Ternary anode material and preparation method thereof

A technology of ternary materials and positive electrode materials, applied in the field of electrochemical materials, can solve the problems of reducing the first discharge capacity, etc., and achieve the effects of improving electrochemical performance, suppressing side reactions, and great practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

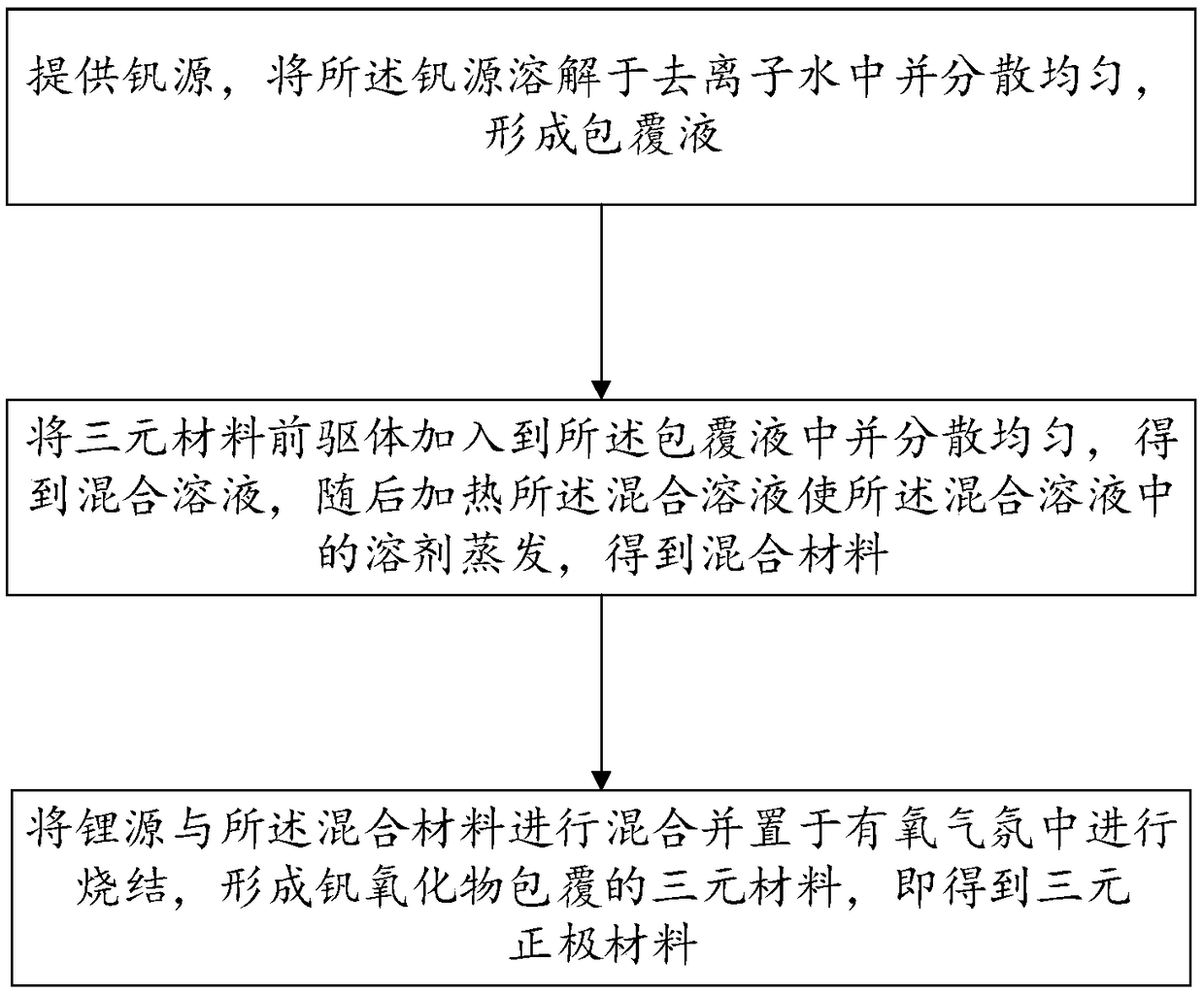

[0033] A method for preparing a ternary positive electrode material provided in an embodiment of the present invention includes the following preparation steps:

[0034] Step 1: providing a vanadium source, dissolving the vanadium source in deionized water and dispersing it uniformly to form a coating solution;

[0035] Step 2: adding the ternary material precursor to the coating solution and dispersing it evenly to obtain a mixed solution, then heating the mixed solution to evaporate the solvent in the mixed solution to obtain a mixed material;

[0036] Step 3: mixing the lithium source with the mixed material and sintering in an oxygen atmosphere to form a vanadium oxide-coated ternary material to obtain a ternary positive electrode material.

[0037]First of all, in the prior art, when the ternary material precursor and the lithium source form a ternary material, a sintering is required, and when the ternary material and the vanadium source form a vanadium oxide-coated tern...

Embodiment 1

[0049] A preparation method of a ternary positive electrode material, comprising the following steps:

[0050] Step 1: Take 15.02g of vanadium pentoxide, dissolve the vanadium pentoxide in 5000g of deionized water, stir and disperse evenly, and form a coating solution;

[0051] Step 2: Add 1kg of Ni 0.8 co 0.1 mn 0.1 (OH) 2 Add it into the coating solution and stir to disperse evenly to obtain a mixed solution, then heat and dry at 100°C for 5 hours, and then grind to obtain a mixed material;

[0052] Step 3: Mix 510.05g of lithium hydroxide monohydrate with the mixed material and place it in oxygen for sintering. The specific process of sintering is to pre-sinter at 600°C for 5 hours from room temperature at a heating rate of 5°C / min, and continue The temperature was raised to 780h at a heating rate of 5°C / min and sintered for 20h to finally obtain a ternary cathode material.

Embodiment 2

[0054] A preparation method of a ternary positive electrode material, comprising the following steps:

[0055] Step 1: Take 10 g of vanadyl oxalate, dissolve vanadyl oxalate in 500 g of deionized water, stir and disperse evenly, and form a coating solution;

[0056] Step 2: Add 1kg of Ni 0.8 co 0.1 mn 0.1 (OH) 2 Add it into the coating solution and stir to disperse evenly to obtain a mixed solution, then heat and dry at 150°C for 3 hours, and then grind to obtain a mixed material;

[0057] Step 3: Mix 510.05g of lithium hydroxide monohydrate with the mixed material and place it in oxygen for sintering. The specific process of sintering is to heat up from room temperature at a rate of 5°C / min to 500°C for 8 hours, and continue The temperature was raised to 900h at a heating rate of 5°C / min and sintered for 10h to obtain a ternary cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com