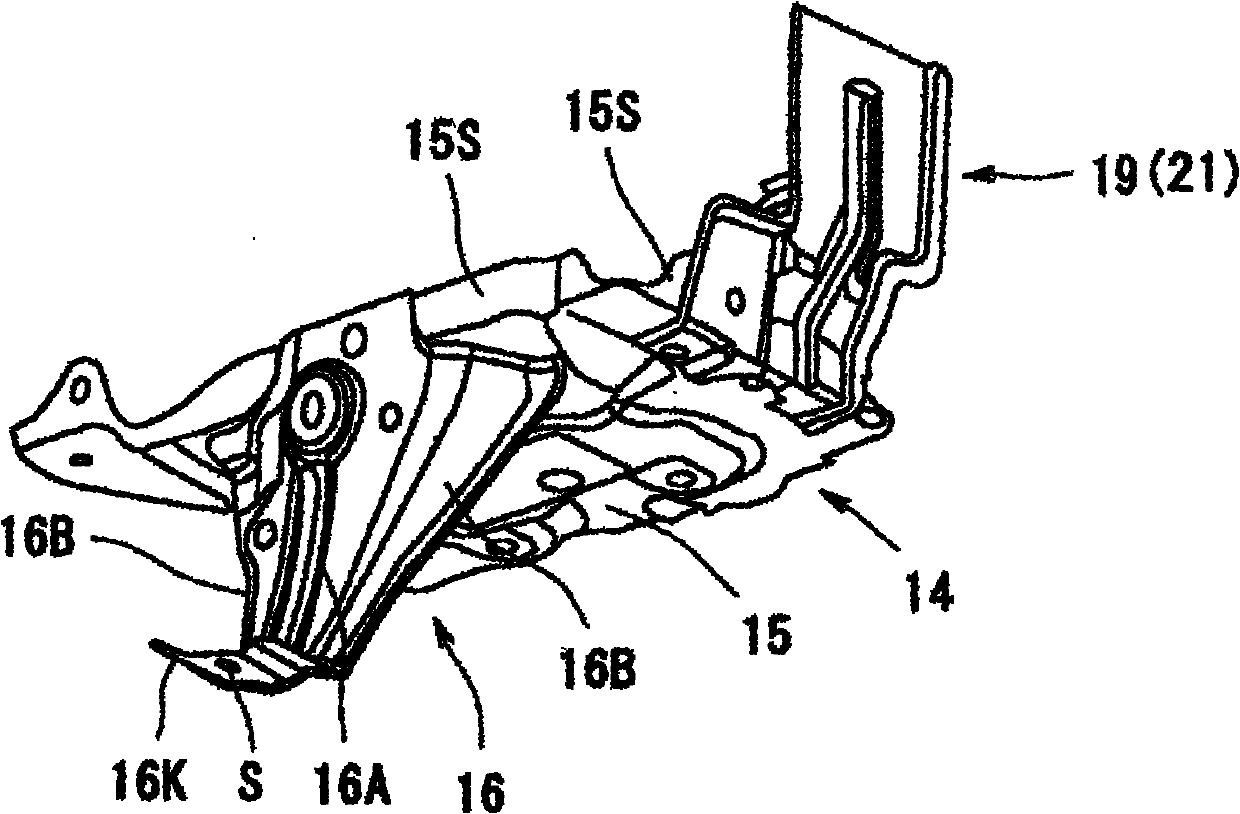

Vehicle body front part structure

InactiveCN102167088AControl vibrationStable supportSuperstructure subunitsJet propulsion mountingRear quarterEngineering

Owner:SUZUKI MOTOR CORP

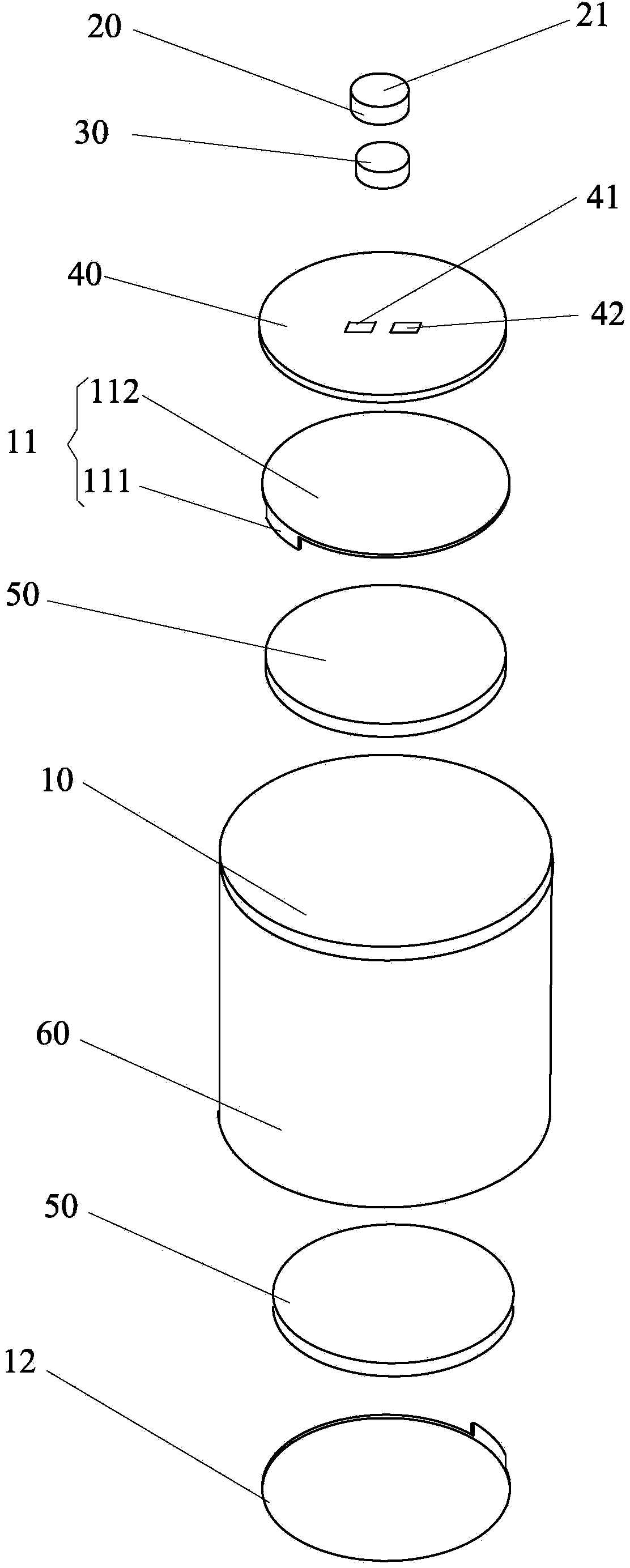

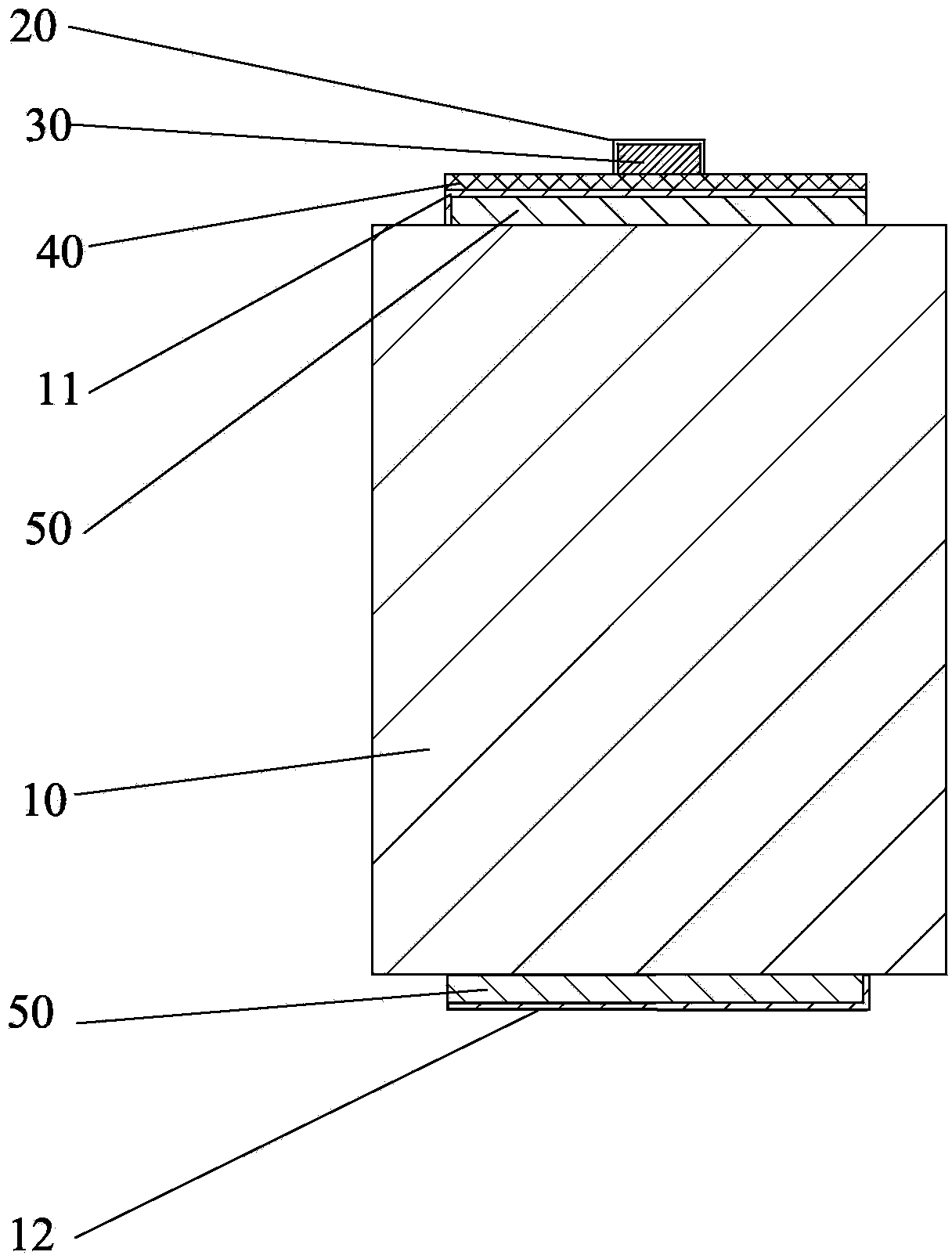

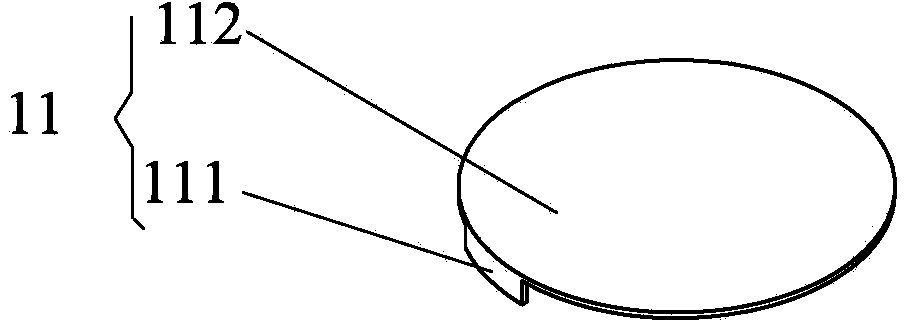

Cylindrical lithium ion battery

ActiveCN104078702AReduce capacityExtended service lifeBatteries circuit arrangementsFinal product manufactureEngineeringLithium-ion battery

The invention provides a cylindrical lithium ion battery. The cylindrical lithium ion battery comprises a battery cell, a battery cover cap and a protection plate, wherein the periphery of the battery cover cap is annular; the central part of the battery cover cap protrudes to form a mounting groove; the protection plate is placed in the mounting groove and is electrically connected with an anode plug and a cathode plug of the battery cell; the protection plate, the cover cap and the battery cell are fixed by low-temperature and low-pressure injection molding. According to the cylindrical lithium ion battery, the protection plate is placed in the battery cover cap so as to effectively utilize the space below the battery cover cap; the capacity of the battery is not reduced; the cylindrical lithium ion battery can be directly connected with an electric appliance for external use and the safety is high.

Owner:东莞市泰有源电池科技有限公司

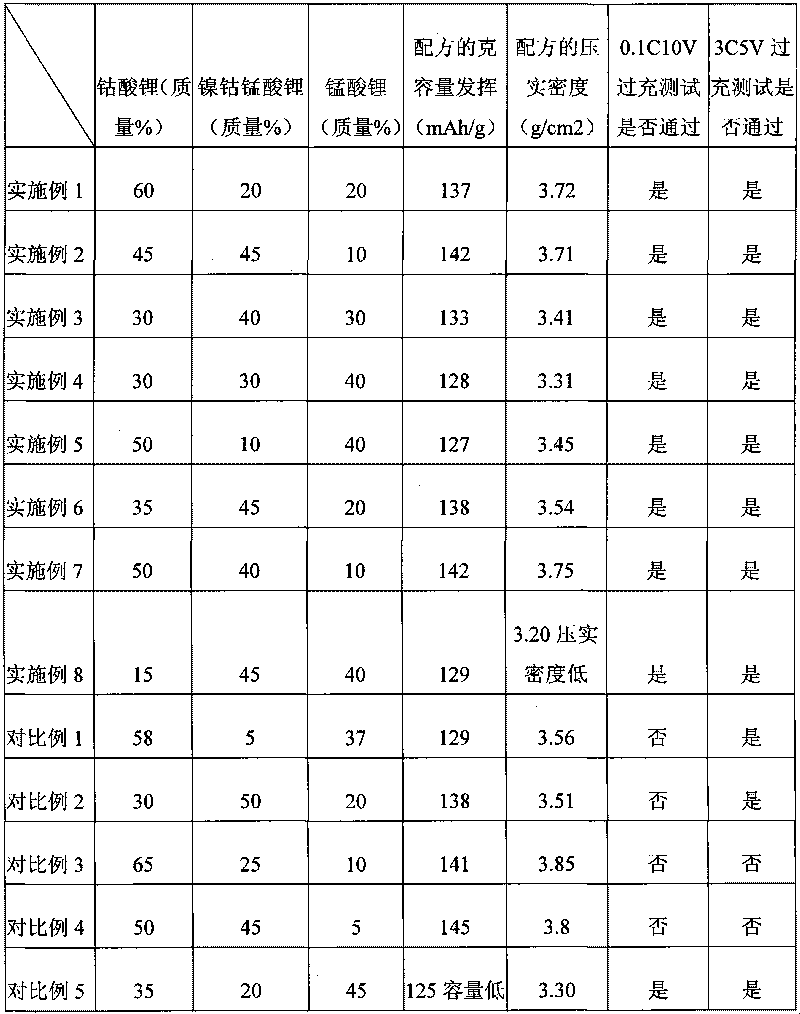

Lithium ion battery anode material and lithium ion battery prepared therefrom

InactiveCN101740765AImprove overcharge resistanceNo reduction in capacityCell electrodesSecondary cellsSpinelManganate

The invention discloses a lithium ion battery anode material and a lithium ion battery prepared therefrom. The anode material comprises15-60% by weight of lithium cobaltate, 10-45% by weight of nickel-cobalt lithium manganate and 10-40% by weight of spinel lithium manganate,. The lithium ion battery anode material prescription and the lithium ion battery made from the material prescription can improve the overcharge property resistance of the lithium ion battery and can not decrease the capacity of the lithium ion battery.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

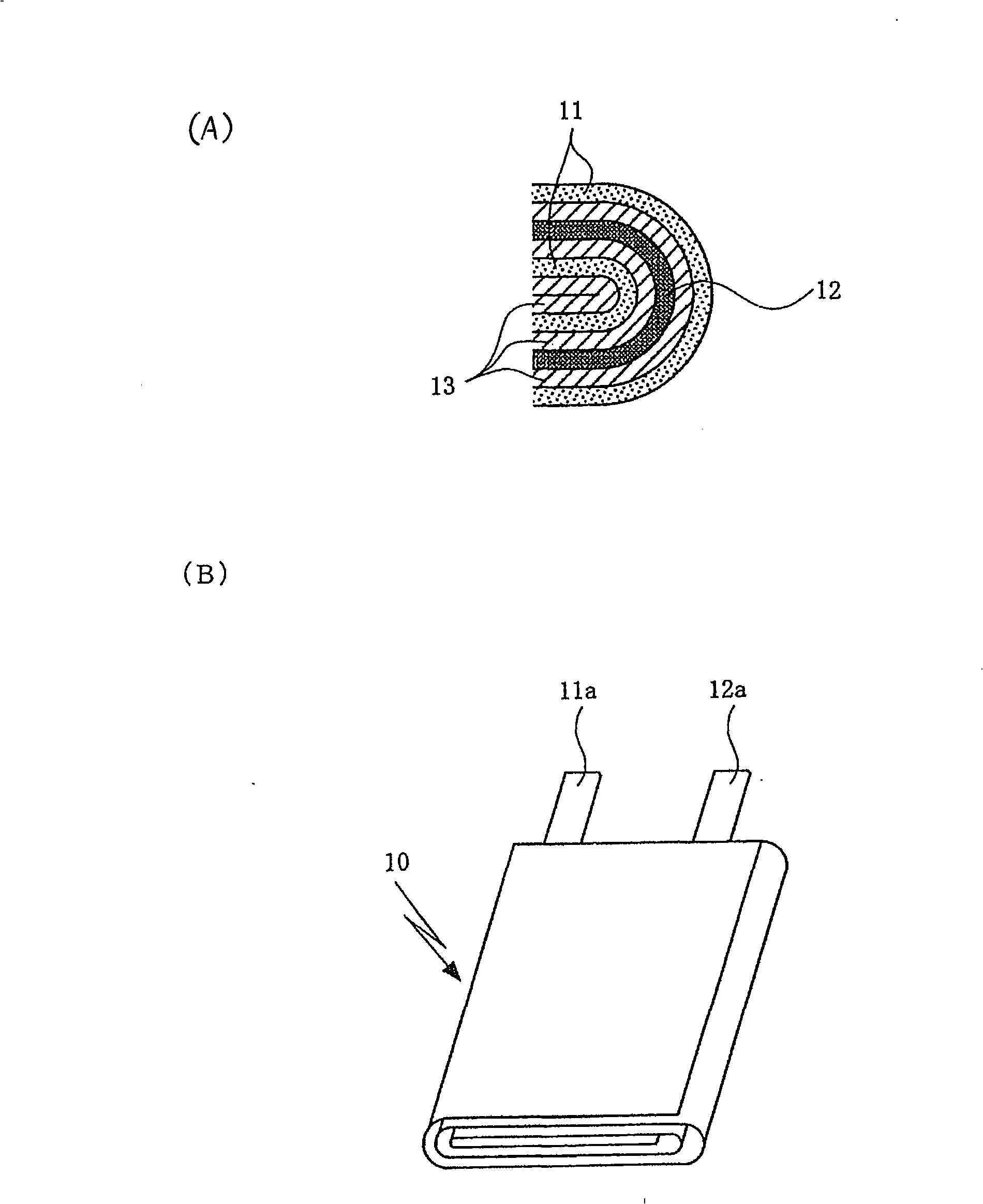

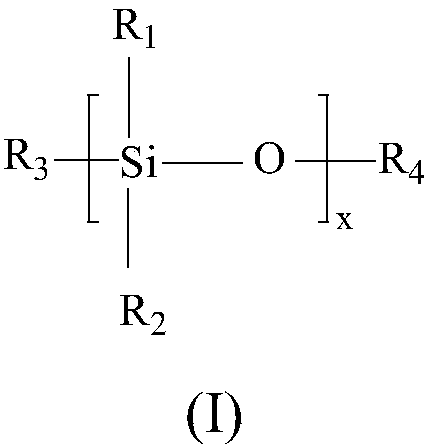

Non-aqueous electrolyte secondary battery

InactiveCN101271987AIncrease capacityNo reduction in capacityCell electrodesLi-accumulatorsCyclic etherSolvent

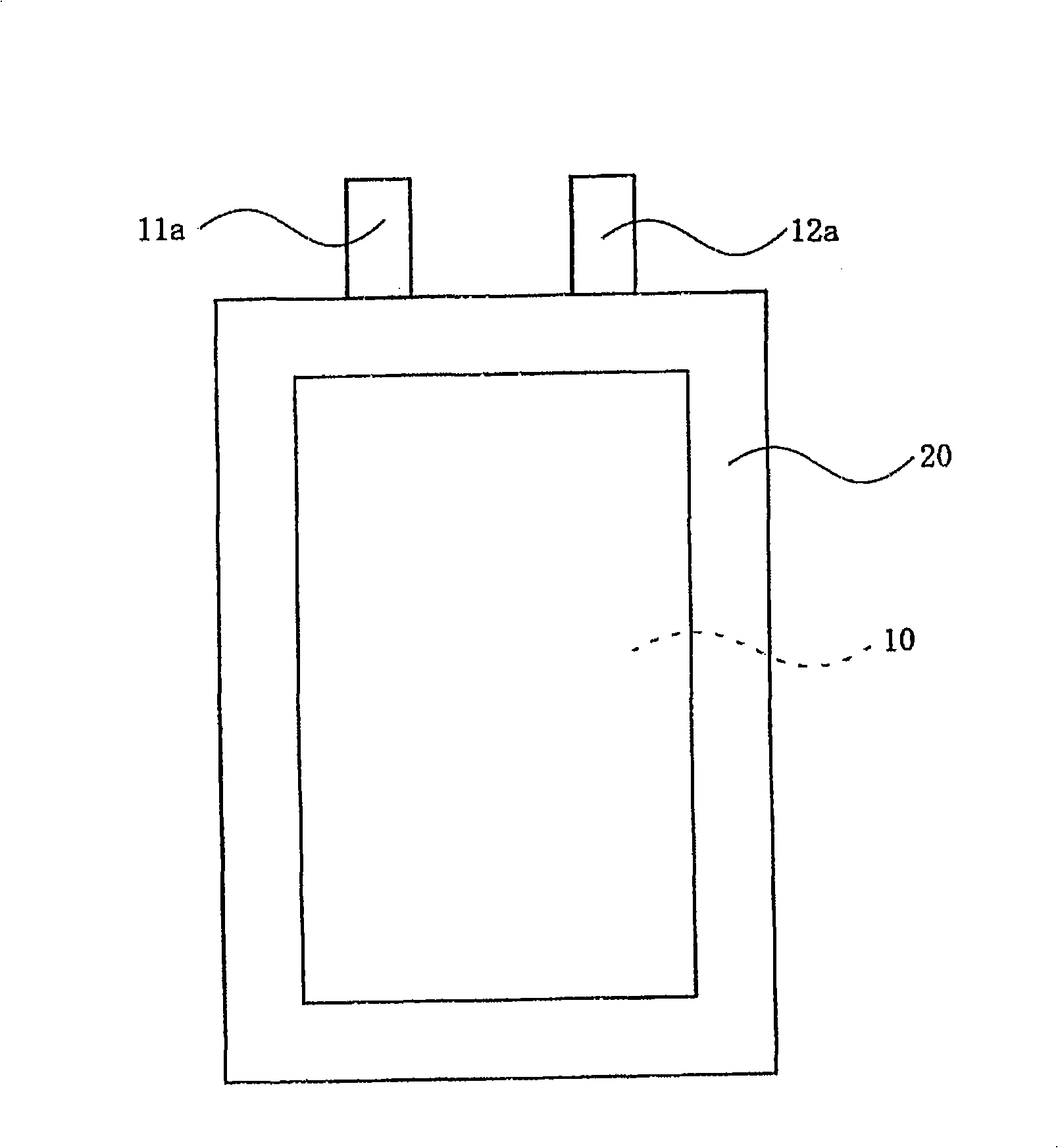

The invention provides a non-aqueous electrolyte secondary battery, under the situation that the non-aqueous electrolyte secondary battery using lithium-containing metal composite oxides comprising lots of nickel in anode active substances is stored in a charging state, the non-aqueous electrolyte secondary battery can avoid the reaction between the anode active substances and non-aqueous electrolyte and further prevent expansion of the battery, and at the same time inhibit reduction of capacity of the non-aqueous electrolyte secondary battery. The invention is a non-aqueous electrolyte secondary battery which includes the anode (11) and the cathode (12) of the anode active substances made of lithium-containing metal composite oxides and having laminated structure, and which has the non-aqueous electrolyte for dissolving the electrolyte in a non-aqueous solvent, characterized in that the anode active substances comprising more than 50 mol% of nickel in the metals of the lithium-containing metal composite oxides other than lithium is used, and cyclic ether is added to the non-aqueous electrolyte simultaneously in the range from 0.1 to 2 volume%.

Owner:SANYO ELECTRIC CO LTD

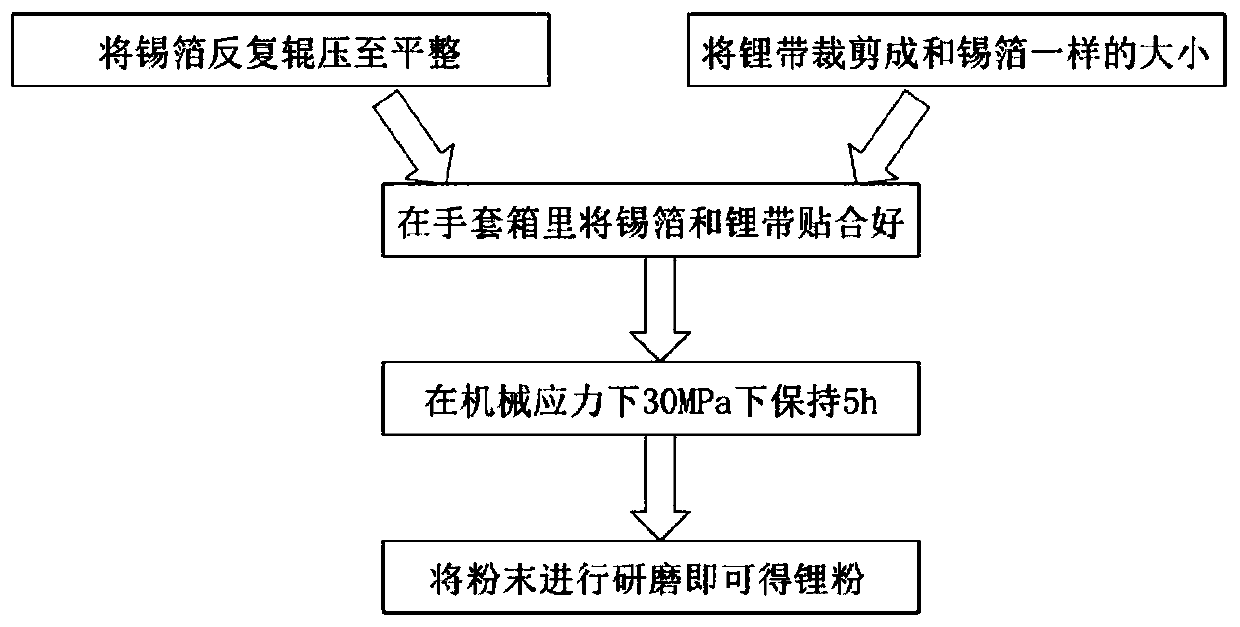

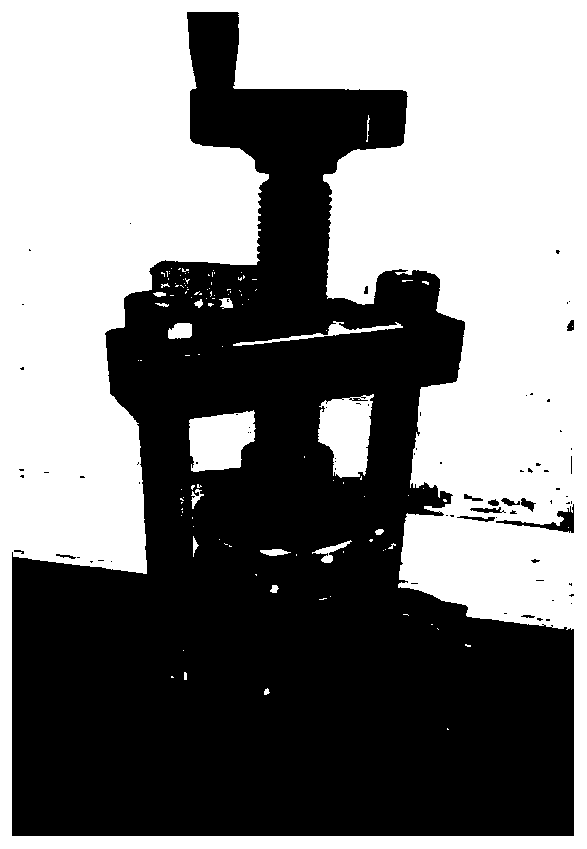

Preparation method and application of lithium tin alloy powder for lithium ion battery negative electrode

InactiveCN111313013AReduce capacityEasy to quantifyNegative electrodesSecondary cellsMetallurgyPhysical chemistry

The invention provides a preparation method and application of lithium tin alloy powder for a lithium ion battery negative electrode, and the preparation method is characterized by comprising the following steps: step 1, flatly attaching tin-based foil and a lithium strip together to obtain a stacked metal sheet; step 2, in a dry and oxygen-free environment, pressing the stacked metal sheets through pressure equipment, so that the tin-based foil is completely embedded into the lithium strip, and a lithium-tin alloy metal sheet is obtained; and step 3, grinding the lithium-tin alloy metal sheetinto lithium-tin alloy powder through grinding equipment in a dry and oxygen-free environment. The particle size of the prepared lithium-tin alloy powder is 10 [mu]m-100 [mu]m, and the lithium-tin alloy powder is added into a negative electrode to supplement lithium, so that the first-circle coulombic efficiency and the cycling stability of the battery can be improved. The lithium tin alloy powder for the negative electrode of the lithium ion battery is simple in preparation operation and mature in technology, and can be used for supplementing lithium for various negative electrode materials,so that the lithium tin alloy powder has a very wide development prospect in a lithium supplementing process of the lithium ion battery.

Owner:TONGJI UNIV

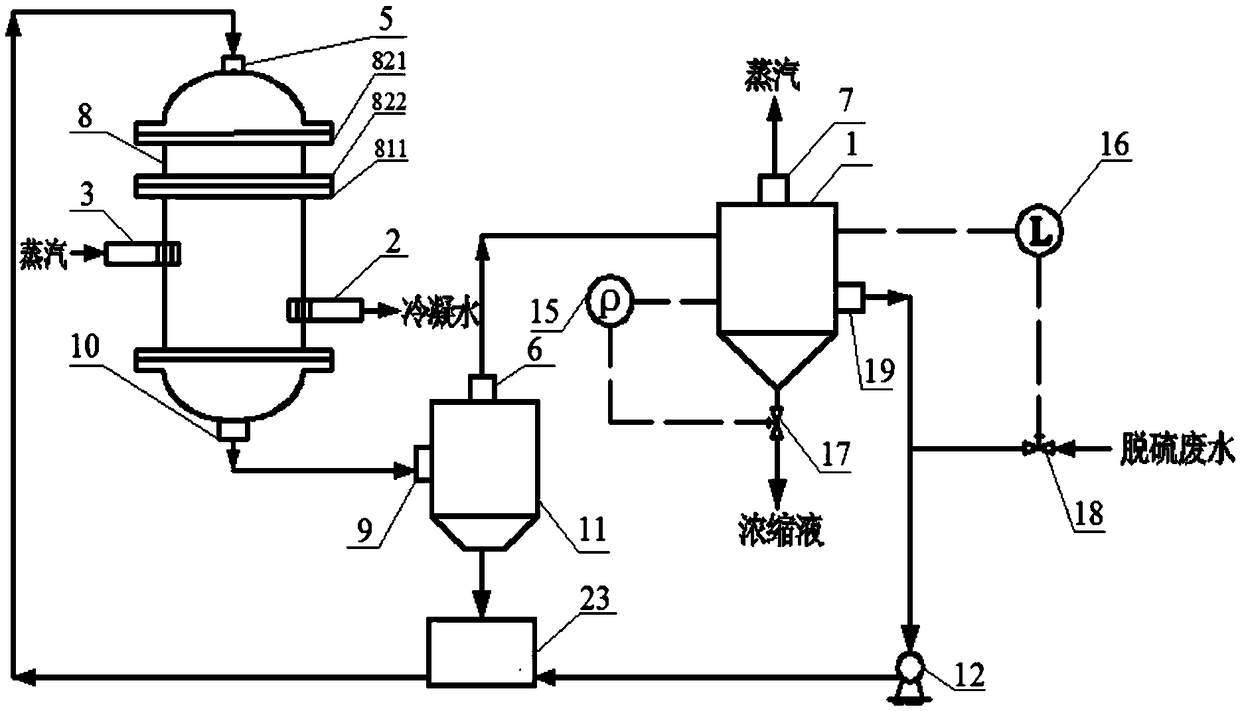

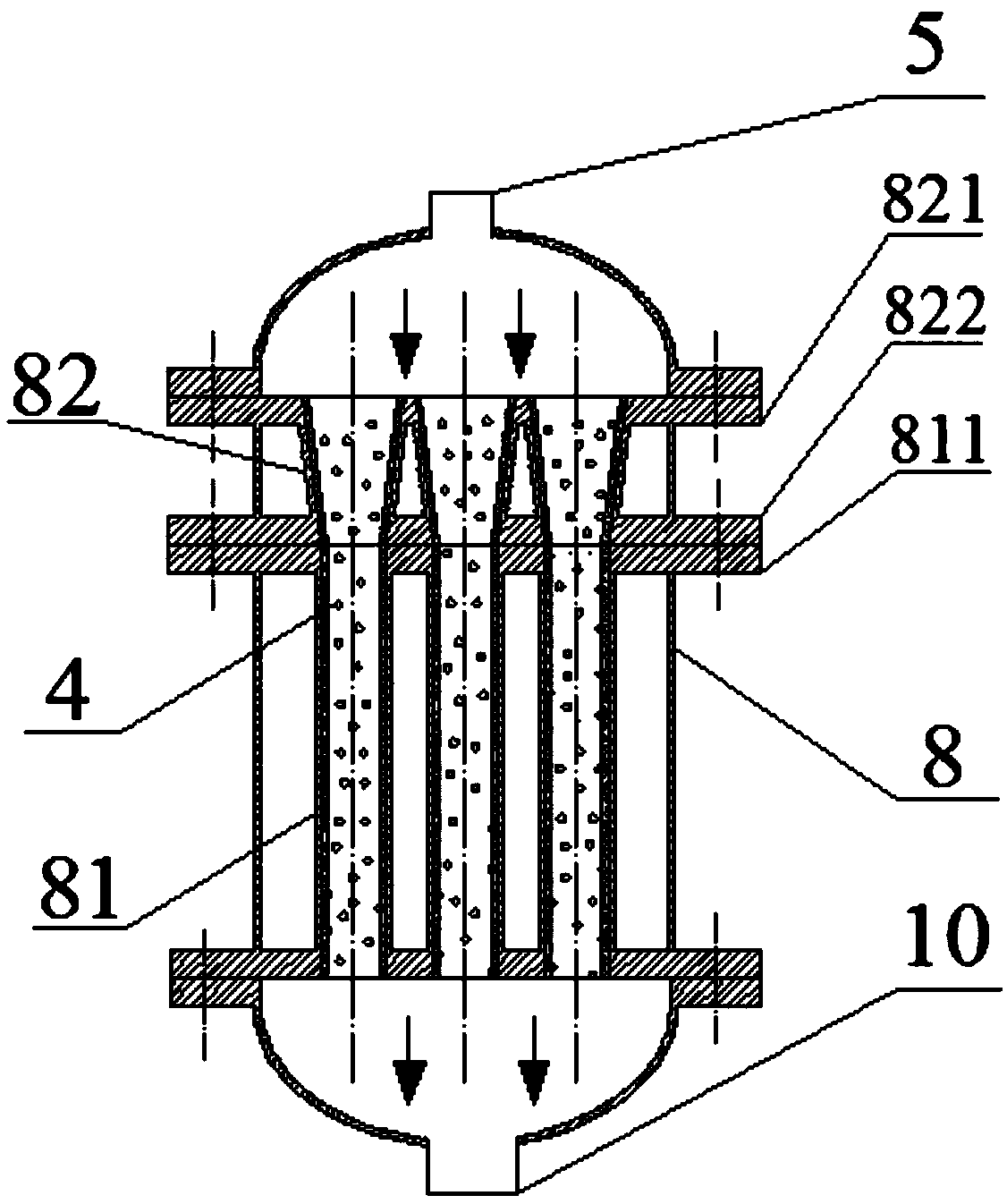

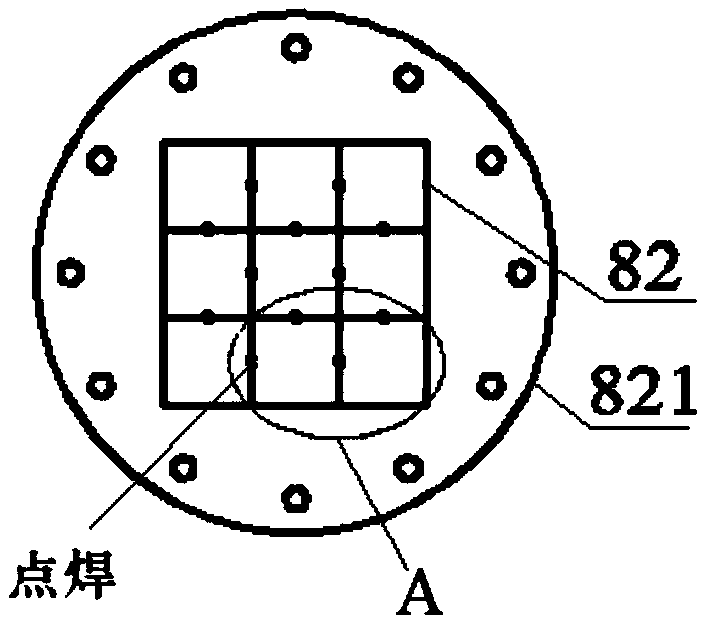

Desulfurization waste water evaporator with inert carrier circling and method

InactiveCN109354090AReduce wearExtend your lifeWaste water treatment from gaseous effluentsWater/sewage treatment by heatingVapor–liquid separatorWastewater

The invention discloses a desulfurization waste water evaporator with inert carrier circling and method. A heater, a solid-liquid mixing device connected with the upper portion of the heater, a solid-liquid separator connected with a discharging port formed in the lower portion of the heater, a gas-liquid separator connected with an upper liquid outlet port of the solid-liquid separator and a circulation pump connecting the gas-liquid separator and the solid-liquid separator, a density gauge is connected with the side face of the gas-liquid separator to regulate the discharging of concentratedliquid, a liquid level gauge is arranged on the side face of the gas-liquid separator to regulate the inlet of desulfurizing waste water, a concentration liquid outlet port is formed in the lower portion, a circulation water outlet is formed in the side face to be connected with the circulation pump, the gathering with inert carriers is achieved through the solid-liquid mixing device, and waste water and the inert carriers enter the heating device together. According to the evaporator, the inert carriers enter the solid-liquid mixing device from the lower end, waste water continuously entersthe gas-liquid separator, and evaporated gas is discharged from a gas discharging hole. The problem of inner scale forming of the evaporator is thoroughly solved, the investment cost is low, the operation is stable, and there exists no environmental secondary pollution.

Owner:SOUTHEAST UNIV +1

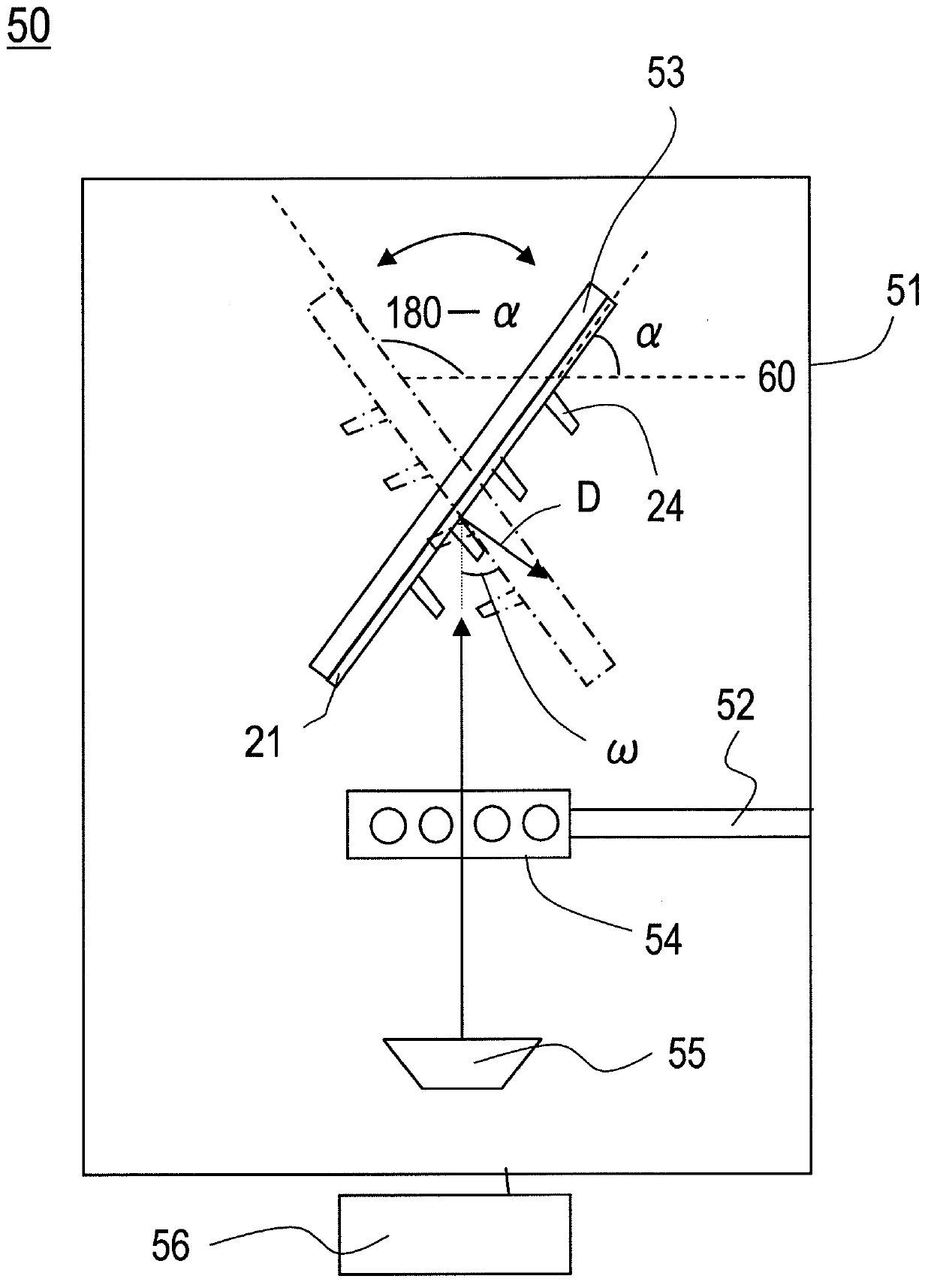

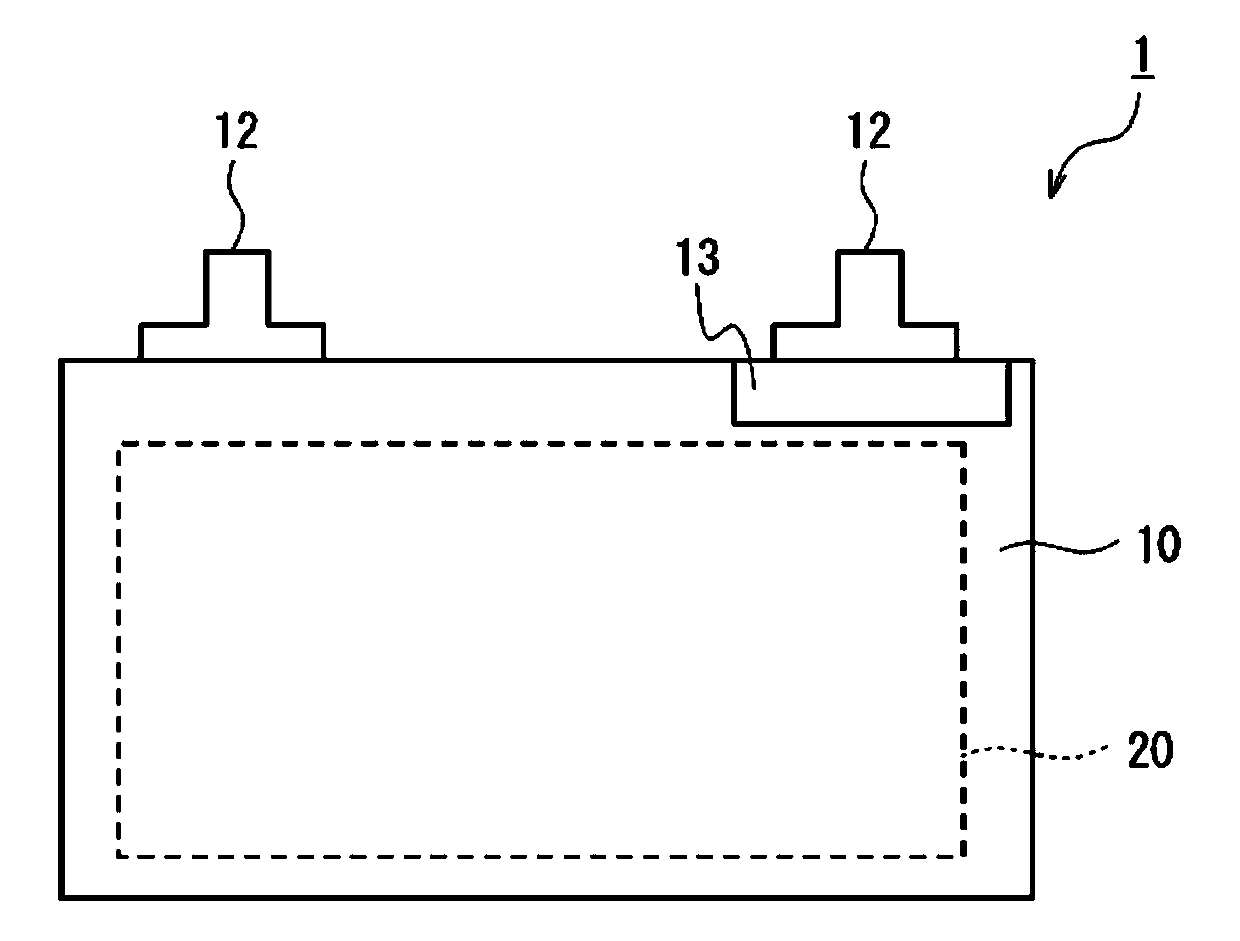

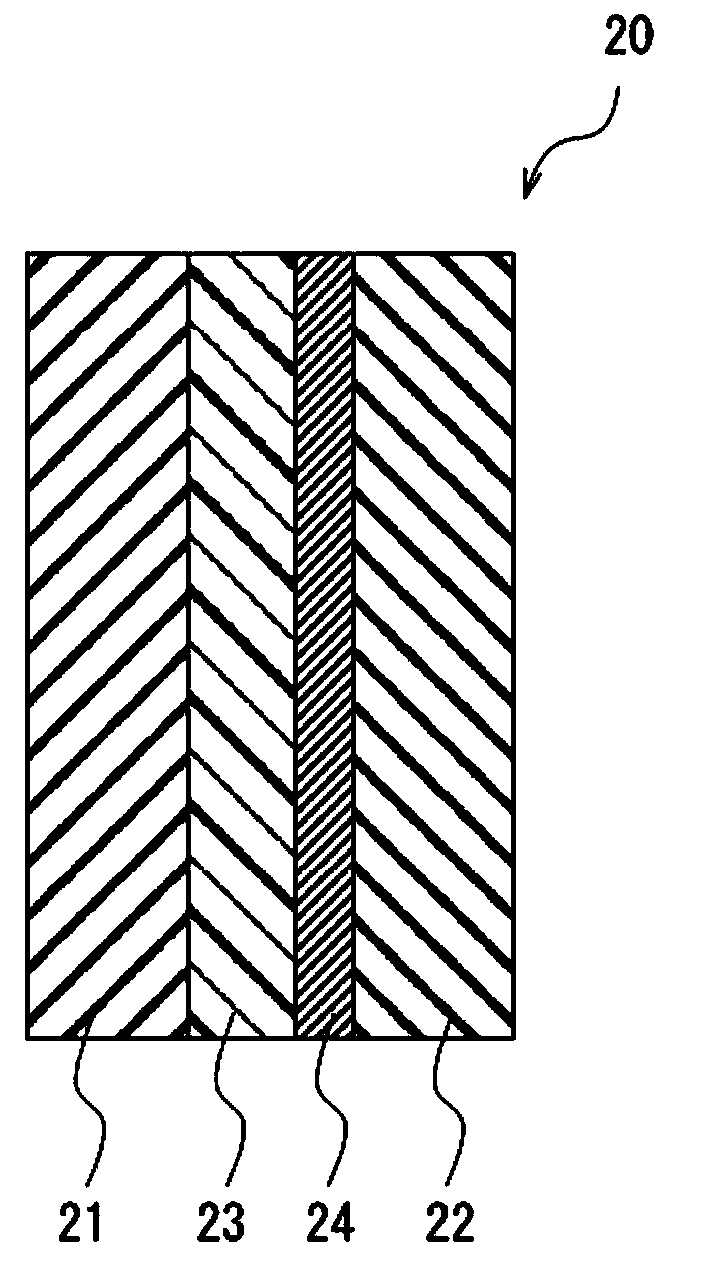

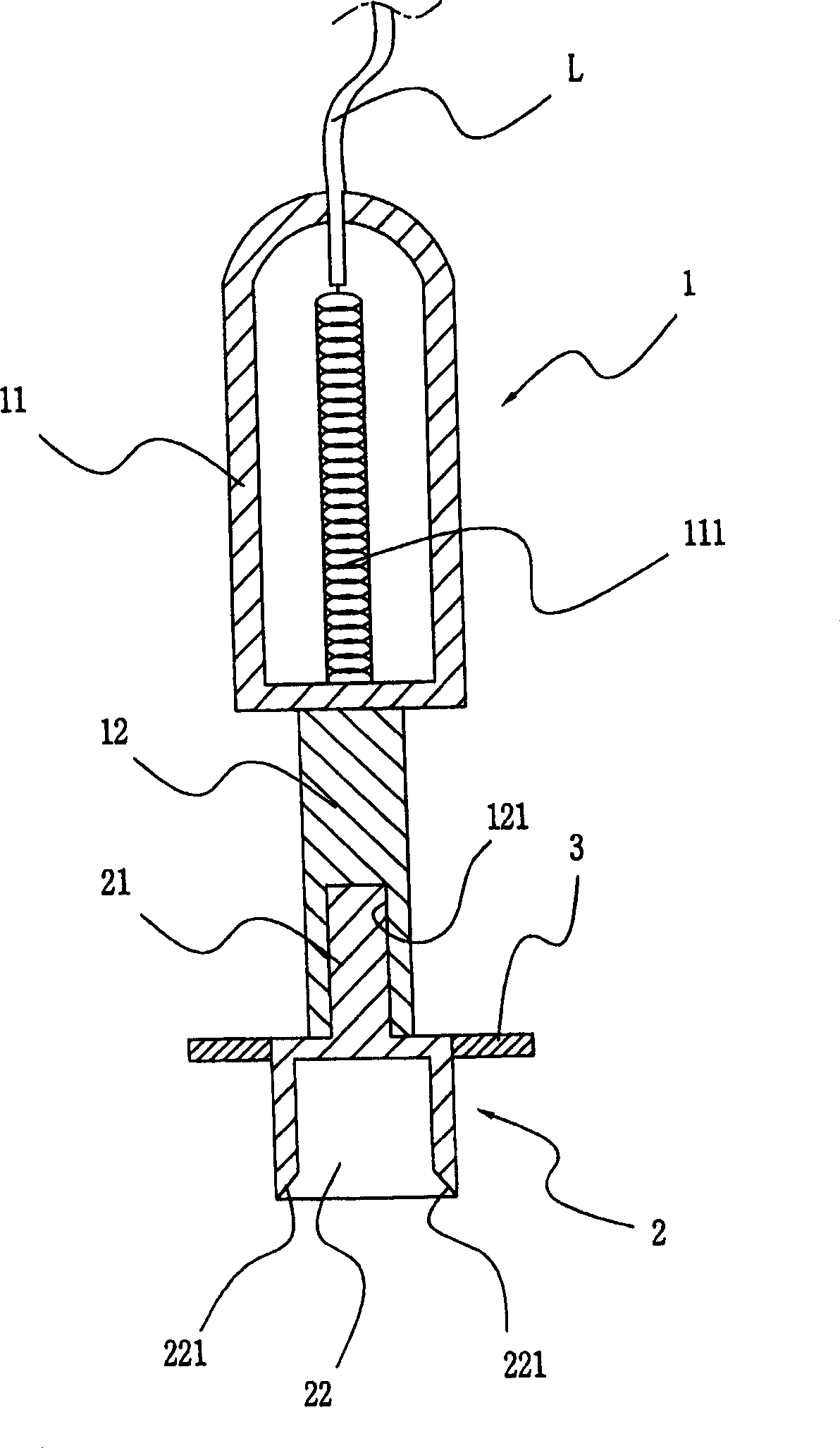

Nonaqueous electrolyte secondary battery

ActiveCN103875119AHigh detection sensitivityExcellent resistance to external stressCell seperators/membranes/diaphragms/spacersFinal product manufactureInternal pressureProton

Provided is a nonaqueous electrolyte secondary battery which has excellent resistance to external stress and is capable of increasing the sensitivity of detecting an increase of the internal pressure at the time of overcharging without lowering battery performances such as battery capacity. This nonaqueous electrolyte secondary battery comprises: a positive electrode (21); a negative electrode (22); a porous heat-resistant layer (24) that is arranged between the positive electrode (21) and the negative electrode (22) and contains an insulating inorganic filler and a binder; a nonaqueous electrolyte to which an overcharge inhibitor that is decomposed and generates protons when overcharged is added; and a current blocking mechanism which interrupts the charging when the internal pressure of the battery reaches a predetermined value or higher during the charging. At least some of the insulating inorganic filler in the porous heat-resistant layer (24) is configured of a proton-conducting ceramic material.

Owner:TOYOTA JIDOSHA KK

Cathode material precursor and preparation method and purpose thereof

ActiveCN109830679AIncrease layer spacingImprove structural stabilityCell electrodesSecondary cellsStructural stabilityMaterials science

The invention relates to a cathode material precursor and a preparation method and purpose thereof. A chemical formula of the cathode material precursor is FeaMnbNicMd(OH)x, wherein 0<a<1, 0<b<1, 0<c<1, a+b+c>=0.90, 0.01<d<=0.1, a+b+c+d=1, and 2<x<3; and M includes any one or two types selected form Al, Cu and Co. The interlayer spacing of the cathode material precursor is increased by doping element M, and further the structural stability of the cathode material precursor is improved; and at the same time, the element M is doped so that the cathode material precursor is less sensitive to theair while the material capacity is not reduced, and the battery stability is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

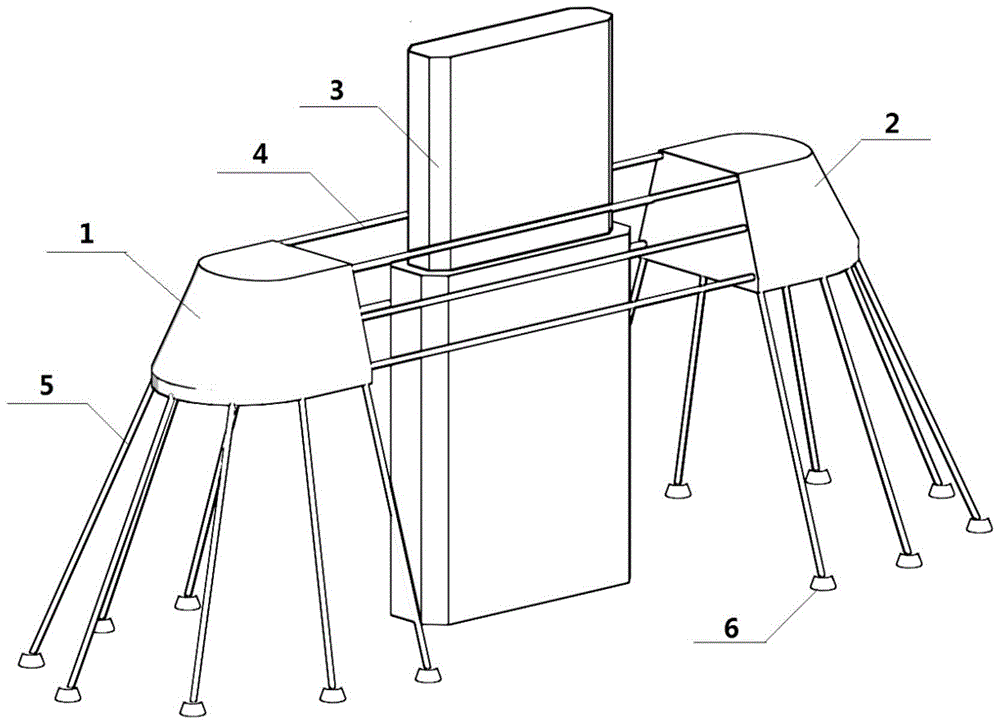

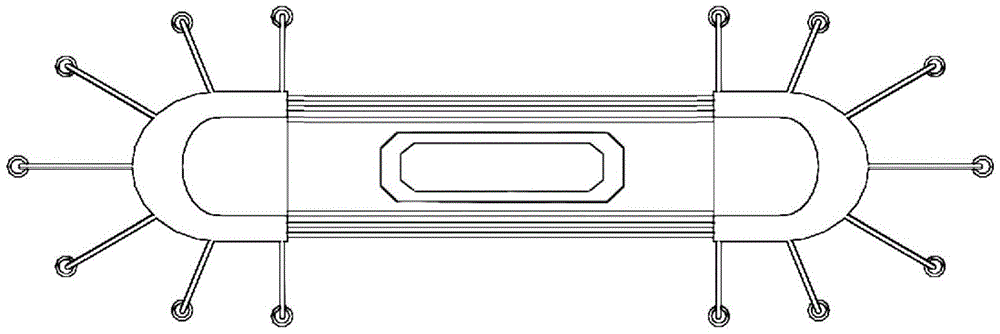

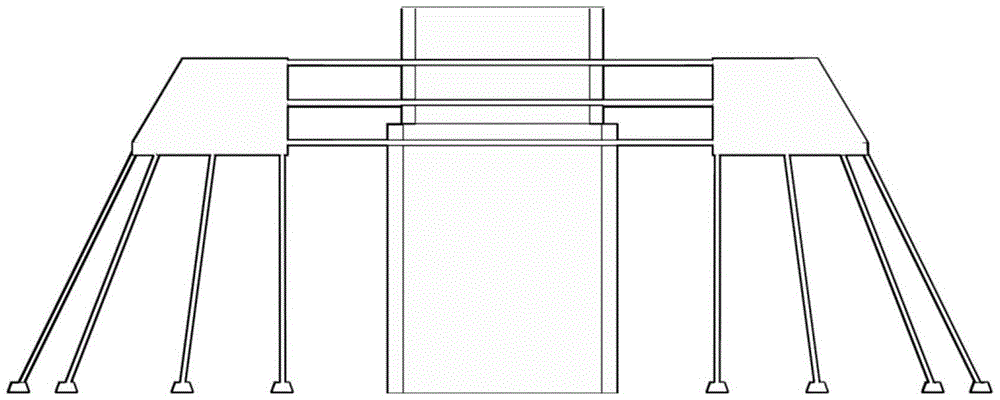

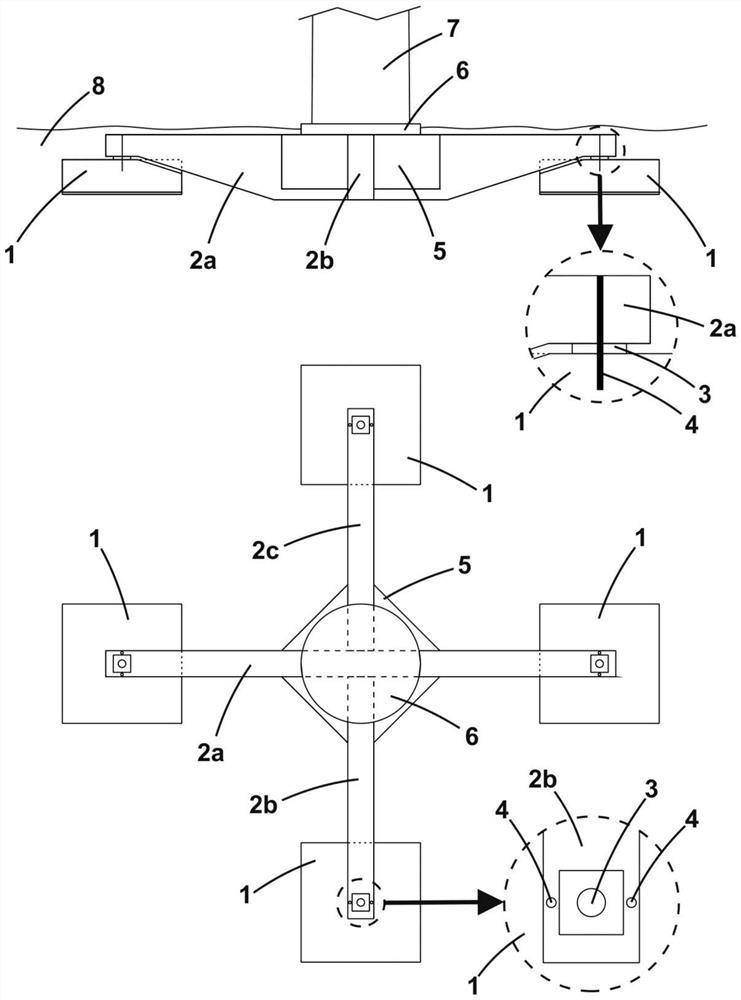

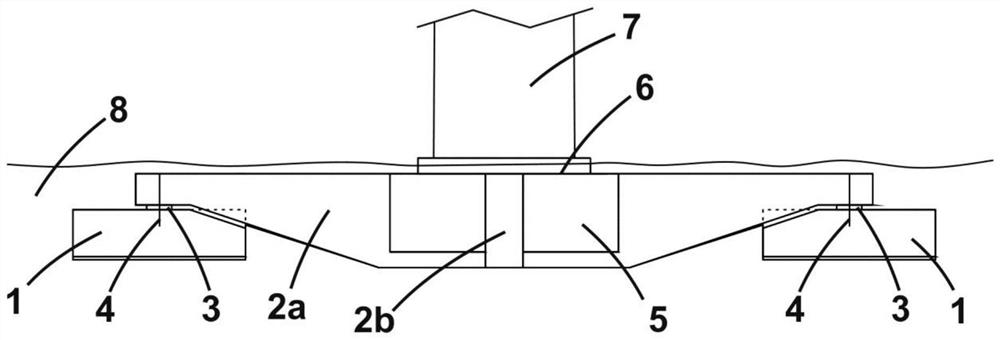

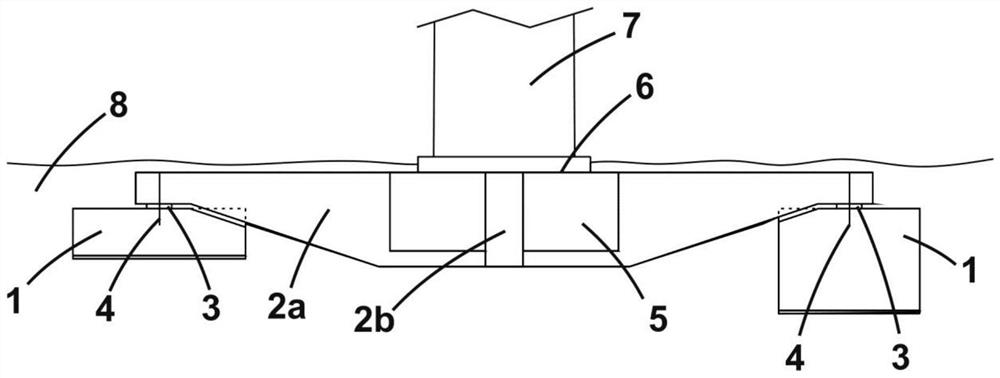

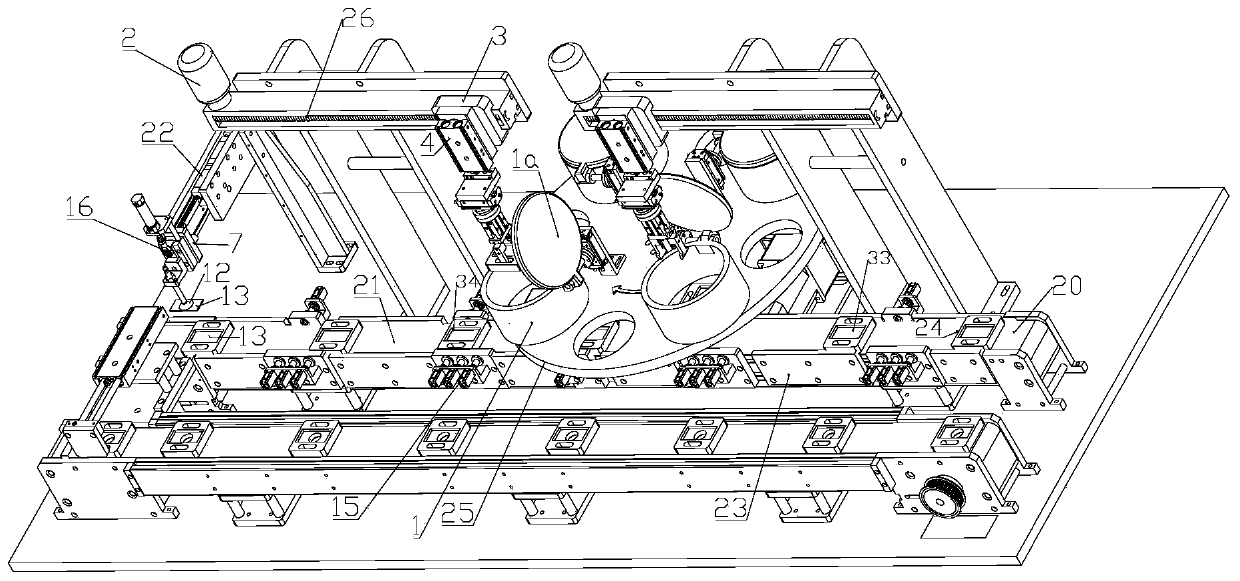

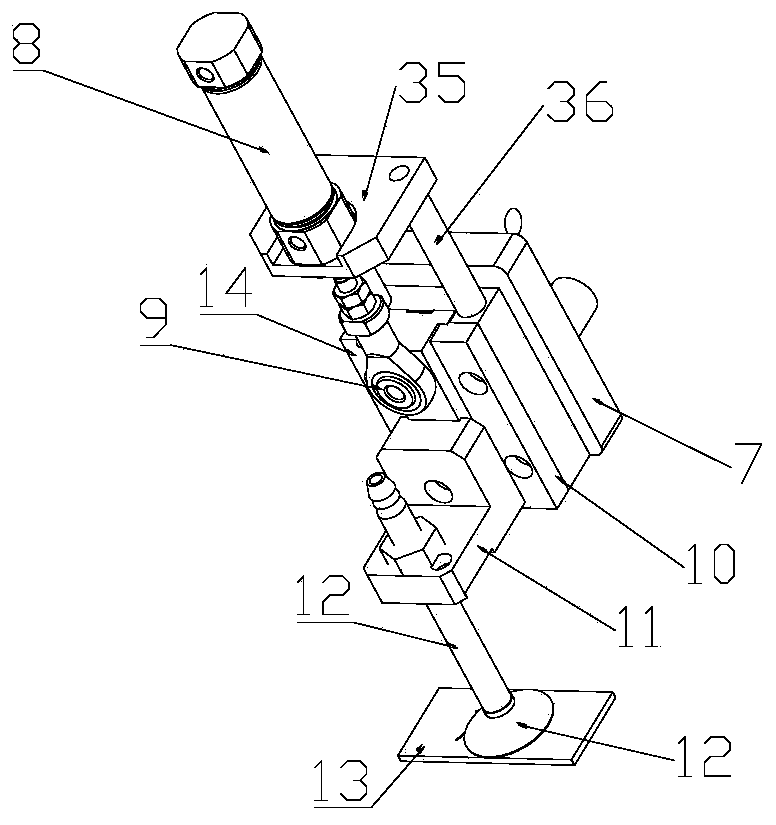

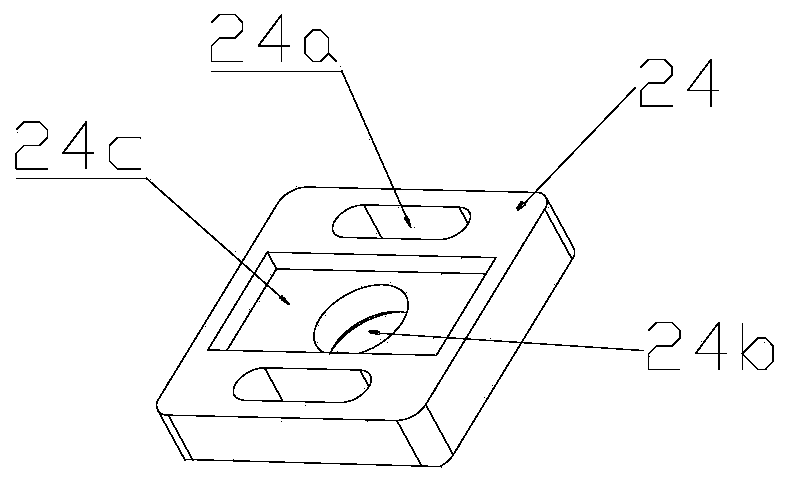

Tension leg floating box pier anti-collision protection device

InactiveCN105064284BDoes not narrow the effective widthNo reduction in capacityClimate change adaptationBridge structural detailsMarine engineeringBuoyancy

Owner:WUHAN UNIV OF TECH

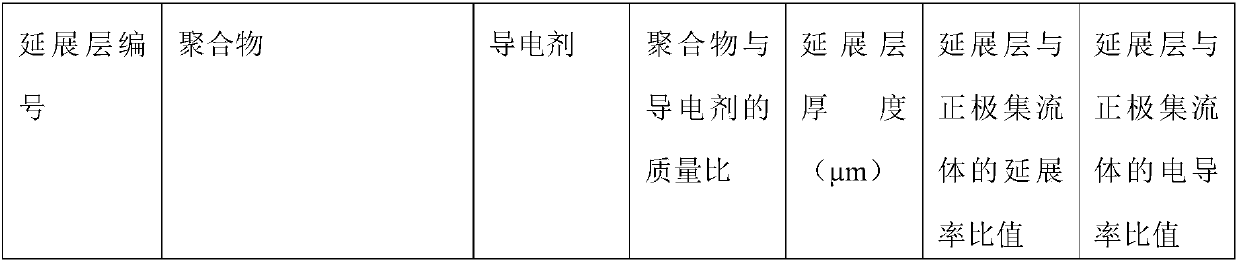

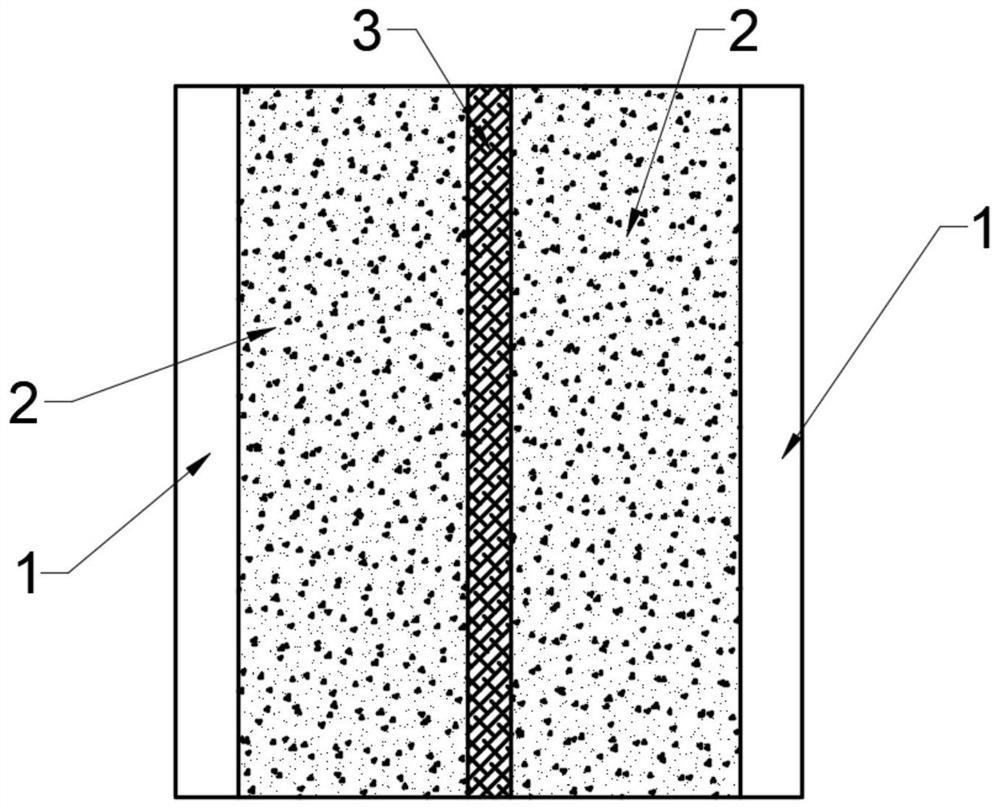

Positive pole piece and secondary battery using same

ActiveCN109560285APrevent high power short circuitNo reduction in capacityElectrode carriers/collectorsSecondary cellsEngineeringPole piece

The present invention relates to a positive pole piece. An extension layer containing specific polymer and a conductive agent is arranged between a positive pole current collector and a positive poleactive material layer. The extension layer comprises a polymer and a conductive agent, and the ratio of the extension layer and the extension rate of the positive pole current collector is (2-10):1. When core is abused, the extension layer can prevent the cell from high-power short circuit and cannot reduce the battery capacity.

Owner:CONTEMPORARY AMPEREX TECH CO

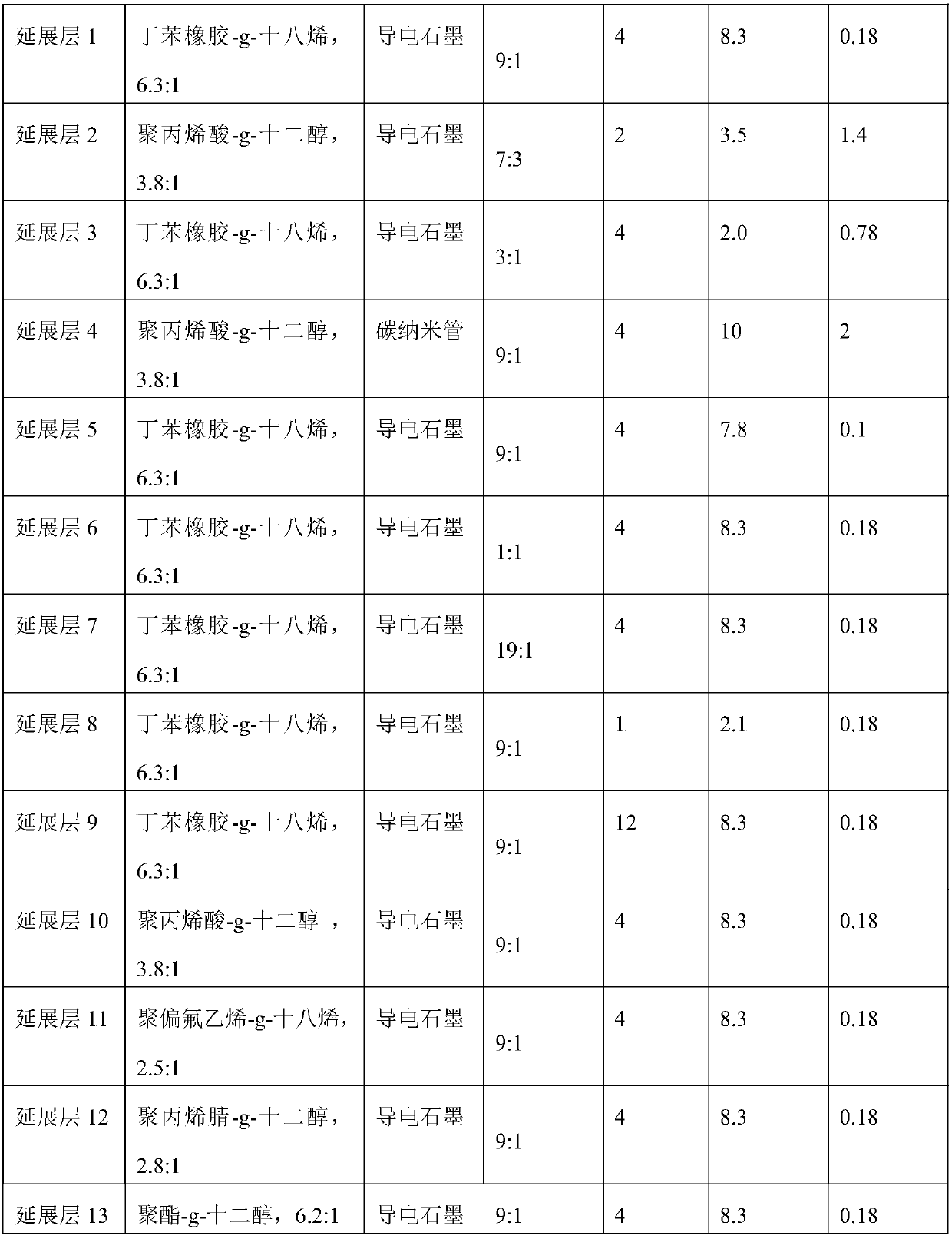

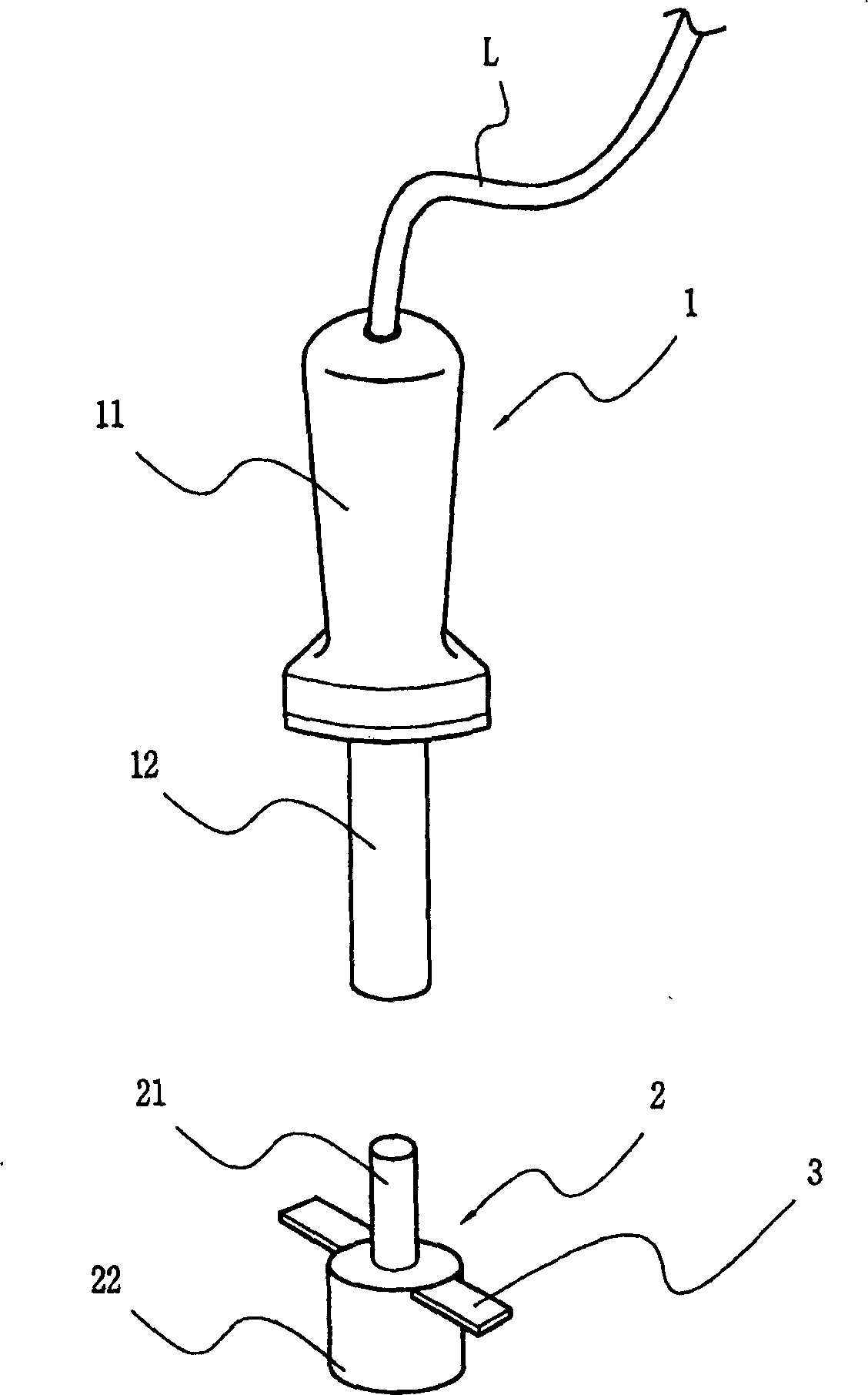

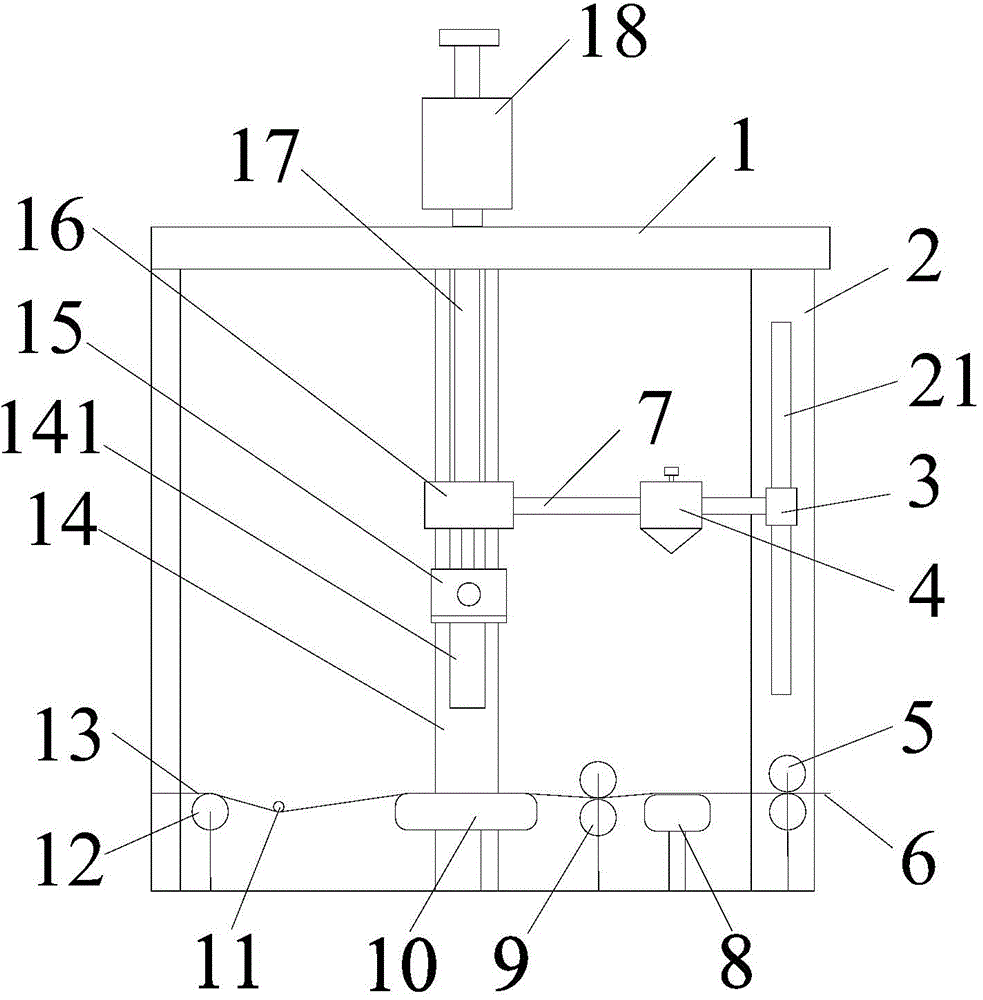

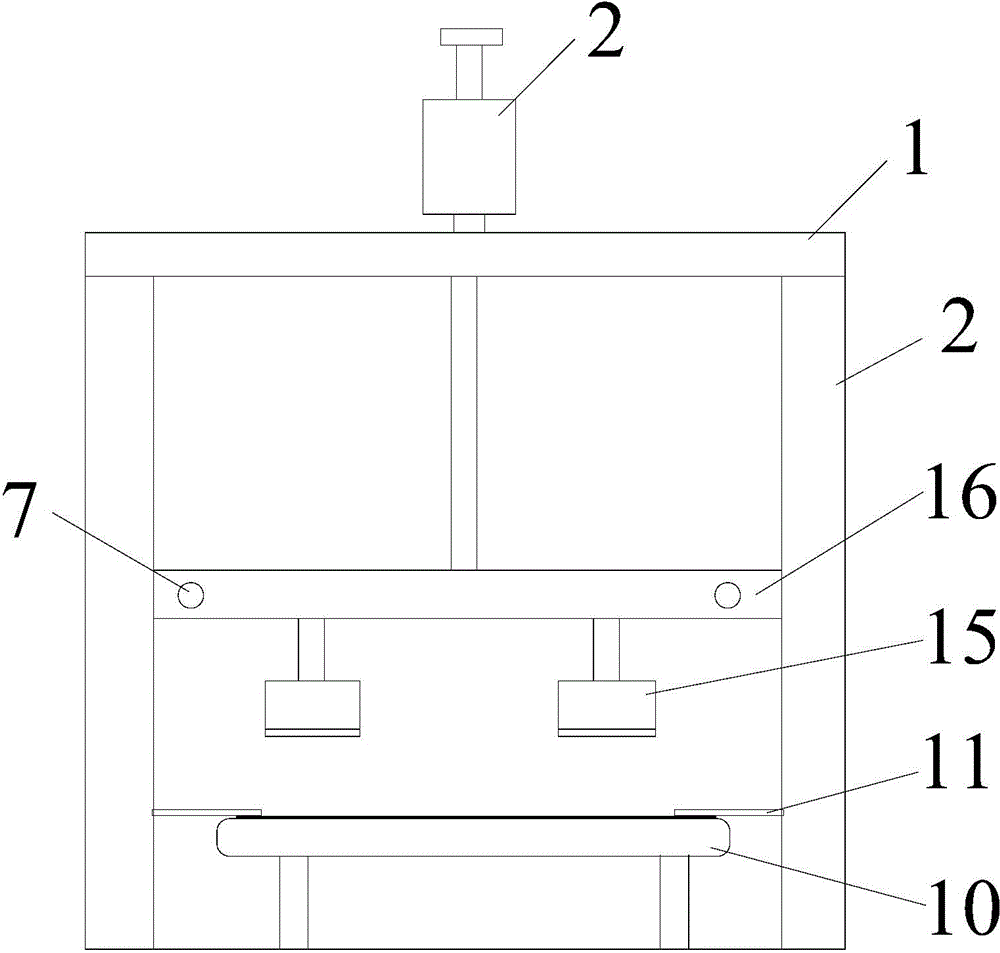

Device for manufacturing opening on ink powder/selenium cartrige for refilling and refilling method

InactiveCN1479180ANo reduction in capacityShorten the timeElectrography/magnetographyElectrical resistance and conductanceEngineering

The present invention relates to device for production of uncorks of dry toner / selenium-coated drum box of rechargeable laser printers as well as a process for recharging said boxes by using said device. Said device comprises a heating member having a handle and a heating shank; a heat treating element having a thermal conduction element (heat conductor), a ring form cut selvedge and holes with interior diameter equal to the cut selvedge; and a stopping member used for preventing the cut selvedge from invading into part of the box. Said process comprises the steps as follows: predetermining a time by utilizing the heating shank of the heating member which works in resistance heating mode; transferring the generated heat to the cut selvedge through the thermal conduction element to heat the cut selvedge to an appropriate temperature; locating the cut selvedge at the predetermined surface of the dry toner / selenium-coated drum box, pushing the cut selvedge with appropriate force to melt said surface, and working out rechargeable uncorks with interior diameter equal to that of the cut selvedge; recharging the containers of the dry toner / selenium-coated drum box with dry toner powder through said uncorks; sealing the uncork with plugs.

Owner:李南求

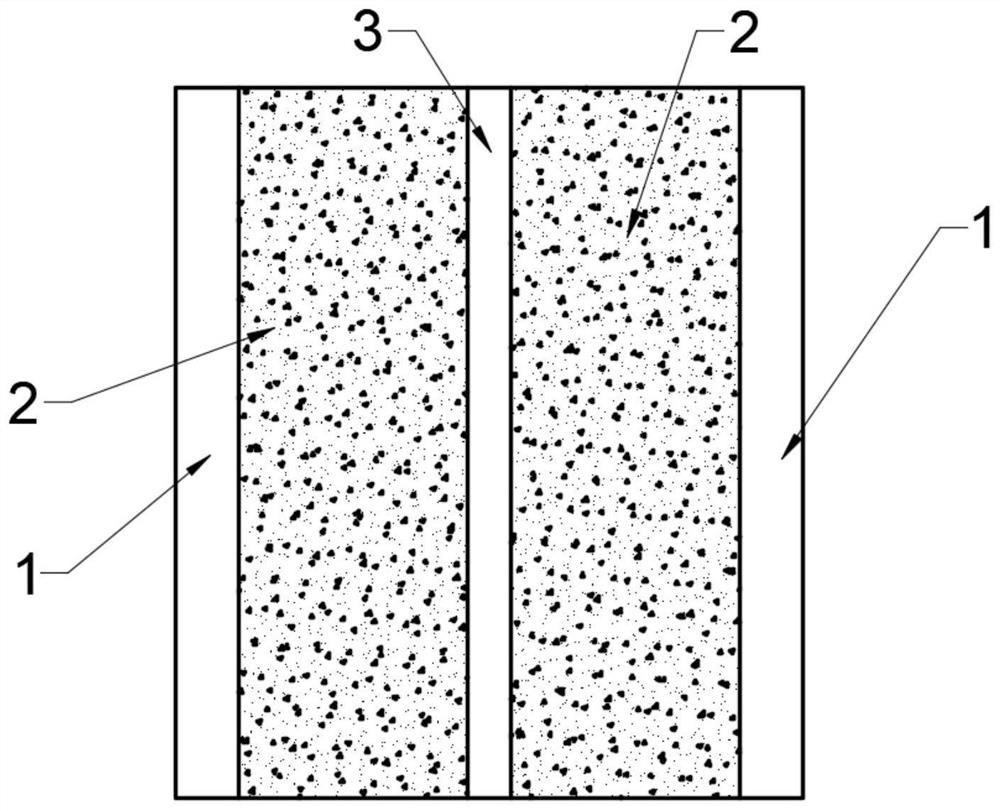

Multi-coating structure, negative pole piece and application of negative pole piece

ActiveCN113113564AAvoid the problem of falling powderConstant widthSecondary cellsElectrode collector coatingVoltage dropEngineering

The invention provides a multi-coating structure, a negative pole piece and application of the negative pole piece. The multi-coating structure comprises a current collector, the current collector is divided into at least one pole piece area along the width direction, and two active areas are arranged in the pole piece area at intervals along the width direction of the current collector. The surface of each active area is provided with an active slurry layer, an area between the active area and the long edge of the pole piece area is a tab empty foil area, an edge coating area is arranged between the active areas. The surface of the edge coating area is provided with an edge coating slurry layer, and the adhesive force of the edge coating slurry layer is greater than that of the active slurry layer. According to the invention, the problem of powder falling during tab cutting and welding can be effectively avoided, the voltage drop of a battery cell is normal, the yield of the battery cell is increased, the capacity of the battery cell is increased, the cycle life of the battery cell is prolonged, and the storage performance of the battery cell is improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

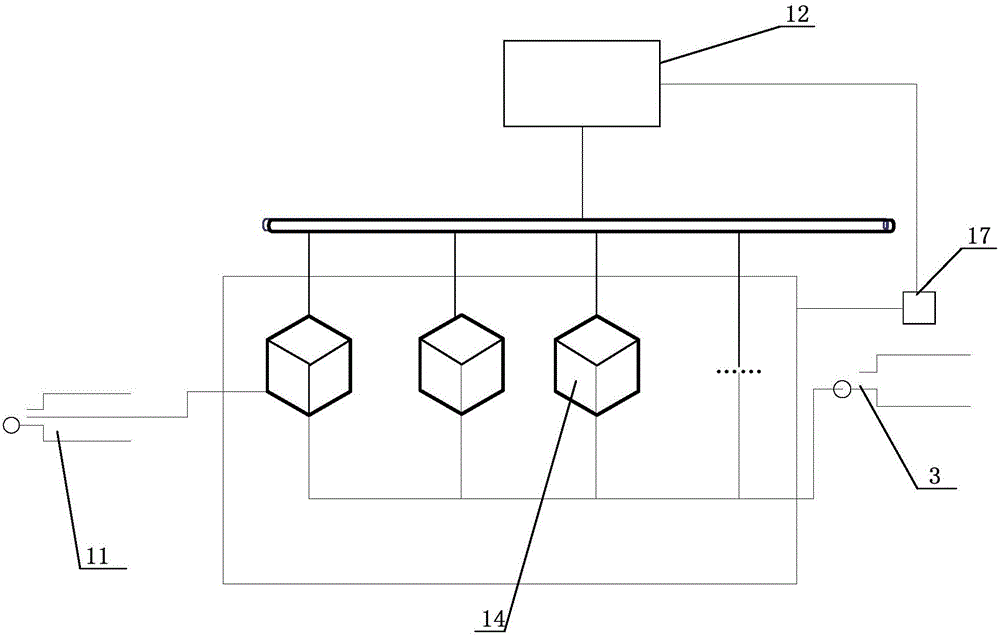

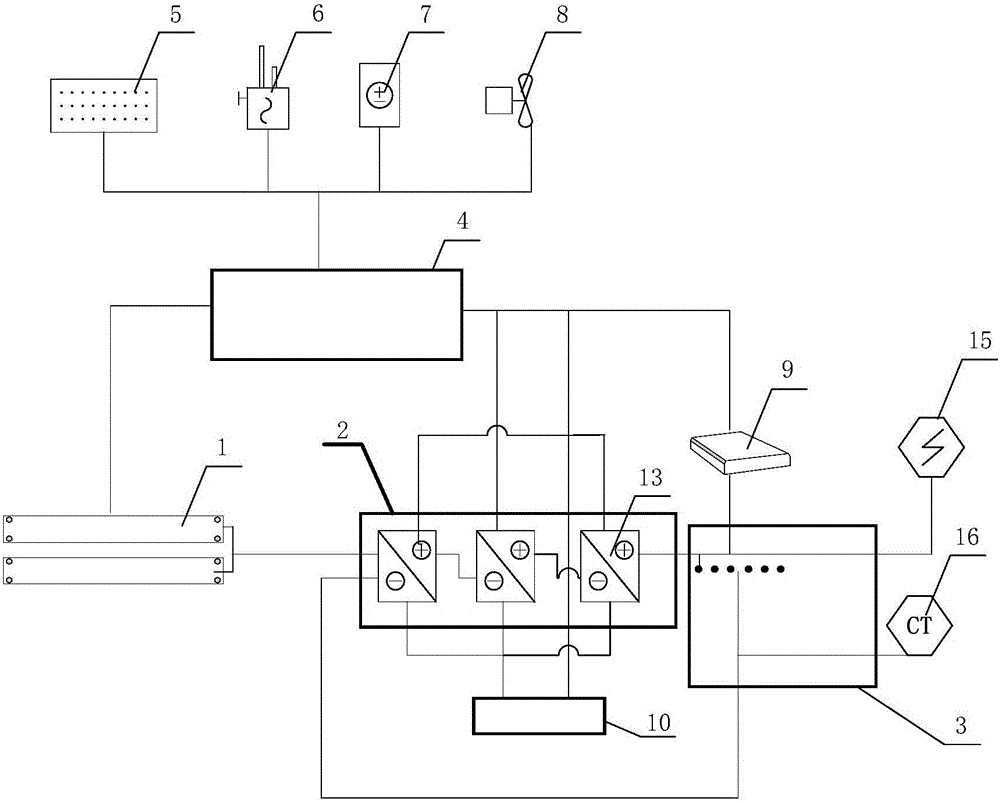

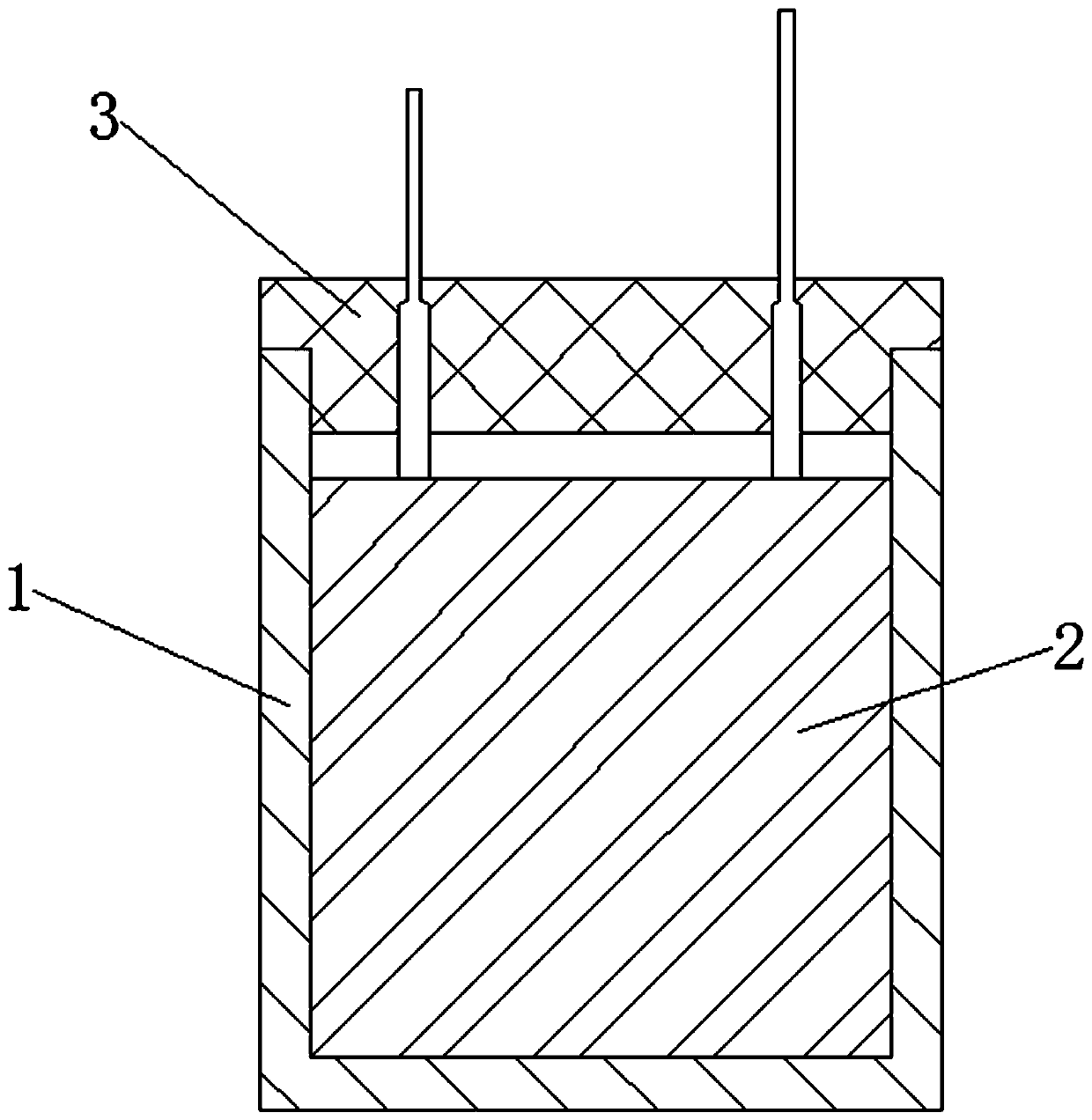

Modular lithium battery DC power system

ActiveCN106160084AExtended service lifeWide operating temperature rangeCharge equalisation circuitParallel/serial switchingControl mannerEngineering

The invention relates to a modular lithium battery DC power system, the system comprises a plurality of lithium battery packs, one of the lithium battery packs comprises an explosion-proof tank, a charging module is arrange in the explosion-proof tank, one end of the charging module is connected with an input end of one lithium battery pack through a wire, the lithium battery group is connected with a battery management system in a explosion-proof case, and the battery management system is separately connected with a fire extinguishing device, a smoke sensor, a heater, a fan, a discharge control unit and a equalization module in the explosion-proof case through wires in sequence; the equalization module is connected with the lithium battery pack through a wire, and the discharge control unit is connected with a DC output end through a wire. According to the invention, the service life is long, the applicable temperature range is wide, the control mode is optimized, the capacity is hardly reduced in maintenance process, the battery packs can perform on-line autonomous equalization, the battery packs can perform off-line autonomous maintenance, the battery packs support hot swap, and the using process is nontoxic and non-polluting.

Owner:BEIJING FANGZHI TECH CO LTD

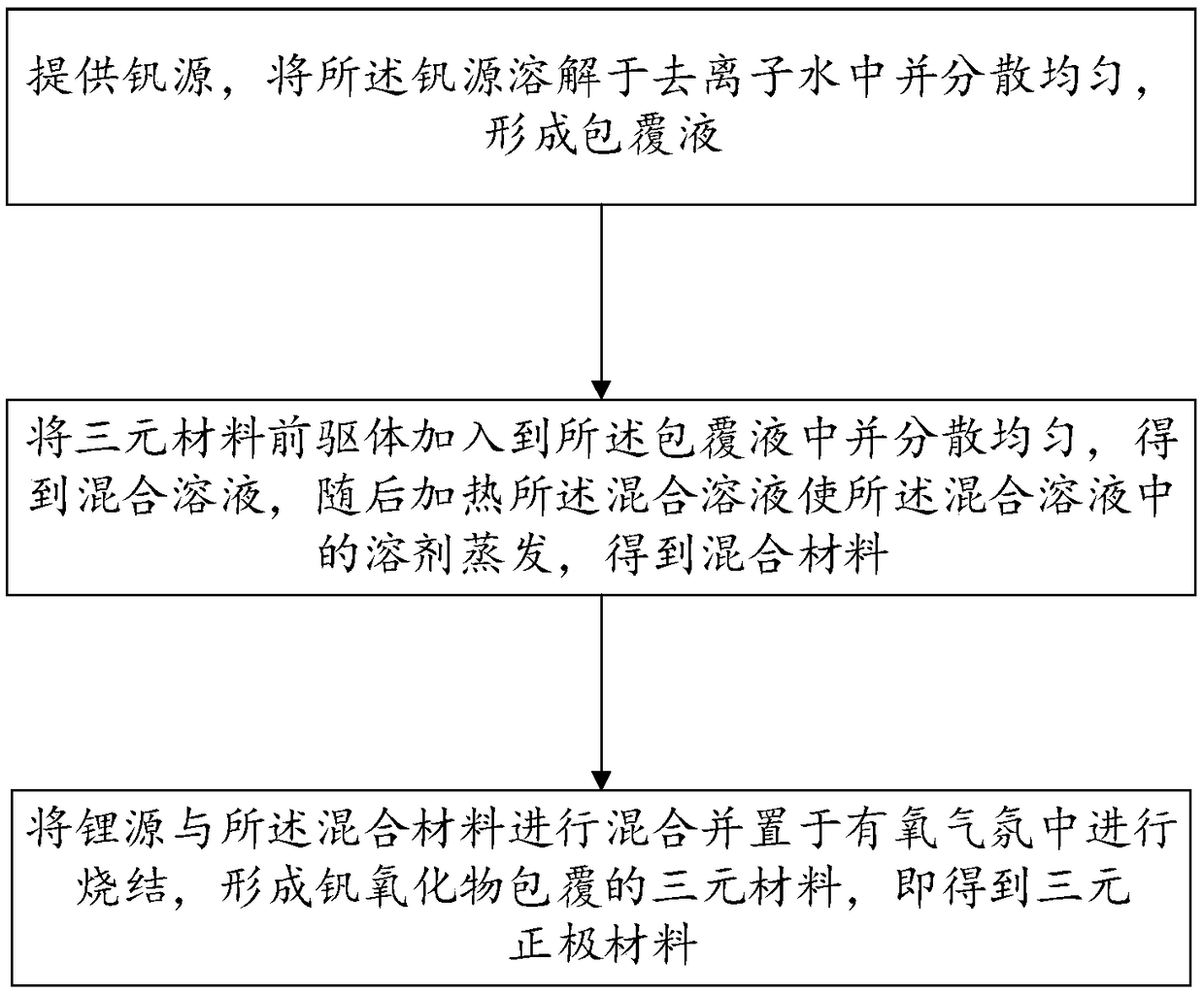

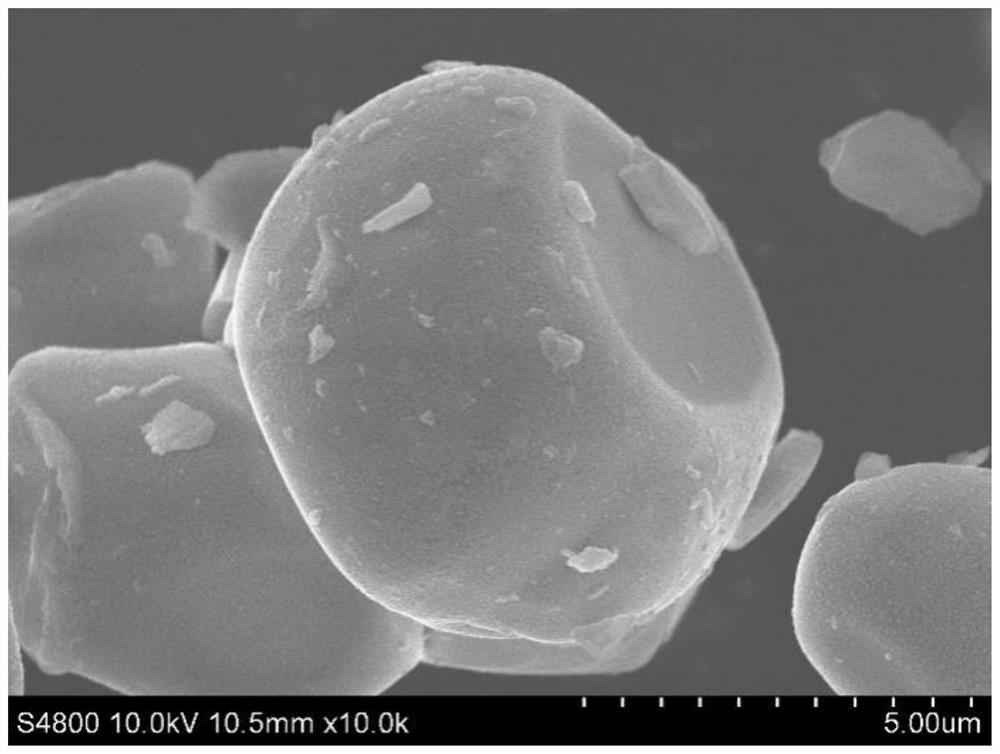

Ternary anode material and preparation method thereof

InactiveCN108899516AImprove cycle performanceImproved magnification performanceCell electrodesSecondary cellsLithiumVanadium oxide

The invention provides a ternary anode material. The material comprises a ternary material and a coating layer coating the surface of the ternary material, wherein the coating layer is prepared from vanadium oxide which is 0.1-10 percent of the mass of the ternary anode material. According to the ternary anode material, the surface of the ternary material is coated with the vanadium oxide layer, so that the transmission rate of the lithium ions of the ternary anode material can be effectively improved, the side reaction generated by direct contact of the ternary material and electrolyte can beinhibited since the contact area between the ternary material and electrolyte is reduced, corrosion of the electrolyte for the surface of the ternary material is reduced, the electrochemical performance of the ternary anode material is improved, and the cycling performance of the ternary anode material is improved. The invention further provides a method for preparing the ternary anode material,the ternary material coated with vanadium oxide can be prepared by once sintering process by improving the preparation process, and time and cost for processing can be greatly reduced.

Owner:FOSHAN DYNANONIC +1

Sodium-ion battery positive electrode material as well as preparation method and application thereof

PendingCN114843499ASimple methodReduce transportation and storage costsCell electrodesSecondary cellsSurface modificationMaterials science

The invention belongs to the technical field of battery materials, and particularly discloses a sodium ion battery positive electrode material and a preparation method and application thereof. The chemical formula of the sodium ion battery positive electrode material is NaxCuyFezMnaMbO2 + delta / (ZcOs + YrXOt), and the structure of the sodium ion battery positive electrode material is a ZcOs + YrXOt surface modified layered structure. The sodium ion battery positive electrode material disclosed by the invention can be obtained by carrying out one-step or multi-step mixing on various raw materials and then carrying out high-temperature sintering. The preparation method is simple, and all-around uniform coating is easy to form; and the prepared sodium ion battery positive electrode material is high in air stability, excellent in rate capability and stable in capacity.

Owner:溧阳中科海钠科技有限责任公司

Plastic bag sealing machine

InactiveCN105819032ANo reduction in capacityMeet the needs of strengthWrapper twisting/gatheringEngineeringUltimate tensile strength

A plastic bag sealing machine provided by the present invention comprises a frame, a driving system, a sealing mechanism and a tensioning mechanism. The sealing mechanism comprises a heat seal seat, heat seal blocks and a dead lever, each heat seal block is provided with a heating unit, and the heat seal seat is positioned below the two heat seal blocks. The tensioning mechanism comprises first material pressing rods and second material pressing rods, and the first material pressing rods and the second material pressing rods are respectively disposed at two sides of the heat seal seat and in contact with a bag mouth side boundary and a bag bottom side boundary of a plastic bag. Compared with the prior art, the plastic bag sealing machine is provided with two heat seal blocks to respectively perform individual widening, heat seal and bonding of side surface seals of the bag mouth and the bag bottom of the plastic bag, use intensity requirements of the plastic bag are satisfied, and capacity of the plastic bag cannot be reduced; and the seals of the bag mouth and the bag bottom of two adjacent plastic bags can be bonded by one-time heat seal operation, so that production efficiency is high, and product quality is good.

Owner:TIANJIN BINHAI NEW DISTRICT JINDA PLASTIC PROD CO LTD

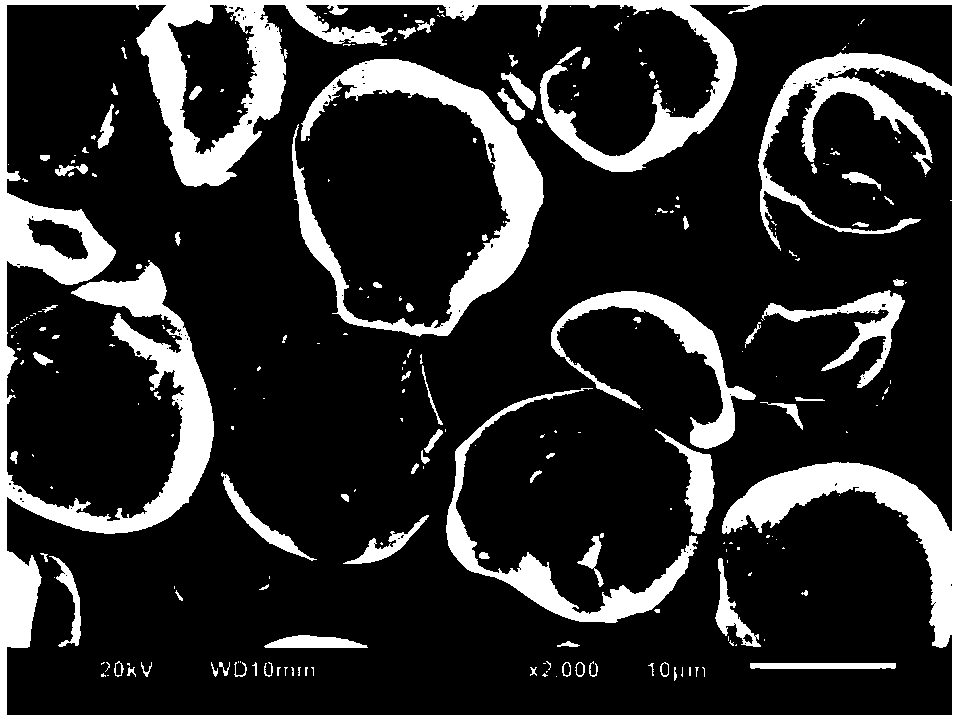

Preparation method of hollow mesoporous carbon material

The invention discloses a preparation method of a hollow mesoporous carbon material. The method comprises the following steps: carrying out surface carbonization on powder by taking the powder of Si, Ti, Cr or W and a gas containing carbon as raw materials so as to obtain a composite powder precursor of which the surface is of a carbide and the middle part is of a simple substance material; etching the obtained composite powder by utilizing chlorine to remove the Si, Ti, Cr or W element from the precursor so as to obtain the hollow mesoporous carbon material. The structure of the hollow mesoporous carbon material disclosed by the invention is different from that of a homogeneous mesoporous material in the prior art, namely, ions are effectively transported by virtue of hollow macropores, so that the fully utilization of micropores is realized. Thus, the phenomenon that the capacitance is obviously reduced due to the 'pore blocking' of a micropore structure is avoided. When the mesoporous carbon material with a hollow structure is applied to an electrode material of a capacitor, the charging efficiency is greatly improved and the charging time is obviously shortened.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

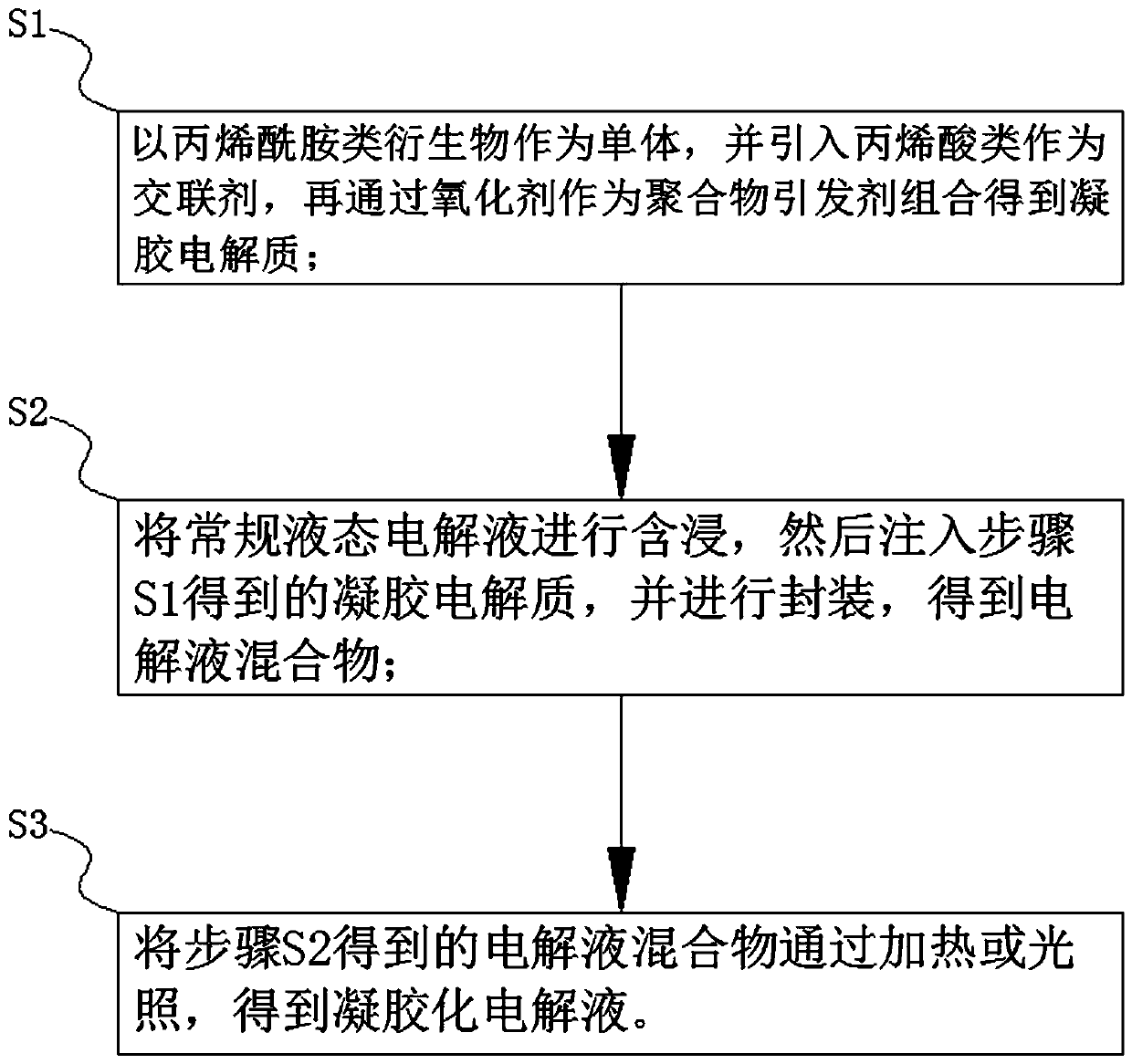

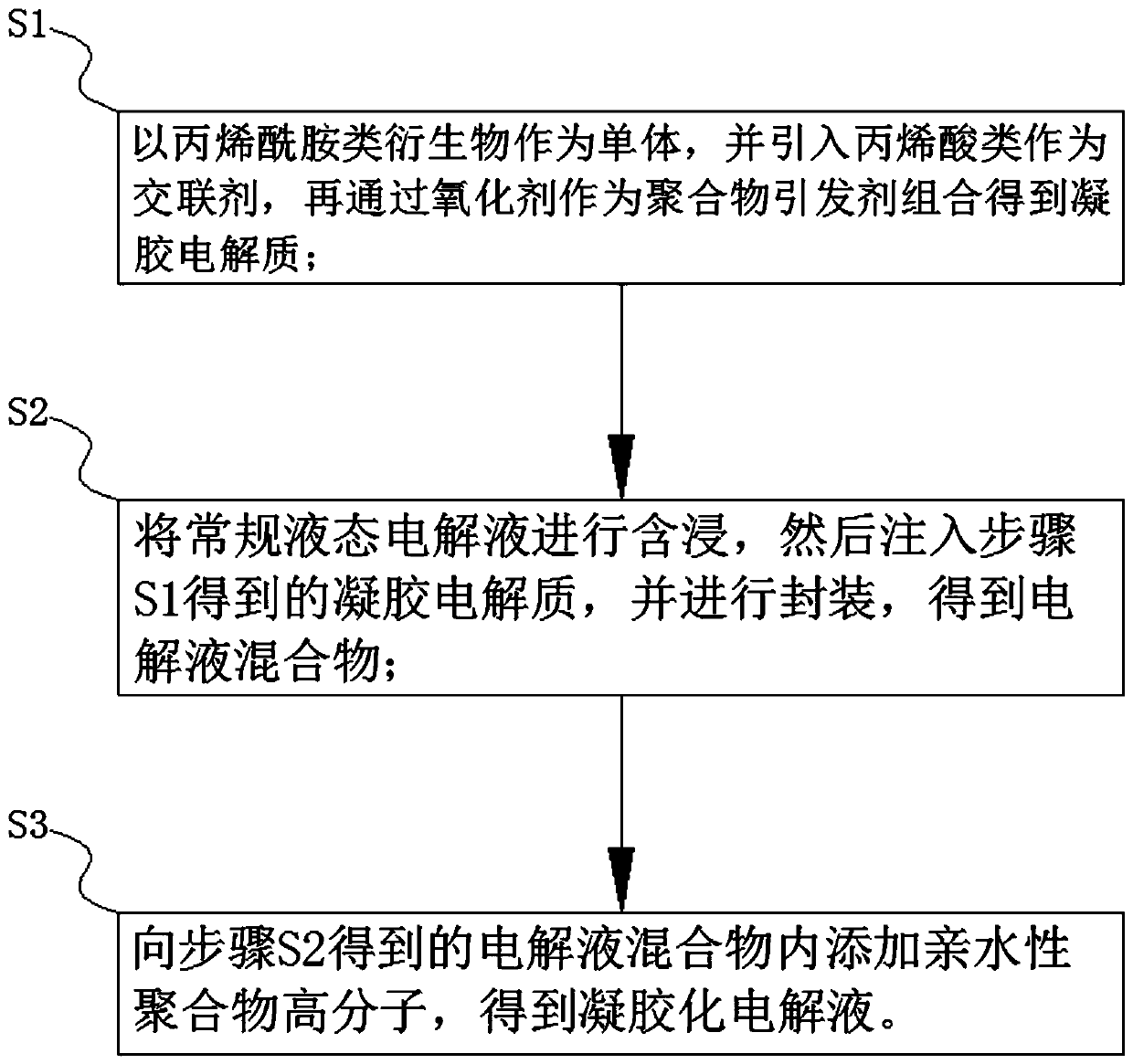

Preparation method of novel gel electrolyte and aluminum electrolytic capacitor

InactiveCN110690050AReduce liquidityEnsure safetySolid electrolytic capacitorsCapacitor electrolytes/absorbentsElectrolytic agentCross linker

The invention discloses a preparation method of a novel gel electrolyte and an aluminum electrolytic capacitor. The preparation method of the novel gel electrolyte comprises the following steps of: taking an acrylamide derivative as a monomer, and introducing acrylic acid as a cross-linking agent; S2, impregnating a conventional liquid electrolyte, injecting the gel electrolyte obtained in the step S1, and performing packaging to obtain an electrolyte mixture; S3, heating or illuminating the electrolyte mixture obtained in the step S2 to obtain a gelatinized electrolyte. The gelatinized electrolyte obtained by the manufacturing method disclosed by the invention can reduce the fluidity of the electrolyte, so that the electrolyte can be in a semi-solidified state in the core package after the core package is soaked in the electrolyte, free liquid electrolyte does not exist, the situation of liquid leakage does not occur, and the safety of the capacitor in use is ensured; and moreover, the capacity of the capacitor cannot be reduced by adopting the gelled electrolyte on the premise of improving the voltage endurance capability of the capacitor.

Owner:厦门法拉和信电子有限公司

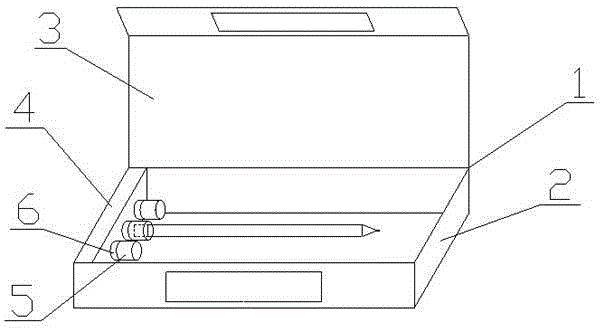

Pencil case capable of preventing pen core from being damaged

InactiveCN102907870ASo as not to damageNo reduction in capacityOther accessoriesMechanical engineeringComposite material

The invention relates to a pencil case capable of preventing a pen core from being damaged. The pencil case comprises a pencil case body; the pencil case body comprises a case body and a case cover; the case body and the case cover are closed through magnetic material; a magnet is mounted on the inner left side of the case body; a rubber pen cap is arranged inside the case body; a magnetic iron sheet is arranged on the end surface of the rubber pen cap; and the rubber pen cap is adsorbed on the magnet through the magnetic iron sheet. The pencil case capable of preventing a pen core from being damaged has the advantages that a pen can be fixed in the pencil case, so that the pen core can not be damaged, and the pen can be taken and used conveniently; and the capacity of the pencil case can not be decreased.

Owner:李雨恬

Foundation for wind turbine towers

PendingCN113195835ALow costEconomic savingsWind motor supports/mountsFoundation engineeringArchitectural engineeringTower

The invention relates to a foundation for wind turbine towers, of the type used to support both metal towers and concrete towers of wind turbines and which uses prefabricated concrete or metal beams combined with small footings constructed in situ with concrete, the beams being structurally connected to the central part of the foundation by means of elements for joining and supporting the tower. The invention provides the main advantage of achieving a significant reduction in the volume of materials used, both concrete and rebar, with a large reduction in assembly time and the consequent large economic saving, in addition to easy adaptation to different terrains.

Owner:HWS CONCRETE TOWERS SL

Freezing device of optical material laminating machine

The invention relates to a freezing device of an optical material laminating machine. The freezing device comprises a conveying belt and is characterized by further comprising a feeding mechanism, a first product carrying mechanism, a refrigerating mechanism and a second product carrying mechanism which are sequentially arranged along the conveying belt, and the refrigerating mechanism comprises arotating disc and four refrigerating boxes which are uniformly distributed on the rotating disc. Compared with the prior art, the freezing device has the following advantages that OCA is refrigeratedin advance through adding the four refrigerating boxes, so that glue overflow during stripping and laminating of the OCA is prevented; and the machine is reasonable in design, the productivity is notreduced after the machine is used, and waste of OCA cost is reduced.

Owner:南京冠石科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com