Compound high-temperature cloth with enhanced structure

A reinforced, high-temperature cloth technology, applied in the direction of synthetic resin layered products, layered products, glass/slag layered products, etc., can solve the problem of poor high and low temperature resistance, corrosion resistance, etc. Safety hazards and other issues, to achieve good dimensional stability, strength will not become lower, maintain the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

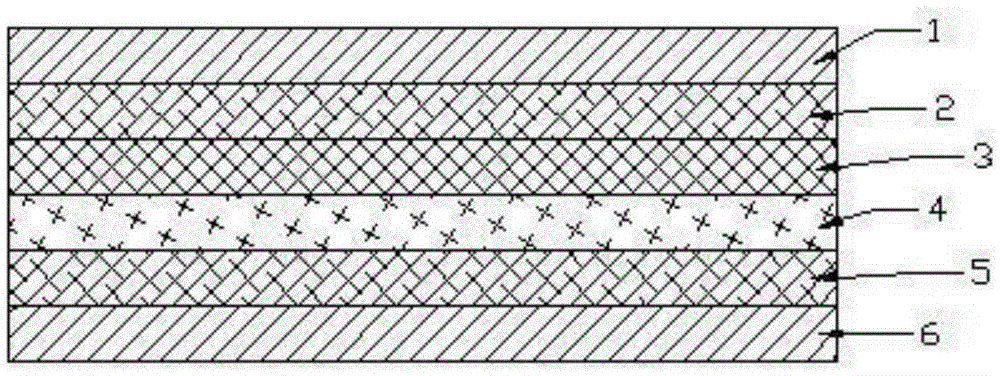

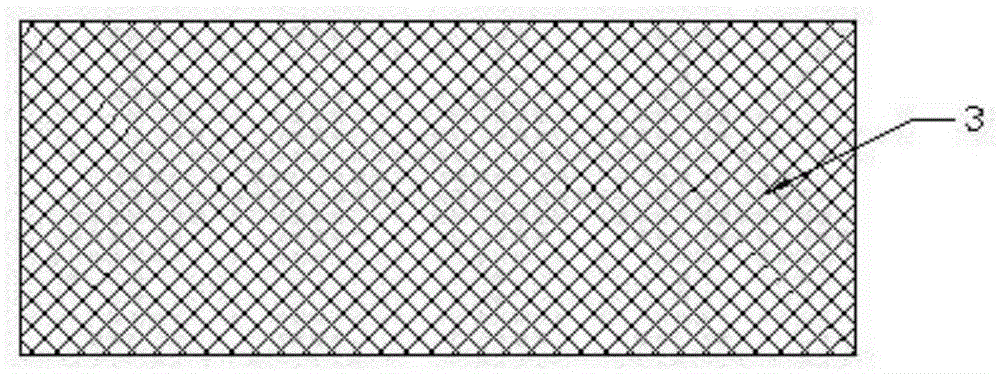

[0019] Such as figure 1 and image 3 A composite high-temperature cloth with a reinforced structure is shown, which consists of a first polytetrafluoroethylene layer 1, a second polytetrafluoroethylene layer 6, and is arranged on the first polytetrafluoroethylene layer 1 and the second polytetrafluoroethylene layer The multi-layer filling layer in the middle of the vinyl layer 6 is composed of; the multi-layer filling layer includes the first glass fiber cloth layer 2, the grid layer 3, the hot melt adhesive layer 4 and the second glass fiber cloth layer 5, wherein the first glass fiber cloth layer The two sides of the cloth layer 2 are respectively connected with the first polytetrafluoroethylene layer 1 and the grid layer 3 , and the two sides of the second glass fiber cloth layer 5 are respectively connected with the second polytetrafluoroethylene layer 6 and the hot melt adhesive layer 4 .

[0020] Further preferably, the thickness of the first polytetrafluoroethylene lay...

Embodiment 2

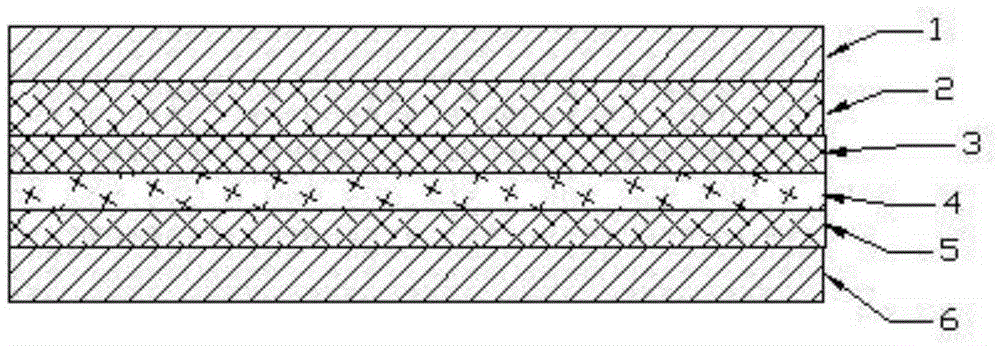

[0022] Such as figure 2 and image 3 A composite high-temperature cloth with a reinforced structure is shown, which consists of a first polytetrafluoroethylene layer 1, a second polytetrafluoroethylene layer 6, and is arranged on the first polytetrafluoroethylene layer 1 and the second polytetrafluoroethylene layer The multi-layer filling layer in the middle of the vinyl layer 6 is composed of; the multi-layer filling layer includes the first glass fiber cloth layer 2, the grid layer 3, the hot melt adhesive layer 4 and the second glass fiber cloth layer 5, wherein the first glass fiber cloth layer The two sides of the cloth layer 2 are respectively connected with the first polytetrafluoroethylene layer 1 and the grid layer 3 , and the two sides of the second glass fiber cloth layer 5 are respectively connected with the second polytetrafluoroethylene layer 6 and the hot melt adhesive layer 4 .

[0023] Further preferably, the first polytetrafluoroethylene layer 1, the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com