Carbon fiber hard felt surface treatment method and carbon fiber hard felt

A surface treatment and carbon fiber technology, applied in the field of carbon fiber hard felt and treatment, carbon fiber hard felt, carbon fiber hard felt surface treatment, can solve the problems of affecting the service life of hard felt, easy powder loss of hard felt, and reduced corrosion resistance of hard felt. , to achieve the effect of increasing corrosion resistance, increasing flexibility and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The specific steps of the carbon fiber hard felt surface treatment method are as follows:

[0032] Step 1: Select a certain size of carbon fiber hard felt, select a predetermined proportion of graphite, glass felt, non-woven fabric, resin and polytetrafluoroethylene and mix them with adhesives to make ingredients and store the ingredients separately;

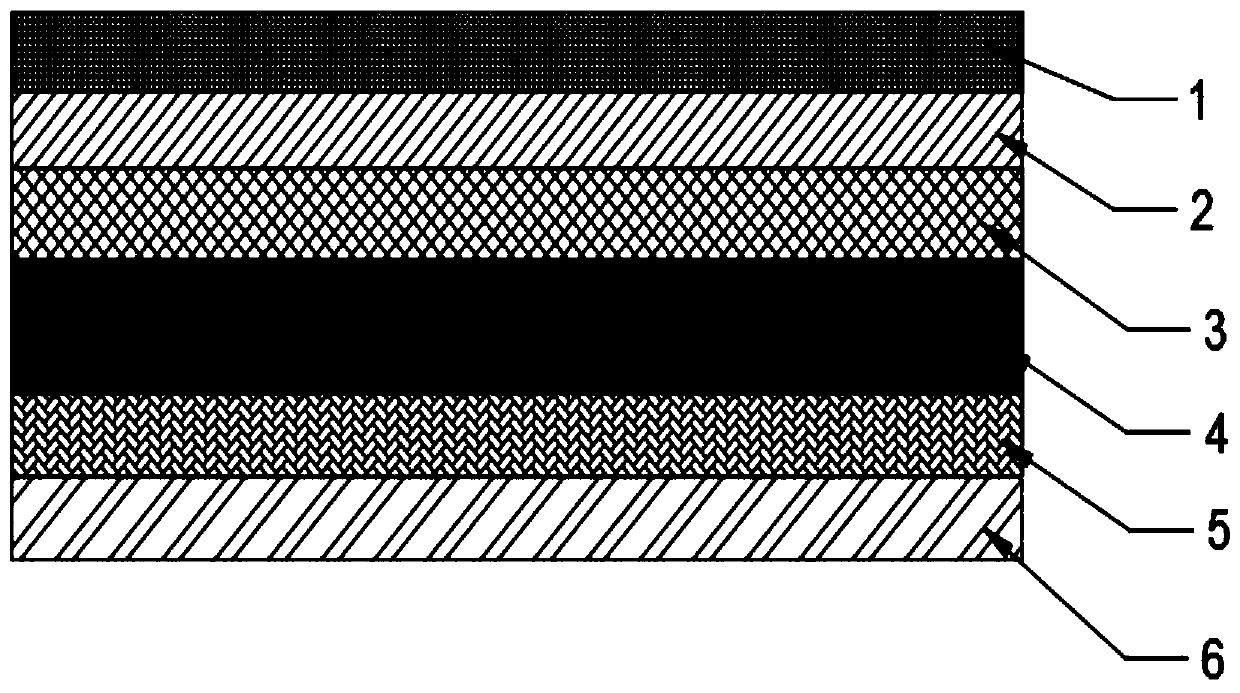

[0033] Step 2: Apply glass mat, non-woven fabric, and resin evenly on the surface of carbon fiber hard felt by machine spraying, and perform heating pretreatment in sequence. The heating temperature is 80°C, and the time is 30 minutes. The principle of laying the top first and then the bottom of the hard felt matrix 4 is sequentially layered and needle-punched to obtain a unit layer;

[0034] Step 3: Apply adhesive and dry the unit layer several times, put it into a press, and paste it at a predetermined temperature of 80°C and a pressure of 2Mpa to form a composite unit layer;

[0035] Step 4: Coating graphite on the to...

Embodiment 2

[0037] The specific steps of the carbon fiber hard felt surface treatment method are as follows:

[0038] Step 1: Select a certain size of carbon fiber hard felt, select a predetermined proportion of graphite, glass felt, non-woven fabric, resin and polytetrafluoroethylene and mix them with adhesives to make ingredients and store the ingredients separately;

[0039] Step 2: Apply glass mat, non-woven fabric, and resin evenly on the surface of carbon fiber hard felt by machine spraying, and perform heating pretreatment in sequence. The heating temperature is 150°C, and the time is 40 minutes. The principle of laying the top first and then the bottom of the hard felt matrix 4 is sequentially layered and needle-punched to obtain a unit layer;

[0040] Step 3: apply adhesive and dry the unit layer several times, put it into a press, and paste it at a predetermined temperature of 80-130°C and a pressure of 3Mpa to form a composite unit layer;

[0041] Step 4: Coat graphite on the ...

Embodiment 3

[0043] The specific steps of the carbon fiber hard felt surface treatment method are as follows:

[0044] Step 1: Select a certain size of carbon fiber hard felt, select a predetermined proportion of graphite, glass felt, non-woven fabric, resin and polytetrafluoroethylene and mix them with adhesives to make ingredients and store the ingredients separately;

[0045] Step 2: Apply glass mat, non-woven fabric, and resin evenly on the surface of carbon fiber hard felt by machine spraying, and perform heating pretreatment in sequence. The heating temperature is 230°C, and the time is 45 minutes. The principle of laying the top first and then the bottom of the hard felt matrix 4 is sequentially layered and needle-punched to obtain a unit layer;

[0046] Step 3: apply adhesive and dry the unit layer several times, put it into a press, and paste it at a predetermined temperature of 80-130°C and a pressure of 4.55Mpa to form a composite unit layer;

[0047]Step 4: Coat graphite on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com