Nanometer metal or alloy composite material and preparation and usage thereof

A composite material and electrode technology, used in electrode manufacturing, battery electrodes, alkaline battery electrodes, etc., to achieve the effects of high ionic conductivity, suppression of damage, and high lithium storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

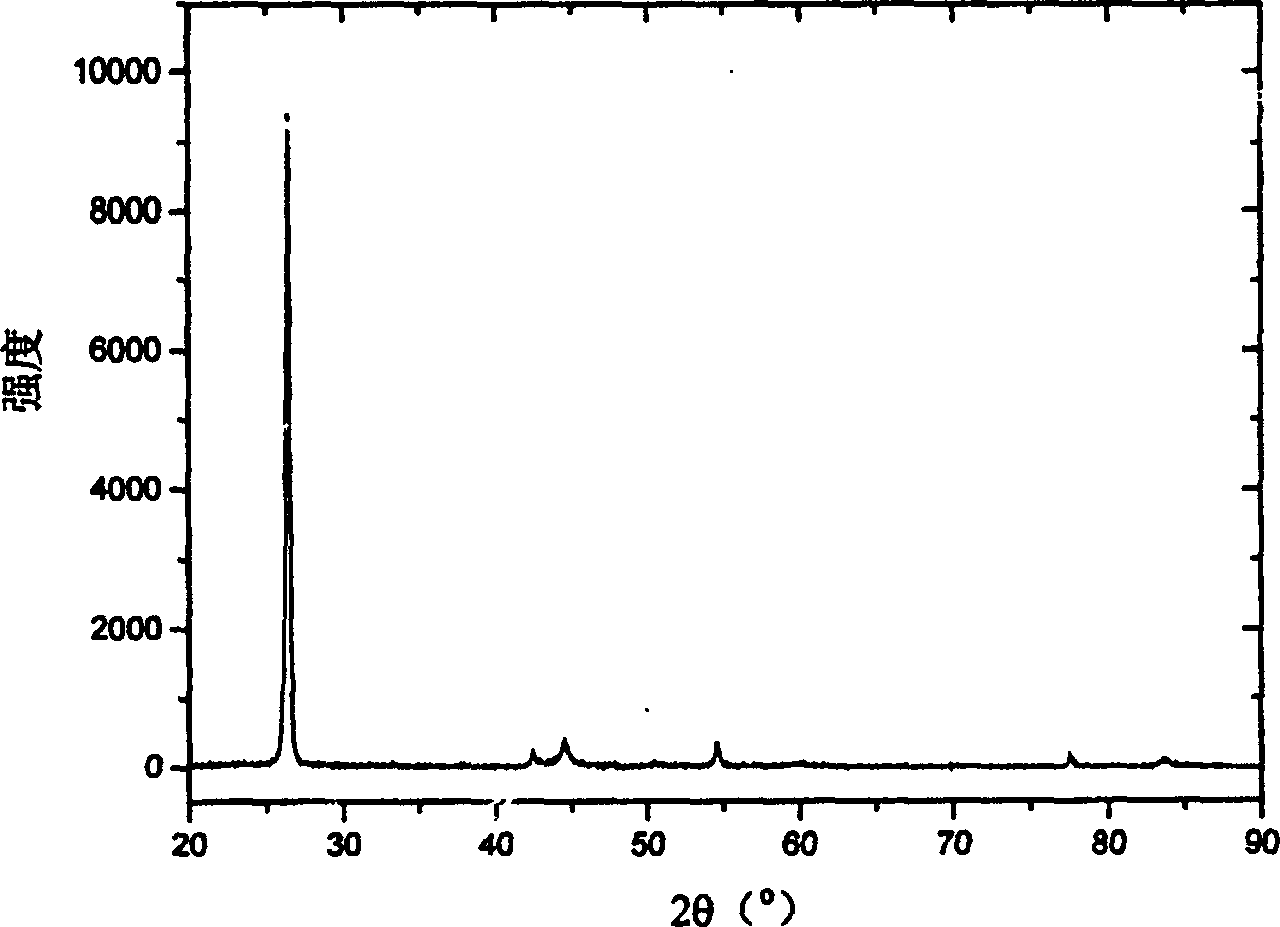

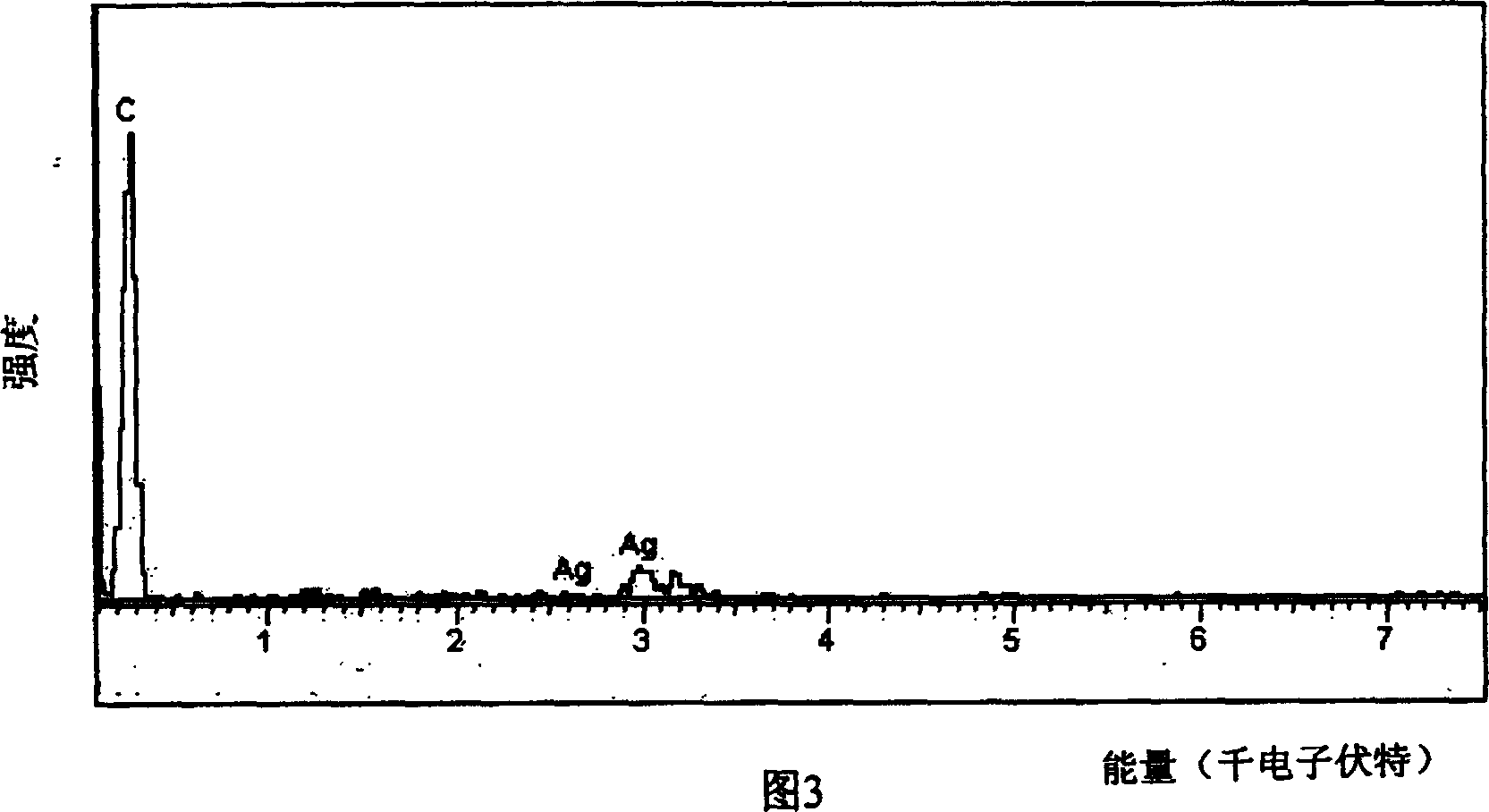

[0047] Embodiment 1, using preparation method one (electroless plating method) to prepare Ag / graphitized mesophase carbon pellets (hereinafter referred to as GMCMB) composite material

[0048] Ag 0.1 / GMCMB 0.9 Preparation of the composite material: (1) Weigh 0.85 grams of silver nitrate and put it into 20 milliliters of anhydrous ethylene glycol to heat and dissolve to form solution 1; (2) Weigh 5 grams of graphitized mesophase carbon pellets and put them into 20 milliliters of ethylene glycol Alcohol and 1,3 propanediol (volume ratio: 1:1) in the mixed solution, stir and mix evenly, then heat to 160 degrees, add the solution 1 obtained in step 1, continue to reflux at 130 degrees for 14 hours and then cool naturally, during the heating and reflux process (3) the black suspension obtained in step 2 is filtered, first rinsed several times with ethylene glycol, and then rinsed with ethanol, and the black substance obtained is in a hollow oven at 100 degrees. After drying for ...

Embodiment 11

[0051] Example 11. Cu / petroleum coke (hereinafter referred to as PC) composite material was prepared by preparation method 2 (self-reduction method).

[0052] Cu 0.05 / PC 0.95Preparation of the composite material: Weigh 0.8 g of copper sulfate and dissolve it in 10 ml of distilled water, add 5 g of petroleum coke particles and stir to form a black slurry. Put the obtained slurry into a tube furnace and heat it up to 800 degrees at 5 degrees per minute, then keep it warm for 2 hours, and take it out after natural cooling for use. During the calcination process, there is always argon protection.

[0053] The nanometer metal or alloy / electrode active material composite material in this example is used in the method of Example 1 to prepare an electrode and assemble it into an experimental battery. The electrolyte solution is a mixed solution of ethylene carbonate and dimethyl carbonate with a volume ratio of 1:1 dissolved in lithium hexafluorophosphate at 1 mol / liter. Other ma...

Embodiment 21

[0055] Example 21. Preparation of Al / natural graphite powder (hereinafter referred to as NG) composite material by preparation method three (chemical vapor deposition method)

[0056] Al 0.2 / NG 0.8 Preparation of composite materials: In a chemical vapor deposition furnace, organic aluminum butylaluminum is used as a precursor, argon is used as a carrier gas, and natural graphite particles are used as a deposition substrate. The deposition temperature is 400 degrees and the deposition time is 15 minutes.

[0057] The nanometer metal or alloy / electrode active material composite material in this example is used in the method of Example 1 to prepare an electrode and assemble it into an experimental battery. Other materials, structures, assembly and testing methods in the battery are the same as those in Embodiment 2.

[0058] Embodiment 22~30, use the same method as embodiment 21 to obtain nine kinds of different composite materials, the test conditions are the same as embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com