Non-aqueous electrolyte secondary battery

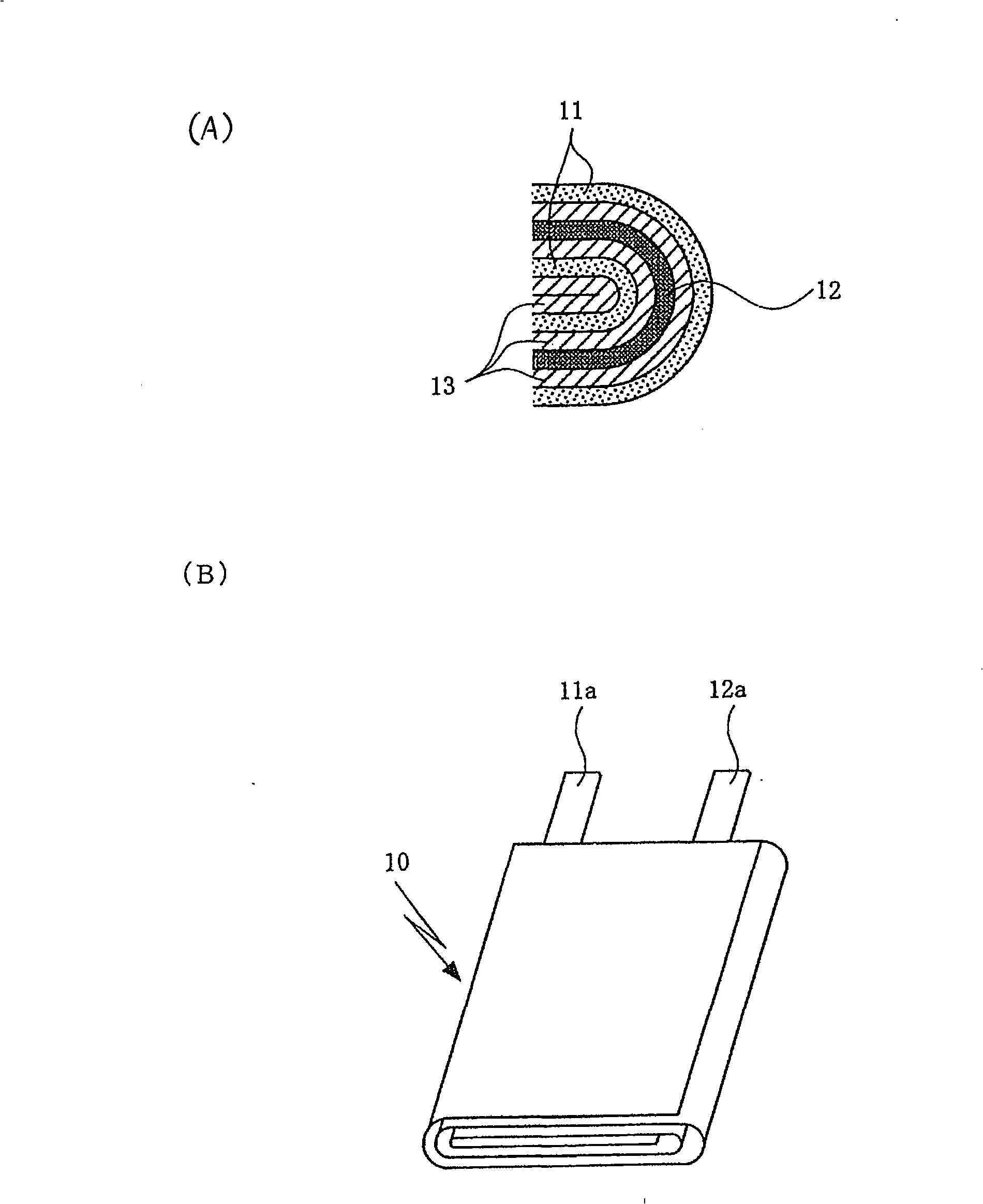

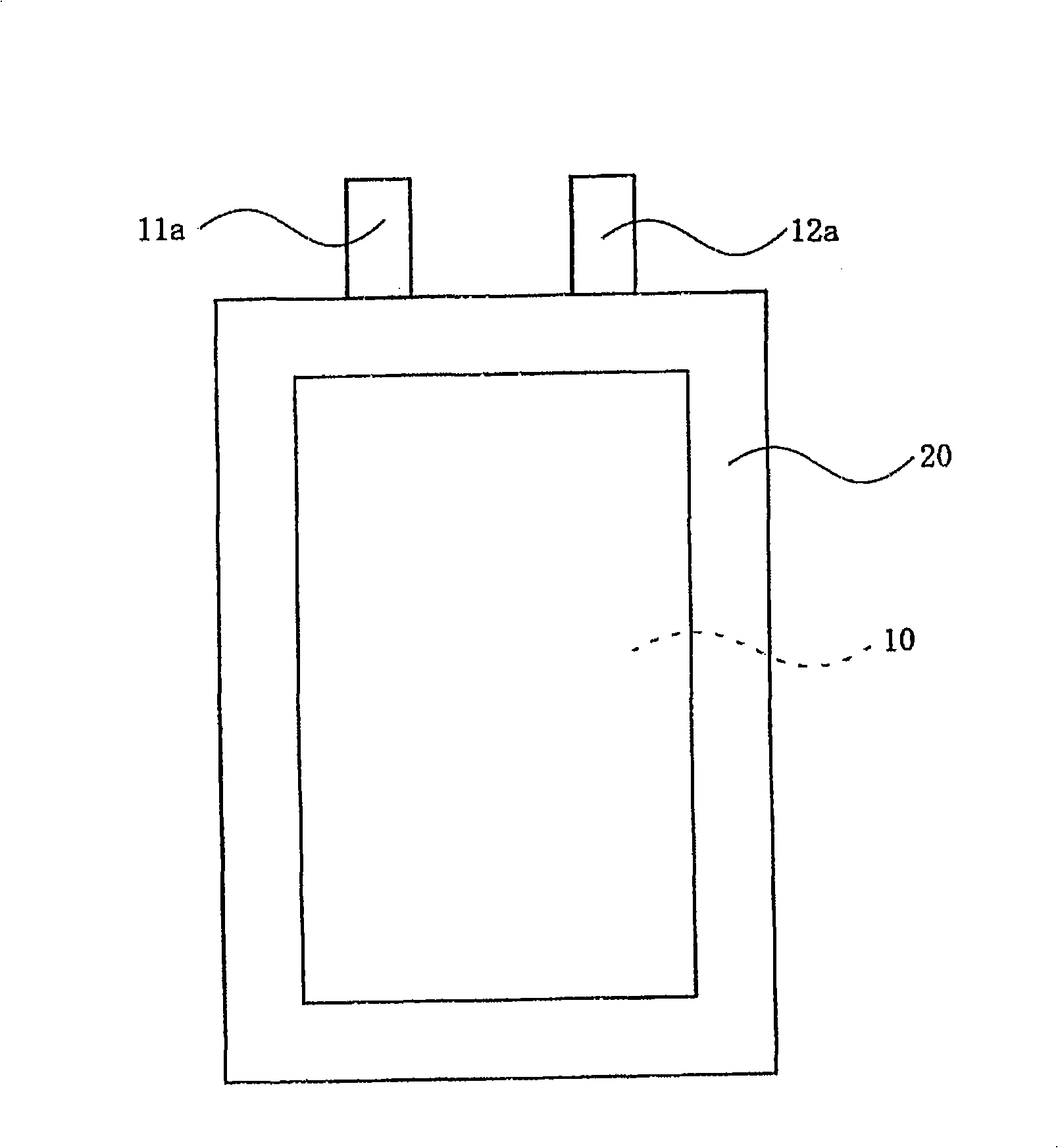

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte batteries, non-aqueous electrolytes, secondary batteries, etc., can solve the problem of increased surface resistance of positive active materials, battery expansion, and the inability to obtain high-capacity non-aqueous electrolyte secondary batteries. Level battery and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In Example 1, positive and negative electrodes and non-aqueous electrolytic solutions prepared as described below were used.

[0039] [making of positive electrode]

[0040] When making the positive electrode, LiOH and Ni, which is a metal composite hydroxide mainly composed of nickel 0.80 C 0.17 Al 0.03 (OH) 2 The molar ratio is 1.05:1, mixed with Ishikawa-type Lake (らいかい) mortar, heat-treated at 720 °C for 20 hours in an oxygen atmosphere, and then pulverized to obtain an average particle size of about 10 μm, composition for Li 1.05 Ni 0.80 C 0.17 Al 0.03 o 2 A positive electrode active material composed of a lithium-containing transition metal composite oxide. Here, 2 g of the positive electrode active material was put into 100 g of water and stirred for 10 minutes, and then the pH of the supernatant was measured, and the pH of the supernatant was 10.8.

[0041] Next, make the above Li 1.05 Ni 0.80 C 0.17 Al 0.03 o 2 The composition of the positive ele...

Embodiment 2

[0049] In Example 2, when preparing the non-aqueous electrolytic solution in the above-mentioned Example 1, 2.0% by weight of vinylene carbonate (VC) and 0.5% by volume of a cyclic ether having an unsaturated bond were added to the above-mentioned non-aqueous electrolytic solution. furan, except that, in the same manner as in the above-mentioned Example 1, a non-aqueous electrolyte secondary battery was produced.

Embodiment 3

[0051] In Example 3, when preparing the non-aqueous electrolytic solution in the above-mentioned Example 1, 2.0% by weight of vinylene carbonate (VC) and 1.0% by volume of a cyclic ether having an unsaturated bond were added to the above-mentioned non-aqueous electrolytic solution. Tetrahydrofuran (THF) was used, and a non-aqueous electrolyte secondary battery was produced in the same manner as in Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com