A kind of lithium ion battery graphite negative electrode material and preparation method thereof

A lithium-ion battery and graphite negative electrode technology, applied in battery electrodes, graphite, negative electrodes, etc., can solve the problems of poor cycle performance and low-temperature performance, and achieve high charge-discharge efficiency, good low-temperature performance, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

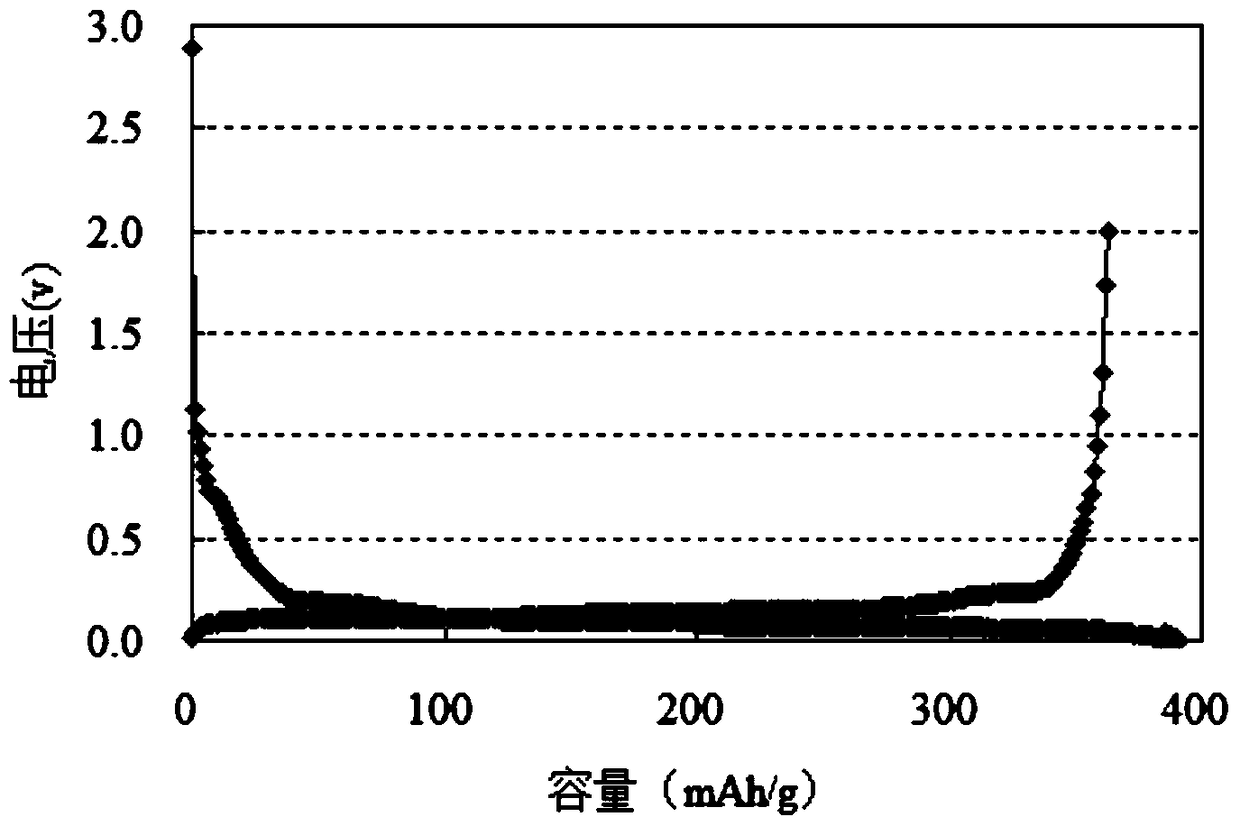

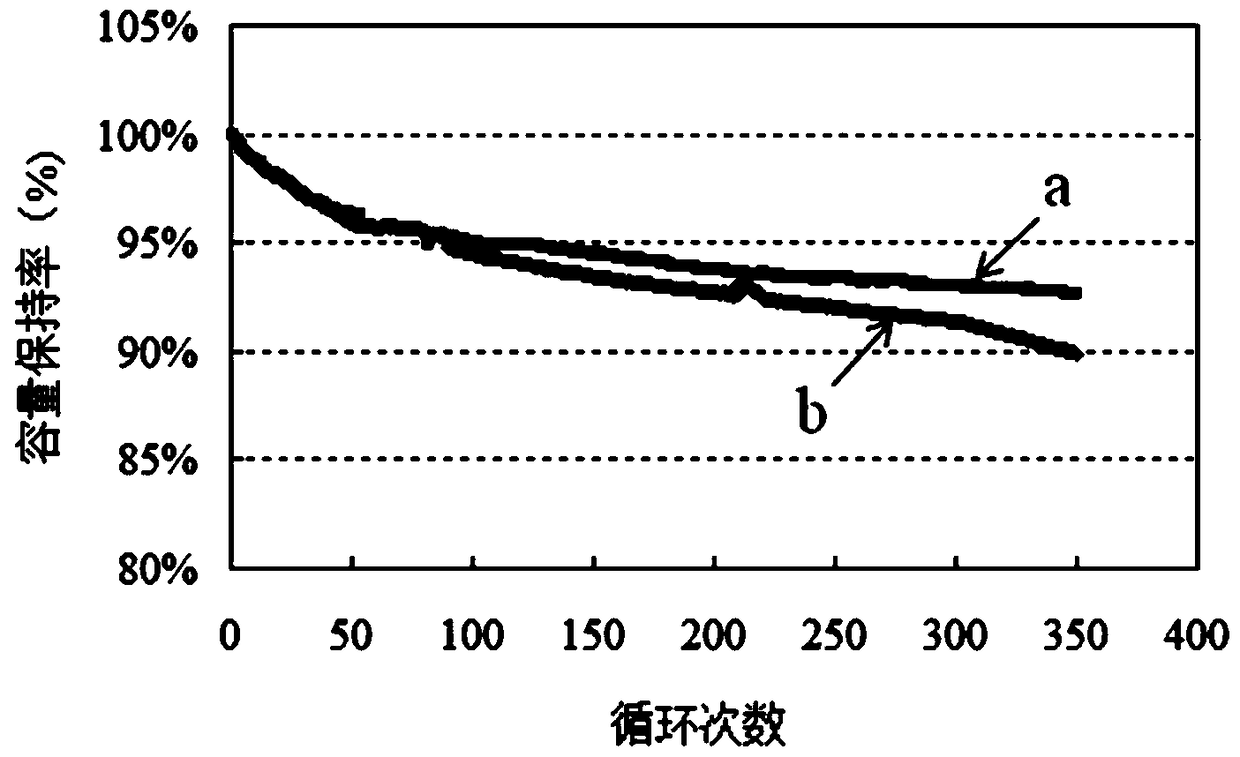

Image

Examples

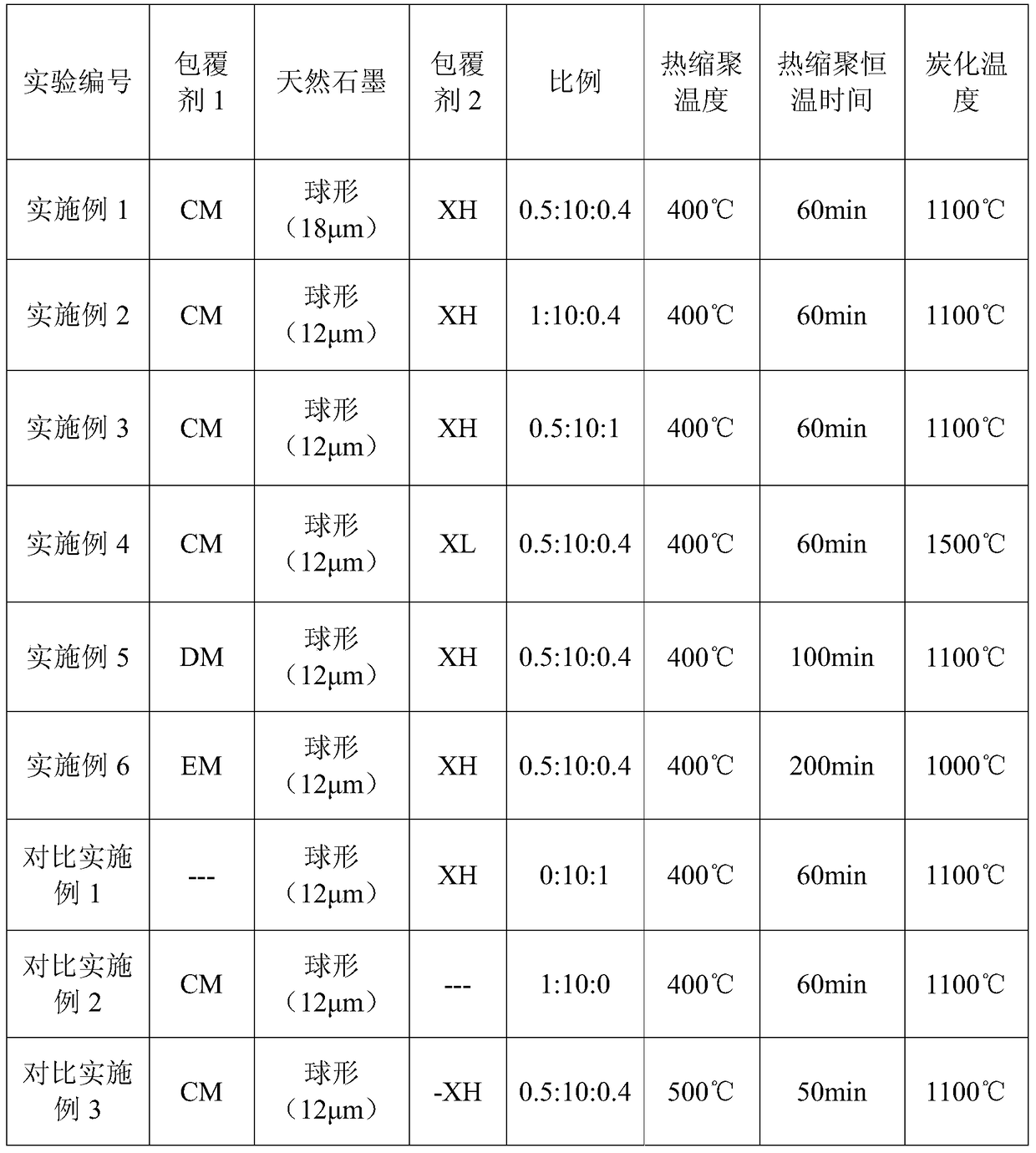

Embodiment 1

[0043] The preparation method of the present embodiment comprises the following steps:

[0044] (1) In an inert gas, fully mix the coating agent 1 phenolic resin and natural graphite at a mass ratio of 0.5:10, then add it to the coating ax and stir, then heat up to 350 °C at 1.5 °C / min, and keep the temperature for 120 min. Carbonization to obtain coatings;

[0045] (2) Add the coating agent 2 petroleum asphalt powder to the coated ax in step (1), and fully stir and mix according to the mass ratio of petroleum asphalt powder and natural graphite at a ratio of 0.4:10, and then press 3.5°C / min The heating rate is raised to 400°C, and the thermal polycondensation reaction is carried out at a constant temperature of 400°C, and finally the temperature is raised to 580°C for 60 minutes to obtain a complex; the polymerization pressure of the thermal polycondensation reaction is 10MPa, and the reaction time of the thermal polycondensation reaction 60min;

[0046] (3) In an inert gas, ...

Embodiment 2

[0048] The preparation method of the present embodiment comprises the following steps:

[0049] (1) In an inert gas, fully mix the coating agent 1 phenolic resin and natural graphite at a mass ratio of 1:10, then add it to the coating ax and stir, then raise the temperature to 350 °C at 1.5 °C / min, and keep the temperature constant for 120 min. Carbonization to obtain coatings;

[0050] (2) Add the coating agent 2 petroleum asphalt powder to the coated ax in step (1), and fully stir and mix according to the mass ratio of petroleum asphalt powder and natural graphite at a ratio of 0.4:10, and then press 3.5°C / min The heating rate is raised to 400°C, and the thermal polycondensation reaction is carried out at a constant temperature of 400°C, and finally the temperature is raised to 580°C for 60 minutes to obtain a complex; the polymerization pressure of the thermal polycondensation reaction is 10MPa, and the reaction time of the thermal polycondensation reaction 60min;

[0051...

Embodiment 3

[0053] The preparation method of the present embodiment comprises the following steps:

[0054] (1) In an inert gas, fully mix the coating agent 1 phenolic resin and natural graphite at a mass ratio of 0.5:10, then add it to the coating ax and stir, then heat up to 350 °C at 1.5 °C / min, and keep the temperature for 120 min. Carbonization to obtain coatings;

[0055] (2) Add the coating agent 2 petroleum asphalt powder to the coated ax in step (1), and fully stir and mix according to the mass ratio of petroleum asphalt powder and natural graphite as 1:10, and then press 3.5°C / min The heating rate is raised to 400°C, and the thermal polycondensation reaction is carried out at a constant temperature of 400°C, and finally the temperature is raised to 580°C for 60 minutes to obtain a complex; the polymerization pressure of the thermal polycondensation reaction is 10MPa, and the reaction time of the thermal polycondensation reaction 60min;

[0056] (3) In an inert gas, carbonize t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com