Graphite negative electrode material of lithium-ion battery and preparation method of graphite negative electrode material

A lithium-ion battery and graphite negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cycle performance and low primary charge capacity, and achieve good cycle performance, excellent cycle performance, and increased cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

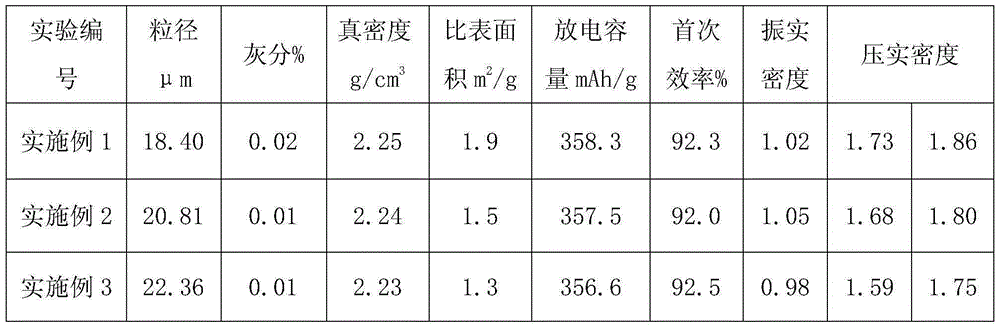

Embodiment 1

[0026] The preparation method of the present embodiment comprises the following steps:

[0027] (1) Mix an artificial graphite raw material with a certain amount of binder and catalyst SiC (content ≥ 92%) at a ratio of 100:6:5. When mixing, it is required to feed materials in a certain order according to the specific gravity of the material , Mixing time 30 ~ 60min.

[0028] (2) In an inert gas, put the material mixed in step (1) into a low-temperature surface modification reaction kettle, and stir while heating up. The frequency of stirring should make the material even, generally controlled at 28-40r / min , The heating time is 180-240min, the temperature is raised to 500-650°C, and the temperature is kept constant for 180-260min to obtain the clad body.

[0029] (3) The clad body in step (2) is subjected to graphitization treatment at 2000-2800° C. for 50-70 hours.

[0030] (4) Put the graphitized coated body and a certain amount of binder in the step (3) into the fusion eq...

Embodiment 2

[0033] The preparation method of the present embodiment comprises the following steps:

[0034] (1) Mix an artificial graphite raw material with a certain amount of binder and catalyst SiC (content ≥ 92%) at a ratio of 100:10:5. When mixing, it is required to feed materials in a certain order according to the specific gravity of the material , Mixing time 30 ~ 60min.

[0035] (2) In an inert gas, put the material mixed in step (1) into a low-temperature surface modification reaction kettle, and stir while heating up. The frequency of stirring should make the material even, generally controlled at 28-40r / min , The heating time is 180-240min, the temperature is raised to 500-650°C, and the temperature is kept constant for 180-260min to obtain the clad body.

[0036] (3) The clad body in step (2) is subjected to graphitization treatment at 2000-2800° C. for 50-70 hours.

[0037] (4) Put the graphitized coated body and a certain amount of binder in the step (3) into the fusion e...

Embodiment 3

[0040] The preparation method of the present embodiment comprises the following steps:

[0041] (1) Mix an artificial graphite raw material with a certain amount of binder and catalyst SiC (content ≥ 92%) at a ratio of 100:12:5. When mixing, it is required to feed materials in a certain order according to the specific gravity of the material , Mixing time 30 ~ 60min.

[0042] (2) In an inert gas, put the material mixed in step (1) into a low-temperature surface modification reaction kettle, and stir while heating up. The frequency of stirring should make the material even, generally controlled at 28-40r / min , The heating time is 180-240min, the temperature is raised to 500-650°C, and the temperature is kept constant for 180-260min to obtain the clad body.

[0043] (3) The clad body in step (2) is subjected to graphitization treatment at 2000-2800° C. for 50-70 hours.

[0044] (4) Put the graphitized coated body and a certain amount of binder in the step (3) into the fusion e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com