Vehicle body front part structure

一种车身前部、腿部的技术,应用在上部结构、上部结构分总成、车辆部件等方向,能够解决铁锈、裙板侧构件易变形等问题,达到提高减震性能、材料质量和板厚度最优化、提高能量吸收效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

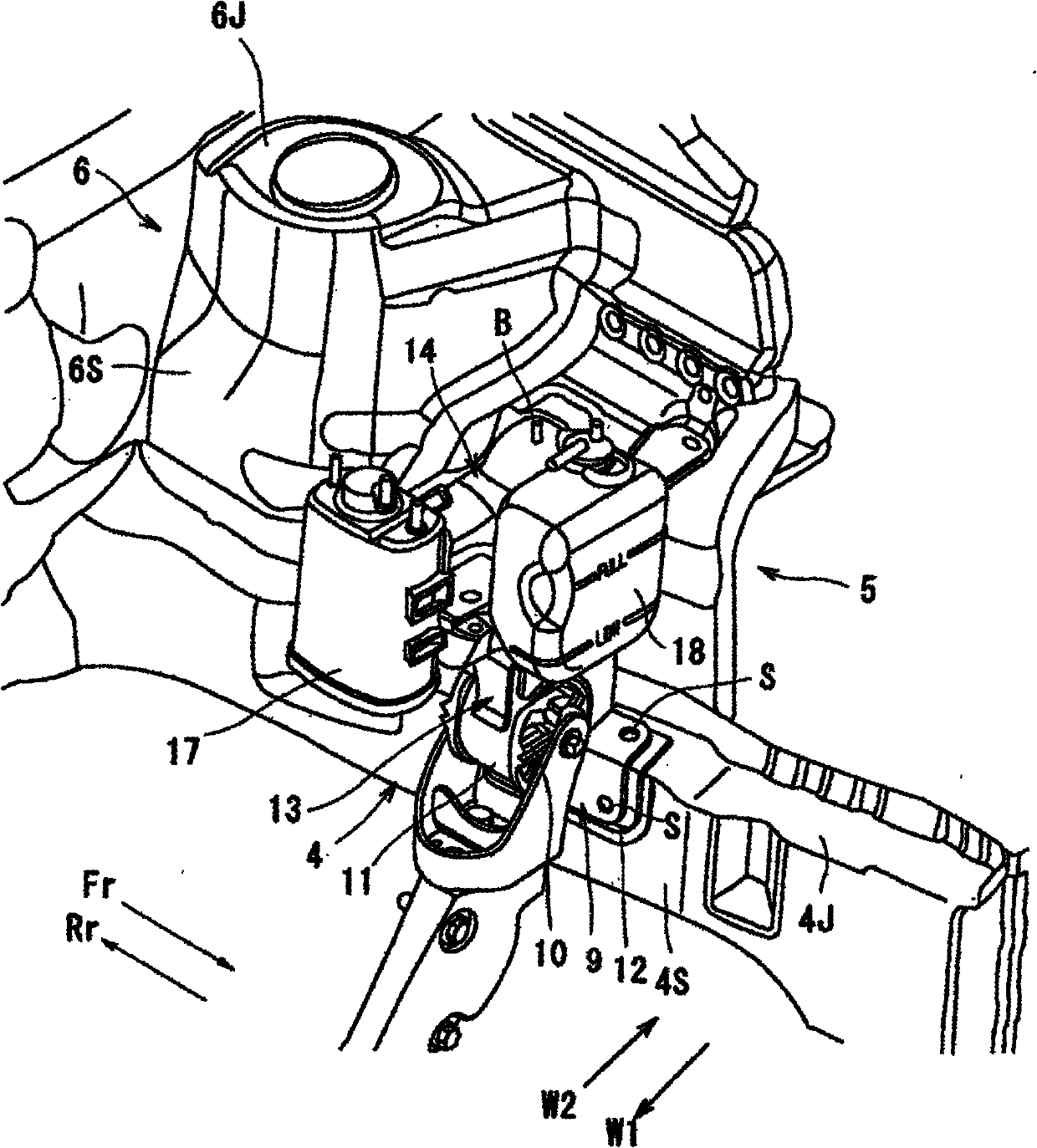

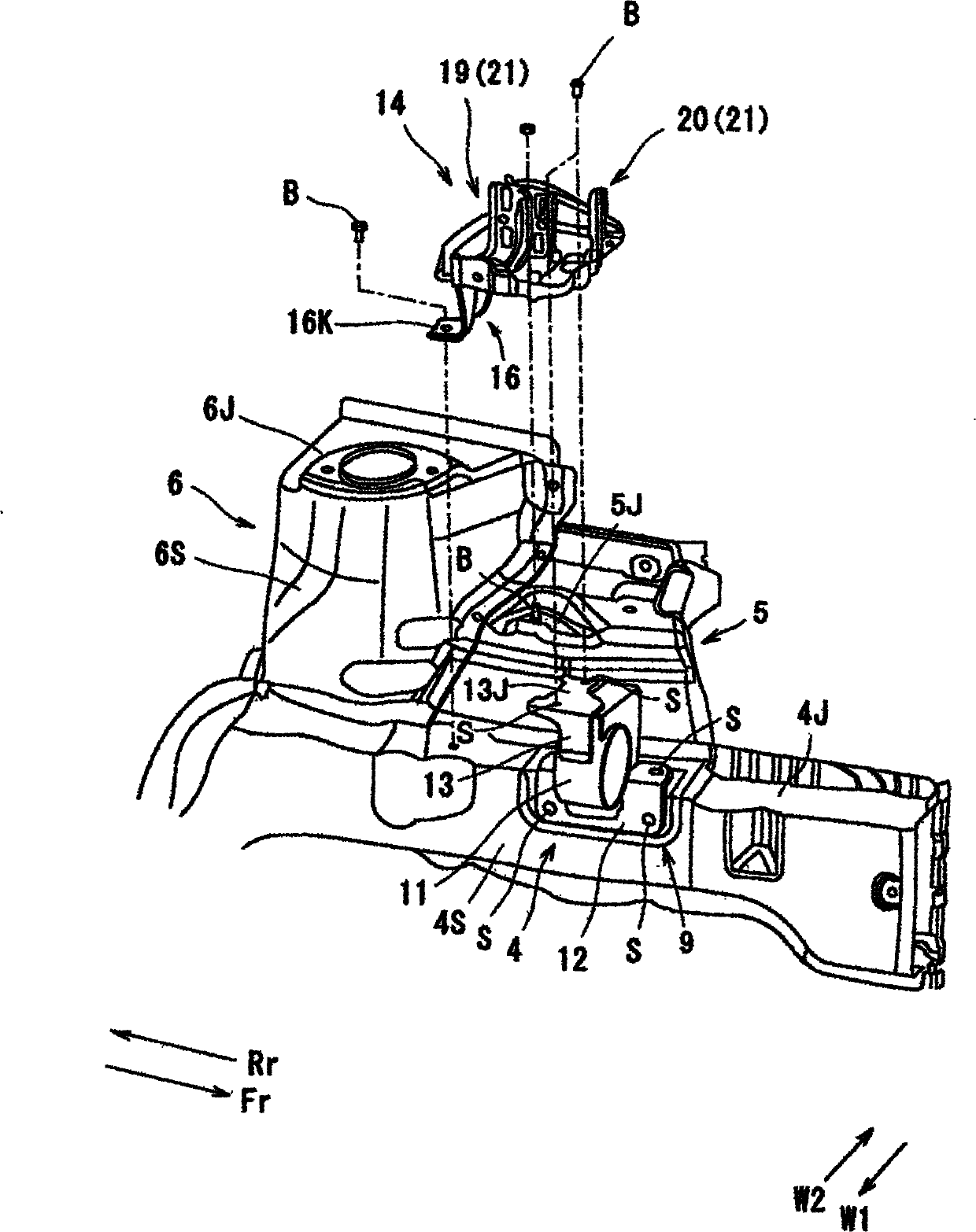

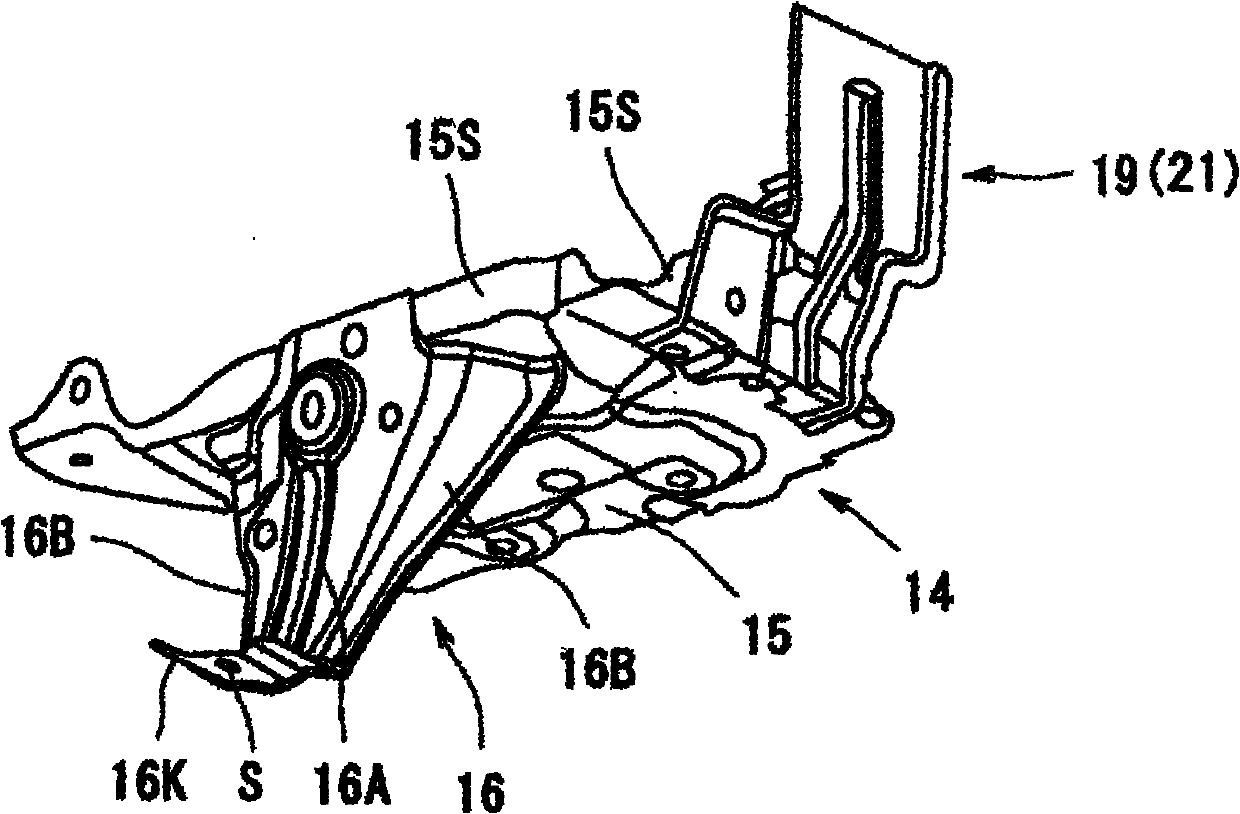

[0031] figure 1 And FIG. 3(a) and FIG. 3(b) show the front structure of the vehicle body of the motor vehicle. The structure of the front part of the vehicle body includes: a dash panel 3 separating the cabin 2 from the engine room 1; a rectangular tubular skirt side member 4 extending in the longitudinal direction of the vehicle; a skirt side plate 5; The interior W1 in the vehicle width direction extends to the strut tower portion 6 in the engine compartment 1 .

[0032] The strut tower portion 6 includes: an outer peripheral wall 6S having a trapezoidal cross-section narrowed toward the inside W1 in the vehicle width direction; and an upper wall 6J connected to the upper end portion of the outer peripheral wall 6S and combined with Suspension for front wheels. The corners in the cross section of the outer peripheral wall 6S are curved in an arc shape. The apron side panel 5 is joined to the apron side member 4 by welding, and a part of the apron side panel 5 protrudes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com