Gradient potential distribution composite electrode, preparation method thereof and power battery

A composite electrode and potential distribution technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as increasing environmental protection requirements, uneven stress distribution, and porosity defects in the second active layer, and improve production. Efficiency and yield, improving uniformity and consistency, avoiding residual porosity defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

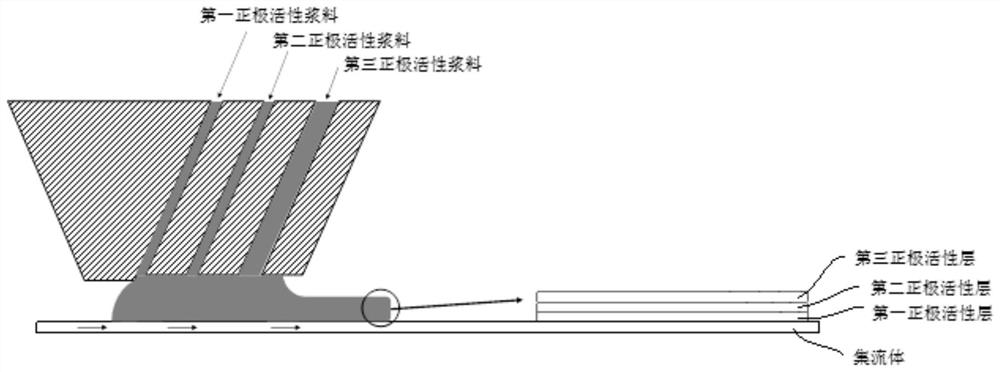

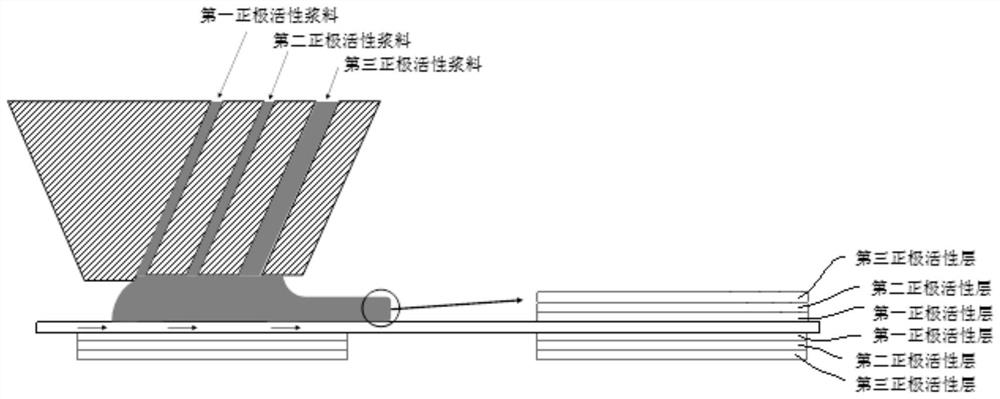

[0035] A preparation method of a composite electrode with gradient potential distribution, comprising the following steps:

[0036] Using a multi-layer co-extrusion coating method, a variety of electrode active slurries are simultaneously coated on the collector side to form a multi-layer electrode active layer, and the electrode active slurries are positive electrode active slurries, In the direction of the fluid, the potential gradient of the multi-layer electrode active layer decreases gradually, or the electrode active slurry is a negative electrode active slurry, and the potential gradient of the multi-layer electrode active layer increases gradually along the direction away from the current collector;

[0037] Using the multi-layer co-extrusion coating method, a variety of electrode active slurries are simultaneously coated on the other side of the current collector to form a multi-layer electrode active layer', with the current collector as the axis, two sides The elect...

Embodiment 1

[0078] This embodiment provides a composite positive electrode with gradient potential distribution and a preparation method thereof, the steps are as follows:

[0079] 1) Preparation of the first positive electrode active slurry

[0080] In terms of parts by mass, mix 96 parts of lithium-rich manganese-based solid solution materials, 2 parts of PVDF, 1 part of SP, 1 part of CNT and 43 parts of NMP (note: a total of 143 parts, of which 100 parts are solid materials, and the remaining 43 parts are liquid The solvent will be baked clean), and the first positive electrode active slurry is prepared, the viscosity at 25° C. is 7000-8000 mPa.s, and the solid content is 70%.

[0081] 2) Preparation of the second positive electrode active slurry

[0082] In terms of parts by mass, 96.5 parts of NCM, 1.5 parts of PVDF, 1 part of SP, 1 part of CNT and 41 parts of NMP were mixed to prepare the second positive electrode active slurry. The viscosity at 25°C was 8000-8500mPa.s, and the sol...

Embodiment 2

[0089] This embodiment provides a composite positive electrode with gradient potential distribution and a preparation method thereof, the steps are as follows:

[0090] 1) Preparation of the first positive electrode active slurry

[0091] In parts by mass, 97 parts of NCM, 1 part of PVDF, 1 part of SP, 1 part of CNT and 46 parts of NMP were mixed to prepare the first positive electrode active slurry. The viscosity at 25°C was 7500-8000mPa.s, and the solid content was 68.5%.

[0092] 2) Preparation of the second positive electrode active slurry

[0093] In parts by mass, 95 parts of LFP, 2.5 parts of PVDF, 1.5 parts of SP, 1 part of CNT and 125 parts of NMP were mixed to prepare the second positive electrode active slurry. The viscosity at 25°C was 8900-9200mPa.s, and the solid content was 44.4%.

[0094] 3) Preparation of composite positive electrode

[0095] Add the first positive electrode active slurry and the second positive electrode active slurry into the coating head ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com