Anti-reflection glass substrate as well as preparation method and application thereof

A technology of anti-reflection glass and glass substrate, which is applied in the field of anti-reflection glass substrate and its preparation, can solve the problems of easy adsorption, large transmittance attenuation, lower film quality and optical performance, etc., and achieve high light transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

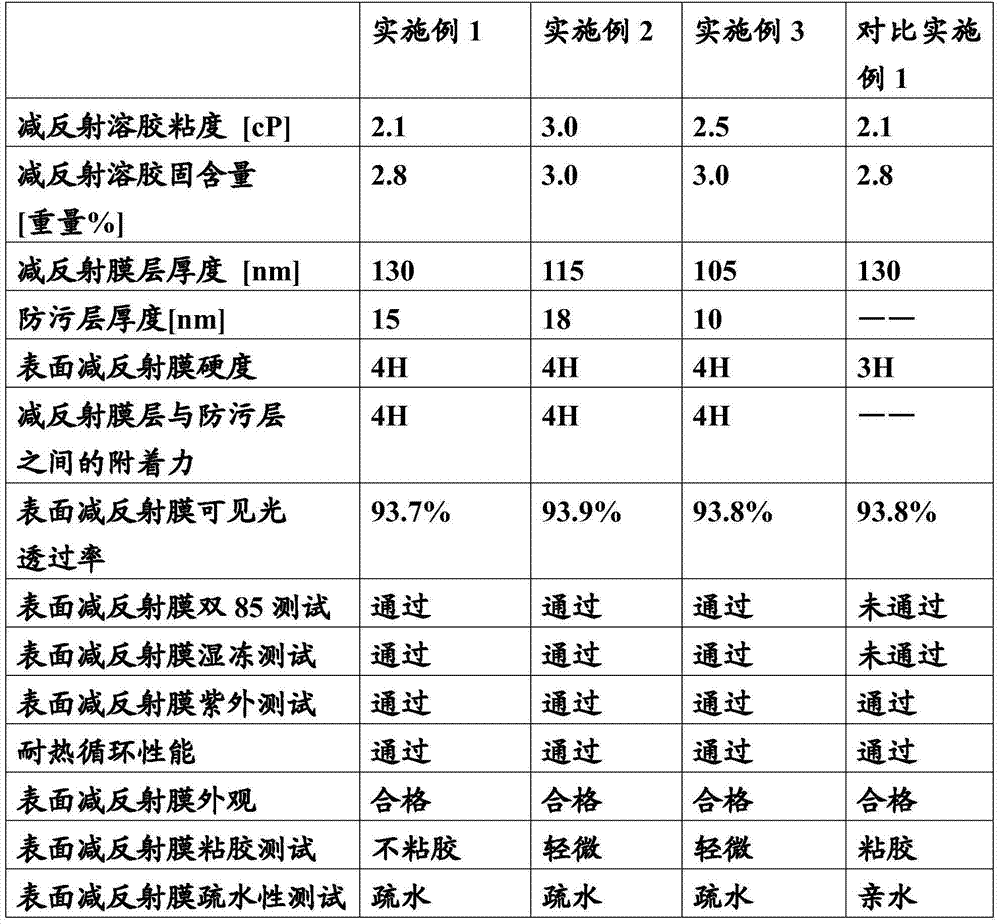

Examples

preparation example Construction

[0013] The preparation method of the anti-reflection glass substrate of the present invention comprises the following steps:

[0014] a) Preparation of anti-reflection sol: acidify the silica sol, add orthosilicate and deionized water to react to form a primary sol, then add an organic solvent, stir, seal and age; add film-forming aids and Control the drying of chemical additives and stir to obtain anti-reflection sol;

[0015] b) coating film: applying the anti-reflection sol in step a) on the surface of the glass substrate to form a glass substrate with an anti-reflection coating;

[0016] c) tempering: tempering the glass substrate in step b) to form an anti-reflection coating;

[0017] d) Applying an antifouling liquid: applying an antifouling liquid on the antireflection film layer of the glass substrate treated in step c), and forming an antifouling layer.

[0018] In step a) of the method of the present invention, the silica sol is preferably a monodisperse silica org...

Embodiment 1

[0055] Take 429g particle size is 30nm and SiO 2 The content is 2.8wt% organosilicon sol (0.2mol SiO 2 , self-made), under stirring, add commercially available concentrated hydrochloric acid dropwise to the silica sol, when the pH value reaches 3, continue stirring for 1 hour, then slowly add 20.8g (0.1mol) ethyl orthosilicate and 7.2g to Ionized water, and add 183g absolute ethanol to keep SiO 2 The content of is still 2.8wt%. After continuing to stir for 4 hours, seal it and place it in a constant temperature drying oven at 40°C for aging for 3 days; add 4.6g of dipropylene glycol monomethyl ether and 46g of N,N-dimethylformamide to the aged sol, and stir for 1 Hours, the antireflection sol was obtained.

[0056] Clean and dry the photovoltaic glass substrate (300mm*600mm, thickness 4.0mm) with deionized water, apply anti-reflection sol on the photovoltaic glass substrate with a roller coater, use a quantitative roller with a mesh number of 100 mesh, coat the roller and g...

Embodiment 2

[0058] Take 400g particle size is 20nm and SiO 2 The content is 3.0wt% organosilicon sol (0.2mol SiO 2 , self-made), add acetic acid dropwise to the silica sol under stirring, when the pH value reaches 1, continue stirring for 1 hour, then slowly add 20.8g (0.1mol) tetraethyl orthosilicate and 7.2g deionized water, And add 165g of isopropanol to keep SiO 2 The content is still 3.0wt%. After continuing to stir for 4 hours, seal it and place it in a constant temperature drying oven at 60°C for aging for 3 days; add 2.2g of dipropylene glycol monomethyl ether and 8.6g of N,N-dimethylformamide to the aged sol, stir After 1 hour, an antireflection sol was obtained.

[0059] Clean and dry the photovoltaic glass substrate (300mm*600mm, thickness 4.0mm) with deionized water, apply anti-reflection sol on the photovoltaic glass substrate with a roller coater, use a quantitative roller with a mesh number of 80 mesh, coat the roller and glass The amount of compression between the subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com