Preparation method and application of lithium tin alloy powder for lithium ion battery negative electrode

A lithium-ion battery, tin alloy technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as industrialization difficulties, complexity, and cost increase, and achieve simple and feasible preparation methods, broad development prospects, and technology. mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

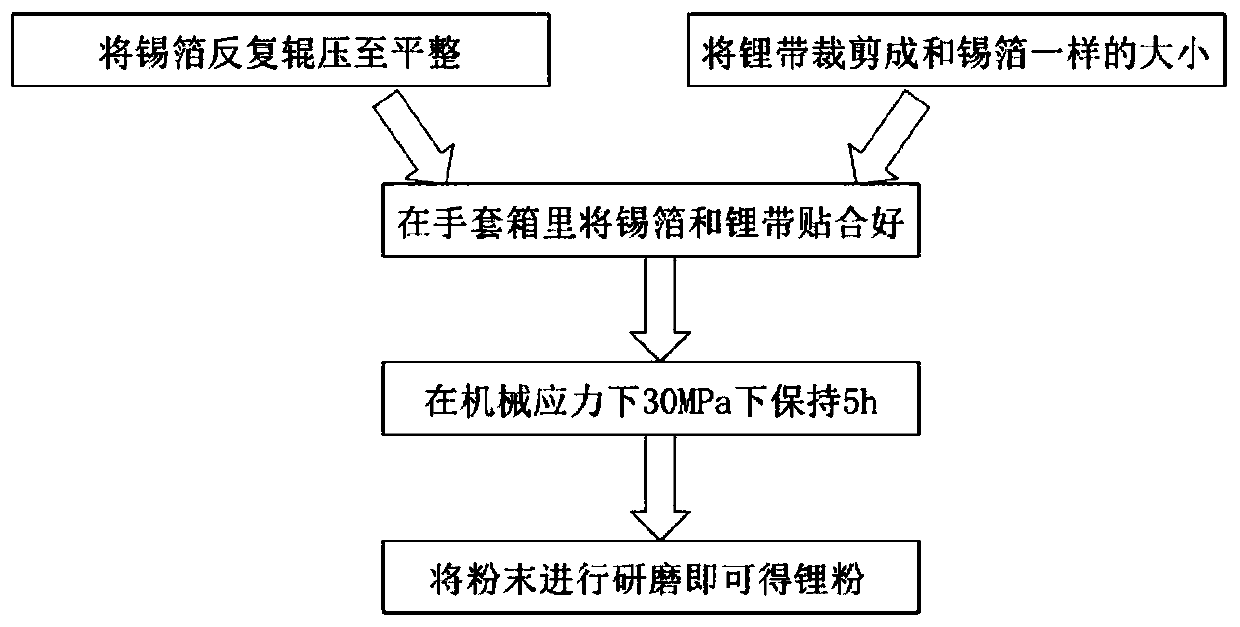

[0042] like Figure 1~4 Shown, in the embodiment of the present invention, a kind of preparation method of lithium-tin alloy powder for negative electrode of lithium ion battery comprises the following steps:

[0043] Step 1: Flatten the tin-based foil and the lithium strip together to obtain a stacked metal sheet;

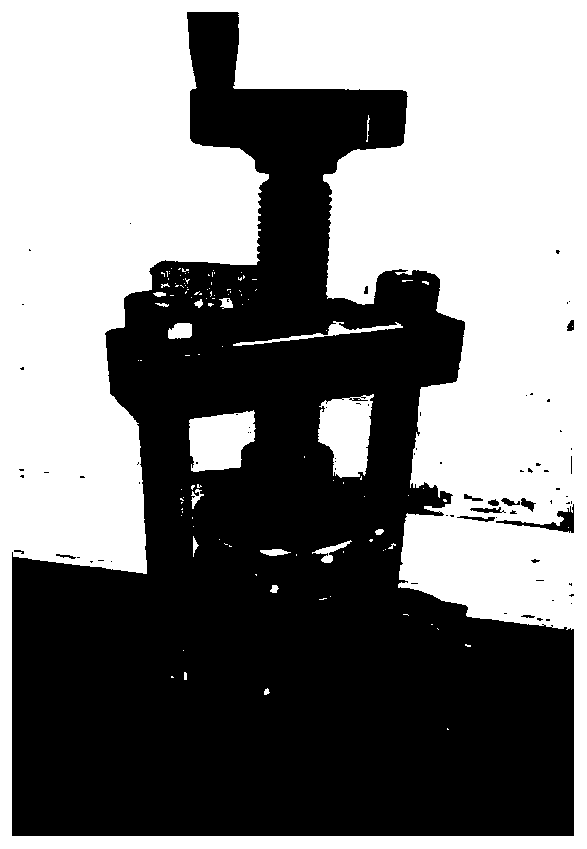

[0044] Step 2: In a dry and oxygen-free environment, the stacked metal sheets are pressed by a pressure device, so that the tin-based foil is completely embedded in the lithium strip, and a lithium-tin alloy metal sheet is obtained;

[0045] Step 3: In a dry and oxygen-free environment, the lithium-tin alloy metal sheet is ground into lithium-tin alloy powder.

[0046] Among them, in step 1, wipe the surface of the tin-based foil with alcohol, roll it repeatedly with a roller press until it is flat, then cut the lithium strip into the same size as the tin-based foil, and place the tin-based foil in the glove box It is flatly attached to the lithium strip, the th...

Embodiment 1

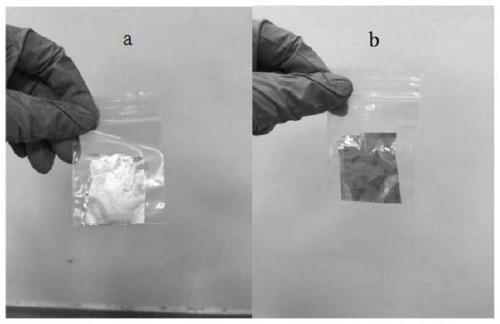

[0052] A pure tin foil with a thickness of 15 μm and a lithium strip with a thickness of 40 μm were selected, pressed in a glove box at 30 MPa for 5 hours with a tablet press, and after grinding, a lithium-tin alloy powder with a particle size of 50 μm was obtained.

[0053] When the anode is a slurry, the powder is added to the hard carbon anode material slurry. That is, in the pulping process, the lithium-tin alloy powder is uniformly mixed with the active material, binder and conductive agent to prepare a pre-lithiated negative electrode sheet, which can improve the first-cycle Coulombic efficiency and cycle stability.

[0054] When the negative pole is used as the pole piece, the lithium-tin alloy powder is hot pressed into the pole piece for lithium supplementation. That is to add lithium-tin alloy powder to the surface of the negative pole piece, and use a hot press to roll it, so that the lithium-tin alloy powder and the pole piece are combined to complete the pre-lithi...

Embodiment 2

[0056] Select a 20 μm thick tin-copper alloy foil (wherein, the mass percentage of tin is 90%, and the mass percentage of copper is 10%) and a 50 μm thick lithium strip, in a glove box, under 40MPa, use a tablet press for 5h , after grinding, a lithium-tin alloy powder with a particle size of 10 μm was obtained.

[0057] When the anode is a slurry, the powder is added to the silicon or silicon-carbon composite material slurry. That is, in the pulping process, the powder is uniformly mixed with active materials, binders, and conductive agents to prepare pre-lithiated pole pieces, which can improve the first-cycle Coulombic efficiency and cycle stability.

[0058] When the negative pole is used as the pole piece, the lithium-tin alloy powder is hot pressed into the pole piece for lithium supplementation. That is to add lithium-tin alloy powder to the surface of the negative pole piece, and use a hot press to roll it, so that the lithium-tin alloy powder and the pole piece are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com