Alkali battery

A technology for alkaline batteries and battery casings, applied in the direction of alkaline storage batteries, alkaline storage battery manufacturing, dry batteries, etc., can solve problems such as difficulty in ensuring the superiority of discharge performance, and achieve the suppression of discharge performance decline and the high discharge performance drop Performance, the effect of improving discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

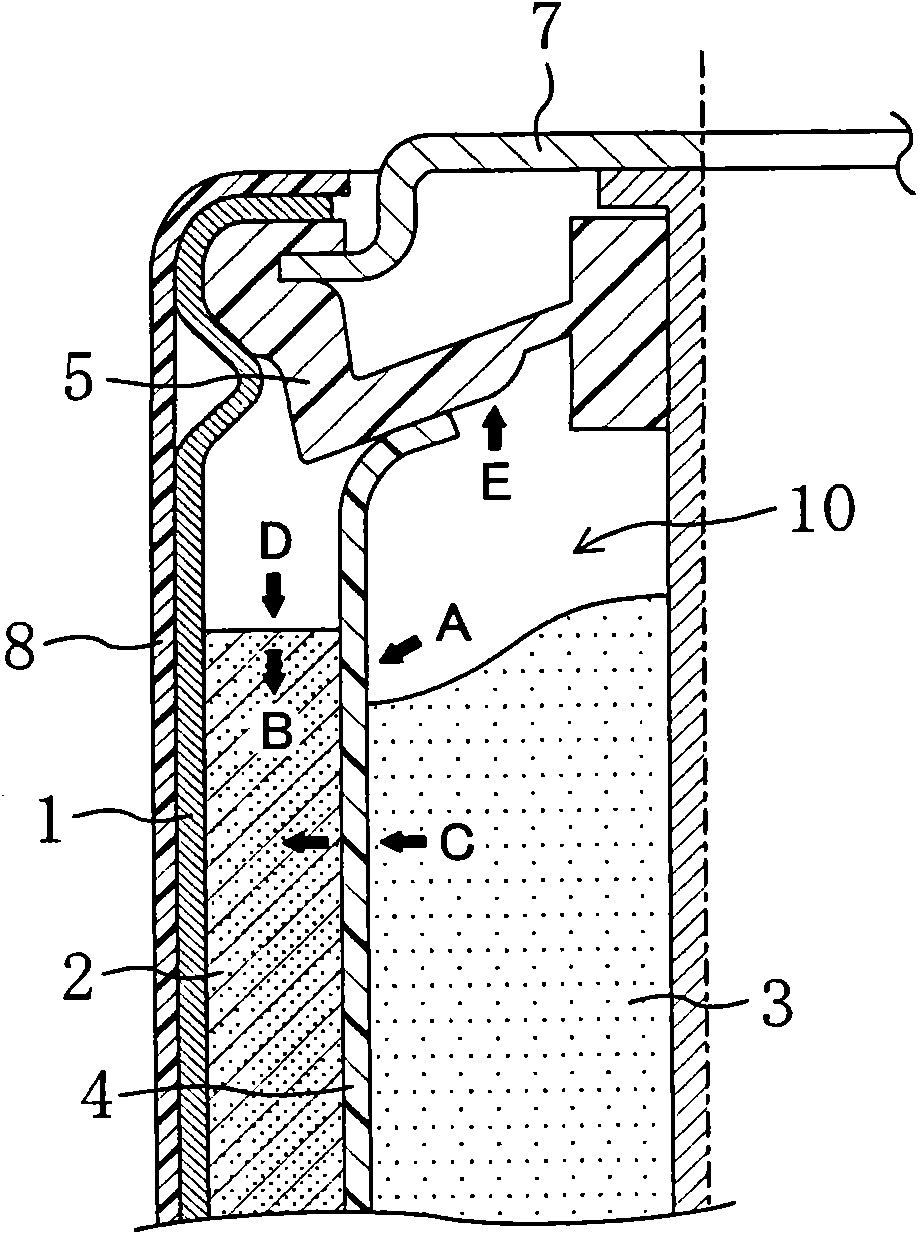

[0033] The inventors of the present application studied factors other than the crystal deformation of manganese dioxide as the reason why the survival rate after storage decreased significantly when high-potential electrolytic manganese dioxide was used, and as a result obtained the following findings.

[0034] That is, the gas in the battery after storage was analyzed, and it was found that most of it was hydrogen gas. This hydrogen gas is considered to be generated by the corrosion of zinc powder in the gelled negative electrode, and it is believed that hydrogen gas is trapped in the closed space formed between the positive and negative electrodes and the gasket in the battery case during storage.

[0035] However, it is generally believed that the deterioration of the storage characteristics of low-potential electrolytic manganese dioxide is due to the oxidation-reduction reaction between manganese dioxide and graphite in the positive electrode mixture, so that the manganese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com