Processing method of high-strength pure copper cable

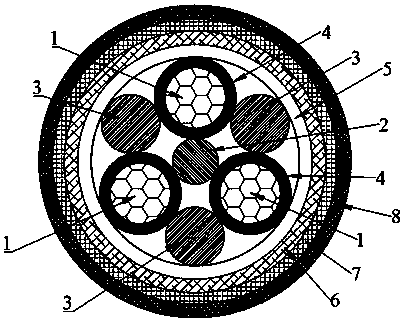

A high-strength, pure copper technology, used in insulated cables, cables, circuits, etc., can solve the problems of high quality, poor flexibility, easy corrosion, etc., and achieve the effect of improving tensile strength, good flexibility, and enhancing cable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the carbon nanotube-polyvinyl alcohol fiber that the present embodiment adopts is:

[0036] (1) Configure the aqueous solution of benzyl alcohol and benzenesulfonamide. The concentration of benzyl alcohol in the aqueous solution of benzyl alcohol and benzenesulfonamide is 0.1g / L, and the concentration of benzenesulfonamide is 3g / L. ℃, then add carbon nanotubes into the solution, the aqueous solution of benzyl alcohol and benzenesulfonamide is 30 times of the weight of the carbon nanotubes added therein, fully stir for 10h, separate the solid and liquid after the stirring is completed, and obtain the solid phase A;

[0037] (2) The concentration of configuring ferrous sulfate is the aqueous solution of 0.6mol / L earlier, then drips sulfuric acid and adjusts the pH of solution to 2, makes the aqueous solution of ferrous sulfate, sulfuric acid, adds ferrous sulfate to described solid phase A In the aqueous solution of ferrous sulfate and sulfuric a...

Embodiment 2

[0043] The preparation method of the carbon nanotube-polyvinyl alcohol fiber that the present embodiment adopts is:

[0044] (1) configure the aqueous solution of benzyl alcohol and benzenesulfonamide, the concentration of benzyl alcohol in the aqueous solution of benzyl alcohol and benzenesulfonamide is 0.2g / L, the concentration of benzenesulfonamide is 3.6g / L, and the solution water bath is kept at a constant temperature to 60~ 65°C, then add the carbon nanotubes into the solution, the aqueous solution of benzyl alcohol and benzenesulfonamide is 30 times the weight of the carbon nanotubes added therein, fully stir for 10h, and separate the solid and liquid after the stirring is completed, to obtain the solid phase A;

[0045] (2) The concentration of configuring ferrous sulfate is the aqueous solution of 0.7mol / L earlier, then drips sulfuric acid and the pH of solution is adjusted to 2, makes the aqueous solution of ferrous sulfate, sulfuric acid, adds ferrous sulfate to desc...

Embodiment 3

[0051] The preparation method of the carbon nanotube-polyvinyl alcohol fiber that the present embodiment adopts is:

[0052] (1) Configure the aqueous solution of benzyl alcohol and benzenesulfonamide. The concentration of benzyl alcohol in the aqueous solution of benzyl alcohol and benzenesulfonamide is 0.3g / L, and the concentration of benzenesulfonamide is 4g / L. ℃, then add carbon nanotubes into the solution, the aqueous solution of benzyl alcohol and benzenesulfonamide is 30 times of the weight of the carbon nanotubes added therein, fully stir for 10h, separate the solid and liquid after the stirring is completed, and obtain the solid phase A;

[0053] (2) The concentration of configuring ferrous sulfate is the aqueous solution of 0.8mol / L earlier, then drips sulfuric acid and adjusts the pH of solution to 3, makes the aqueous solution of ferrous sulfate, sulfuric acid, adds ferrous sulfate to described solid phase A In the aqueous solution of ferrous sulfate and sulfuric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com