Ink-jet printing material and method for preparing ink-jet printing material

A technology of inkjet printing and ink-absorbing coating, applied in the direction of copying/marking method, printing, coating, etc., which can solve the problems that inkjet printing materials need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

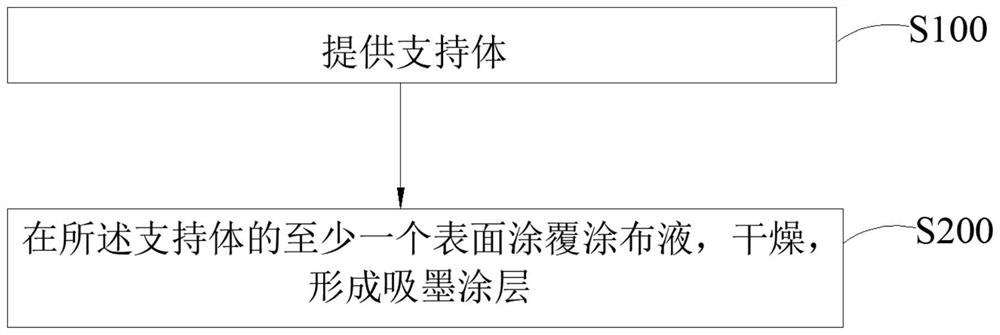

[0060] 10 grams of silicon dioxide with a diameter of 1 micron, 40 grams of polyvinyl alcohol (PVA) (polymerization degree 1700, degree of hydrolysis 99%) with a mass fraction of 10%, and a polyacrylic acid emulsion (nuclear polymer) with a mass fraction of 50% Add 4 grams of boric acid, 0.01 grams of boric acid, 5 grams of ethanol, and 40.99 grams of water into the container, disperse with high-speed stirring at 10,000 rpm for 1 hour, and ultrasonically defoam for 30 minutes , to prepare the coating solution.

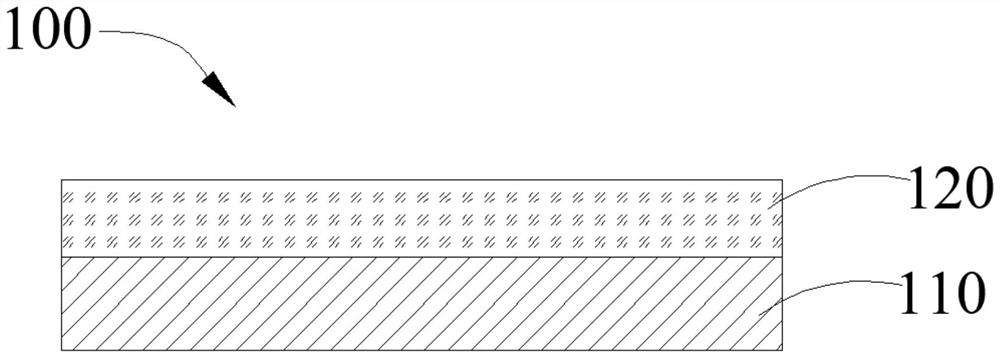

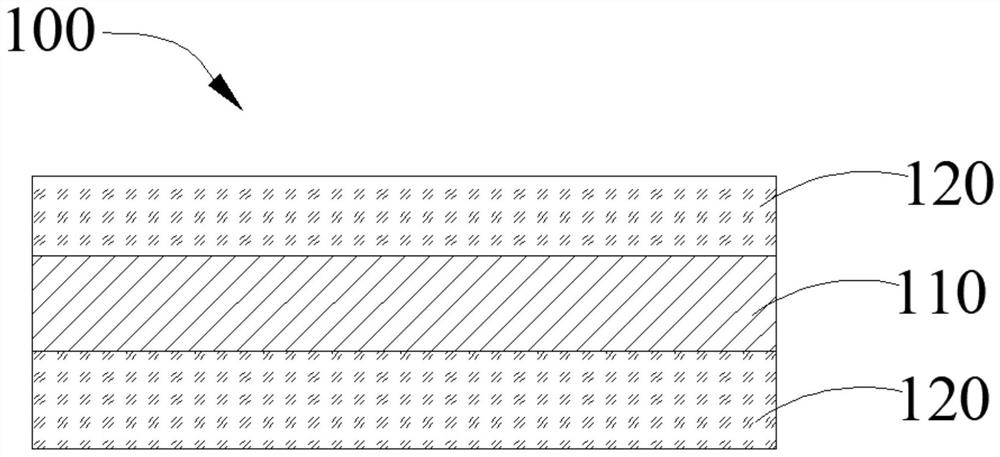

[0061] Use the RDS coating rod to coat the obtained coating solution on a plastic-coated paper base with a thickness of 210 microns, and dry it at a temperature of 50°C for 2 to 3 minutes to obtain ink-jet printing with an ink-absorbing coating thickness of 2 microns. Material.

Embodiment 2

[0063] 30 grams of aluminum oxide with a diameter of 0.14 microns, 20 grams of polyvinyl alcohol (PVA) (4000 degrees of polymerization, 99 percent degree of hydrolysis) in a mass fraction of 10 percent, and 50 percent of a polyacrylic acid emulsion (nuclear polymer and The glass transition temperatures of the shell polymers are 20°C and 150°C respectively) 4 grams, 0.1 grams of boric acid, 10 grams of N,N-dimethylformamide, and 45.9 grams of water were added to the container, and dispersed at 10,000 rpm with high-speed stirring for 1 Hours, ultrasonic defoaming for 30 minutes to prepare a coating solution.

[0064] The obtained coating solution was coated on PET with a thickness of 100 micrometers using an RDS coating rod, and dried at a temperature of 50° C. for 2 to 3 minutes to obtain an ink-jet printing material with an ink-absorbing coating thickness of 15 micrometers.

Embodiment 3

[0066] 20 grams of silicon dioxide with a diameter of 5 microns, 6 grams of gelatin with a mass fraction of 50%, and a polyacrylic acid emulsion with a mass fraction of 50% (the glass transition temperatures of the core polymer and the shell polymer are 0 ° C and 150 ° C respectively. ℃) 20 grams, 0.01 grams of aziridine, 5 grams of isopropanol, and 48.99 grams of water were added into the container, dispersed at 10,000 rpm for 1 hour with high-speed stirring, and ultrasonically defoamed for 30 minutes to prepare a coating liquid.

[0067] The coating solution was coated on PVC with a thickness of 200 micrometers using an RDS coating rod, and dried at a temperature of 50° C. for 2 to 3 minutes to obtain an ink-jet printing material with an ink-absorbing coating thickness of 10 micrometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com