Method for producing gtitanium dioxide with sulphuric acid method

A technology of titanium dioxide and sulfuric acid method, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problem of serious pollution of titanium dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

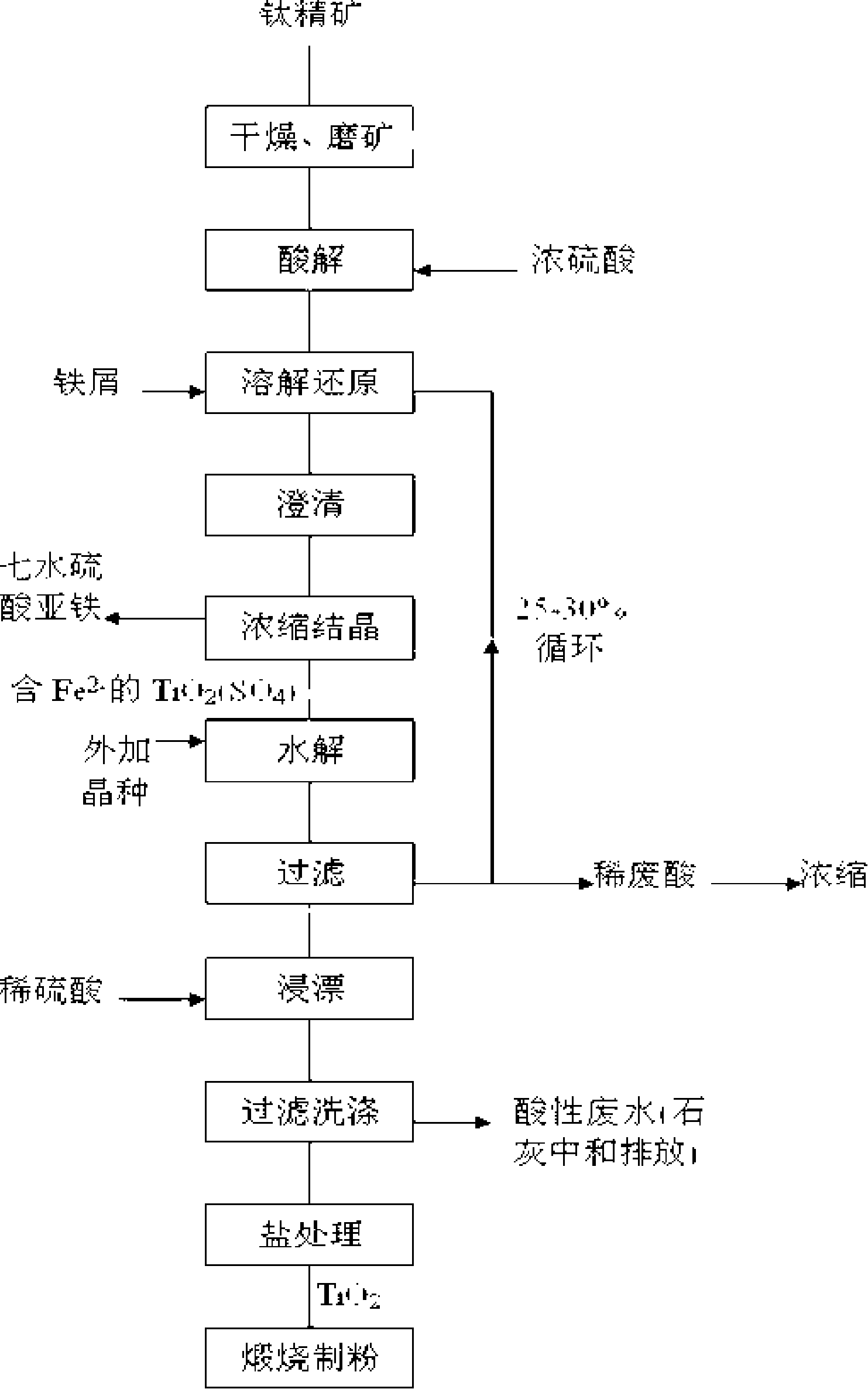

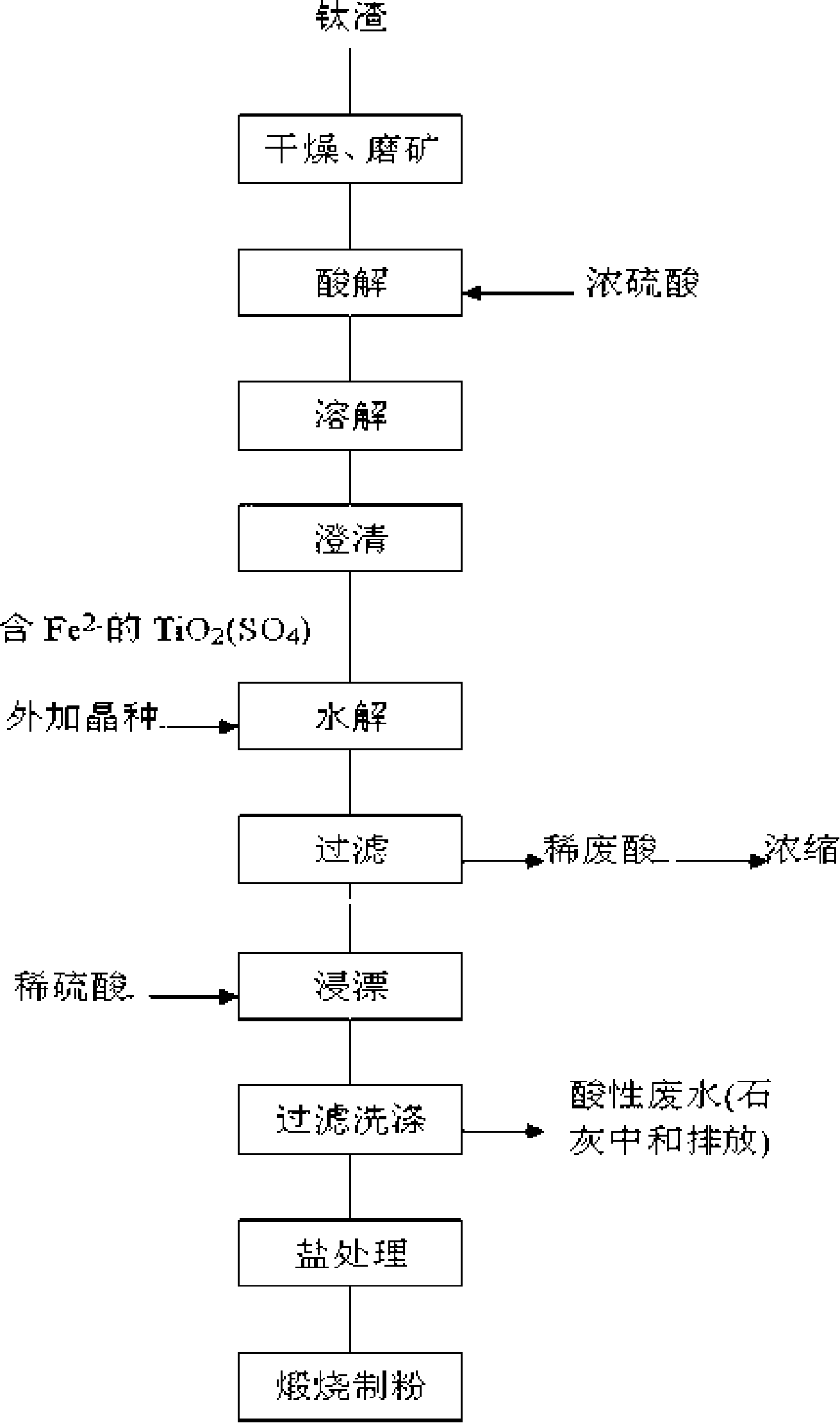

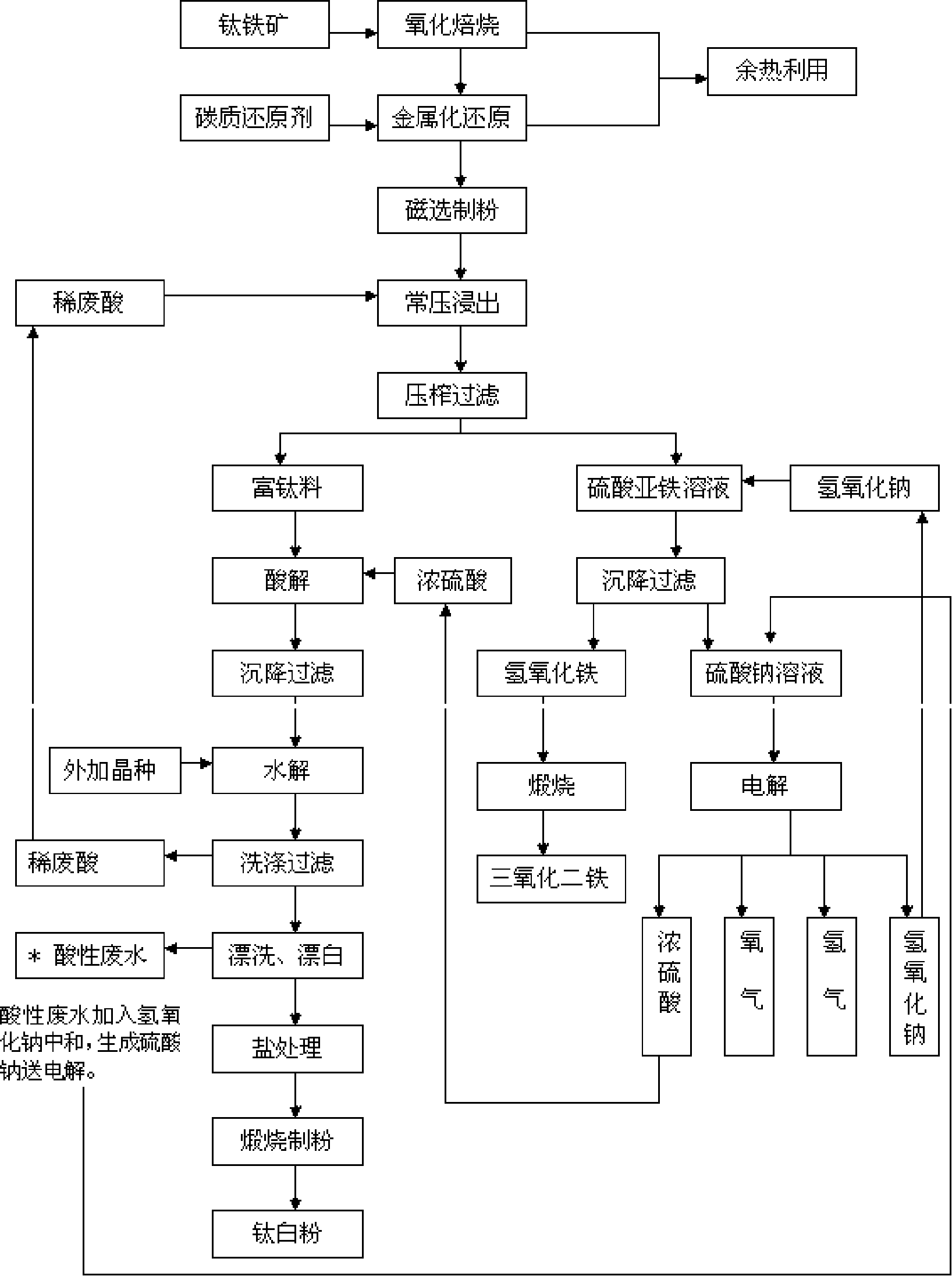

[0011] The method for preparing titanium dioxide by the sulfuric acid method of the present invention comprises the steps of acidolysis of titanium ore, sedimentation, hydrolysis, washing, filtering, rinsing, bleaching, salt treatment, and calcining to make powder. It is characterized in that the acidic waste water produced in rinsing and bleaching is Sodium hydroxide or potassium hydroxide is added for neutralization, and the sodium sulfate or potassium sulfate produced by neutralization is electrolyzed to generate concentrated sulfuric acid; then the sulfuric acid produced by electrolysis is applied to the acidolysis step.

[0012] The method for preparing titanium dioxide by sulfuric acid method of the present invention comprises the steps:

[0013] A. Ilmenite is made into titanium-rich material, which is acidified by adding concentrated sulfuric acid;

[0014] B. Sedimentation filtration, hydrolysis, washing and filtration; among them, when the dilute waste acid produced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com