Modified natural graphite and preparation method thereof

A natural graphite, modified technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of unstable structure, uneven coating, poor cycle performance, etc., to achieve high retention rate and good adaptability , the effect of large discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

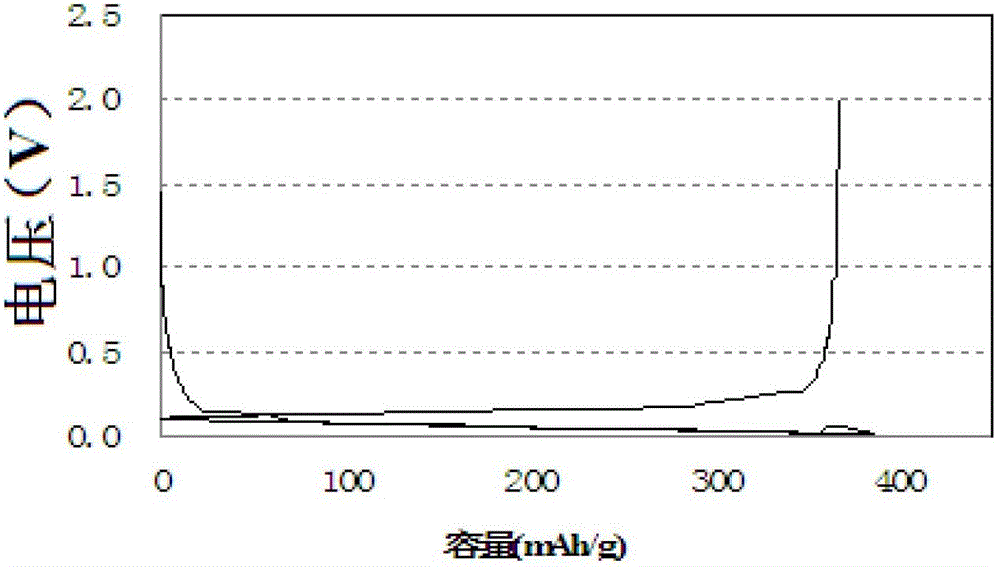

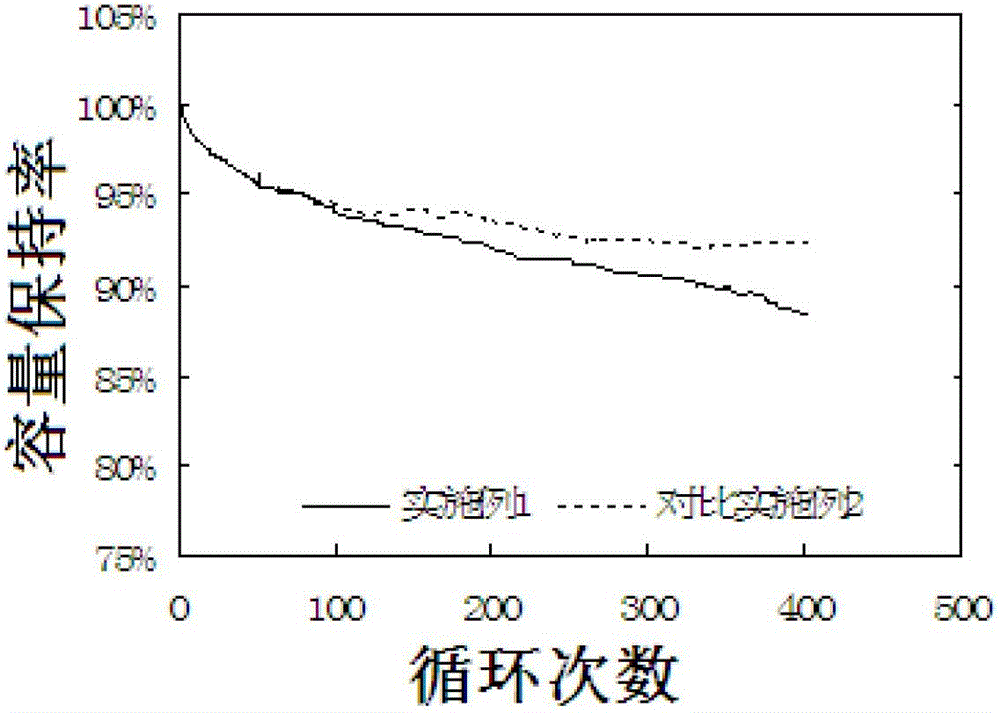

Image

Examples

Embodiment 1~8

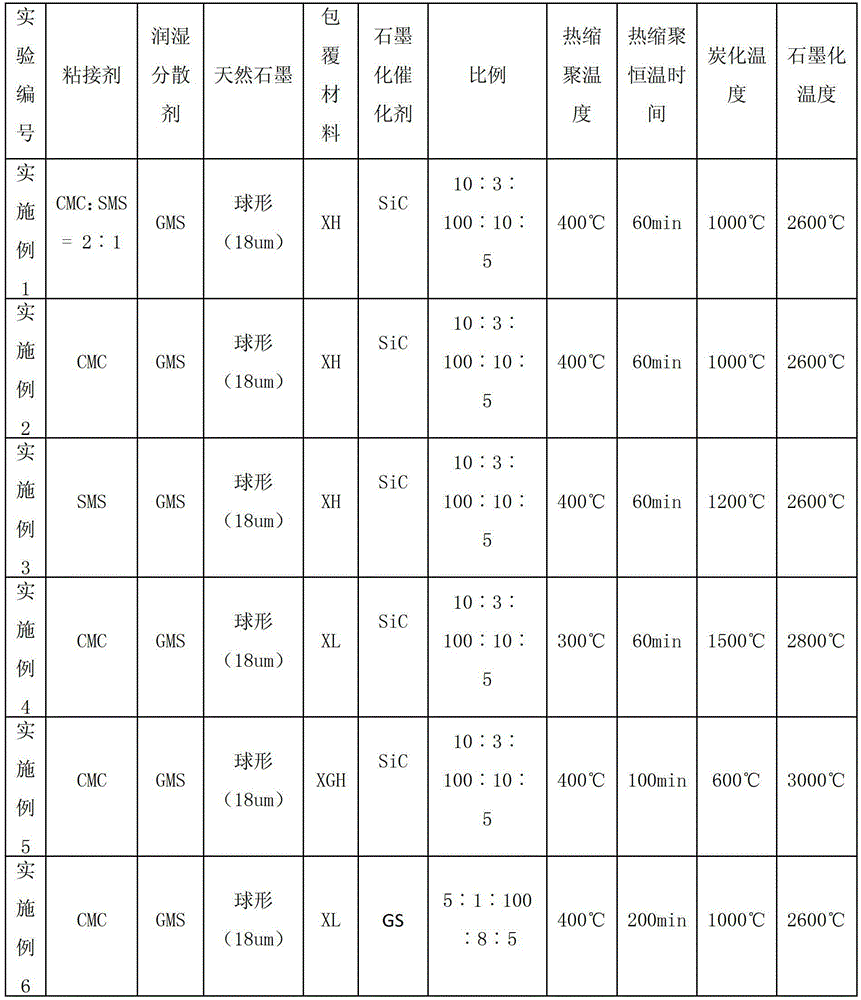

[0043] Examples 1 to 8, Comparative Examples 1 to 2

[0044] As shown in Table 1, CMC is sodium carboxymethyl cellulose, coal pitch is XH, petroleum pitch is XL, GMS is stearic acid monoglyceride, SMS is silane coupling agent, phenolic resin is XGH, and silicon carbide is SiC, carbonized boron is GS.

[0045] Table 1

[0046]

[0047]

[0048] In Table 1, the ratio refers to the weight ratio of the binder, wetting and dispersing agent, natural graphite, coating material and graphitization catalyst.

[0049] The preparation method is as follows:

[0050] Wherein, the preparation steps of Example 1 include:

[0051] (1) Add the adhesive and the wetting and dispersing agent to deionized water, mix them thoroughly, and make a mixed solution with a mass concentration of 30%;

[0052] (2) Add natural graphite to the mixed solution prepared in step (1), mix thoroughly and dry until the water content of natural graphite is less than 200 ppm; the D50 value of the natural graphite is measured to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com