Operating method of cold continuous rolling mill equipment for eliminating start band head coiling

A technology of cold tandem rolling mill and operation method, applied in rolling mill control devices, metal processing equipment, metal rolling, etc., can solve the problems of non-compliance and large thickness difference, and achieve no weight loss, consistent thickness, and guaranteed thickness tolerance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

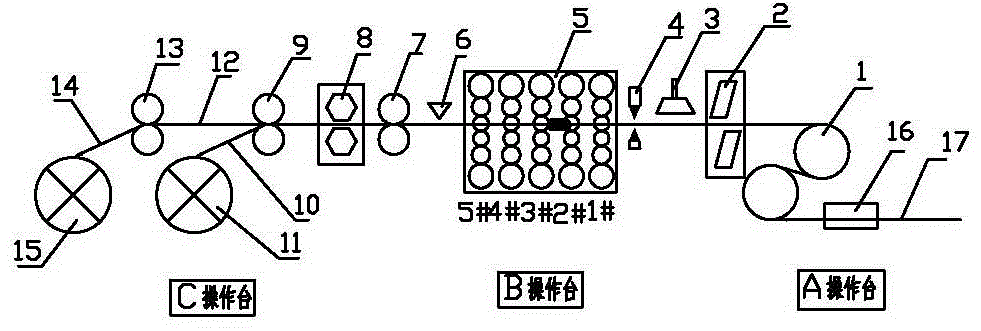

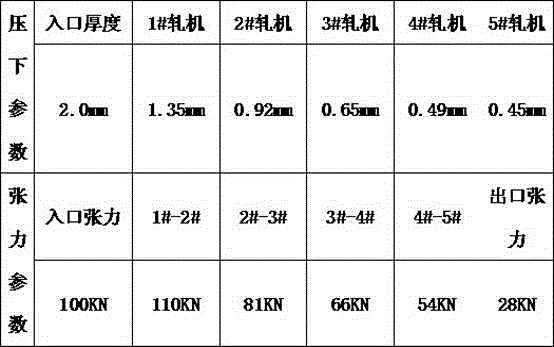

[0032] figure 1 A schematic diagram of equipment assembly according to an embodiment of the present invention is given. refer to figure 1 The implementation of the present invention is further described. The 900MM tandem cold rolling mill in our company conducts production trial rolling.

[0033] The tandem cold rolling mill equipment eliminates the operation method of starting the lead coil, and the tandem cold rolling mill equipment includes an entrance tension roll group 1, an entrance slitting shear 2, an entrance table pressure plate 3, a weld detector 4, a cold tandem rolling unit 5, and an exit tester. Thickness meter 6, exit pinch roller 7, flying shear 8, 1# steering pinch roller 9, 1# threading guide table with magnetic belt 10, 1# coiler 11, transition guide table with magnetic belt 12, 2# Steering pinch roller 13, 2# belt threading guide table with magnetic belt 14, 2# coiler 15, welding machine 16, the strip steel 17 welded by welding machine 16 passes through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com