Part of vehicle frame

A component and frame technology, which is applied in the field of auto parts, can solve the problems of reduced bearing capacity, failure to recycle, and insufficient strength to meet the requirements, and achieve the effects of reduced manufacturing and operating costs, not easy to rust, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0048] According to the vehicle frame component described in the first embodiment, the specific length of each parameter that can be used for different automobiles is shown in the following table:

[0049]

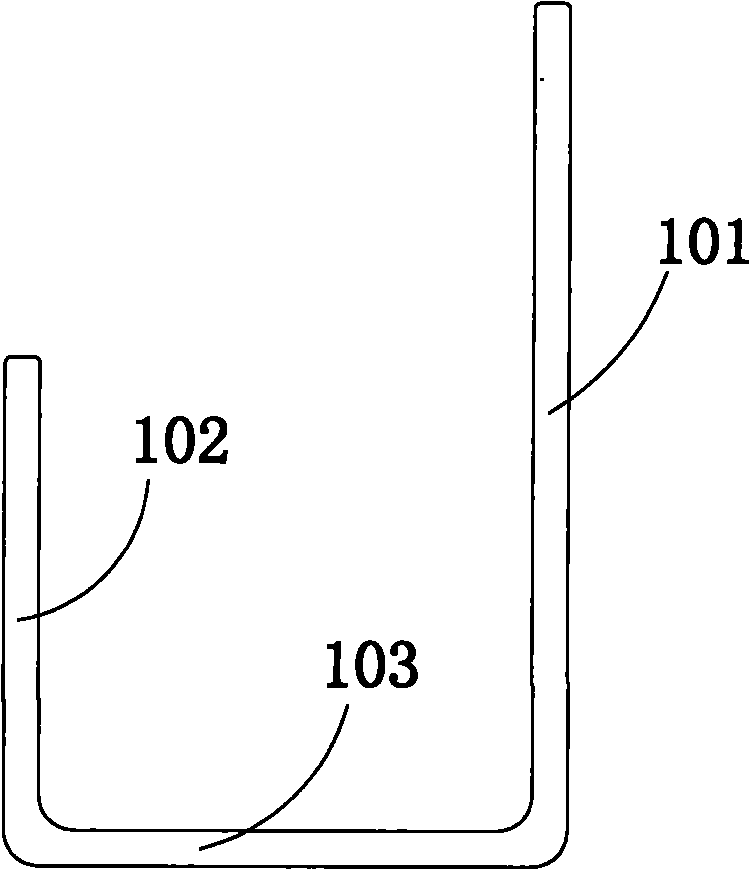

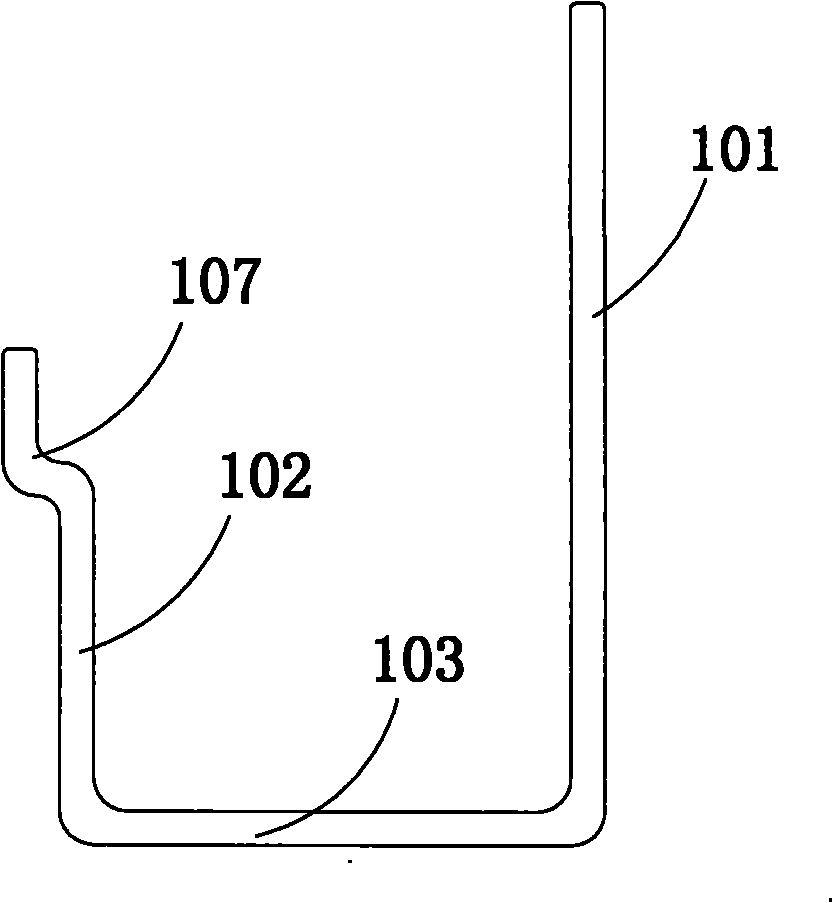

[0050] Such as figure 2 As shown, in the frame component 1 according to the second embodiment of the present invention, the width of the first and second sides 101 and 102 is 20 to 150 mm, and the width of the first and second sides 101 and 102 is more The preferred width is 30-120mm; the width of the bottom edge 103 is 30-80mm, the more preferred width of the bottom edge 103 is 30-60mm, and the bottom edge 103 of the frame component is provided with a The groove 106, the width of the groove 106 is 0-80mm, the more preferred width of the groove 106 is 5-55mm; the depth of the groove 106 is 0.5-25mm, and the groove 106 is more The preferred depth is 1 to 10 mm.

Embodiment 6-10

[0052] According to the vehicle frame component described in the second embodiment, the specific length of each parameter that can be used for different automobiles is shown in the following table:

[0053]

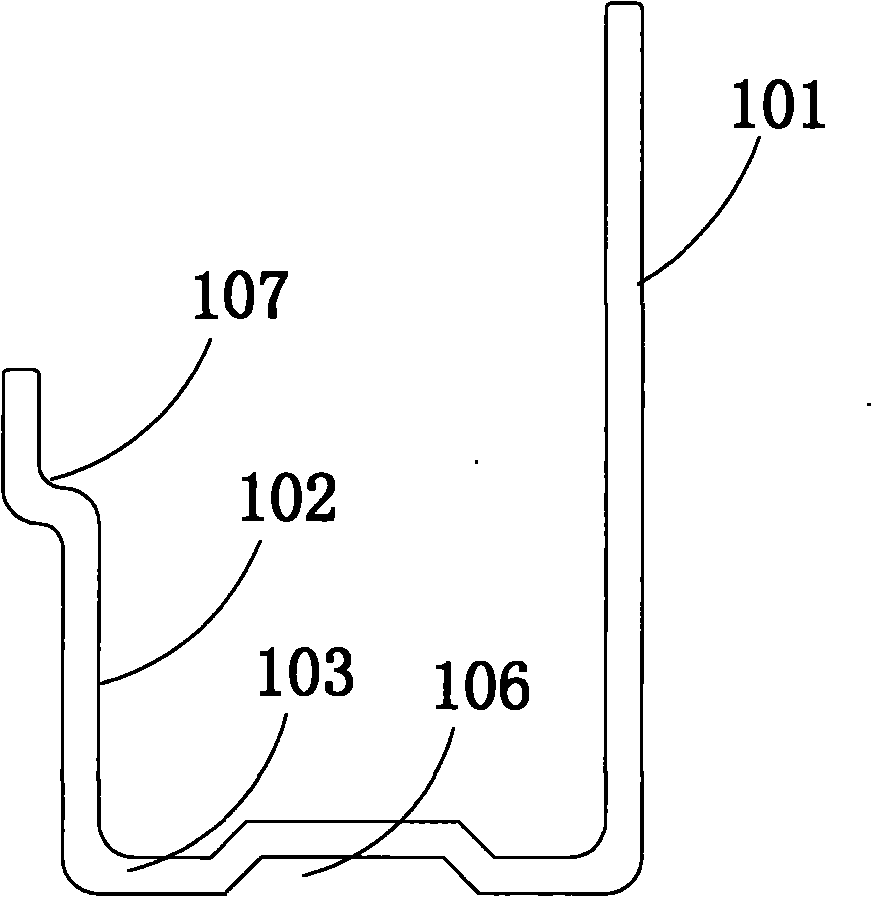

[0054] Such as image 3 As shown, in the frame component 1 according to the third embodiment of the present invention, the width of the first and second sides 101 and 102 is 20 to 150 mm, and the width of the first and second sides 101 and 102 is more The preferred width is 30-120 mm; the width of the bottom edge 103 is 30-80 mm, and the more preferred width of the bottom edge 103 is 30-60 mm. The bottom edge 103 of the frame component is provided with a groove 106, The width of the groove 106 is 0-80 mm, and the more preferred width of the groove 106 is 5-55 mm; the depth of the groove 106 is 0.5-25 mm, and the more preferred depth of the groove 106 is 1-10 mm; the second side 102 of the frame component is provided with a curved arm 107, and the radius of the ...

Embodiment 11-15

[0056] According to the vehicle frame component described in the third embodiment, the specific length of each parameter that can be used for different automobiles is shown in the following table:

[0057]

[0058] Such as Figure 4 As shown, in the frame component 1 according to the fourth embodiment of the present invention, the width of the first and second sides 101 is 20-150 mm, and the width of the first and second sides 101 is more preferably 30-120mm; the width of the bottom edge 103 is 30-80mm, and the more preferred width of the bottom edge 103 is 30-60mm; the first side 101 of the frame component is provided with a groove 106, The width of the groove 106 is 0-80 mm, and the more preferred width of the groove 106 is 5-55 mm; the depth of the groove 106 is 0.5-25 mm, and the more preferred depth of the groove 106 is 1~10mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com