Multi-coating structure, negative pole piece and application of negative pole piece

A negative pole piece and coating technology, which is applied in the field of negative pole piece, negative pole piece, and multi-coating structure, can solve the problem of powder drop of the pole piece, and achieve the effect of normal pressure drop and improvement of yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

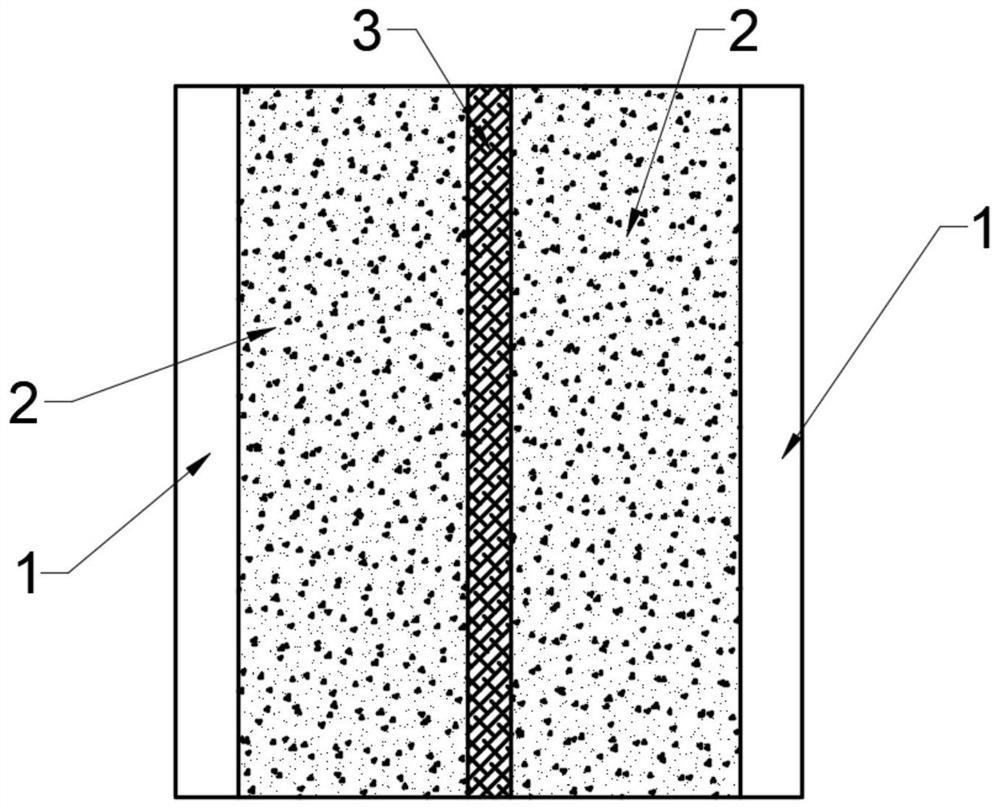

[0072] This embodiment provides a plurality of coating structures based on a plurality of coating structures provided in a specific embodiment, wherein there is a pole region on the current collector, and the width of the side coating zone 3 is 4mm, and the slurry is slurry. The dry weight mass of the layer is 2.5%, and the dry weight mass of the dispersant is 2.0%, and the weight mass of the conductive agent is 2.0%, and the weight mass of the negative electrode active material is 93.5. %. The solid content of the slurry slurry was 45%, the viscosity was 2250 MPa · s. The binder mass in the slurry layer is greater than 1.3% of the binder mass in the active slurry layer, and the mass mass of the conductive agent in the slurry layer is greater than that of the active slurry layer is 1.0. %.

[0073] Among them, the negative electrode active material is an intermediate phase carbon microsphere graphite; the adhesive is styrene butadiene; the dispersant is sodium carboxymethylcellulo...

Embodiment 2

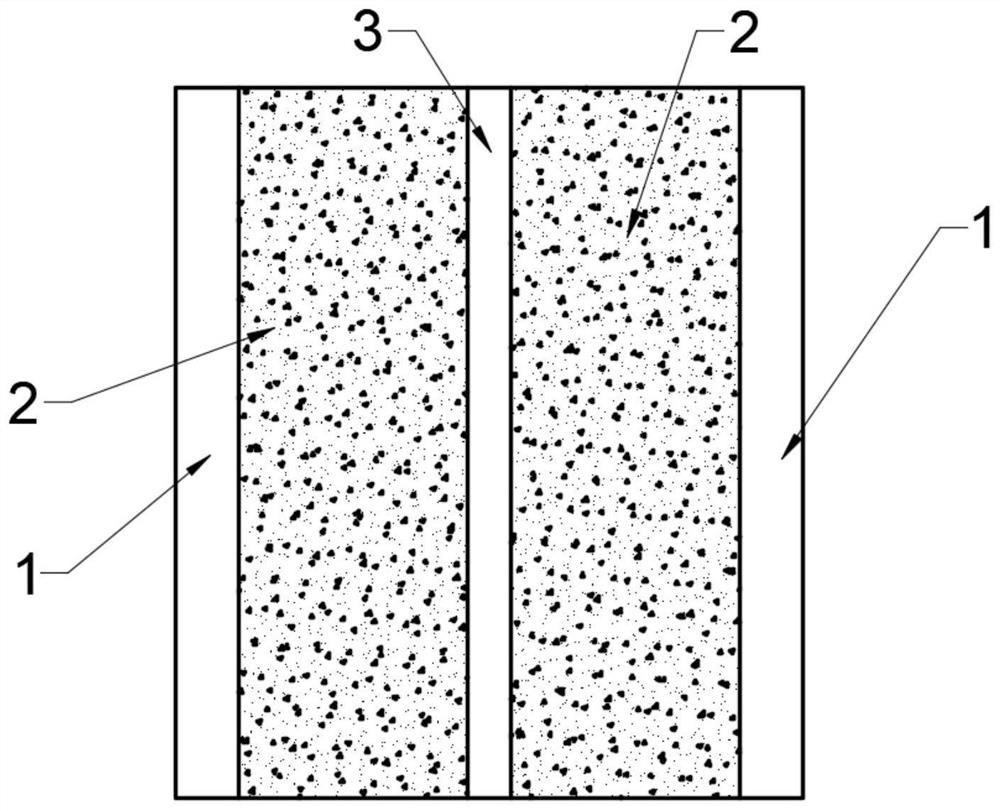

[0076] This embodiment provides a plurality of coating structures, based on a plurality of coating structures provided in a specific embodiment, wherein there are two die regions on the current collector, and the width of the edge coating zone 3 is 2mm, and the slurry is slurry. The dry weight mass of the binder in the material is 2%, and the weight mass of the dispersant is 2.5%, and the weight mass of the conductive agent is 1.5%, and the weight quality of the negative electrode active material is proportional. 94%. The solid content of the slurry material is 50%, the viscosity is 1800 mPa · s. The binder mass in the slurry layer is greater than 0.8% comparison of the binder mass in the active slurry layer, and the mass mass of the conductive agent in the slurry layer is greater than that in the active slurry layer is 0.5 %.

[0077] Among them, the negative electrode active material is a single particulate human graphite; the adhesive is a styrene acrylate; the dispersant is ca...

Embodiment 3

[0080] This embodiment provides a plurality of coating structures based on a plurality of coating structures provided in a specific embodiment, wherein there are three pole regions on the current collector, and the width of the side coating zone 3 is 3 mm, and the slurry is slurry. The dry weight mass of the layer in the layer is 3%, and the weight mass of the dispersant is 0.5%, and the weight mass of the conductive agent is 2.5%, and the dry weight mass of the negative electrode active material is 94. %. The solid content of the slurry slurry was 43%, the viscosity was 2000 MPa · s. The binder mass in the slurry layer is greater than 1.8% of the binder mass in the active slurry layer, and the mass mass in the slurry layer is larger than the conductive agent mass than the active slurry layer. %.

[0081] Among them, the negative electrode active material is hard carbon graphite; the adhesive is a polyacrylic acid-acrylamide copolymer; the dispersant is sodium carboxyethylcellulos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com