Button cell

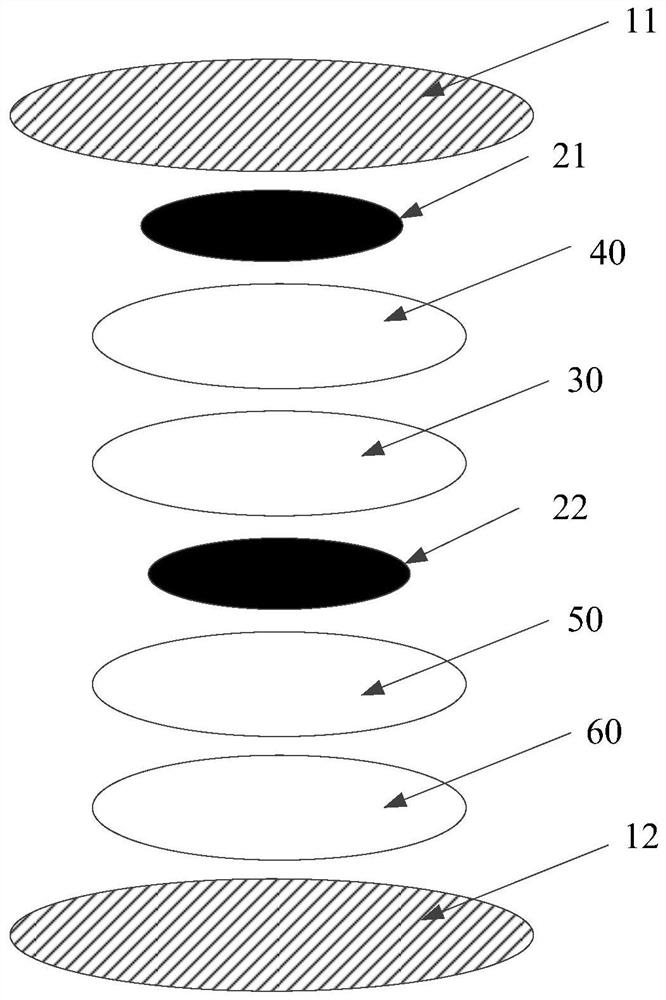

A button battery and electrode sheet technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of lithium dendrites easily formed on the negative electrode sheet, battery short circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

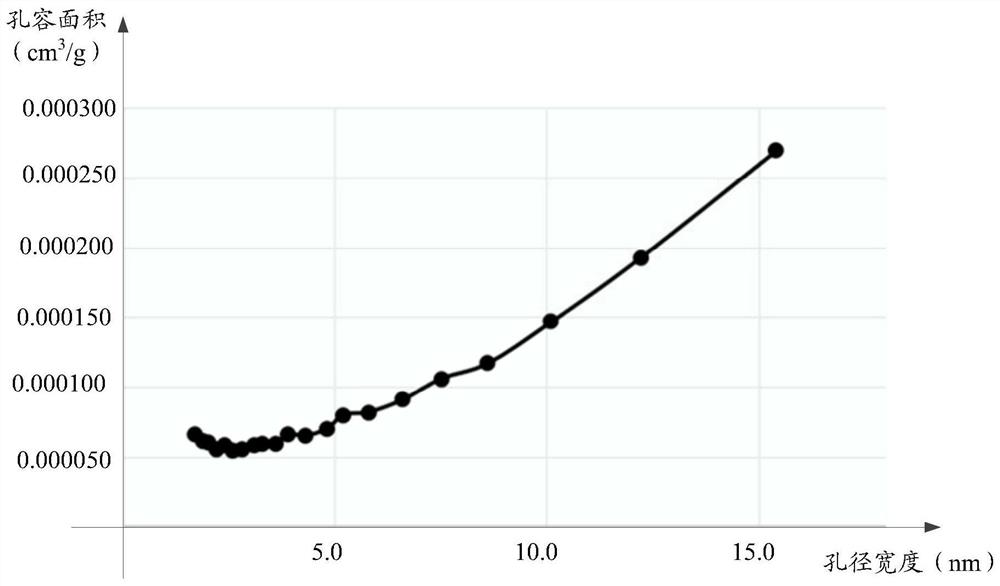

[0039] In conjunction with Table 1, it can be seen that the porosity of the negative electrode active material layer in Example 1 is 52.73%; the thickness of the negative electrode sheet configuring the negative electrode active material layer of Example 1 is 0.223mm; The pore volume of the material layer is 0.000033cm 3 / g; the aperture in embodiment 1 is that the pore volume value of the negative electrode active material layer of 15.4nm is 0.000270cm 3 / g.

[0040] The negative electrode active material layer involved in Example 1 was subjected to a 60 bar rolling test, and the ratio of the porosity of the negative active material layer after rolling to the porosity of the negative active material layer before rolling was 69.3%.

[0041] Carry out 60bar rolling test to the negative electrode active material layer that embodiment 1 relates to, the pore volume value of the negative electrode active material layer that the hole diameter after rolling is 1.7nm is the pore volu...

Embodiment 2

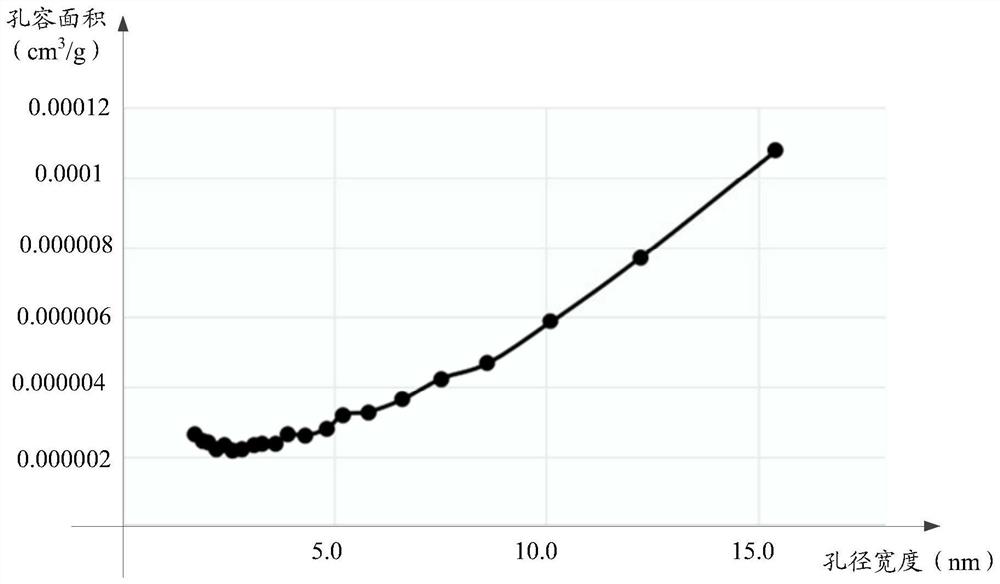

[0044] In conjunction with Table 1, it can be seen that the porosity of the negative electrode active material layer in Example 2 is 54.89%; the thickness of the negative electrode sheet configuring the negative electrode active material layer of Example 2 is 0.203mm; The pore volume of the material layer is 0.000029cm 3 / g; the aperture in embodiment 2 is that the pore volume value of the negative electrode active material layer of 15.4nm is 0.000237cm 3 / g.

[0045] The negative electrode active material layer involved in Example 2 was subjected to a 60bar rolling test, and the ratio of the porosity of the negative active material layer after rolling to the porosity of the negative active material layer before rolling was 70.61%.

[0046] Carry out 60bar rolling test to the negative electrode active material layer that embodiment 2 involves, the pore volume value of the negative electrode active material layer that the hole diameter after rolling is 1.7nm is the pore volume o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com