Li4Ti5O12 negative material and lithium titanate battery prepared from same

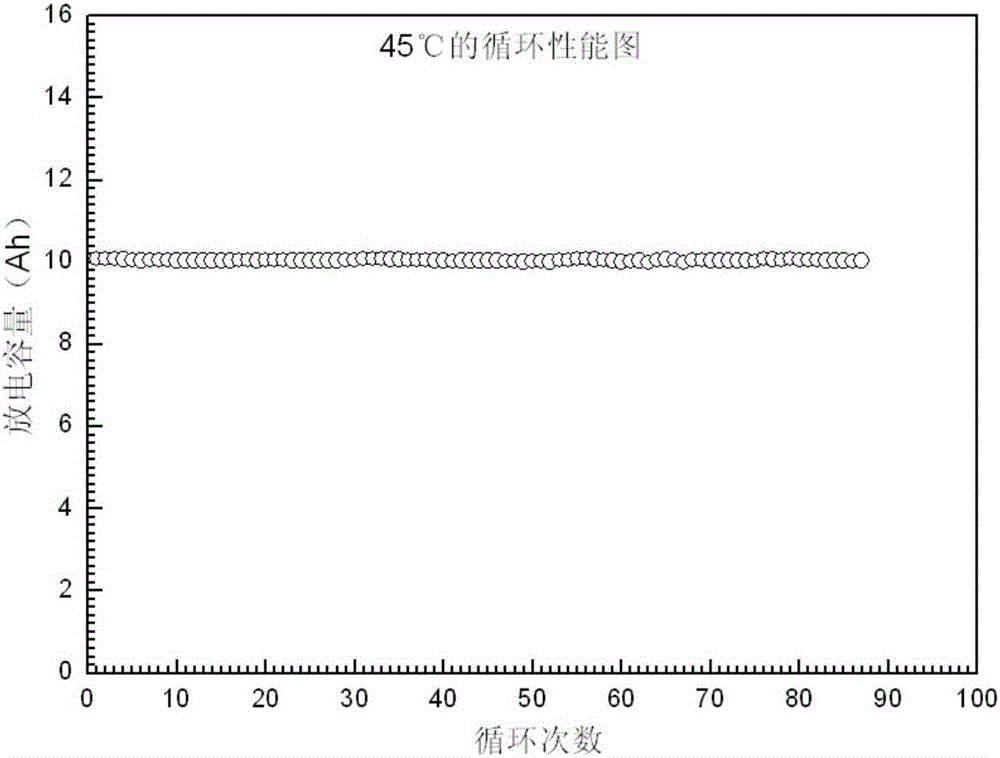

A technology of negative electrode materials and powder materials, which is applied in the field of electrochemistry, can solve the problems of poor decontamination effect of fillers, etc., and achieve the effects of good reversibility of lithium deintercalation, high ion conductivity, and inhibition of reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Li used in the lithium titanate battery of the present embodiment 4 Ti 5 o 12 Negative electrode material, the specific composition is Li 4 Ti 5 o 12 For 96 parts, Li 1+2x m 2y Ti (2-x-y) P 3 o 12-x (x=0.1, y=0.1, M=Mg) is 3 parts, and the carbon layer is 1 part. Li 4 Ti 5 o 12 Negative material. The preparation steps are as follows:

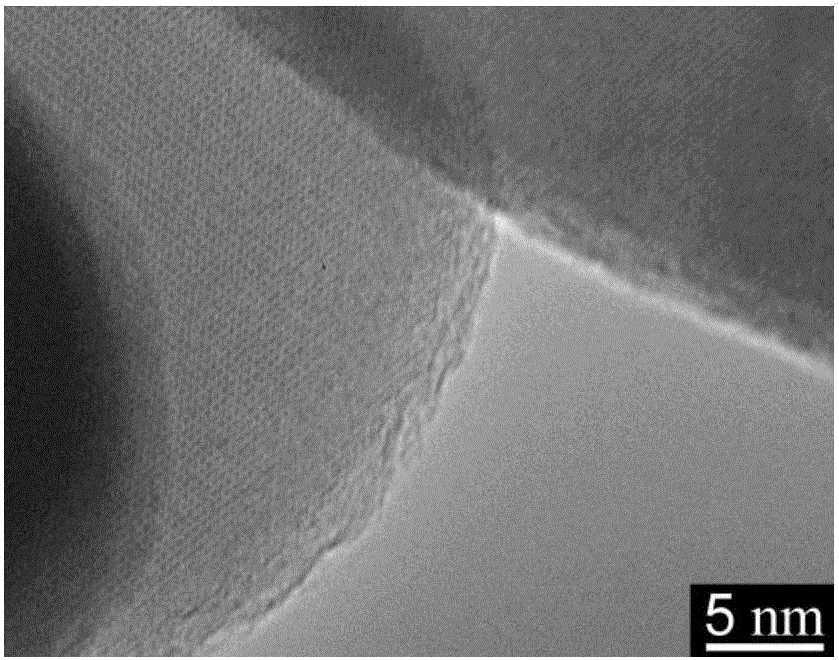

[0025] First, lithium carbonate, titanium dioxide, ammonium dihydrogen phosphate and magnesium carbonate are weighed according to the stoichiometric ratio. Secondly, mix the weighed powder material and deionized water according to the mass ratio of 1:10 by ball milling, and after the ball milling is evenly mixed, the slurry is stirred and dried. The dried powder was placed in a muffle furnace, calcined at 980 °C for 12 hours, and cooled naturally to obtain Li 4 Ti 5 o 12 / Li 1.2 Mg 0.2 Ti 1.8 P 3 o 11.9 Powder material. Will Li 4 Ti 5 o 12 / Li 1.2 Mg 0.2 Ti 1.8 P 3 o 11.9 The powder, Tween 80, and deionized...

Embodiment 2

[0029] Li used in the lithium titanate battery of the present embodiment 4 Ti 5 o 12 Negative electrode material, the specific composition is Li 4 Ti 5 o 12 For 98 parts, Li 1+2x m 2y Ti (2-x-y) P 3 o 12-x (x=0.1, y=0.1, M=Mg) is 2 parts, and the carbon layer is 0.1 part. Li 4 Ti 5 o 12 Negative material. The preparation steps are as follows:

[0030] First, lithium hydroxide, titanium dioxide, ammonium hydrogen phosphate and magnesium carbonate are weighed according to the stoichiometric ratio. Secondly, the weighed powder material and deionized water are ball milled and mixed according to the mass ratio of 1:50, and the slurry is stirred and dried after the ball mill is evenly mixed. The dried powder was placed in a muffle furnace, calcined at 800 °C for 20 hours, and cooled naturally to obtain Li 4 Ti 5 o 12 / Li 1.2 Mg 0.2 Ti 1.8 P 3 o 11.9 Powder material. Will Li 4 Ti 5 o 12 / Li 1.2 Mg 0.2 Ti 1.8 P 3 o 11.9 The powder, Tween 60, and deioniz...

Embodiment 3

[0033] Li used in the lithium titanate battery of the present embodiment 4 Ti 5 o 12 Negative electrode material, the specific composition is Li 4 Ti 5 o 12 For 95 parts, Li 1+2x m 2y Ti (2-x-y) P 3 o 12-x (x=0.1, y=0.2, M=Al) is 4 parts, and the carbon layer is 0.1 part. Li 4 Ti 5 o 12 Negative material. The preparation steps are as follows:

[0034] First, lithium hydroxide, titanium dioxide, ammonium hydrogen phosphate and aluminum oxide are weighed according to the stoichiometric ratio. Secondly, the weighed powder material and deionized water are ball milled and mixed according to the mass ratio of 1:50, and the slurry is stirred and dried after the ball mill is evenly mixed. The dried powder was placed in a muffle furnace, calcined at 1200 °C for 6 hours, and cooled naturally to obtain Li 4 Ti 5 o 12 / Li 1.2 Al 0.4 Ti 1.6 P 3 o 11.9 Powder material. Will Li 4 Ti 5 o 12 / Li 1.2 Al 0.2 Ti 1.8 P 3 o 11.9 The powder, Tween 60, and deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com