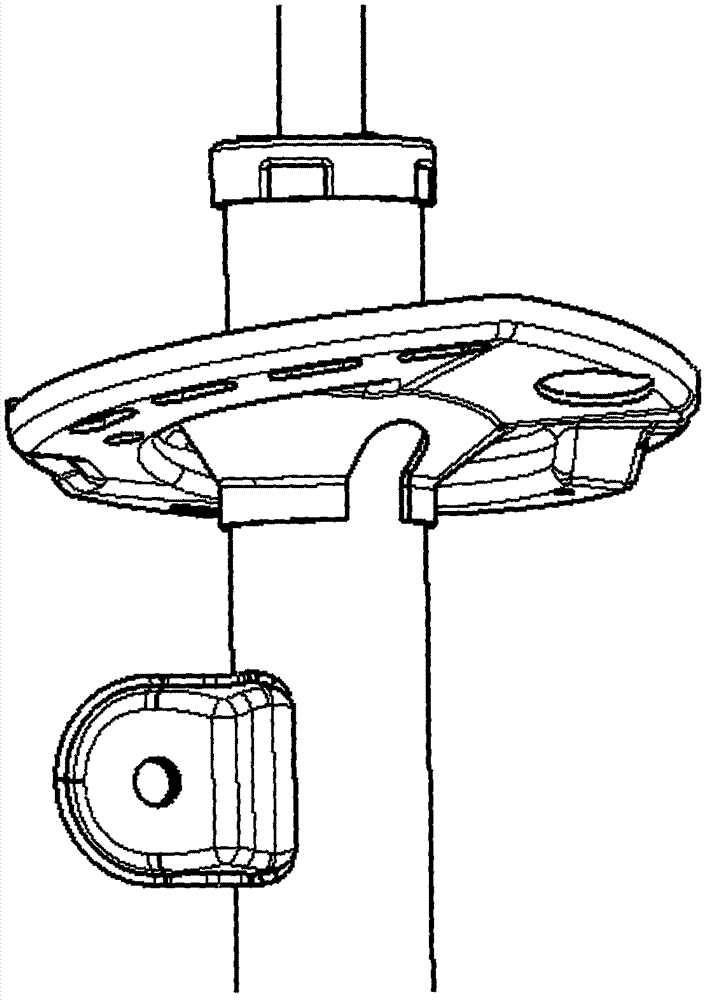

Sliding column aluminium alloy spring lower tray structure

A technology of aluminum alloy and sliding column, which is applied in the direction of spring/shock absorber, shock absorber, shock absorber, etc., can solve the problems of large plate thickness, poor overall precision, and affecting the strength of the cylinder, so as to reduce the use cost, Easy maintenance and adjustment, high structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

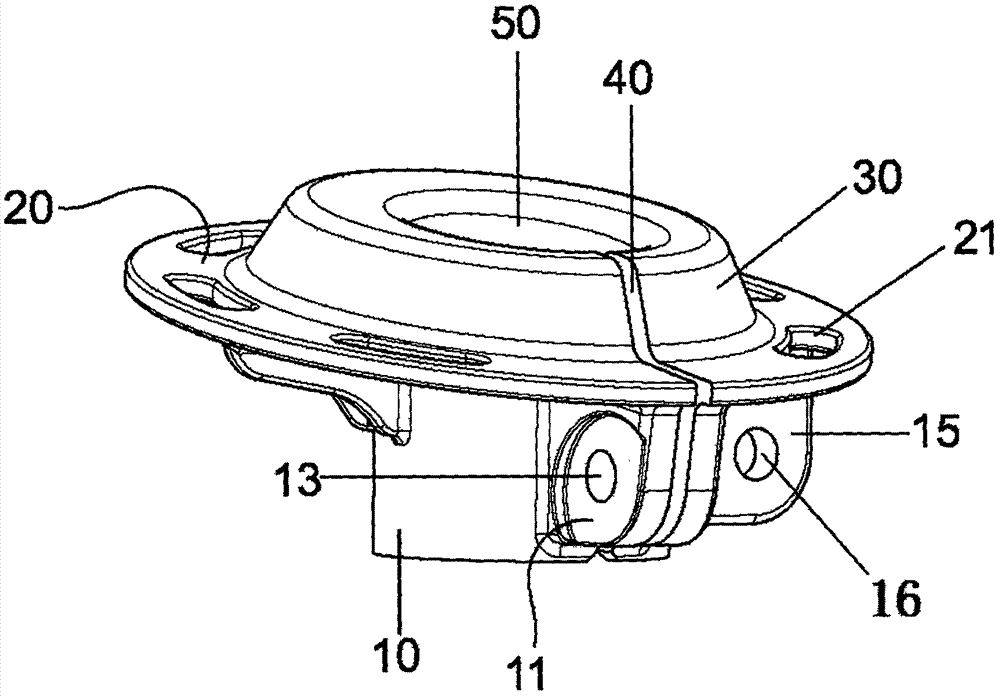

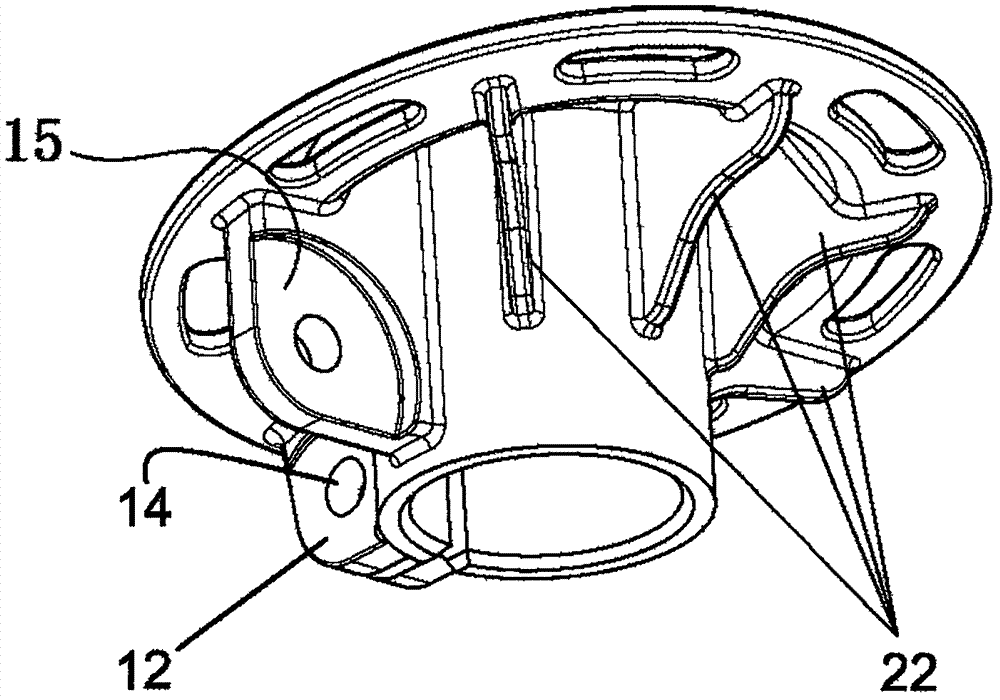

[0024] Such as Figure 2-3 As shown, the sliding column aluminum alloy spring tray structure of this embodiment includes a cylindrical cylinder 10, the upper end surface of the cylindrical cylinder 10 is provided with a circular spring lower end ring mounting plate 20, and the circular spring lower end ring is installed The inner peripheral side of the plate 20 extends upward to form a conical truncated conical structure 30; from the upper end surface of the conical truncated conical structure 30 to the lower end surface of the cylindrical cylinder 10, a through central hole 50 is processed; and from the central hole The axis of 50 begins to shear from the upper end surface of the conical truncated conical structure to the lower end surface of the cylindrical cylinder so that the A cutout structure 40 is formed on one side, and the width of the cutout structure is 3-5mm, so that the underspring tray can be used for the circumferential clamping of the shock absorber cylinder. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com