Composite graphite negative electrode material for lithium ion batteries and preparation method thereof

A lithium-ion battery, composite graphite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low cycle performance and one-time charge capacity, high electrolyte requirements, and poor liquid absorption on the surface of natural graphite, achieving excellent Charge rate performance and cycle performance, simple processing and preparation method, high discharge platform and high platform retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

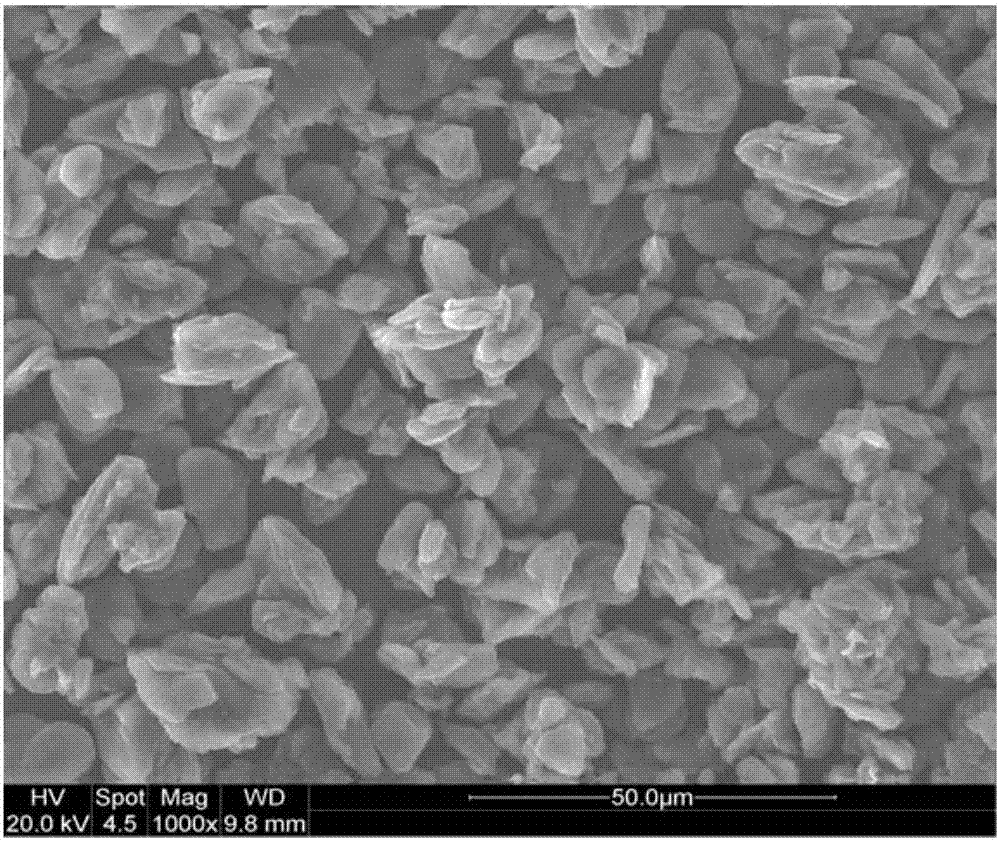

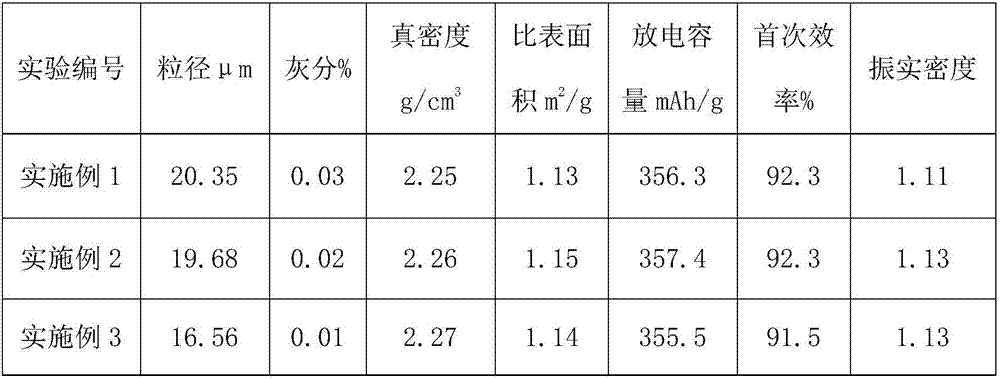

[0023] A lithium-ion battery composite graphite negative electrode material, consisting of the following raw materials in parts by mass: 100 parts of artificial graphite raw materials, 55 parts of natural graphite raw materials, and 5 parts of binder; the artificial graphite raw materials are calcined petroleum coke, with an average particle diameter of D50 The natural graphite raw material is 7-10 μm; the natural graphite raw material is a graphite material with a relatively regular shape after shaping treatment, and the average particle diameter D50 is 6-9 μm; the binder is high-temperature modified pitch.

[0024] The preparation method of described lithium-ion battery composite graphite negative electrode material comprises the following steps:

[0025] (1) Mix the artificial graphite raw material with the natural graphite raw material and the binder in a mass ratio of 100:55:5 to make it evenly mixed, and the mixing time is 45-60 minutes;

[0026] (2) In an inert gas, put...

Embodiment 2

[0032] A lithium-ion battery composite graphite negative electrode material, consisting of the following raw materials in parts by mass: 100 parts of artificial graphite raw materials, 60 parts of natural graphite raw materials, and 5 parts of binder; the artificial graphite raw materials are calcined petroleum coke, with an average particle diameter of D50 The natural graphite raw material is 7-10 μm; the natural graphite raw material is a graphite material with a relatively regular shape after shaping treatment, and the average particle diameter D50 is 6-9 μm; the binder is high-temperature modified pitch.

[0033] The preparation method of described lithium-ion battery composite graphite negative electrode material comprises the following steps:

[0034] (1) Mix the artificial graphite raw material with the natural graphite raw material and the binder in a mass ratio of 100:60:5 to make it evenly mixed, and the mixing time is 45-60 minutes;

[0035] (2) In an inert gas, put...

Embodiment 3

[0040]A lithium-ion battery composite graphite negative electrode material, consisting of the following raw materials in parts by mass: 100 parts of artificial graphite raw materials, 65 parts of natural graphite raw materials, and 5 parts of binder; the artificial graphite raw materials are calcined petroleum coke, with an average particle diameter of D50 The natural graphite raw material is 7-10 μm; the natural graphite raw material is a graphite material with a relatively regular shape after shaping treatment, and the average particle diameter D50 is 6-9 μm; the binder is high-temperature modified pitch.

[0041] The preparation method of described lithium-ion battery composite graphite negative electrode material comprises the following steps:

[0042] (1) Mix the artificial graphite raw material with the natural graphite raw material and the binder according to the mass ratio of 100:65:5 to make it evenly mixed, and the mixing time is 45-60 minutes;

[0043] (2) In an ine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com