PET aluminum-plated base membrane and preparation method thereof

A base film, aluminized technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems affecting the performance of aluminized film, insufficient gloss, low light transmittance and surface tension, etc. The effect of high layer adhesion, uniform coating and excellent surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

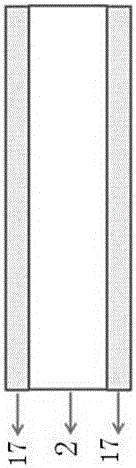

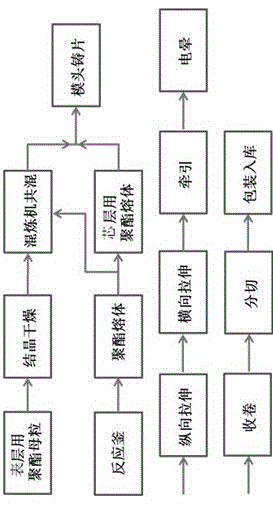

[0032] Such as Figure 1-Figure 4 As shown, a PET aluminized base film includes a core layer 2 positioned in the middle and surface layers 17 arranged on both surfaces of the core layer 2, and the surface layer 17 and the core layer 2 are integrally formed by co-extrusion and biaxial stretching. The core layer 2 is a PET layer, and the surface layer 17 is a PET layer mixed with an anti-blocking agent.

[0033] The weight ratio of the raw material components of the surface layer 17 and the core layer 2 is: surface layer 17: 80% to 90% of polyester melt for film, 10% to 20% of anti-blocking agent masterbatch; core layer 2: polyester melt for film Body 100%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com