A kind of lithium-ion battery negative electrode sheet and manufacturing method thereof

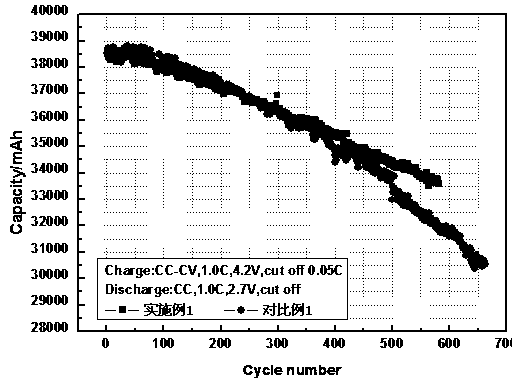

A lithium ion battery and a manufacturing method technology, applied in the field of lithium ion battery negative electrode sheet and its manufacturing, can solve problems such as poor battery cycle performance, achieve high rate performance, good compatibility, and improve cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for making a negative electrode sheet of a lithium ion battery, the method comprising the following steps: a) Preparation of a negative electrode slurry: dissolving 20 g of sodium carboxymethylcellulose CMC in 1230 g of deionized water, stirring and dispersing for 5 hours to obtain a solid CMC glue with a content of about 1.6%, then add 10g VGCF and 10g SP into the CMC glue for 1 hour of stirring and dispersion, then add 935g of natural graphite in 2 times on average, and the interval between adding negative electrode materials is 0.5h , after high-speed stirring for 3 hours, then add 25g of styrene-butadiene rubber SBR emulsion with a solid content of 50%, and evenly stir for 2 hours to detect that the viscosity of the slurry is 2600cps, and the solid content of the slurry is 36% at this time;

[0030] b) Uniformly coat the prepared negative electrode slurry on the negative electrode current collector copper foil with a thickness of 10 μm, and the coating surfa...

Embodiment 2

[0036] A method for making a negative electrode sheet of a lithium ion battery, the method comprising the following steps: a) Preparation of a negative electrode slurry: dissolving 10 g of sodium carboxymethylcellulose CMC in 545.55 g of deionized water, stirring and dispersing for 4 hours to obtain CMC glue with a solid content of about 1.8%, then add 2.5g of conductive graphite and 2.5g of SP into the CMC glue for 1.5h of stirring and dispersion, and then add 960g of natural graphite in 4 times on average, each time the negative electrode material is added The interval time is 0.5h. After stirring at high speed for 5.5h, add 15g of styrene-butadiene rubber SBR emulsion with a solid content of 50%, and stir evenly for 3 hours. After stirring for 3 hours, the viscosity of the slurry is detected to be 5600cps, and the solid content of the slurry is 46% at this time;

[0037] b) Uniformly coat the prepared negative electrode slurry on the negative electrode current collector copp...

Embodiment 3

[0043] A method for manufacturing a negative electrode sheet of a lithium ion battery, the manufacturing method comprising the following steps: a) Preparation of negative electrode slurry: dissolving 25g of carboxymethylcellulose sodium CMC in 1641.67g of deionized water, stirring and dispersing for 5 hours to obtain CMC glue with a solid content of about 1.5%, then add 60g of superconducting carbon into the CMC glue for 2 hours of stirring and dispersion, then add 880g of natural graphite in 3 times on average, and the interval between each addition of negative electrode material is 0.5h , after high-speed stirring for 6 hours, then add 35g of styrene-butadiene rubber SBR emulsion with a solid content of 50%, and evenly stir for 4 hours to detect that the viscosity of the slurry is 8000cps, and the solid content of the slurry is 36% at this time;

[0044] b) Uniformly coat the prepared negative electrode slurry on the negative electrode current collector copper foil with a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com