Device for manufacturing opening on ink powder/selenium cartrige for refilling and refilling method

A technology for refilling and toner, applied in the field of devices with openings, which can solve the problems of reduced capacity, falling in, and inability to accurately make openings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

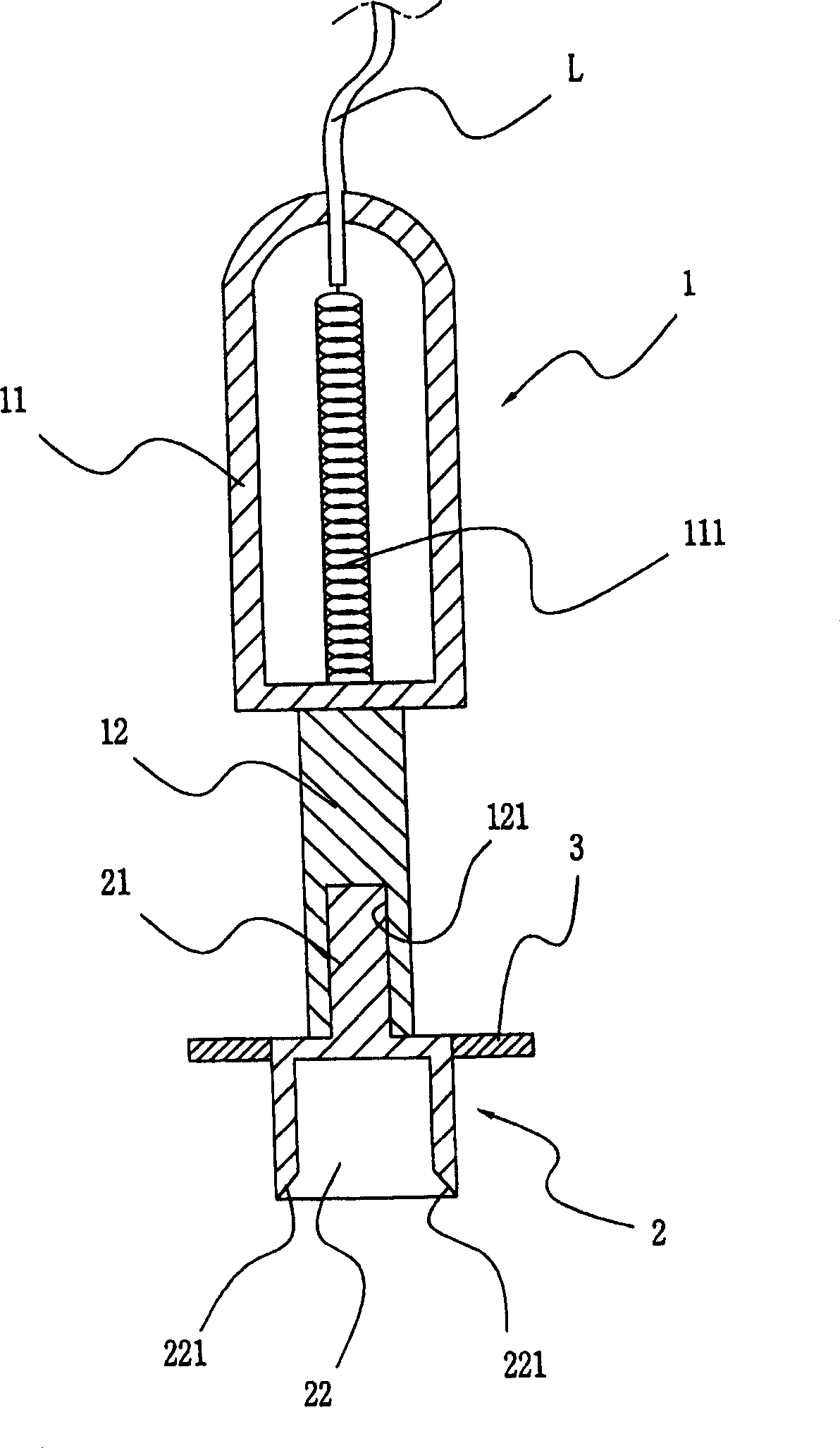

[0024] The invention will now be described more fully hereinafter with reference to the accompanying drawings showing preferred embodiments of the invention.

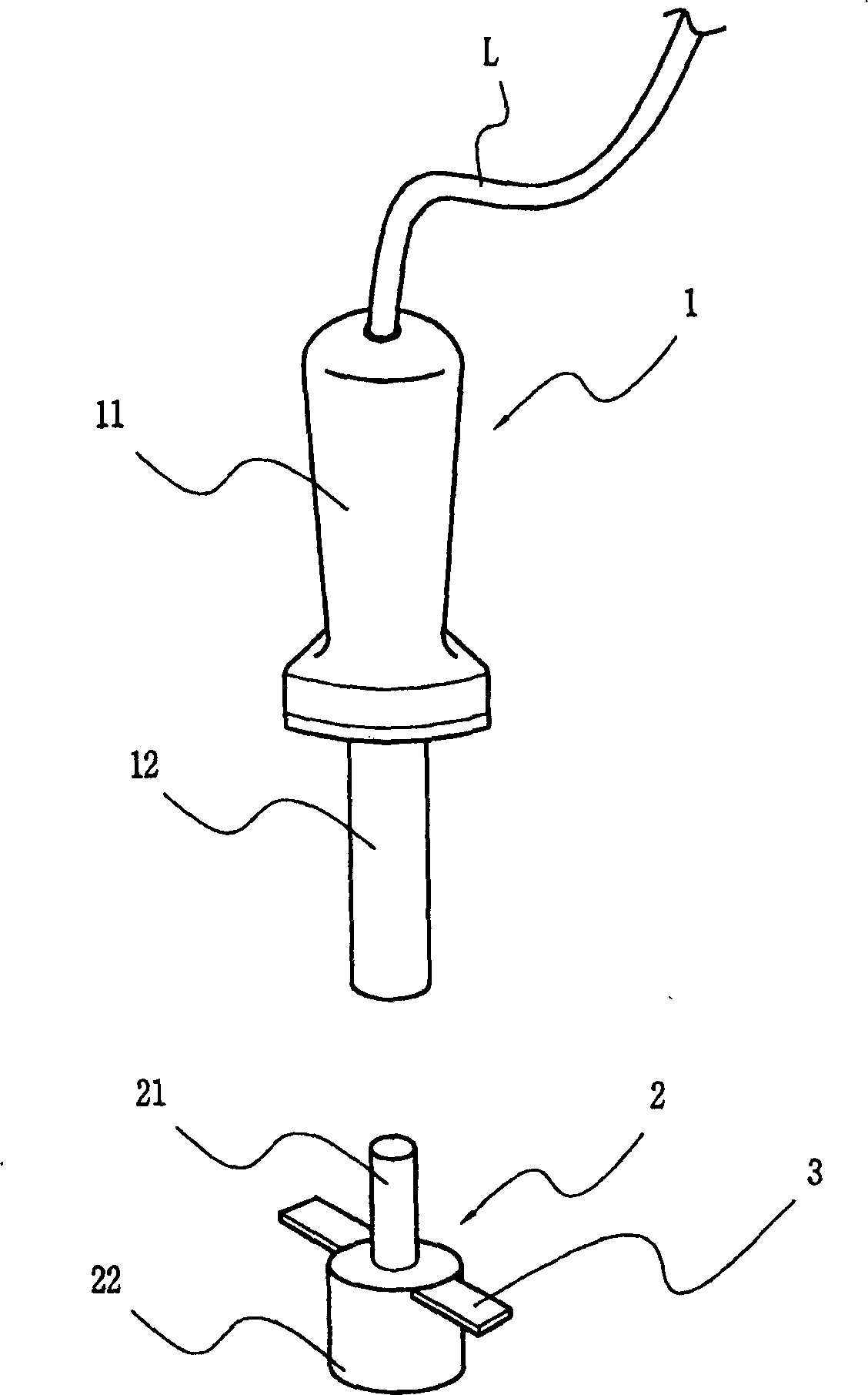

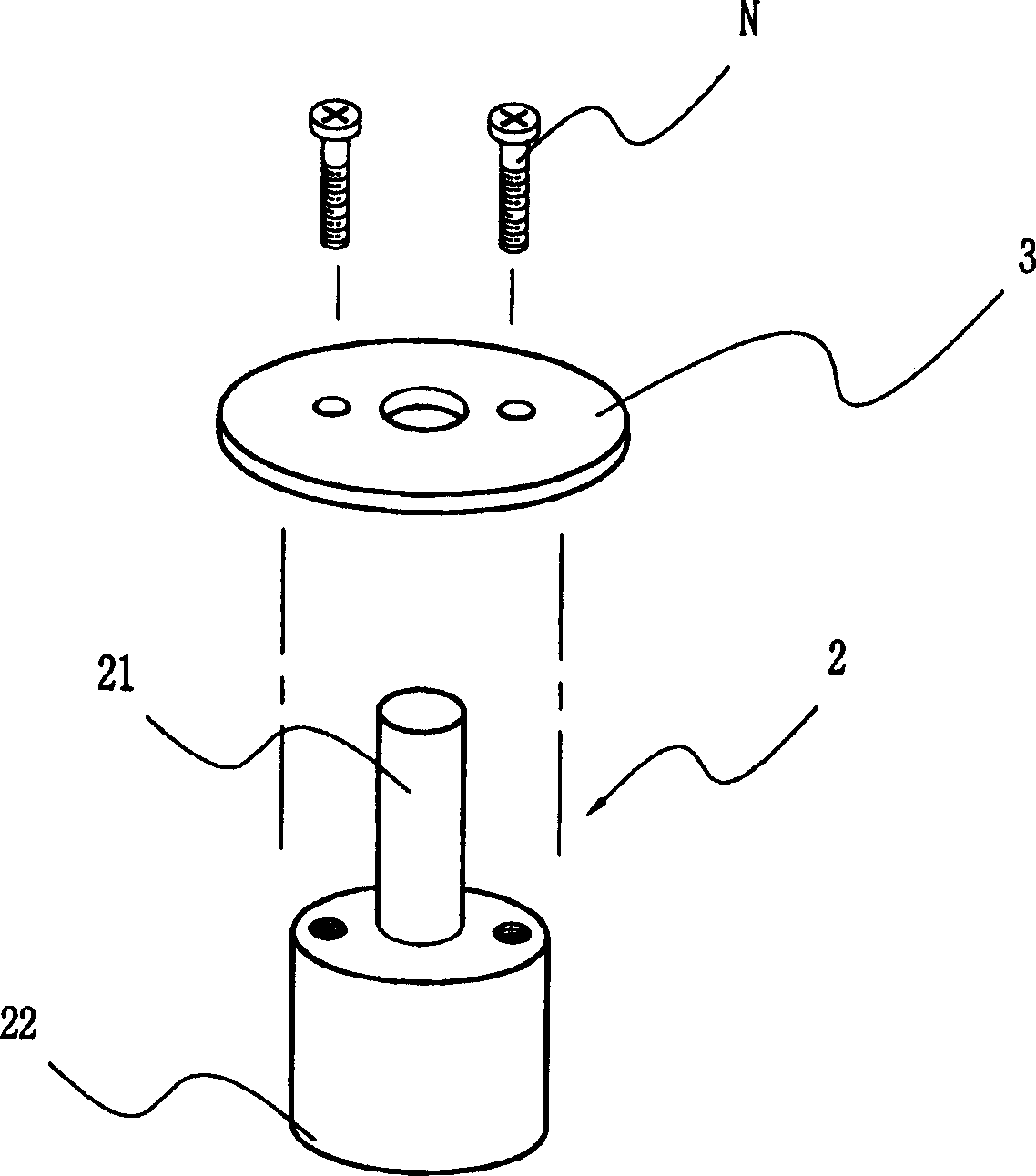

[0025] figure 1 showing the disassembled device used to make the refill opening on the surface of the toner / drum cartridge, figure 2 shows the device for making openings according to the invention assembled, image 3 The device is shown in use according to the invention.

[0026] The device according to the invention has a heating body 1 , a heat treatment element 2 and a stop 3 .

[0027] The heating body 1 is a heat generating device utilizing electric resistance. Such as Figure 1-2 As shown, the heating body 1 includes a rod-shaped handle 11 which has a cavity, a heating coil 111 arranged in the cavity, and a heating element 12 protruding from one end of the heating body 1 . One end of the heating coil 111 is connected to the electric wire L, and the other end is connected to the heating member 12 which is rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com