Hydrophobic coating liquid, and preparation method, coating method and application thereof

A technology of hydrophobic coating and coating method, applied in the direction of coating, etc., can solve the problems of not prolonging the anti-adhesion effect of products with viscosity, and achieve the effects of prolonging the non-stick failure time, avoiding adhesion, and avoiding volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

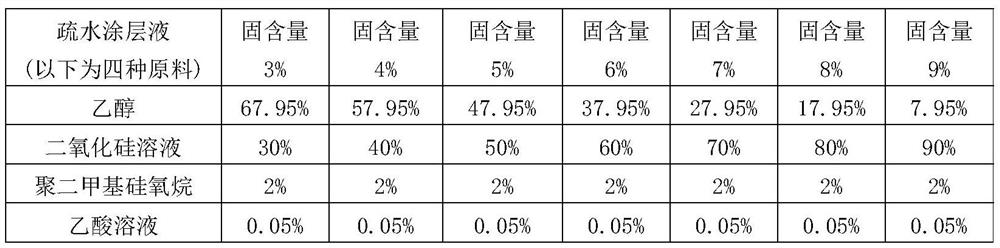

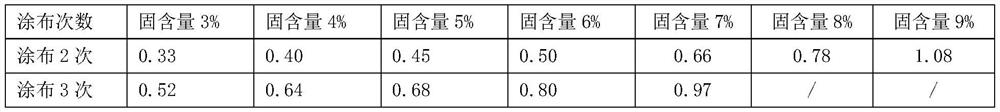

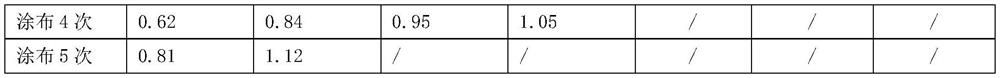

[0041] A kind of hydrophobic coating liquid, its raw material composition is as shown in table 1.

[0042] Table 1

[0043]

[0044] The silicon dioxide solution in the above table 1 is a mixed solution made by mixing 10wt% silicon dioxide and 90wt% ethanol, and the solid content of the silicon dioxide solution is 10%, that is, silicon dioxide is mixed with silicon dioxide. The content in the solution is 10%, and the particle size of the silicon dioxide is between 500nm and 2000nm. The ethanol in Table 1 and the ethanol in the silica solution are absolute ethanol with a concentration of 99.9%; the mass concentration of the acetic acid solution is 2%, and the solvent in the acetic acid solution is distilled water. That is, in this embodiment, the solid particle is silicon dioxide, the hydrophobic silane is polydimethylsiloxane, and the pH regulator is acetic acid.

[0045] Taking the hydrophobic coating solution with a solid content of 3% as an example, the ethanol with a ...

Embodiment 2

[0081] The difference between this example and Example 1 is that in this example, raw materials with different proportions are used for preparation, as shown in Table 3 below:

[0082] table 3

[0083] raw material Solid content 4% Solid content 4% Solid content 4% ethanol 58.92% 58.44% 57.92% Silica solution 40% 40% 40% Polydimethylsiloxane 1% 1.5% 2% Acetic acid solution 0.08% 0.06% 0.08%

[0084] The three kinds of hydrophobic coating liquids with a solid content of 4% in the above table 3 are a kind of non-stick film obtained by coating three times respectively. The test results of the non-stick effect of the three kinds of non-stick film are the same, and the effect is as follows: The area is 10%, the contact angle is 150°, and the rolling angle is 5°; after standing still for 3 months, the non-stick effect has not failed; there is no powder falling (coating solid falling off) phenomenon.

Embodiment 3

[0086] The difference between this embodiment and Example 1 is that different types of raw materials of the hydrophobic coating liquid are used for preparation in this embodiment, as shown in Table 4 below:

[0087] Table 4

[0088]

[0089] The solid content of the corresponding solid particles in the above-mentioned solid particle solution is 10%. The solvent used in the solid particle solution is the same as the solvent type recorded in the corresponding numbering. The solvent of the pH regulator is distilled water. The above-mentioned solid particles in the hydrophobic coating liquid The solid content is 5%.

[0090] The above-mentioned hydrophobic coating liquid is a kind of non-stick cover film obtained by applying the same coating method in Example 1 for 3 times, and its non-stick effect is good, specifically:

[0091]The contact angle of No. 1 is 150°, the rolling angle is 3°, and the milk-stained area is 10%; after standing still for 3 months, the non-stick effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com