Lithium cobalt oxide material of core-shell structure and preparation method of lithium cobalt oxide material

A technology for the structure of lithium cobalt oxide and lithium cobalt oxide is applied in the field of lithium cobalt oxide materials, core-shell structure lithium cobalt oxide materials and their preparation, and can solve the problems of large internal resistance, no electrochemical activity, and poor rate performance of batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051]According to a preferred embodiment of the present invention, the weight percentage of the doping element A in the core is 0-3 wt%.

[0052] In a further preferred embodiment, the weight percentage of the doping element A in the core is 0.001-2 wt%.

[0053] In a further preferred embodiment, the weight percentage of the doping element A in the core is 0.01-1 wt%.

[0054] Among them, no doping or a small amount of doping is carried out in the core.

[0055] According to a preferred embodiment of the present invention, the weight ratio of the doping element X to the shell is 0.01-5 wt%.

[0056] In a further preferred embodiment, the weight ratio of the doping element X to the shell is 0.3-3 wt%.

[0057] In a further preferred embodiment, the weight ratio of the doping element X to the shell is 0.9-1.5 wt%.

[0058] Among them, doping is carried out on the shell, and the doping amount is higher than that in the core, because the side reaction of lithium cobalt oxide ...

Embodiment 1

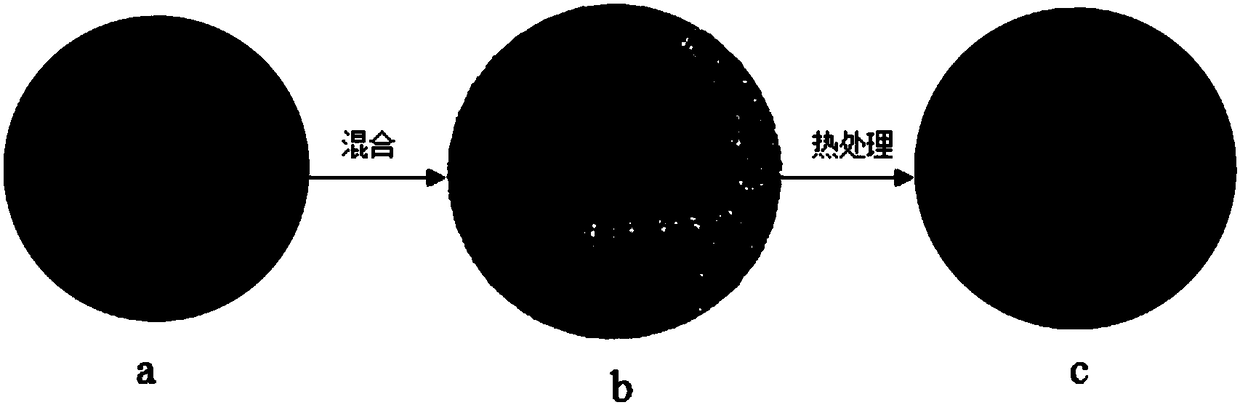

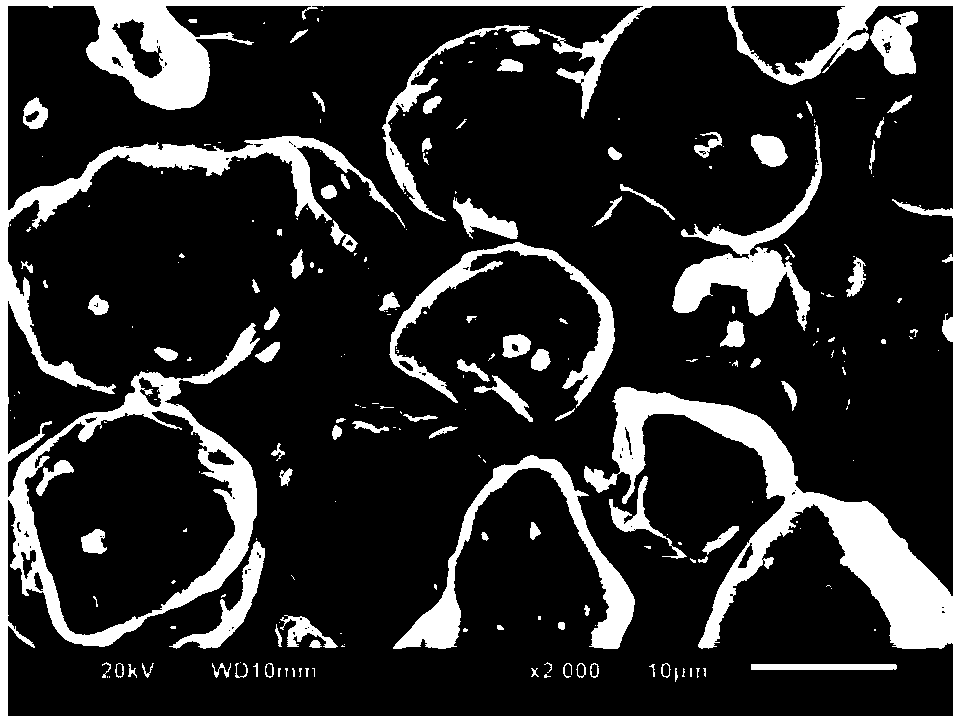

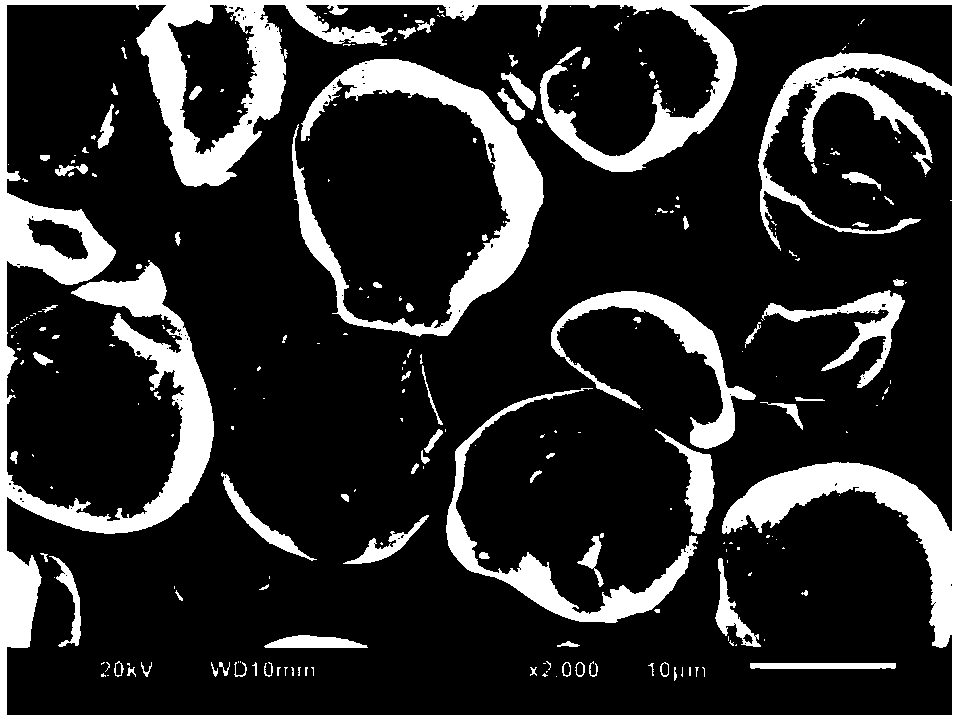

[0120] Mix 100g of cobalt tetroxide and 47.4g of lithium carbonate, wherein the Li:Co molar ratio is 1.03, and then add 0.5g of nanometer Al 2 o 3 , ball milled and mixed for 2 hours, and the homogeneously mixed material was sintered at 1040° C. for 10 hours, cooled naturally to room temperature, crushed and sieved to obtain a core matrix material.

[0121] 20g nano cobalt carbonate and 6.3g nano lithium carbonate are mixed, wherein, Li:Co molar ratio is 1.01, adds the nano Al of 0.3g 2 o 3 , ball milled and mixed for 2h to obtain the shell precursor.

[0122] The core matrix material and the shell precursor were mixed by ball milling for 2 hours, then sintered at 1000° C. for 10 hours, cooled naturally to room temperature, crushed and sieved to obtain a lithium cobalt oxide material with a core-shell structure.

Embodiment 2

[0124] Mix 100g of cobalt tetroxide and 47.4g of lithium carbonate, wherein the Li:Co molar ratio is 1.03, ball mill and mix for 2 hours, sinter the uniformly mixed material at 1040°C for 10 hours, cool naturally to room temperature, crush and sieve to obtain the core matrix material.

[0125] Mix 20g nanometer cobalt carbonate and 6.4g nanometer lithium carbonate, wherein, Li:Co molar ratio is 1.01, add 0.1g nanometer Al 2 o 3 , 0.1g nanometer MgO and 0.1g nanometer TiO 2 , ball milled and mixed for 2h to obtain the shell precursor.

[0126] The core matrix material and the shell precursor were mixed by ball milling for 2 hours, then sintered at 1000° C. for 10 hours, cooled naturally to room temperature, crushed and sieved to obtain a lithium cobalt oxide material with a core-shell structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com