Patents

Literature

48results about How to "No weight loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

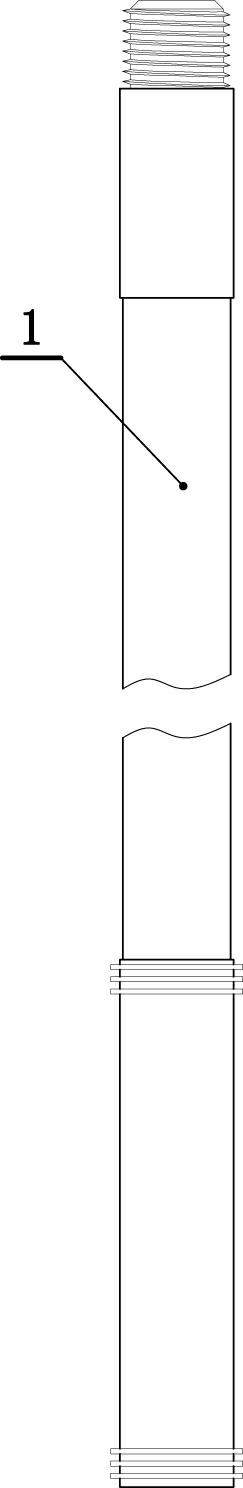

Environment-friendly concrete pole

ActiveCN103225439ASmall electric fluxNo weight lossCeramic shaping apparatusTowersSlagMesh reinforcement

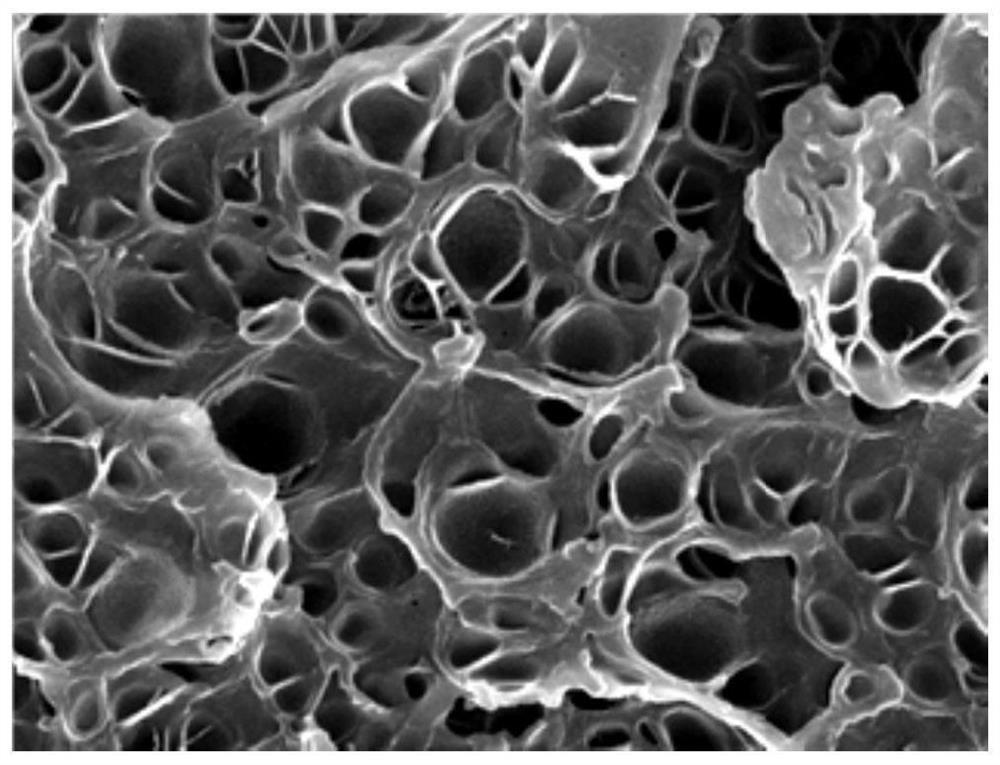

The invention relates to the field of transmission equipment, in particular to a concrete pole. Concrete is uniformly distributed on a reinforcing steel bar mesh, so that the pole is formed. The concrete comprises raw materials in parts by mass as follows: 480-550 parts of low-alkaline Portland cement or ordinary Portland cement with an average grain diameter of 30-60 mu m, 120-140 parts of silica fume with an average grain diameter of 0.18 mu m and the SiO2 content of no less than 85%, 80-110 parts of I-level pulverized fuel ash with an average grain diameter of 10-20 mu m, 110-140 parts of slag powder with the level higher than S95 and an average grain diameter of 10-30 mu m, 510-550 parts of quartz sand with a grain diameter of 0.16-1.63 mm, 860-920 parts of cobbles with a grain diameter of 5-14 mm, 14-18 parts of a compound high-efficiency slushing agent with a water-reducing rate higher than 30%, 7-12 parts of a corrosion inhibitor, 120-140 parts of water, 70-110 parts of a copper plating steel fiber with a diameter of 0.18-0.25 mm and a length of 10-15 mm and 0.8-1.5 parts of a polypropylene fiber. Prestressed wires with a diameter of 4.8-10.7 mm and taken as main bars and high-strength hard-drawn wires with a diameter of 3.0-5.0 mm and taken as circular structural bars are woven, so that the reinforcing steel bar mesh is formed.

Owner:黄贺明

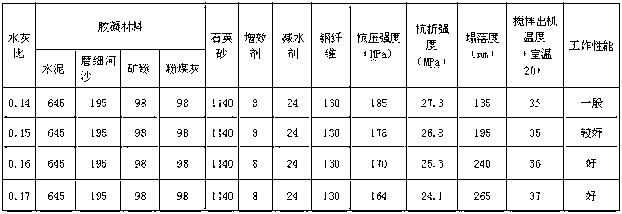

Environment-friendly ground fine river sand powder concrete

ActiveCN103224358ANo weight lossReduce usageCeramic shaping apparatusWater reducerToxic industrial waste

The invention relates to the technical field of concrete, and more specifically relates to an environment-friendly ground fine river sand powder concrete. The concrete is prepared by the following raw materials by mass: 590-700 parts of 52.5 grade portland cement with average particle sizes of 30-60 [mu]m; 180-210 parts of ground fine river sand powder with average particle sizes of 5-20 [mu]m, ignition loss lower than or equal to 0.4% and SiO2 content higher than or equal to 93%, 85-100 parts of I grade fly ash with average particle sizes of 10-30 [mu]m, 85-100 parts of mineral powder higher than S95 grade with average particle sizes of 10-30 [mu]m, 1,030-1,200 parts of quartz sand with average particle sizes of 0.16-1.63 mm, 22-26 parts of a high efficiency water-reducing agent with a water-reducing rate higher than 30%, 6-10 parts of a synergist, 7-12 parts of a corrosion inhibitor, 135-165 parts of water and 80-160 parts of copper-coated ultrafine steel fibers with diameters of 0.13-0.20 mm and lengths of 6-18 mm. The concrete is low in comprehensive cost, wide in material source and large in mixing amount of industrial waste materials, has good chemical resistance, good self-compactness, low hydration heat and large adjustment range of workability, and is suitable for manufacturing process requirements of different construction members.

Owner:黄贺明

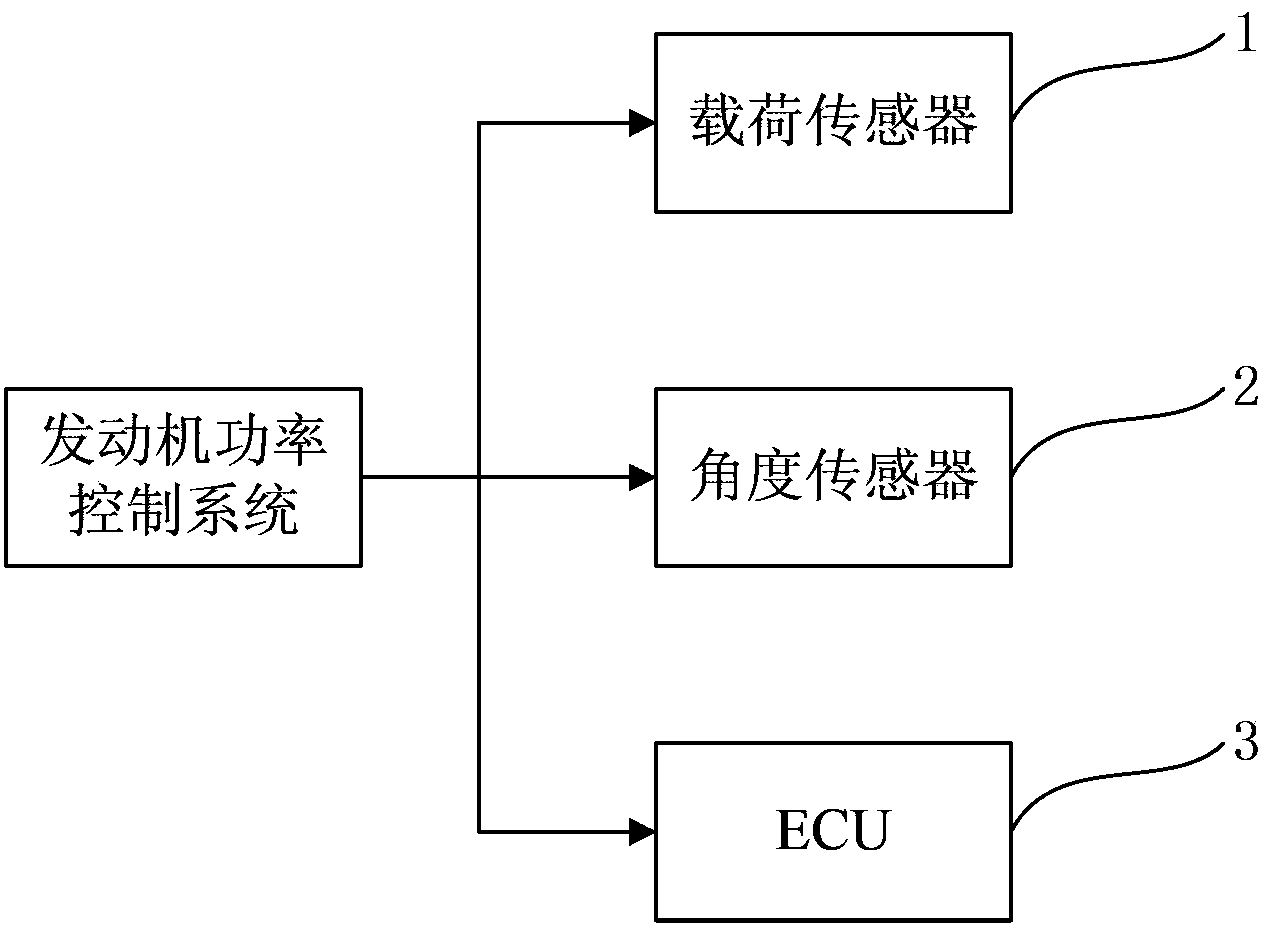

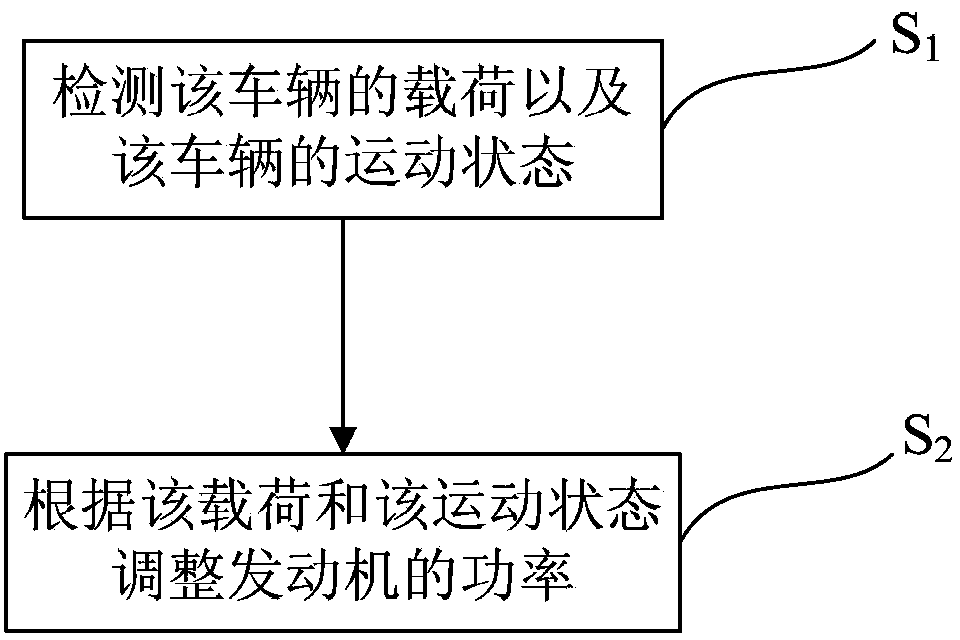

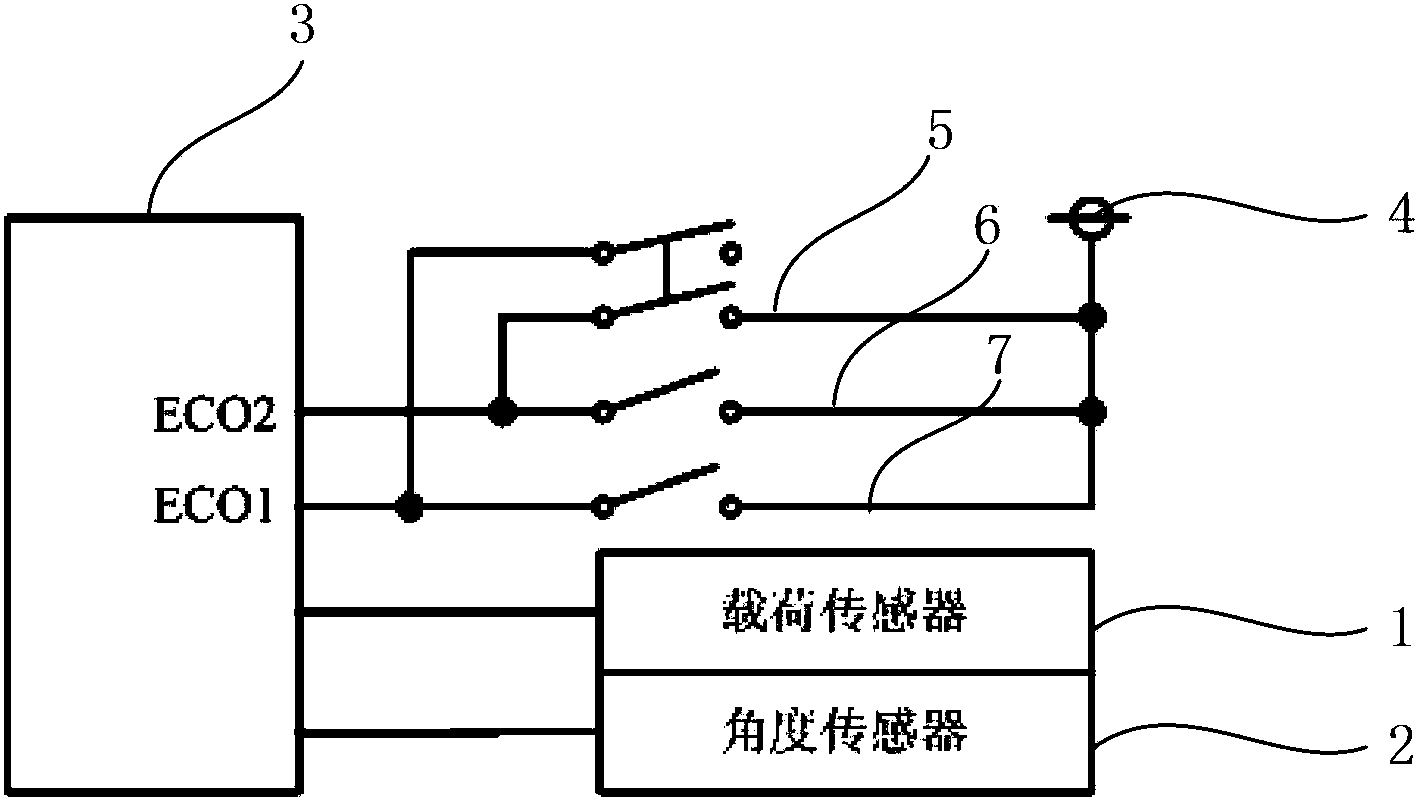

Engine power control system and method

InactiveCN104343552ALose weightMeet the needs of fuel economyEngine controllersMachines/enginesControl systemEngine power

The invention discloses an engine power control system and method. The engine power control system comprises a load sensor for detecting the load of a vehicle, an angle sensor for detecting the motion state of the vehicle, and an ECU (Engine Control Unit) for adjusting power of the engine according to the load and the motion state. With utilization of the sensors, the engine can automatically recognize the load of the vehicle and select the optimally economic running mode on the premise of ensuring the driving force, so as to practically meet the requirements on fuel economy for users; in addition, a manual adjustment manner can be adopted in the meantime, and the system can recognize commands inputted by a user to adjust the power. Therefore, the engine power control system is more flexible in power adjustment, and meanwhile ensures that the engine runs at the optimal power without lightening the weight of the vehicle or sacrificing the security of driving.

Owner:SHANGHAI HINO ENGINE

Green environment-friendly light-weight high-strength powder concrete

ActiveCN103396064ANo weight lossImprove poor self-compactingSolid waste managementMetal fiberGreen environment

The invention relates to the technical field of concrete, and particularly relates to green environment-friendly light-weight high-strength powder concrete which is prepared from the following raw materials in parts by mass: 550-650 parts of silicate cement, 125-150 parts of silica fume, 90-115 parts of fly ash, 110-130 parts of ore powder, 650-800 parts of shale ceramsite sand, 21-26 parts of high-efficiency water reducing agent and 105-130 parts of water. According to the invention, metal fibers, quartz sand and other high-cost raw materials are eliminated by means of the powder concrete accumulation principle; and the light-weight ultrahigh-strength powder concrete of which the volume weight is 1950kg / m<3> or below is obtained by introducing the high-strength ceramsite sand.

Owner:黄贺明

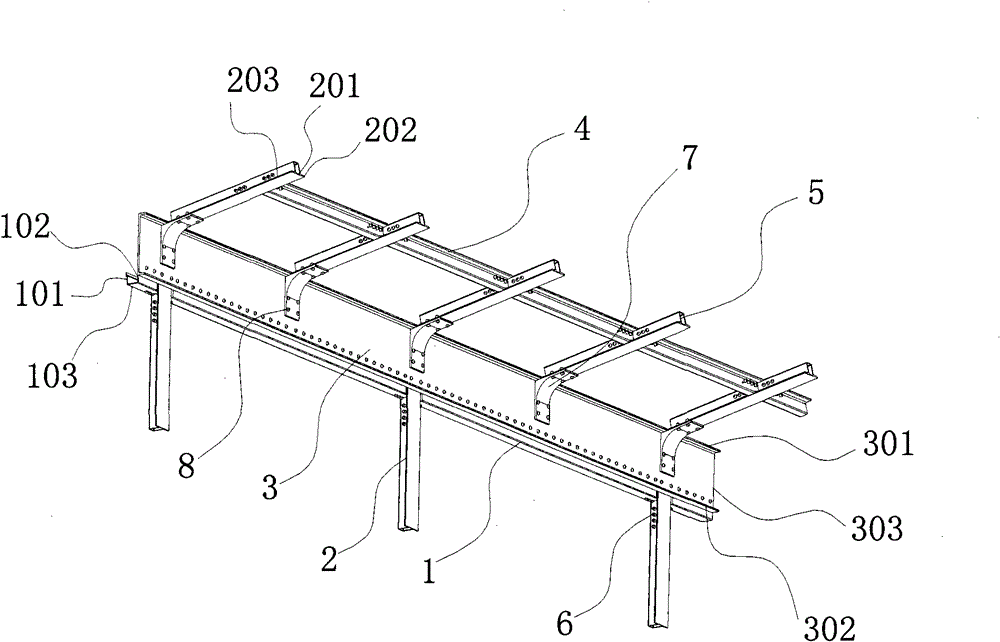

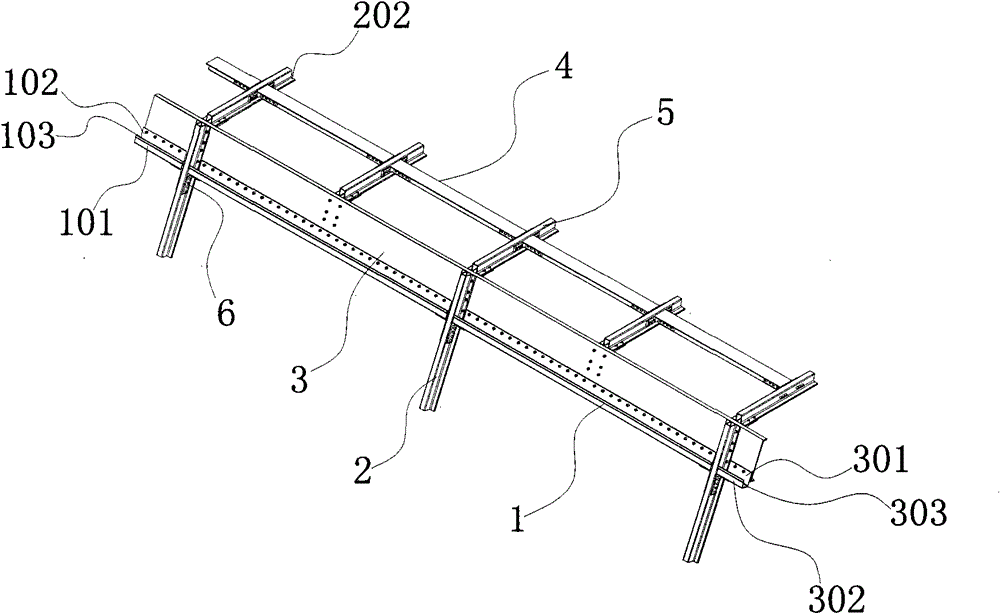

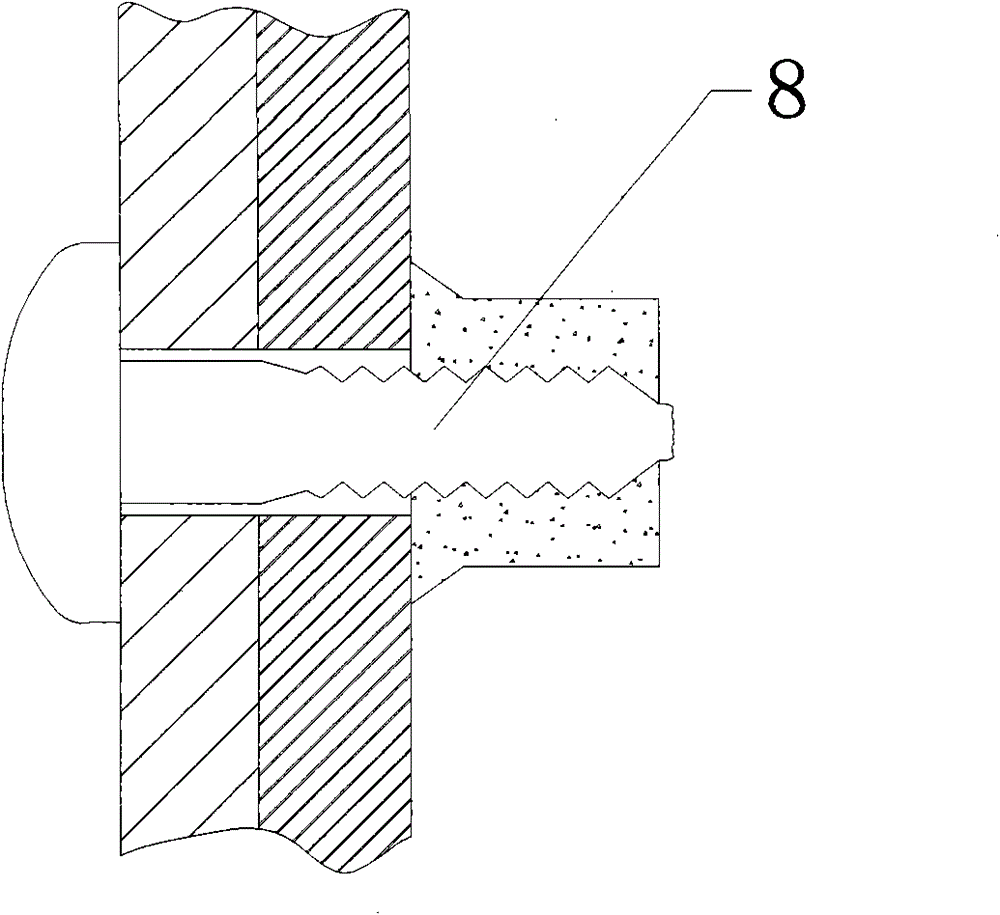

Car frame connecting structure

ActiveCN102009698AReduce intensityNo drop in strengthSuperstructure connectionsPassenger vehicle superstructuresStress concentrationVehicle frame

The invention relates to a car frame connecting structure comprising a side window longitudinal beam, an upright column, a stiffening beam, a top cap longitudinal beam and a top cap horizontal beam, wherein the side window longitudinal beam is riveted with the upright column through a medium corner; the side window longitudinal beam is riveted with the lower part of the stiffening beam; the upright column is riveted with the stiffening beam; the upper part of the stiffening beam is riveted with the top cap horizontal beam through a large corner; and the top cap longitudinal beam is riveted with the top cap horizontal beam through the medium corner. The car frame connecting structure is made of aluminium alloys or magnesium alloys. The invention achieves the effect on reducing weight approximate to a half under the conditions of same or similar strength of steels by adopting the car frame connecting structure made of the aluminium alloys or the magnesium alloys, thereby greatly reducing the weight of a car body without reducing the strength; and in addition, the invention has the advantages of reduced manufacturing and operating cost, long service life and more energy saving and environmental protection, prevents the stress concentration caused by adopting a welding mode through riveting connection and has firm connection without generating cracks.

Owner:北京绿程锦绣能源科技有限公司

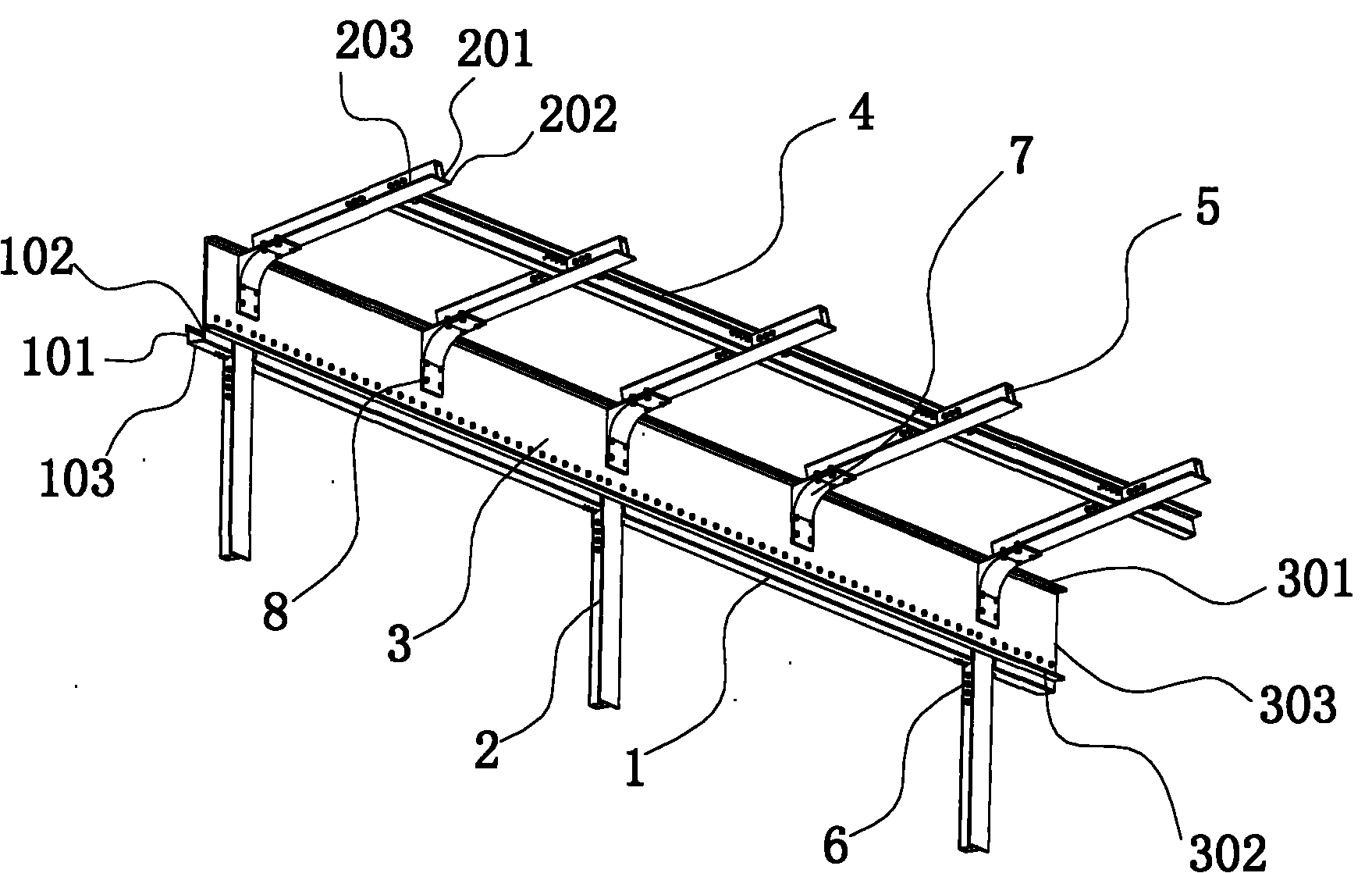

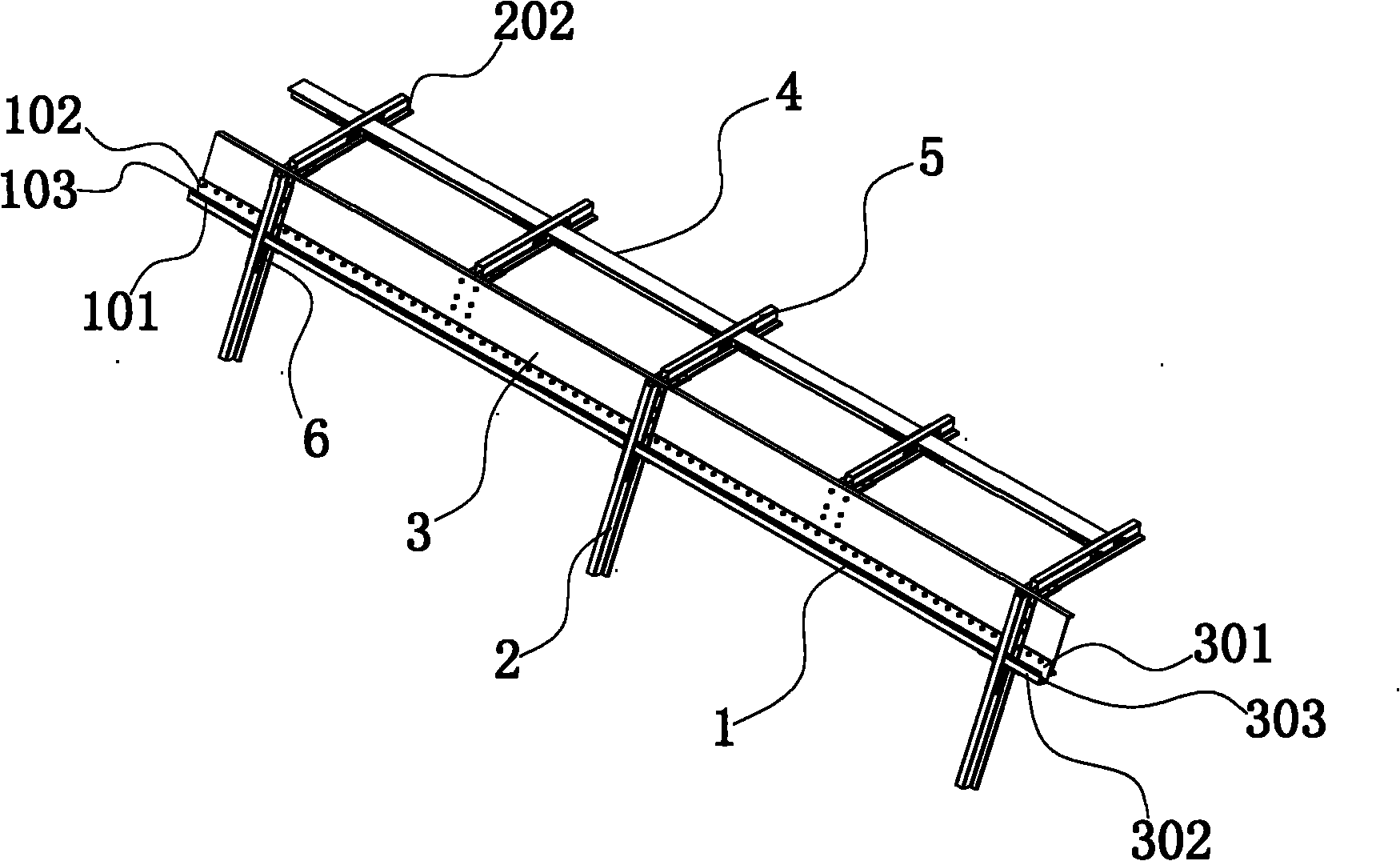

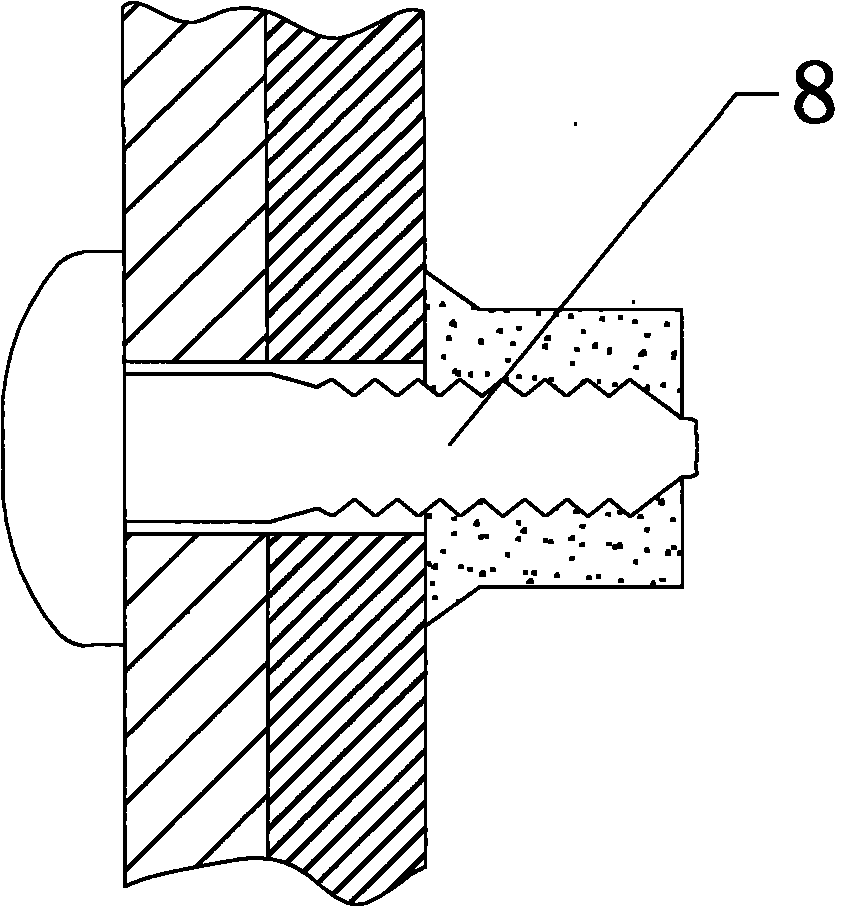

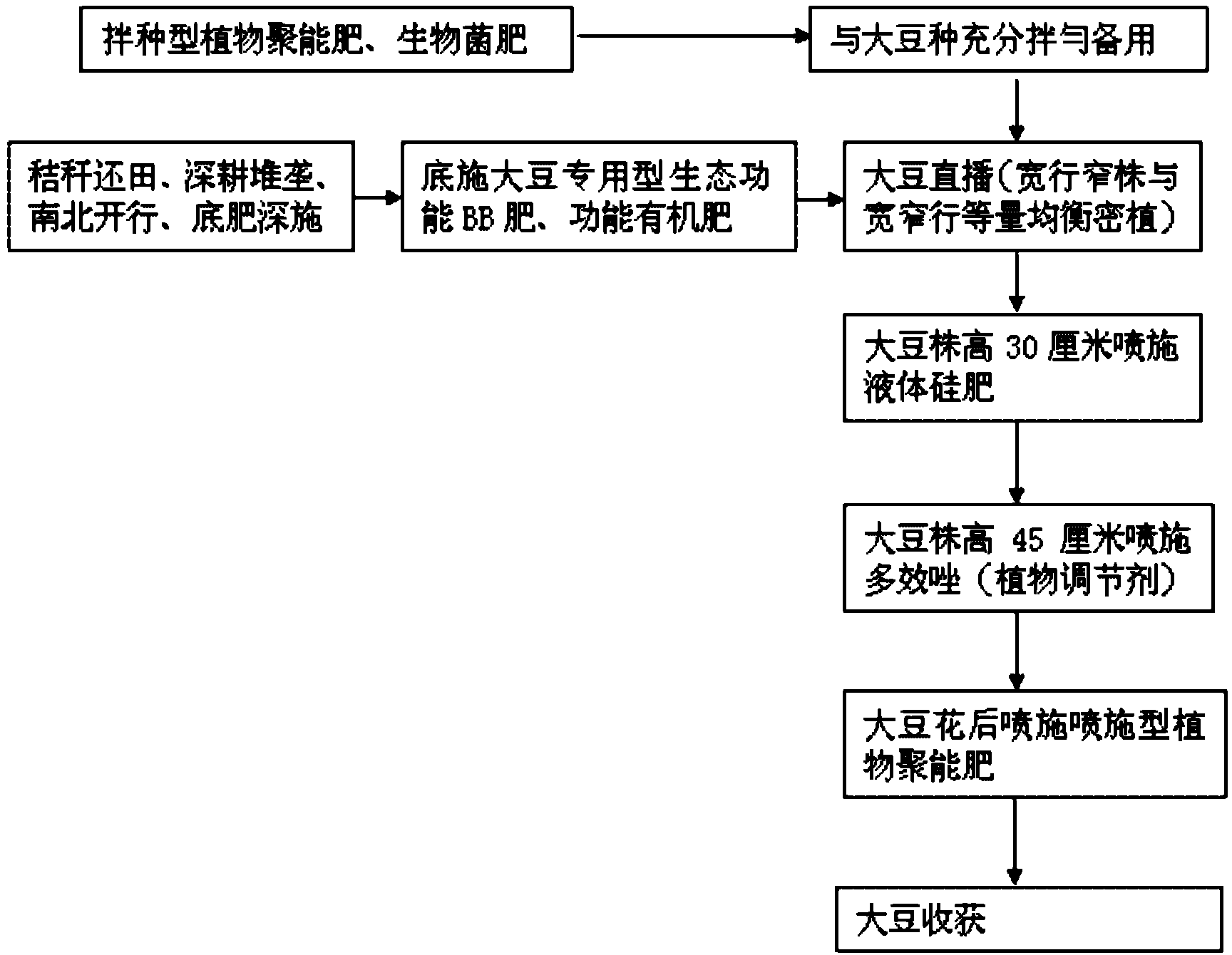

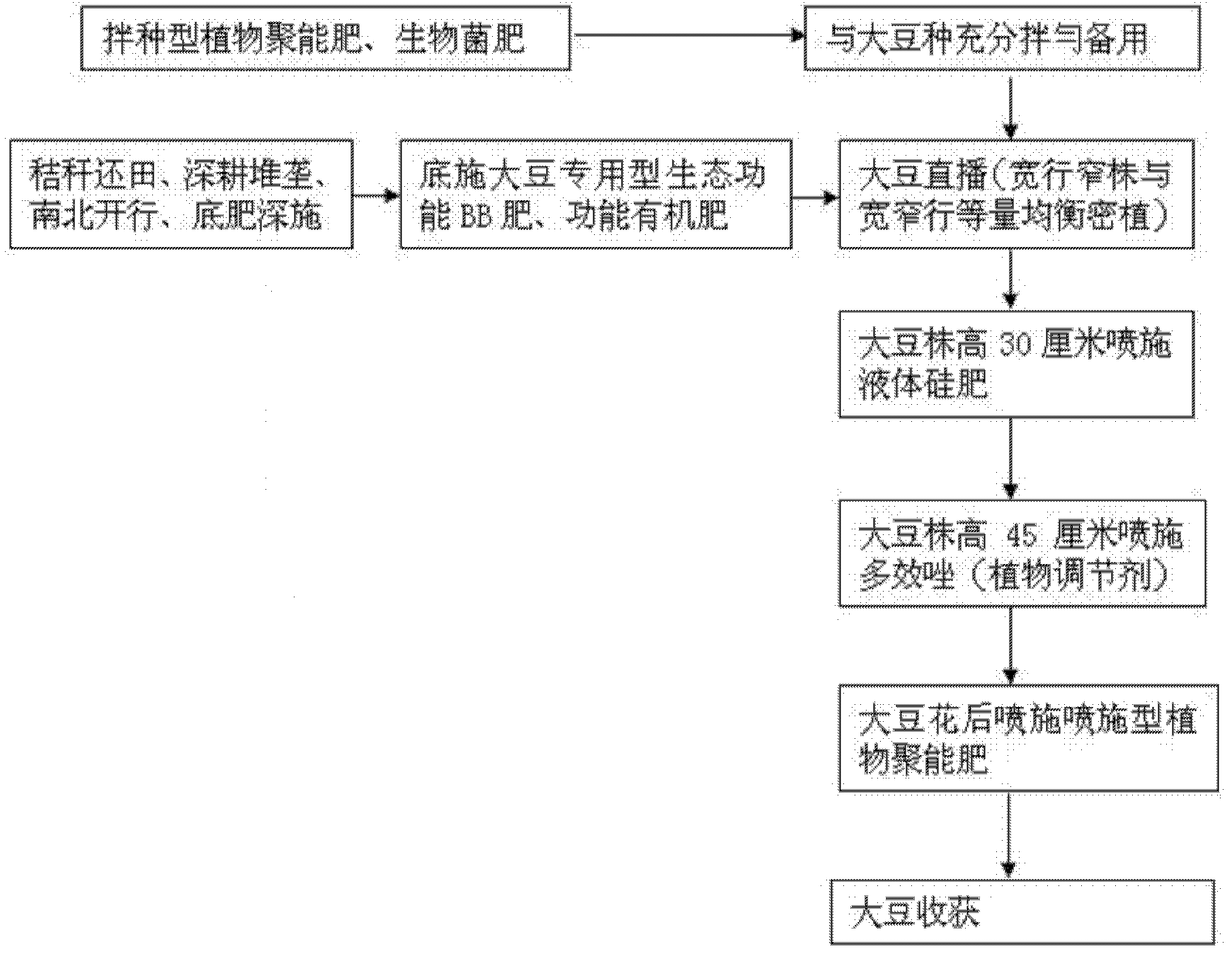

Comprehensive cultivation method of soybeans

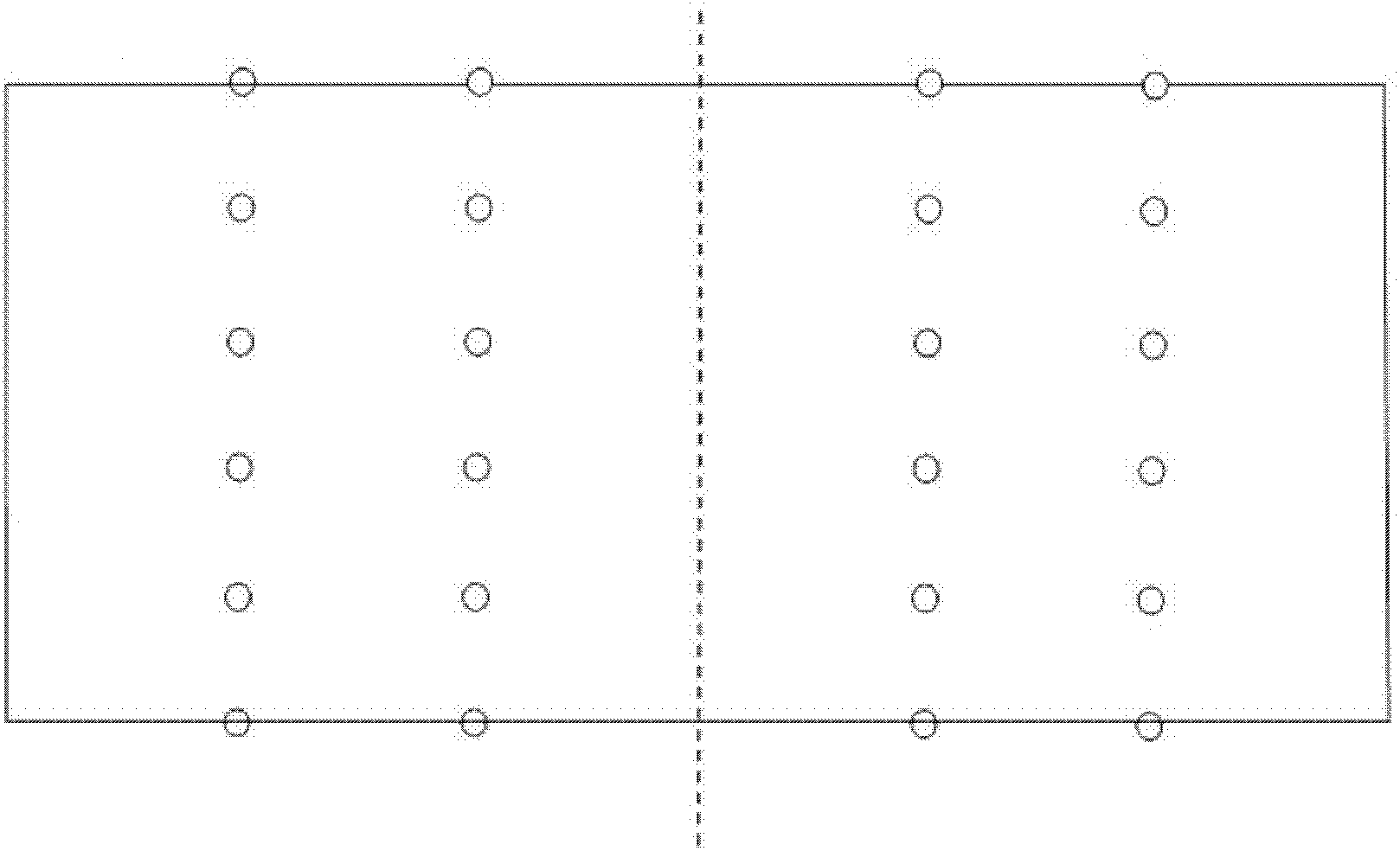

InactiveCN102301899AWith ventilation and light transmissionImprove the living environmentHorticultureSoil scienceEngineering

The invention discloses a comprehensive cultivation method of soybeans, which is completed through four measures comprising new type planting, precise fertilization, deep ploughing and piling, and stems returning back to the field. The method provided by the invention can improve quality and yield of the good soybean variety and can improve the function of preserving soil, fertilizer and water of soil and the functions of cold resistance, drought resistance, lodging resistance and plant diseases and insect pests resistance; under the precondition of guaranteeing the high yield of the soybeans, the applying amount of chemical fertilizer is reduced; and the method saves cost and increases yield for farmers and saves energy for our country.

Owner:吴成祥

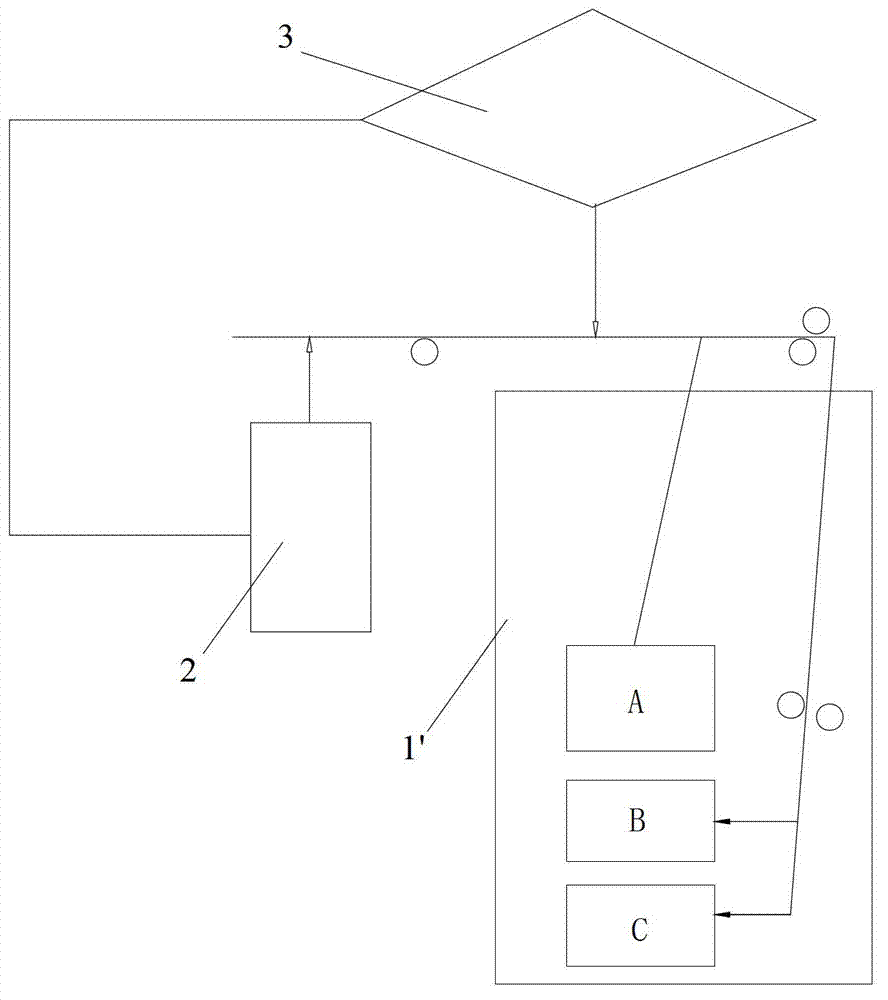

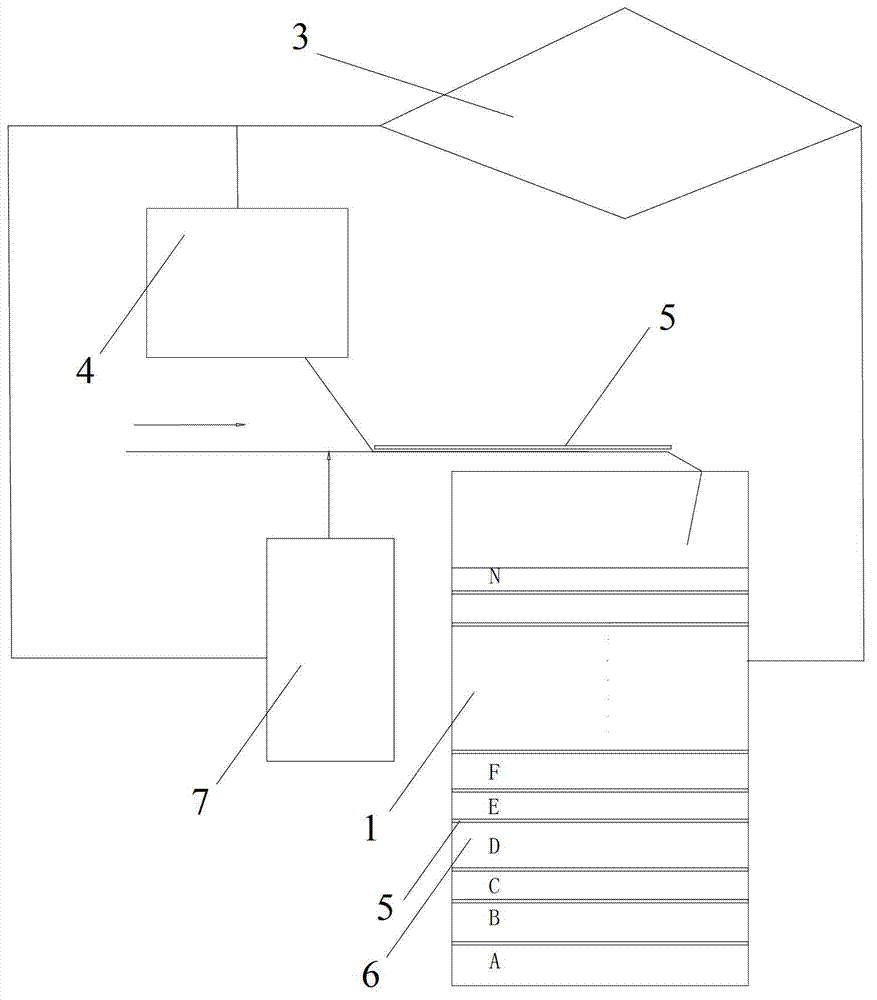

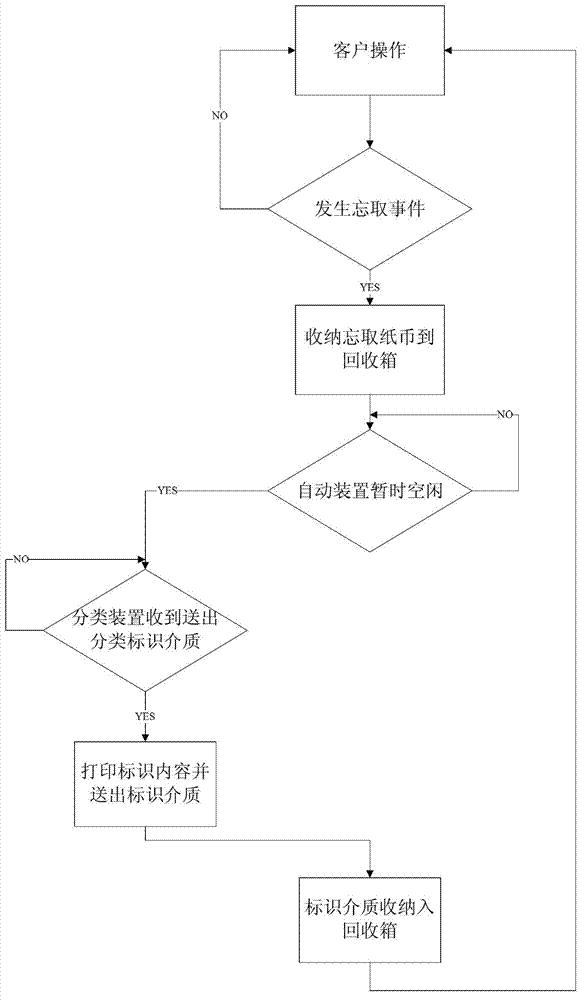

Paper currency recovery method and paper currency recovery device

InactiveCN103198557ANo reduction in capacityNo weight lossCoin/currency accepting devicesATM depositingRecovery methodPulp and paper industry

The invention discloses a paper currency recovery method and a paper currency recovery device. After a recovery box of an automatic transaction device recycles each sum of paper currency, a sorter is used for printing recorded information corresponding to the sum of paper currency on an identification medium, and storing the identification medium to the recovery box and placing the identification medium on the sum of recovery paper currency. An independent mechanism with the functions of printing, storing and distinguishing the identification medium is additionally arranged, if distinction is required, the identification medium with identification information is stored in the recovery box after each sum of paper currency is recycled, detailed information corresponding to the sum of recovery paper currency can be printed on the identification medium, so that the recovery box can meet the requirement of multiple classifications without partitions. The capacity of the recovery is not reduced, the weight of the recovery box is not increased, and meanwhile the phenomena of out of service due to the fact that multiple sums of recovery paper currency with same categories can not be distinguished, and therefore a service rate of the automatic transaction device is greatly improved.

Owner:GRG BAKING EQUIP CO LTD

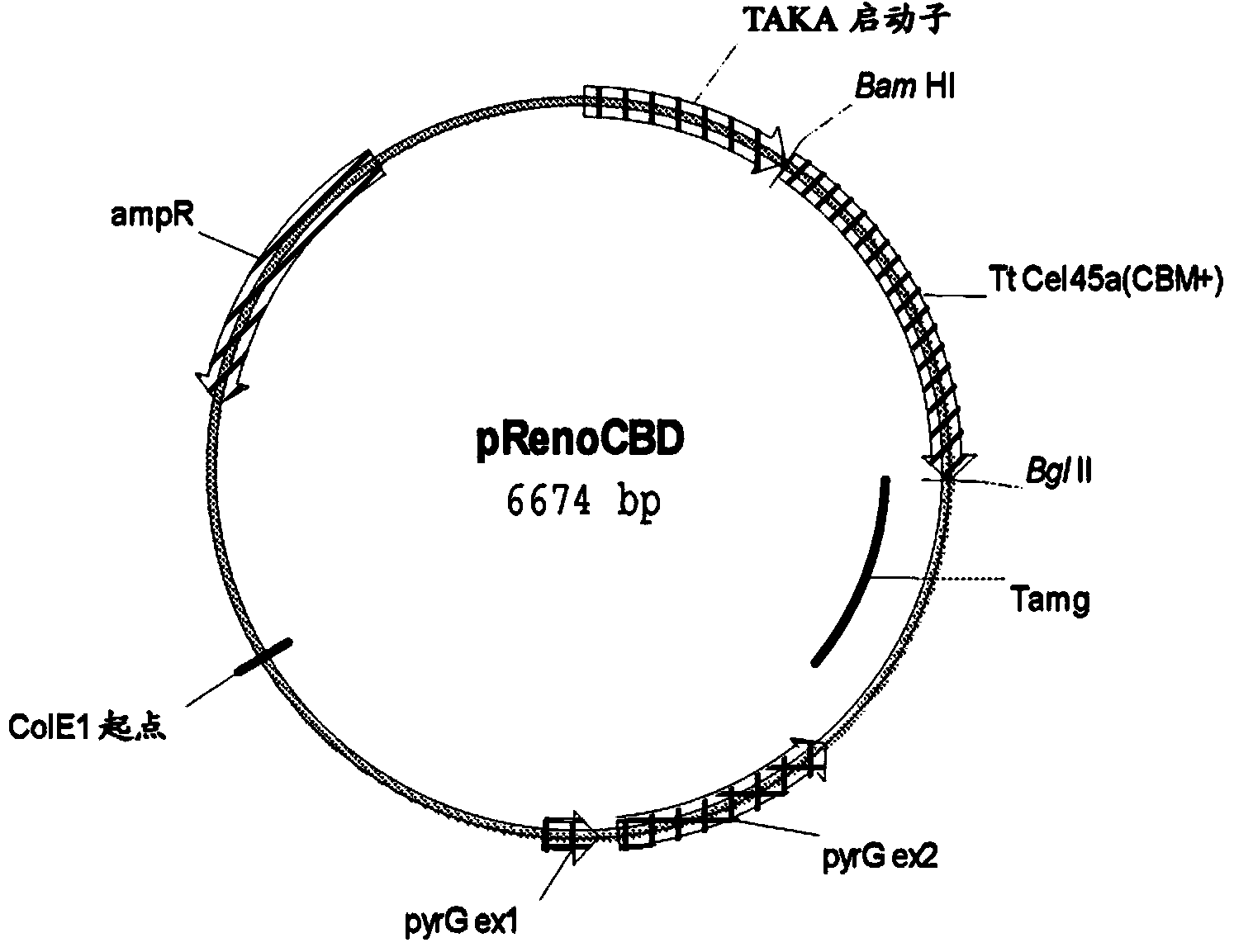

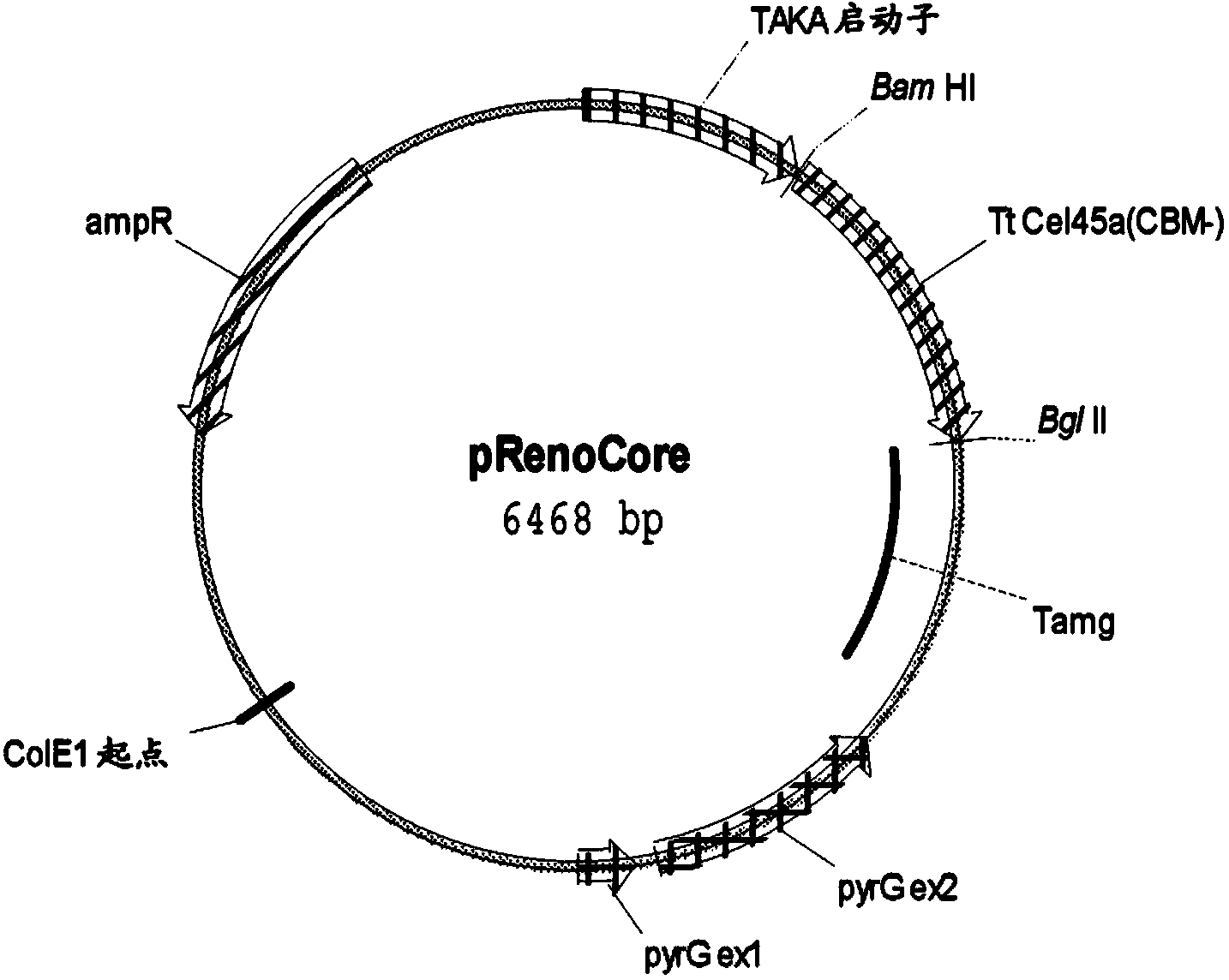

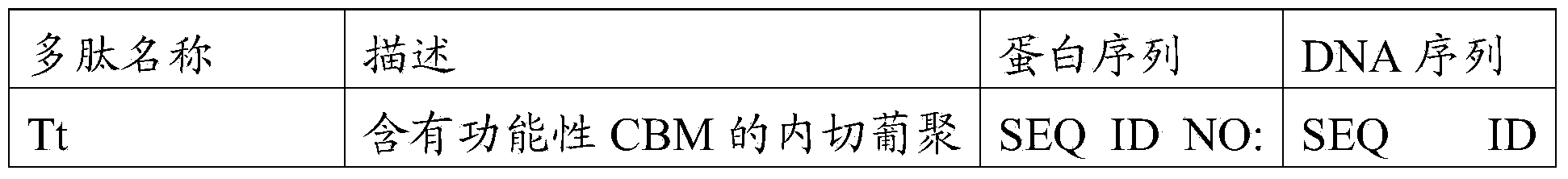

Method for treating textile with endoglucanase

InactiveCN103429736ASave energyNo weight lossBiochemical fibre treatmentDetergent compounding agentsEngineeringEndoglucanase activity

The present invention relates to the method for manufacturing textile, by treating textile with an isolated polypeptide having endoglucanase activity, especially in biostoning and bio- polishing process.

Owner:NOVOZYMES AS

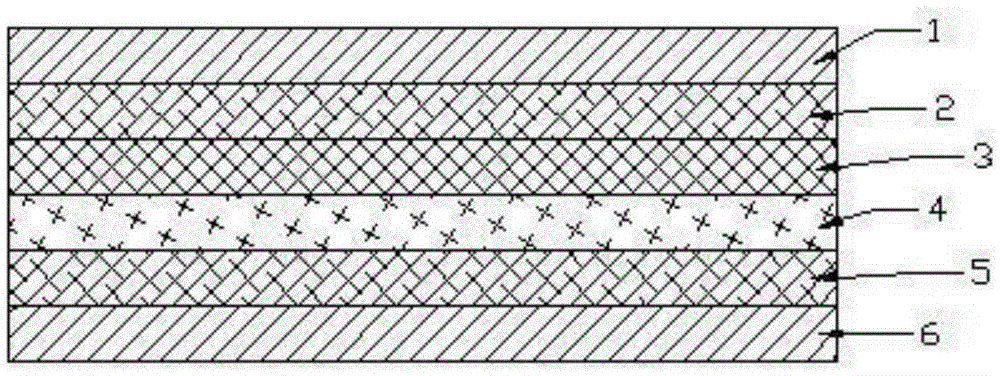

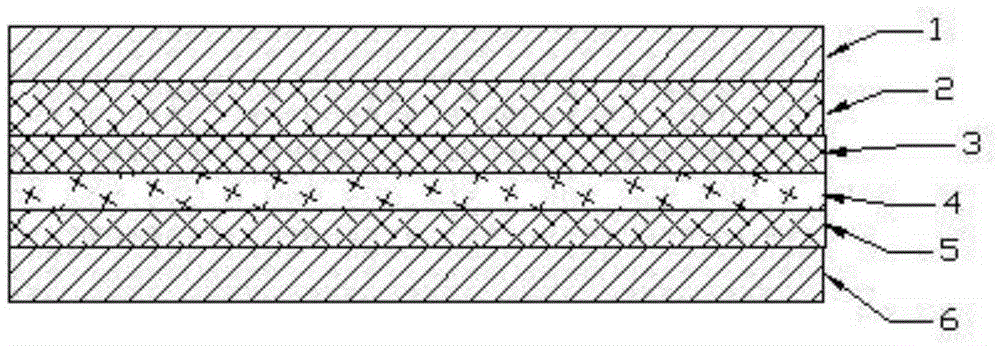

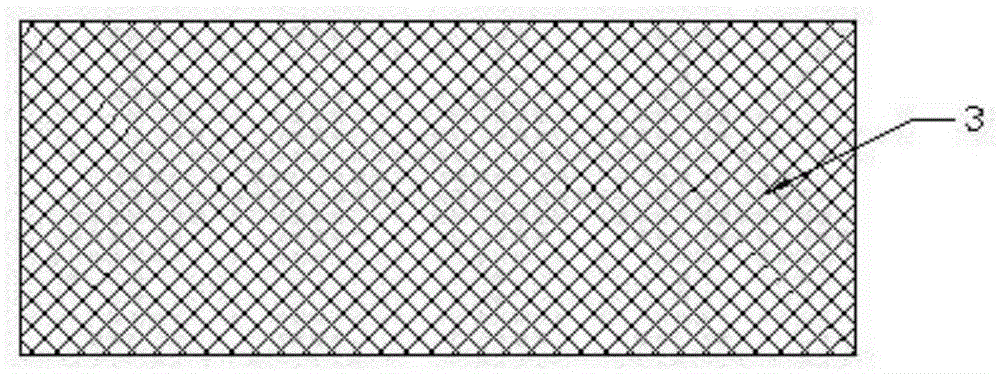

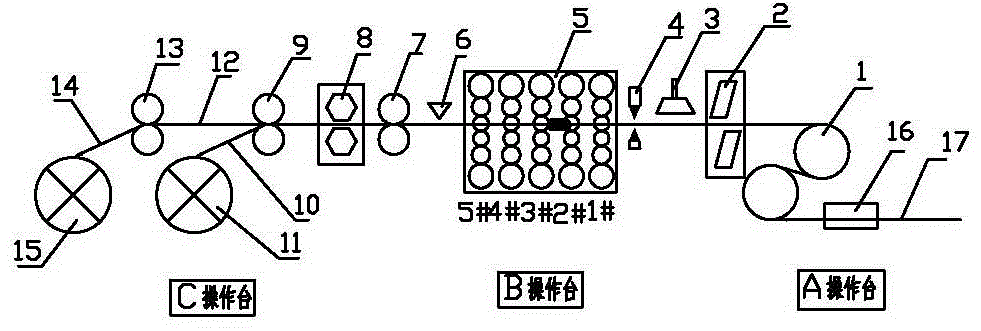

Compound high-temperature cloth with enhanced structure

InactiveCN105383120AWeather resistantGood dimensional stabilitySynthetic resin layered productsGlass/slag layered productsUltimate tensile strengthToughness

The invention belongs to the technical field of high-temperature cloth application, and in particular discloses composite high-temperature cloth with an enhanced structure. The composite high-temperature cloth consists of a first polytetrafluoroethylene layer, a second polytetrafluoroethylene layer and multiple layers of packing layers arranged between the first polytetrafluoroethylene layer and the second polytetrafluoroethylene layer. The composite high-temperature cloth with the enhanced structure, provided by the invention has the following beneficial effects: 1, the size stability is good (the coefficient of elongation is less than 5 per thousand), the strength is high and the mechanical property is good; 2, the cloth is used between the low temperature of subzero 70 DEG C and the high temperature of 260 DEG C, has weather fastness and is anti-aging, and through practical application, such as by continuously placing at the high temperature of 250 DEG C for 200 days, the strength cannot be decreased, and the weight is also not reduced, meanwhile, by placing at the high temperature of 350 DEG C for 120h, the weight is only reduced by about 0.6 percent and at the ultra low temperature of subzero 180 DEG C, no crack generates, and the original softness is kept; 4, a gridding layer effectively increases the toughness of the whole composite structure, and the objective of reuse is realized.

Owner:TAICANG HONGSHAN ENVIRONMENTAL PROTECTION TECH CO LTD

Nutritious rice flour for infants

InactiveCN107751376AReduce in quantitySpeed up buildMilk preparationHave ConstipationAdditive ingredient

The invention relates to the technical field of infant foods and in particular relates to nutritious rice flour for infants. The nutritious rice flour for the infants is prepared from the following raw materials in parts by weight: 100 to 120 parts of rice, 10 to 30 parts of milk powder, 3 to 8 parts of lactose, 0.1 to 1.2 part of n-3 polyunsaturated fatty acid, 0.1 to 0.6 part of an infant mineral substance, 0.3 to 1.0 part of a compound vitamin, 0.05 to 0.15 part of a digestive enzyme and probiotics. According to the nutritious rice flour for the infants, provided by the invention, the riceflour is designed according to the growth requirements of the infants and nutrient match is reasonable and abundant; components which are used for promoting the development of bodies and brains are added, and the probiotics and the digestive enzyme, which are used for promoting the digestion, are added, so that the intestinal environment of the infants is remarkably improved and the absorption ofother nutrients is promoted; and the nutritious rice flour is easily digested and absorbed by the infants and has an intestine and stomach strengthening function, the infants do not easily have constipation and the health of the infants is maintained.

Owner:张艳群

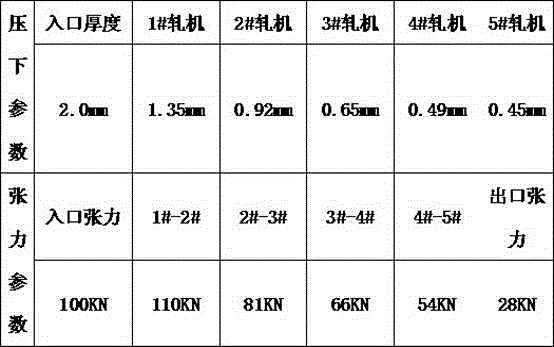

Operating method of cold continuous rolling mill equipment for eliminating start band head coiling

ActiveCN106345820ATo avoidReduce economic lossRare end control deviceMetal rolling arrangementsEconomic benefitsEngineering

The invention discloses an operating method of cold continuous rolling mill equipment for eliminating start band head coiling. Existing cold continuous rolling mill equipment is used, and normal halting, abnormal halting and halting caused by the reasons of equipment maintenance and overhauls and fault treatment and a starting mode after halting are overall improved in the normal rolling process of a cold continuous rolling mill unit. The operating method is characterized by including the steps that the thickness of band steel is changed dynamically before the cold continuous rolling mill unit is halted, manual halting is carried out after a flying shear shears the band steel, the band steel in the cold continuous rolling mill unit retracts to an inlet table pressing plate through an inlet tension roller set, and during starting, the band steel is threaded and sequentially passes a weld joint thickness gauge, the cold continuous rolling mill unit, an outlet thickness gauge and an outlet pinch roller to reach the position between the flying shear and a 1# steering pinch roller; band steel losses generated in an existing cold continuous rolling mill unit halting and starting operating method are eliminated; by means of the operating method, raw material consumption generated during first volume starting of the cold continuous rolling mill unit can be reduced; remarkable economic benefits are achieved.

Owner:SHANDONG TAISHAN STEEL GROUP

Waxberry storage and fresh-keeping method

InactiveCN104186642ANo rotSweet and sour tasteFruits/vegetable preservation by freezing/coolingEngineeringRelative air humidity

The invention relates to a waxberry storage and fresh-keeping method which comprises the following steps: (1) postharvest pre-cooling, to be specific, putting harvested waxberries into a pre-cooling room to pre-cool and ensuring that the temperature in the pre-cooling room is 1-5 DEG C, and the relative air humidity is 85-90 percent, so that the temperature of the waxberries is reduced to 5 DEG C; (2) vacuum packaging, to be specific, equivalently sub-packing the waxberries into vacuum fresh-keeping bags, pumping and sealing with a vacuum packaging machine, wherein the pressure of the vacuum packaging machine is 12-15 mmHg; (3) packing and ice block sprinkling, to be specific, correspondingly putting a bag of waxberries in a foam box, capping and sealing, and sprinkling ice blocks which are not lighter than the waxberries around the bottom and the periphery of the vacuum fresh-keeping bag; (4) fresh-keeping at a low temperature, to be specific, piling and storing the foam boxes in a refrigerator, wherein the temperature in the refrigerator is minus 3- minus 5 DEG C, and the relative humidity is 90-95 percent. Though the adoption of the waxberry storage and fresh-keeping method, the waxberries can be subjected to lasting fresh-keeping for 18-20 days, the assistance of a chemical agent and complicated equipment is avoided, the operation is simple, the cost is low, and the popularization is facilitated.

Owner:WENLING WUGEN STRAWBERRY PROFESSIONAL COOP

Green environment-friendly light-weight high-strength powder concrete

The invention relates to the technical field of concrete, and particularly relates to green environment-friendly light-weight high-strength powder concrete which is prepared from the following raw materials in parts by mass: 550-650 parts of silicate cement, 125-150 parts of silica fume, 90-115 parts of fly ash, 110-130 parts of ore powder, 650-800 parts of shale ceramsite sand, 21-26 parts of high-efficiency water reducing agent and 105-130 parts of water. According to the invention, metal fibers, quartz sand and other high-cost raw materials are eliminated by means of the powder concrete accumulation principle; and the light-weight ultrahigh-strength powder concrete of which the volume weight is 1950kg / m<3> or below is obtained by introducing the high-strength ceramsite sand.

Owner:黄贺明

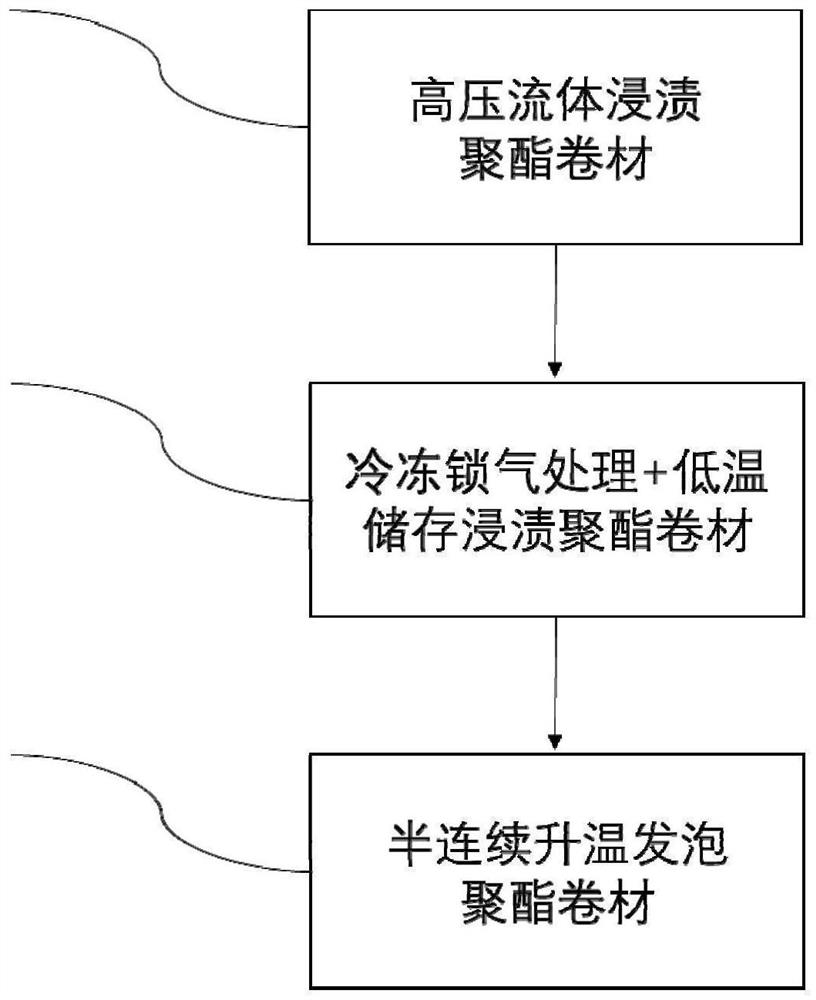

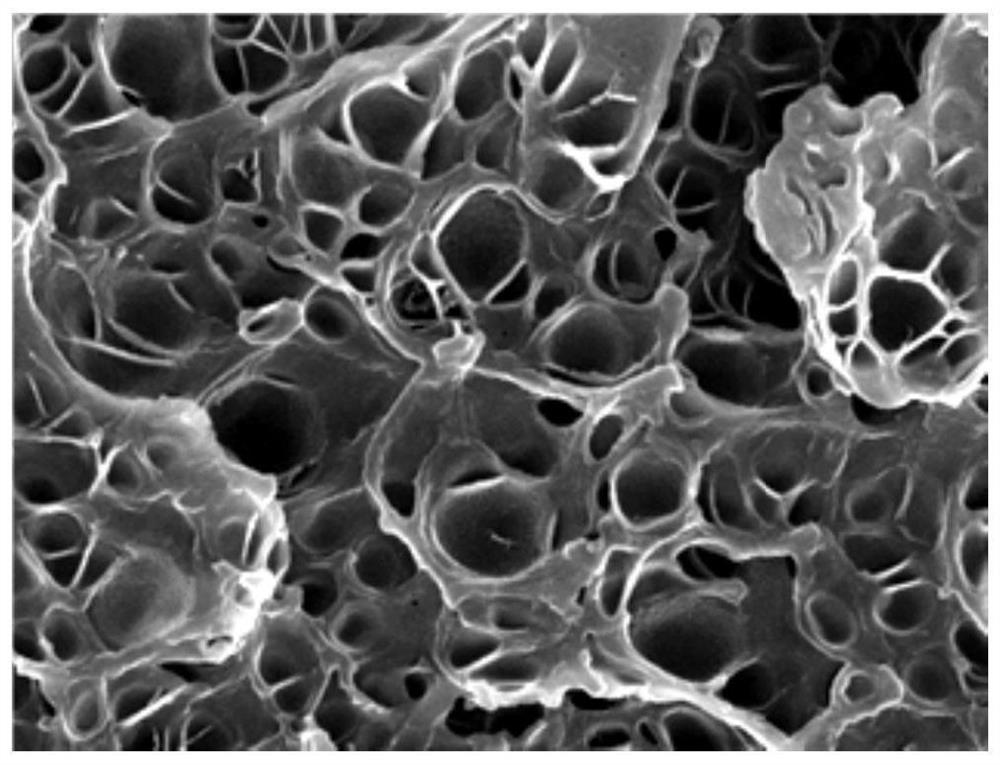

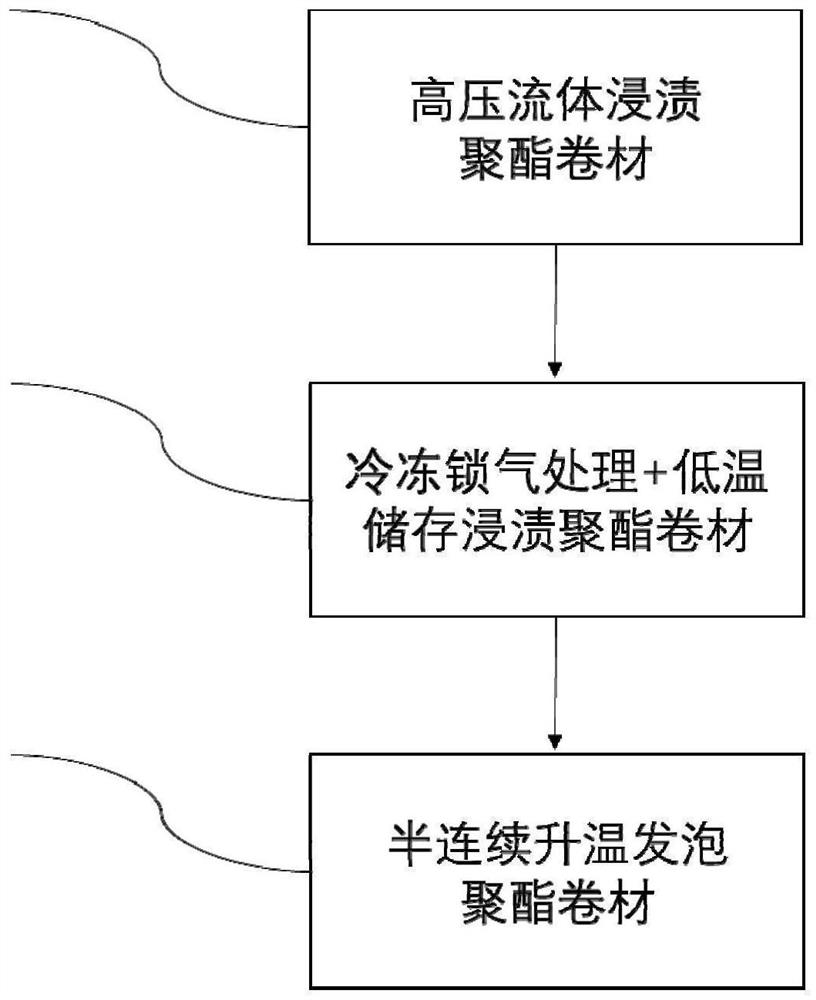

Polyester foamed sheet and semi-continuous preparation method thereof

The invention discloses a polyester foamed sheet and a semi-continuous preparation method thereof, and belongs to the field of polymer foamed sheets. According to the polyester foamed sheet and the semi-continuous preparation method thereof, the dissolution content of a high-pressure fluid in the polyester sheet is controlled, and then the material is subjected to rapid freezing gas locking treatment at a specific temperature, so that desorption escape of the high-pressure fluid is inhibited; the problem that in the prior art, high-quality foaming or remote transportation cannot be achieved due to the high-pressure fluid escape phenomenon of impregnated foaming polyester is solved, the obtained impregnated sheet can be stored for a long time at the low temperature or can be transported remotely, meanwhile, semi-continuous heating foaming can be stably conducted, the weight loss rate is obviously reduced, and the feasibility is obviously improved. The invention also discloses the polyester foamed sheet prepared by the method. The product has a smooth and flat surface, a thickness of 0.2-3.0 mm, a length of not less than 50m, a crystallinity of 20-45%, a density of 0.1-0.6 g / cm < 3 >, and a luminous reflectance of 90% or more.

Owner:SUN YAT SEN UNIV

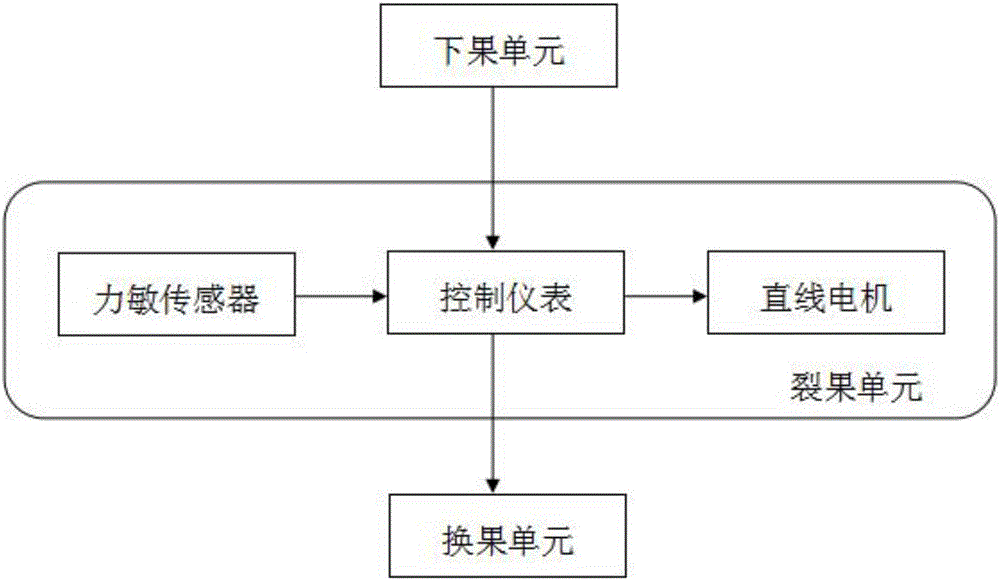

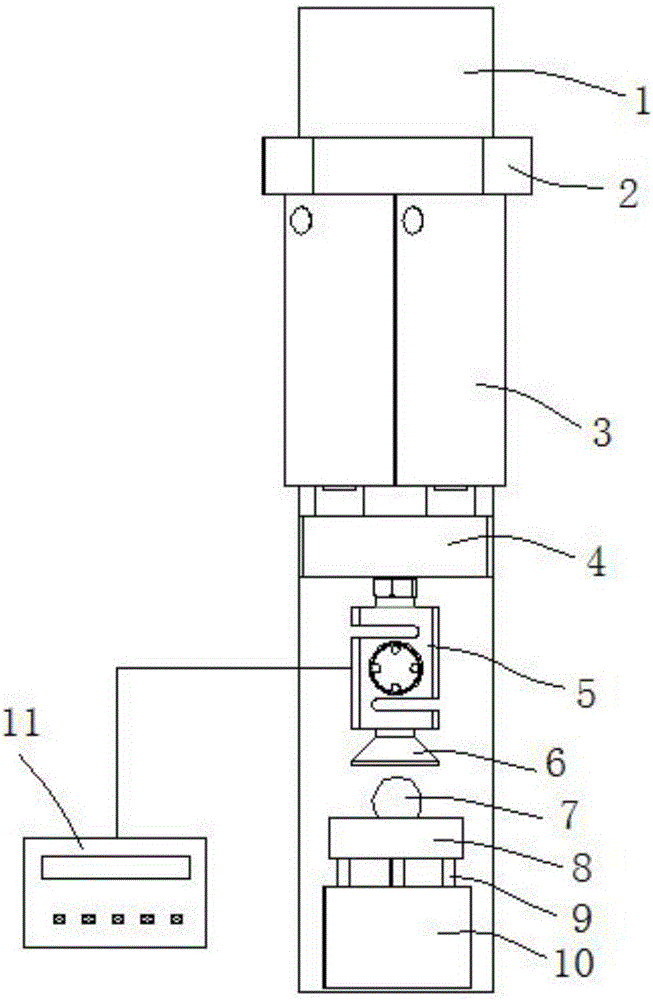

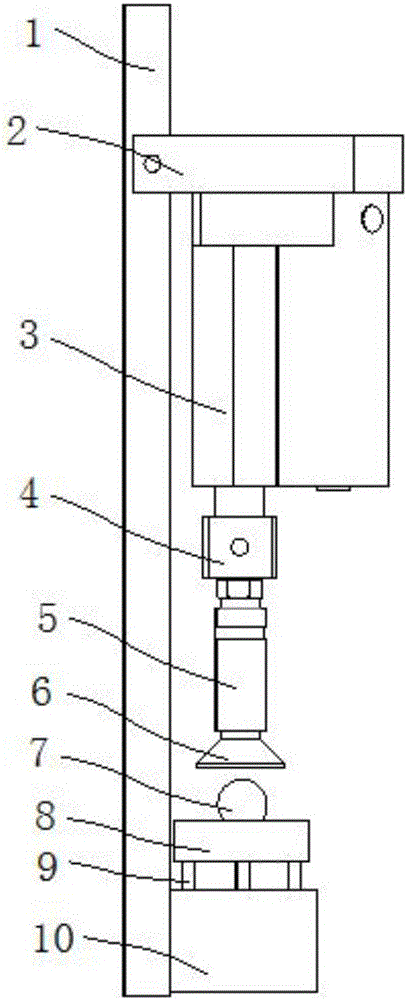

Full-automatic nutshell cracker

InactiveCN106617140ASolve the cracking shell problemNo weight lossHuskingHullingDrive shaftLinear motor

The invention discloses a full-automatic nutshell cracker. The full-automatic nutshell cracker comprises a nut feeding unit, a nut cracking unit and a nut changing unit, wherein the nut cracking unit comprises a force sensor, linear motors and a control instrument, wherein the tail ends of the two linear motors are fixed on the upper portion of a vertical assembly plate through a motor mounting plate, driving shafts of the two linear motors are arranged downwards vertically and are connected with a bearing plate, the lower side face of the bearing plate is fixedly connected with one end of the force sensor, the force sensor is connected to the control instrument through a wire, a pressing disk is connected to the lower end of the force sensor, a tray is arranged at a position under the pressing disk, and a nut is disposed in the tray. The full-automatic nutshell cracker has the advantages that difficulty in nut cracking without weight loss is overcome, and nutshells are cracked without breaking to pieces; kernel completeness is not destroyed, and nut weight loss is avoided after cracking; manual operation is basically avoided, and full-automatic cracking is achieved.

Owner:BENGBU TIANGUANG SENSOR

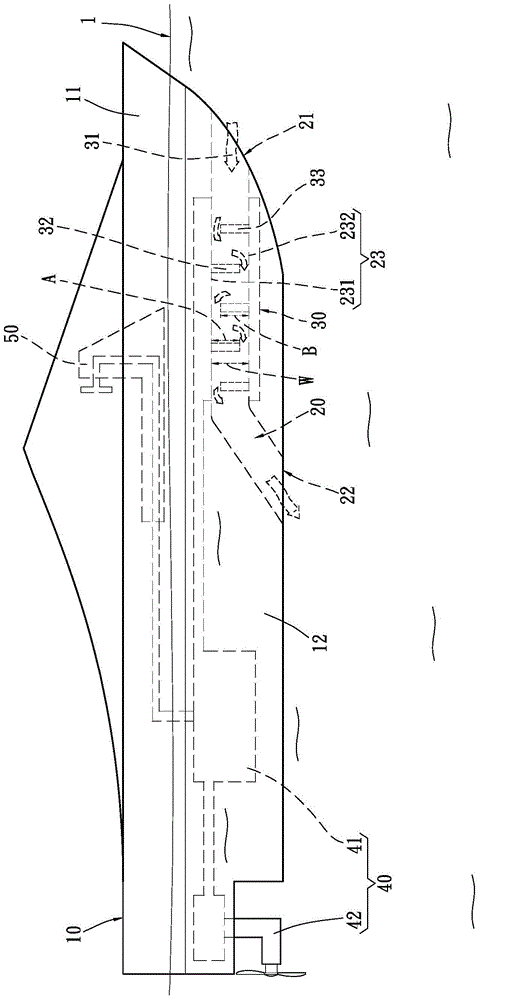

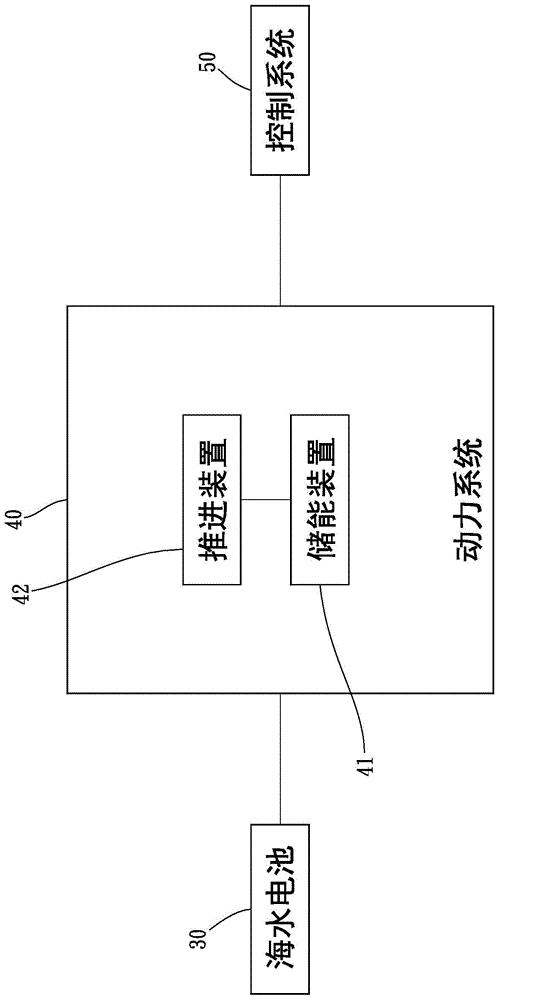

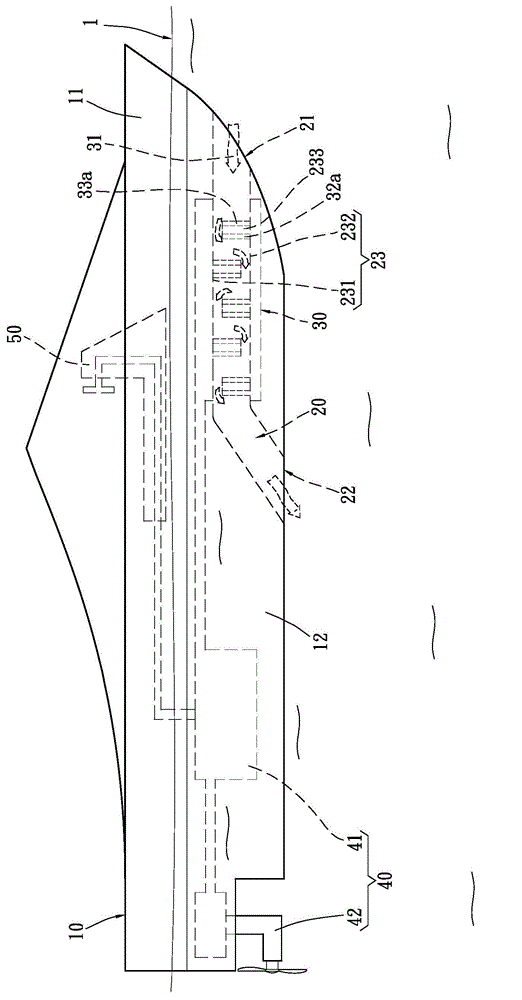

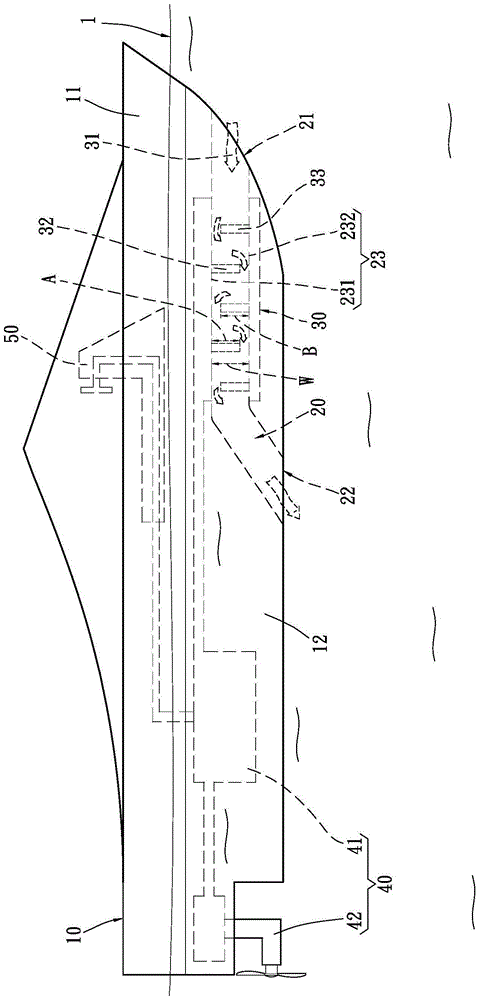

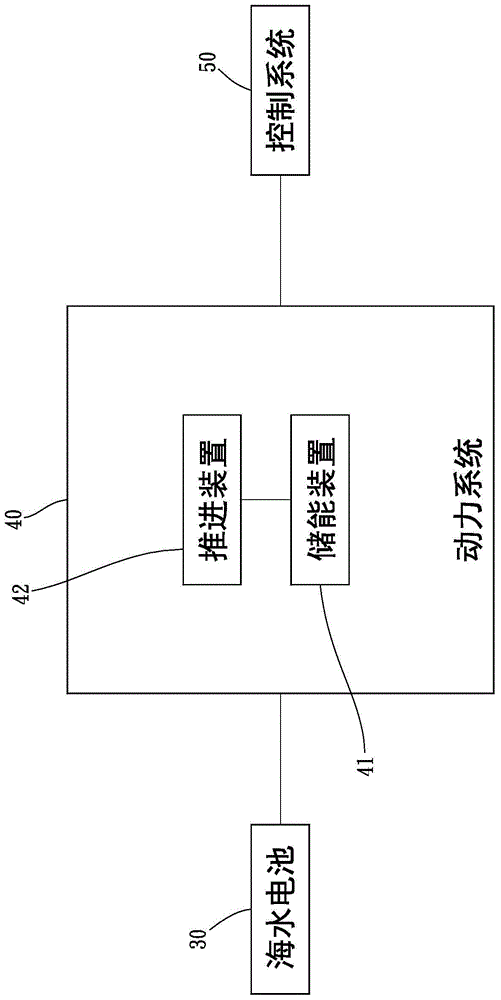

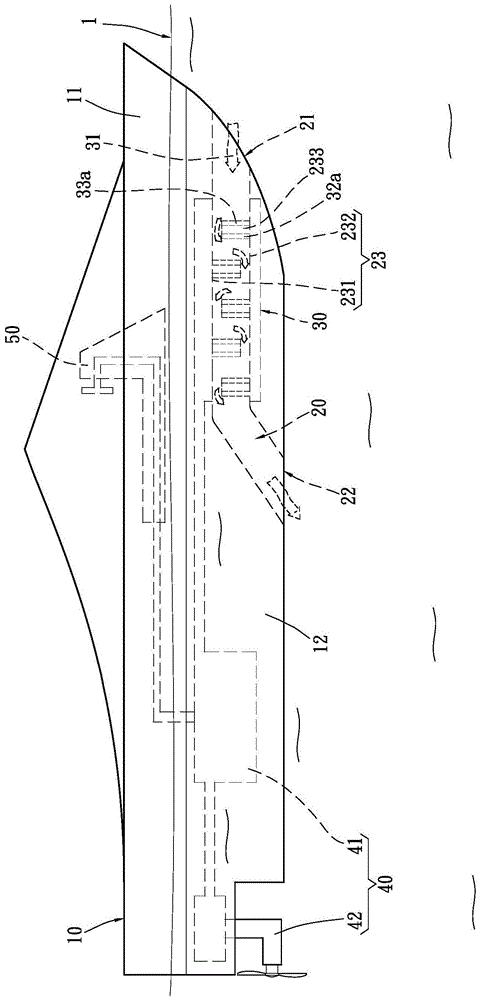

Seawater battery-driven water vehicle

ActiveCN104129490ADoes not take up load spaceNo weight lossWatercraft hull designPropulsive elementsElectrochemical responseSeawater

This invention relates to a seawater battery-driven water vehicle for sailing in the ocean, including a main body, a flow channel, a seawater battery and a power system. The flow channel is disposed in the main body and includes an inlet, an outlet and a wall. The seawater battery is installed inside the flow channel, and includes the seawater that flows into the flow channel and a cathode and an anode that are connected with the wall respectively and separated from each other while contacted with the seawater. The power system is equipped on the main body and is electrically connected with the seawater battery and contacted with the ocean outside the main body. In this invention, accordingly, the seawater is performed an electrochemical reaction respectively with the anode and the cathode in the flow channel to generate electric power, and the power system is driven by the electric power to push the main body to move in the ocean, so as to have a stable supply of electricity without reducing the carrying load of vehicle in water.

Owner:TAIWAN CARBON NANO TECHNOLOGY CORPORATION

Reaction container for growing single crystal and method for growing single crystal

InactiveCN102272358ANo weight lossAfter-treatment apparatusPolycrystalline material growthSingle crystalOxygen

In the method of growing a single crystal by the flux method of a sodium-containing solution, a flux is contained in a reaction vessel composed of yttrium, aluminum, and garnet. Compared with the case of using alumina container or yttrium oxide container, the amount of impurities such as oxygen and silicon can be significantly reduced, and a single crystal with low residual carrier concentration, high electron mobility, and high resistivity can be successfully obtained .

Owner:NGK INSULATORS LTD +2

Preparation method of ceramic precursor modified phosphate adhesive

ActiveCN113185921AAvoiding the Problem of Acid ChangesNo stratificationNon-macromolecular adhesive additivesSolid waste managementAdhesive cementPhosphate

The invention discloses a preparation method of a ceramic precursor modified phosphate adhesive, and relates to the field of preparation of phosphate adhesives. The invention aims to solve the technical problems that the existing phosphate adhesive is high in ultralow-temperature outdoor construction viscosity and difficult to construct. The method comprises the following steps: preparing crystalline chromium aluminum dihydrogen phosphate by acquiring a saturated salt solution; preparing a chromium aluminum dihydrogen phosphate polymer solution and a polyaluminocarbosilane solution; preparing a modified non-aqueous phosphate adhesive matrix; preparing a curing agent; and mixing and curing the modified non-aqueous phosphate adhesive matrix and the curing agent. The adhesive matrix disclosed by the invention is relatively low in viscosity under a low-temperature condition, has excellent low-temperature construction performance and can be cured at low temperature or normal temperature, and the cured adhesive can be used in a high-temperature environment of 1800 DEG C for a long time. The method is used for preparing the ceramic precursor modified phosphate adhesive.

Owner:HARBIN ENG UNIV

Nutritional soil for raising seedlings of physalis alkekengi in greenhouse and application of nutritional soil

InactiveCN104671966ANatural raw materialsPrevent diseaseHorticultureFertilizer mixturesDiseaseGreenhouse

The invention relates to nutritional soil for raising seedlings of physalis alkekengi in a greenhouse and application of the nutritional soil. The application soil provided by the invention comprises the following components in mass percentage: 92.5%-92.7% of turf soil, 6.9%-7.1% of a biological organic fertilizer and 0.3-0.5% of a seedling strengthening agent. According to the nutritional soil provided by the invention, the turf soil is used as a soil medium, and the biological organic fertilizer and the seedling strengthening agent are used for matching, thereby providing nutritional space for raising the seedlings, enabling the growth of the seedlings to be robust, realizing strong disease resistance, enabling crops to appear on the market in advance and increasing the income by 3000 yuan per mu; and the cost is relatively low, which is saved by above 50% in comparison with conventional seedling raising cost.

Owner:DONGGANG FENGHUI FERTILIZER

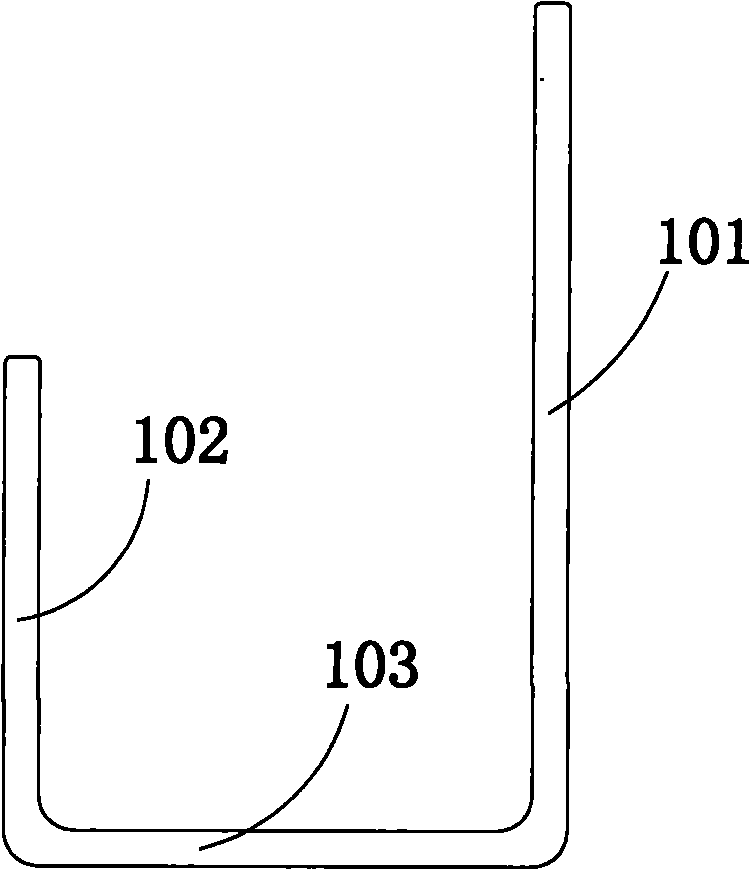

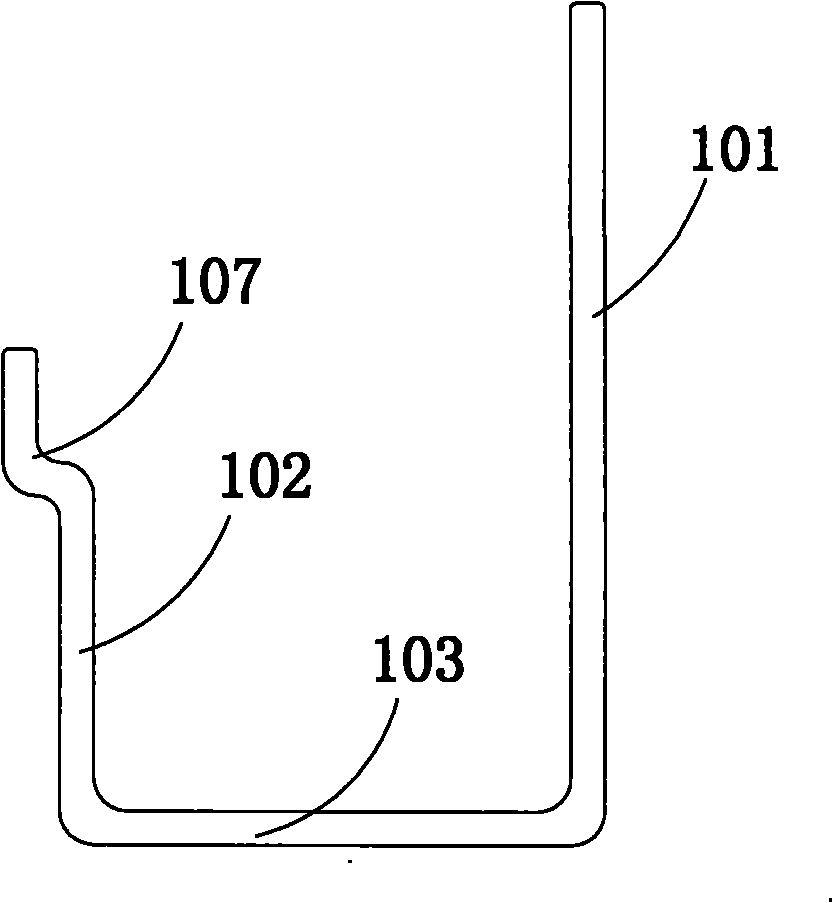

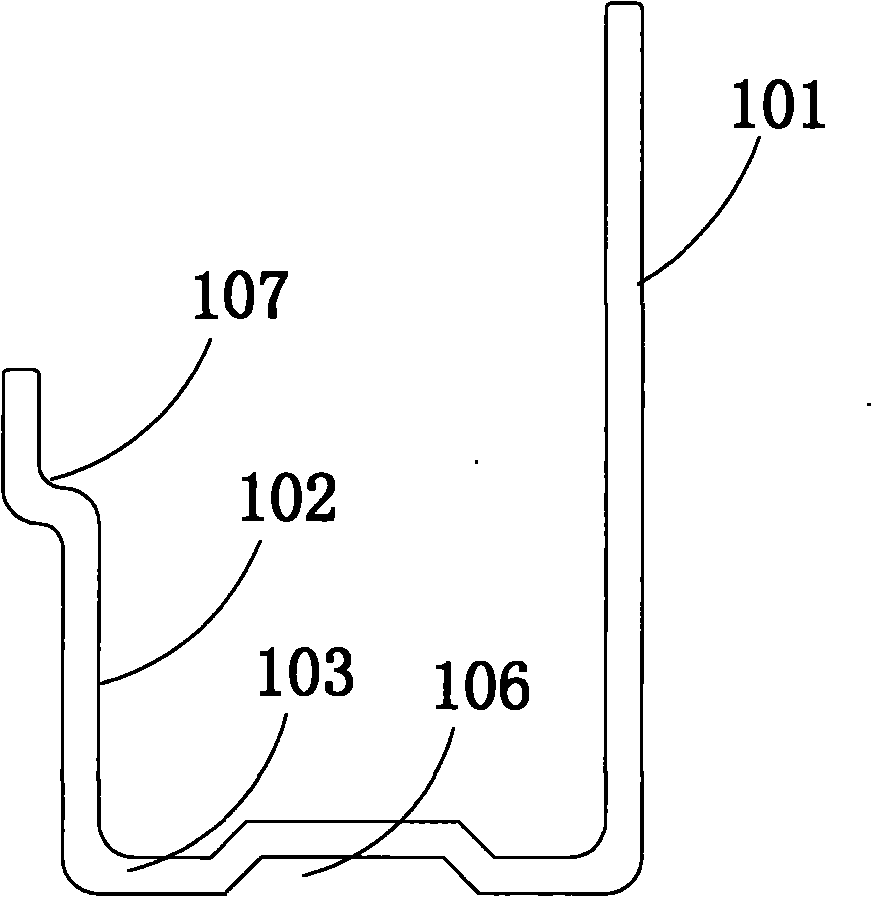

Part of vehicle frame

InactiveCN102009696AReduce intensityNo drop in strengthRailway transportAxle-box lubricationVehicle frameEngineering

The invention relates to a part of a vehicle frame. The cross section of the part of the vehicle frame is U-shaped; two sides of the U-shaped section are respectively provided with a first side edge and a second side edge; the bottom part of the U-shaped section is provided with a bottom edge; the first side edge is parallel with the second side edge; the bottom edge is relatively perpendicular to the first side edge and the second side edge; the thickness of the wall of the part of the vehicle frame is 1-8mm; and the wall is manufactured by using an aluminum alloy or a magnesium alloy. The invention has the advantages that a rectangular steel pipe of the traditional vehicle body frame is replaced by the part of the vehicle frame which acts on a vehicle body and is manufactured by utilizing the thickening aluminum alloy or magnesium alloy with the U-shaped cross section so as to achieve the effect that the weight is reduced by almost half under the condition of the same or similar strength with steel products, therefore, the weight of the combined vehicle body is greatly reduced without decreasing the strength, the manufacturing cost and the running cost are lowered, and the part of the vehicle frame is more environmentally-friendly, saves more energy, and is capable of adapting the installation of different positions of the vehicle body.

Owner:贾秉成

Humic acid biological fertilizer

InactiveCN104387149AThe effect of suppressing the spread of the spreadPromote incomeAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSoil sciencePhosphate

The invention relates to a humic acid biological fertilizer, belongs to the field of biological fertilizers, and particularly relates to a novel biological fertilizer, which comprises the following raw materials by weight: 90-120 parts of a mother liquor, 7-12 parts of potassium dihydrogen phosphate, 2-7 parts of potassium sulfate, 4-8 parts of urea, 0.5-3 parts of borax, 0.1-0.4 part of zinc, 0.1-0.4 part of a preservative, and 0.1-0.4 part of molybdenum+magnesium+iron. The humic acid biological fertilizer of the present invention has the following characteristics that: the environment can not be polluted, harmful substances in chemical elements can be degraded into the micro-toxin, and the humic acid biological fertilizer can be suitable for requirements of various crops, and contains large-medium-trace elements.

Owner:WENSHAN XINGYAO BIOTECH CO LTD

Special foliage fertilizer for perilla frutescens and preparation method of special foliage fertilizer for perilla frutescens

InactiveCN108440195ANo weight lossNo fat deficiencySewage/sludge fertilisersOrganic fertiliser preparationGibberellinAmmonium sulfate

The invention discloses a special foliage fertilizer for perilla frutescens and a preparation method of the special foliage fertilizer for perilla frutescens. The special foliage fertilizer is prepared from sugarcane and citrus ferments, fructus momordicae extract liquid, radix perillae extract liquid, feather extract liquid, calcium nitrate, ammonium sulfate, ferment bacteria, gibberellins and water. The special foliage fertilizer contains various elements required in a growth process of various crops; by proportioning according to maximum values of various nutrients required by the crops onthe basis of a balanced fertilization theory and by fertilizer efficacy promoting and preserving effects of the sugarcane and citrus ferments, the crops are guaranteed against fertilizer loss and deficiency in a whole growth period, and accordingly high yield is realized.

Owner:XIANGZHOU COUNTY INST OF SCI & TECHN INFORMATION

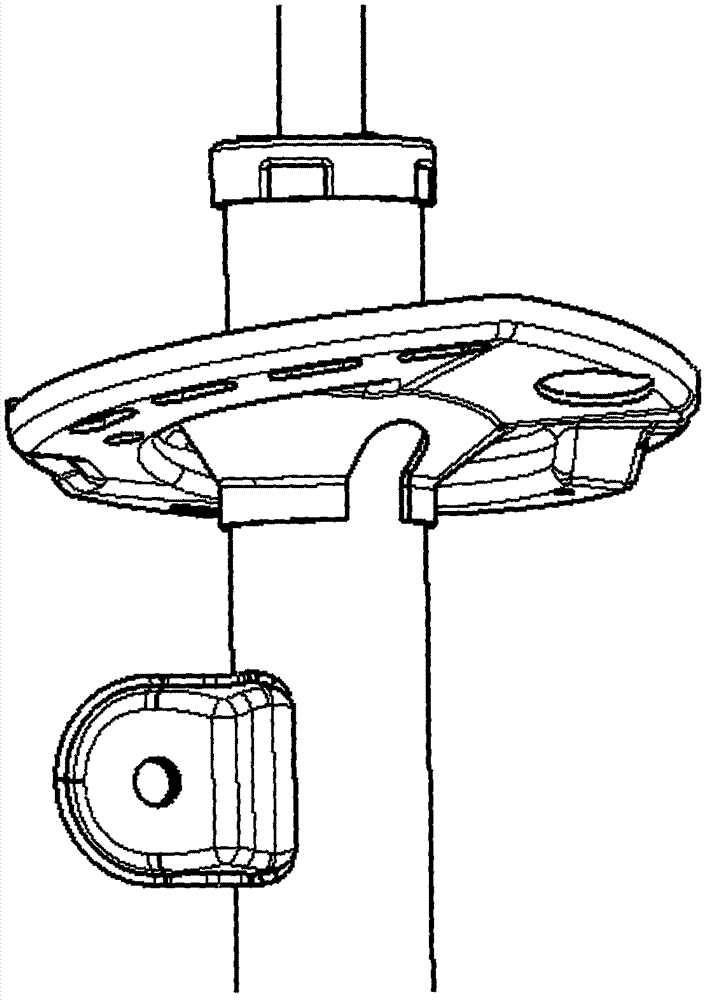

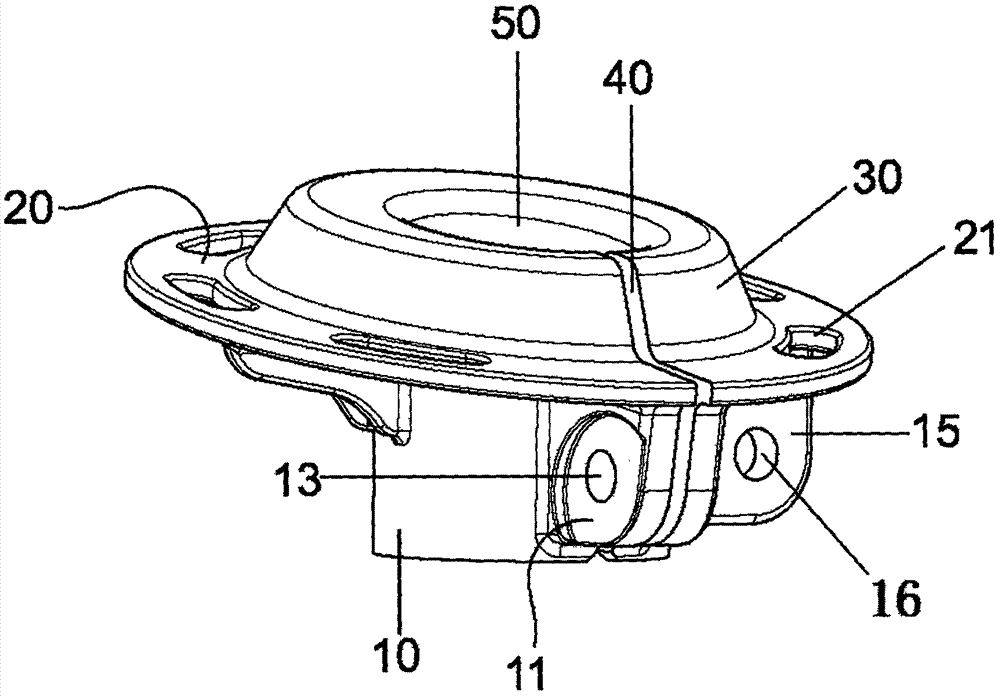

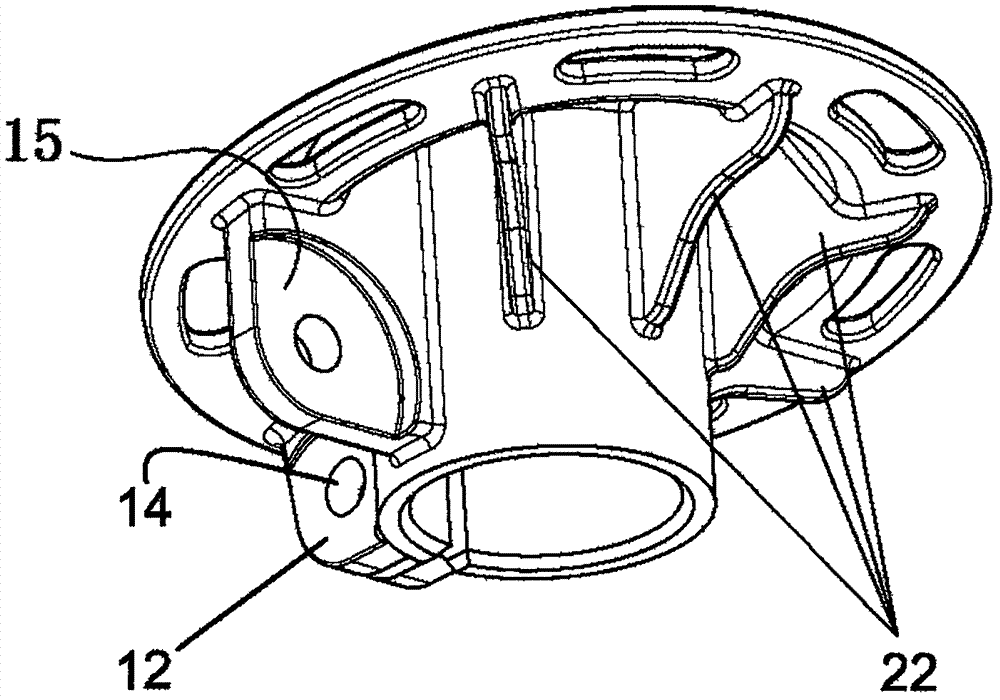

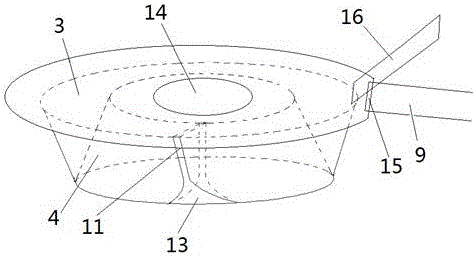

Sliding column aluminium alloy spring lower tray structure

PendingCN108006137AImprove structural rigidityHighly integratedShock absorbersAutomobile designMaterials science

The invention relates to a sliding column aluminium alloy spring lower tray structure and belongs to the technical field of automobile design and manufacture. The sliding column aluminium alloy springlower tray structure comprises a columnar cylinder, wherein a circular spring lower end ring mounting plate is arranged on the upper end face of the columnar cylinder; a conical circular truncated cone structure is formed on the inner circumferential side of the circular spring lower end ring mounting plate; a central hole is processed from the conical circular truncated cone structure to the columnar cylinder; a notch structure is formed in one side of each of the conical circular truncated cone structure, the circular spring lower end ring mounting plate and the columnar cylinder; a first tightening arm and a second tightening arm are oppositely arranged on the columnar cylinder outer circumferential walls on the two sides of the notch structure; and the normal direction of the circularspring lower end ring mounting plate inclines by certain angle relative to the axial direction of the central hole. The sliding column aluminium alloy spring lower tray structure can use light material, is large in structural stiffness and higher in integration level and is movably connected with an absorber cylinder barrel to realize the effects of free of welding, reducing weight, being convenient to repair and adjust and reducing the using cost.

Owner:IAT AUTOMOBILE TECH

A kind of polyester foam sheet and its semi-continuous preparation method

Owner:SUN YAT SEN UNIV

Special leaf fertilizer for radix abri cantoniensis hance and preparation method thereof

InactiveCN108358708ANo weight lossNo fat deficiencyAnimal corpse fertilisersBioloigcal waste fertilisersSugar caneGibberellin

The invention relates to a special leaf fertilizer for herba abri cantoniensis hance and a preparation method thereof. The special leaf fertilizer is prepared by mixing the following raw materials inparts by weight: sugarcane and orange enzyme, fructus momordicae grosvenori extraction liquid, abrus cantoniensis hance root extraction liquid, feather extraction liquid, calcium nitrate, ammonium sulfate, enzyme bacteria, gibberellin and water. The special leaf fertilizer contains various elements required in various crop growth processes; according to the balance fertilization theory, the proportioning is performed according to the maximum quantity of various nutrients required by the crops; the fertilizer fattening and fertilizer maintenance effects of the sugarcane and orange enzymes are added; the crops are enabled not to generate any fertilizer lose and fertilizer lack phenomena in the whole growth period, so that the effects of rich yield and high yield are achieved.

Owner:XIANGZHOU COUNTY INST OF SCI & TECHN INFORMATION

Car frame connecting structure

ActiveCN102009698BReduce intensityNo drop in strengthSuperstructure connectionsPassenger vehicle superstructuresStress concentrationVehicle frame

The invention relates to a car frame connecting structure comprising a side window longitudinal beam, an upright column, a stiffening beam, a top cap longitudinal beam and a top cap horizontal beam, wherein the side window longitudinal beam is riveted with the upright column through a medium corner; the side window longitudinal beam is riveted with the lower part of the stiffening beam; the upright column is riveted with the stiffening beam; the upper part of the stiffening beam is riveted with the top cap horizontal beam through a large corner; and the top cap longitudinal beam is riveted with the top cap horizontal beam through the medium corner. The car frame connecting structure is made of aluminium alloys or magnesium alloys. The invention achieves the effect on reducing weight approximate to a half under the conditions of same or similar strength of steels by adopting the car frame connecting structure made of the aluminium alloys or the magnesium alloys, thereby greatly reducing the weight of a car body without reducing the strength; and in addition, the invention has the advantages of reduced manufacturing and operating cost, long service life and more energy saving and environmental protection, prevents the stress concentration caused by adopting a welding mode through riveting connection and has firm connection without generating cracks.

Owner:北京绿程锦绣能源科技有限公司

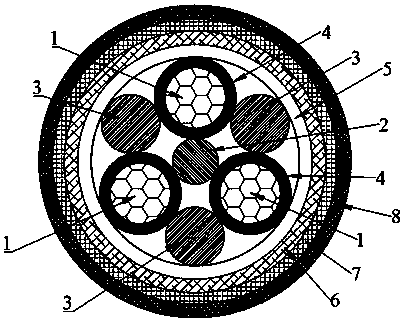

Processing method of high-strength pure copper cable

ActiveCN109754928AHigh tensile strengthHigh strengthInsulated cablesConjugated synthetic polymer artificial filamentsCopper conductorFiber

The invention discloses a high-strength pure copper cable and a fabrication method thereof. The cable comprises a pure copper conductor and a tensile component, wherein the tensile component comprisesa core part tensile fiber and a surrounding tensile fiber, the core tensile fiber is arranged at an axis of the cable, the pure copper conductor and the surrounding tensile fiber are arranged in a way encircling the core copper conductor, an insulation layer wraps the pure copper conductor, an internal sheath layer wraps an outer side of the surrounding tensile fiber, a shielding layer wraps an outer side of the internal sheath layer, an armoring layer wraps an outer side of the shielding layer, an outer sheath wraps the armoring layer, the cable is characterized in that the core tensile fiber and the surrounding tensile fiber both are made of carbon nanotube-polyvinyl alcohol fibers. Compared with the cable in the prior art, the cable tensile component prepared by the method has the advantages of more excellent tensile strength, so that the tensile strength of the cable is remarkably improved, cable weight is not reduced, and the application range is wider.

Owner:江西沪昌电缆有限公司

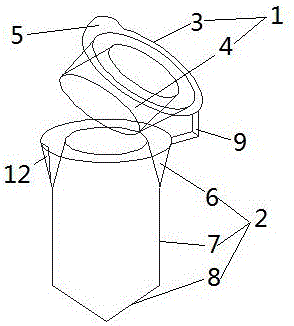

Centrifugal pipe

InactiveCN105728075AAvoid pollutionPrevent overflowLaboratory glasswaresFluid controllersHigh probabilityFolded structure

The invention discloses a centrifugal pipe which comprises a pipe cover and a pipe body, wherein the pipe cover consists of a cover top and a cover edge, the cover edge consists of a cover edge inner wall and a cover edge outer wall, and a structure with a V-shaped longitudinal section is formed between the cover edge inner wall and the cover edge outer wall; the pipe body consists of a pipe orifice, a pipe barrel and a pipe bottom, the pipe barrel is of a cylindrical structure, the pipe bottom is a conical bottom, and the pipe orifice consists of a pipe orifice inner wall and a pipe orifice outer wall, and a space with a V-shaped longitudinal section is formed between the pipe orifice inner wall and the pipe orifice outer wall and is matched and clamped with the V-shaped structure; the cover top is connected with the pipe orifice outer wall through a soft folding structure; the diameter of the opening position of the pipe orifice inner wall is smaller than that of the pipe barrel; an inserting piece is arranged on the inner side of the pipe orifice outer wall; a slot is formed in the outer wall of the cover edge, and a socket of the slot has a wide lower part and a narrow upper part. The centrifugal pipe disclosed by the invention solves the problem of high probability of sample and environment pollution.

Owner:张洪美

Underwater vehicles powered by seawater batteries

ActiveCN104129490BDoes not take up load spaceNo weight lossWatercraft hull designPropulsive elementsElectrochemical responseChemical reaction

This invention relates to a seawater battery-driven water vehicle for sailing in the ocean, including a main body, a flow channel, a seawater battery and a power system. The flow channel is disposed in the main body and includes an inlet, an outlet and a wall. The seawater battery is installed inside the flow channel, and includes the seawater that flows into the flow channel and a cathode and an anode that are connected with the wall respectively and separated from each other while contacted with the seawater. The power system is equipped on the main body and is electrically connected with the seawater battery and contacted with the ocean outside the main body. In this invention, accordingly, an electrochemical reaction respectively with the anode and the cathode in the flow channel is performed in the seawater to generate electric power, and the power system is driven by the electric power to push the main body to move in the ocean, so as to have a stable supply of electricity without reducing the carrying load of vehicle in water.

Owner:TAIWAN CARBON NANO TECHNOLOGY CORPORATION

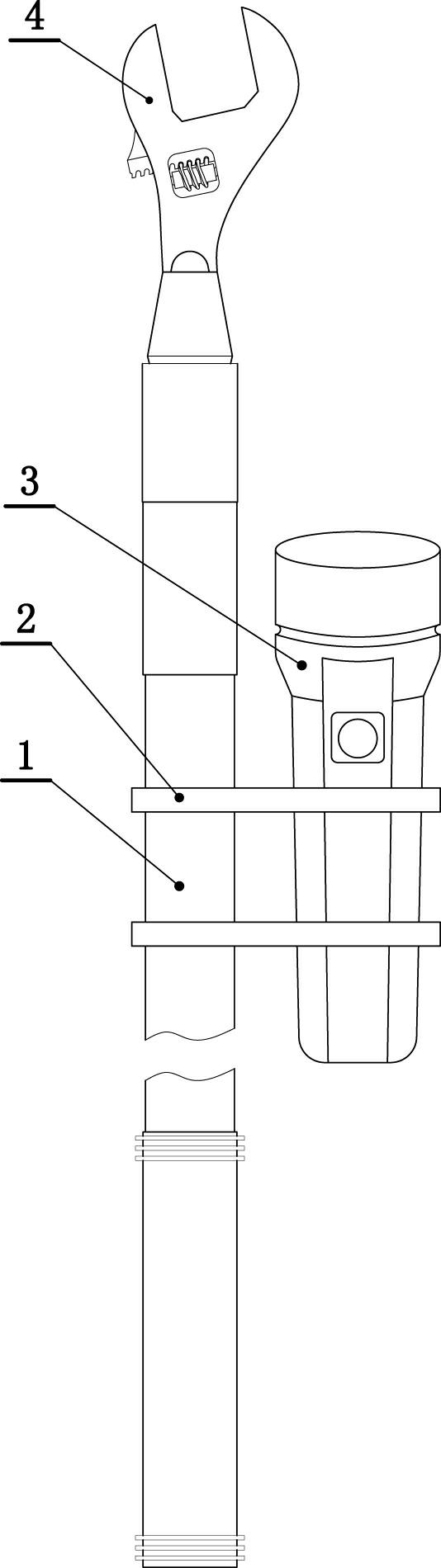

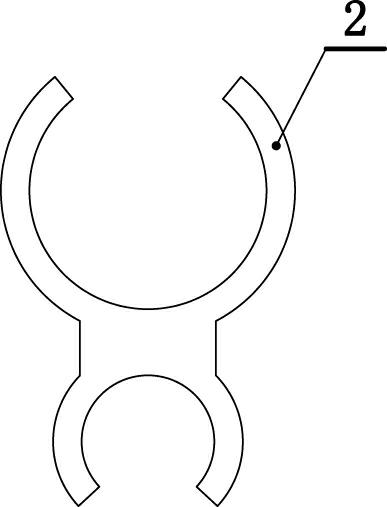

Portable line-tracking combinational tool

InactiveCN102593754ANo reduction in varietyReduce typesMulti-purpose toolsApparatus for overhead lines/cablesEngineeringTorch

The invention provides a portable line-tracking combinational tool which has a simple structure and is convenient to use. The portable line-tracking combinational tool comprises a telescopic rod, wherein a fixing clamp with a B-shaped structure is connected to the telescopic rod; openings are formed at the upper end and the lower end of the fixing clamp; an electric torch is connected to the interior of the other opening of the fixing clamp; and the front end of the telescopic rod is in threaded connection with a wrench, a hammer, a sickle or an axe. As multiple tools in the portable line-tracking combinational tool share one telescopic rod, the structure is simplified, the operation and the use are also very convenient, and when the portable line-tracking combinational tool is carried to track lines on foot, the carrying weight is greatly reduced while the variety of the used tools is not reduced, thereby greatly saving the physical strength of the line-tracking personnel, shortening the time used for the line-tracking range of the same length and improving the work efficiency.

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com