Environment-friendly ground fine river sand powder concrete

A powder concrete, green and environmentally friendly technology, applied in the field of concrete, to achieve the effect of reducing usage, reducing cost and improving reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

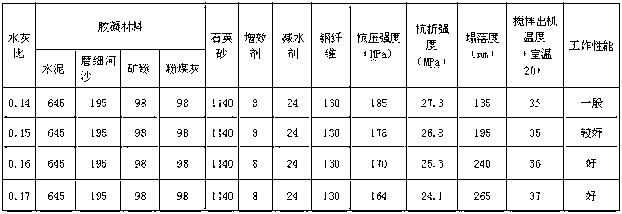

Embodiment 1

[0048] Prepare concrete raw materials according to the following proportions:

[0049] 645 parts of 52.5 grade Portland cement with an average particle size of 30-60 μm;

[0050] Average particle size 5~20μm, loss on ignition ≤0.4%, SiO 2 195 parts of finely ground river sand powder with content ≥93%;

[0051] 98 parts of low-calcium grade I fly ash with an average particle size of 10-30 μm (calcium oxide content ≤ 10%);

[0052] 98 parts of mineral powder above S95 grade with an average particle size of 10-30 μm;

[0053] 1140 parts of continuously graded quartz sand with a particle size of 0.16~1.63mm;

[0054] 24 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0055] 9 parts of rust inhibitor (3:1 of triethanolamine borate and organic silicon composite rust inhibitor);

[0056] 8 parts of synergist;

[0057] 150 parts of water;

[0058] 105 pieces of copper-coated steel fibers with a diameter of 0.13~0.20mm and a length of 6...

Embodiment 2

[0076] Prepare concrete raw materials according to the following proportions:

[0077] 590 parts of 52.5 grade Portland cement with an average particle size of 30-60 μm;

[0078] Average particle size 5~20μm, loss on ignition ≤0.4%, SiO 2 180 parts of finely ground river sand powder with content ≥93%;

[0079] 85 parts of low-calcium Class I fly ash with an average particle size of 10-30 μm (calcium oxide content ≤ 10%);

[0080] 85 parts of mineral powder above S95 grade with an average particle size of 10-30 μm;

[0081] 1030 parts of continuously graded quartz sand with a particle size of 0.16~1.63mm;

[0082] 22 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0083] 7 parts of rust inhibitor (3:1 of triethanolamine borate and organic silicon composite rust inhibitor);

[0084] 6 parts of synergist;

[0085] 135 parts of water;

[0086] 80 pieces of copper-coated steel fibers with a diameter of 0.13~0.20mm and a length of 6~...

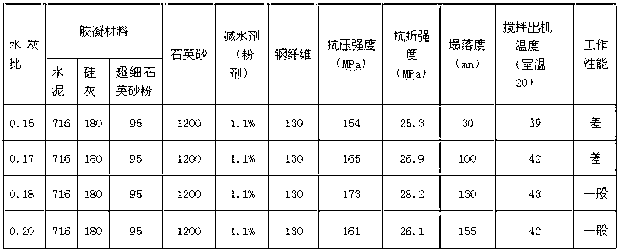

Embodiment 3

[0100] Prepare concrete raw materials according to the following proportions:

[0101] 700 parts of 52.5 grade Portland cement with an average particle size of 30-60 μm;

[0102] Average particle size 5~20μm, loss on ignition ≤0.4%, SiO 2 210 parts of finely ground river sand powder with content ≥93%;

[0103] 100 parts of low-calcium Class I fly ash with an average particle size of 10-30 μm (calcium oxide content ≤ 10%);

[0104] 100 parts of mineral powder above S95 grade with an average particle size of 10-30 μm;

[0105] 1200 parts of continuously graded quartz sand with a particle size of 0.16~1.63mm;

[0106] 26 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0107] 12 parts of rust inhibitor (3:1 triethanolamine borate and organic silicon composite rust inhibitor);

[0108] 10 parts of synergist;

[0109] 165 parts of water;

[0110] 160 pieces of copper-plated steel fibers with a diameter of 0.13~0.20mm and a length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com