A kind of environmentally friendly high-temperature acidification corrosion inhibitor and preparation method thereof

An acidified corrosion inhibitor and an environment-friendly technology, applied in the field of environment-friendly high-temperature acidified corrosion inhibitor and its preparation, can solve the problems of easy coking, high temperature resistance, delamination, etc., so as to reduce the corrosion rate and improve the activation energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

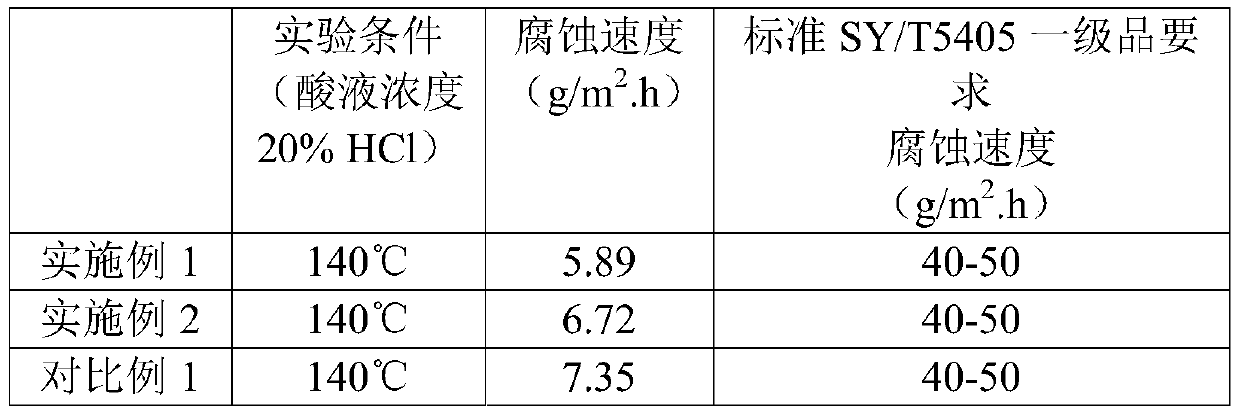

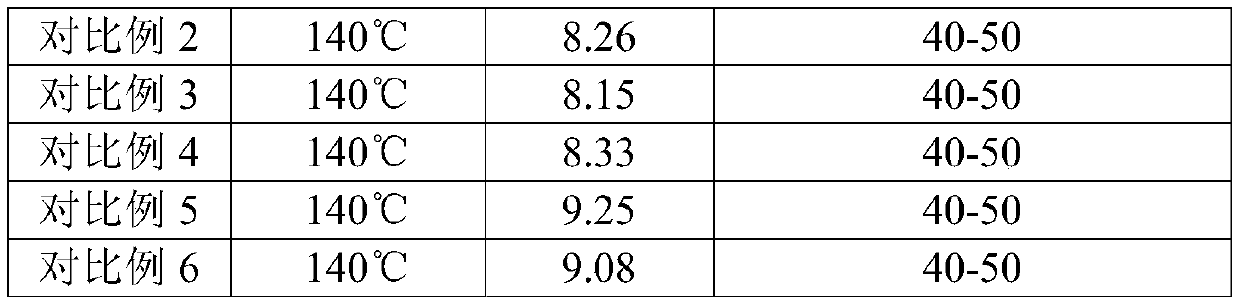

Examples

preparation example Construction

[0026] The preparation method of described quinoline quaternary ammonium salt comprises the following steps:

[0027] Add quinoline and benzyl chloride to the reactor, stir and heat up to 80°C, then slowly add polyoxyethylene fatty alcohol ether dropwise, continue to heat up to 160°C, add ethanol, keep warm for 3 hours, after the reaction, cool down to room temperature , to obtain quinoline quaternary ammonium salt.

[0028] In one embodiment, the raw materials for the preparation of the imidazole-type quaternary ammonium salt in the main agent of the corrosion inhibitor include diethylenetriamine, benzoic acid, dimethyl carbonate and 1,4-dibromobutane.

[0029] In one embodiment, the diethylenetriamine, the benzoic acid, the dimethyl carbonate and the 1,4 -The molar ratio of dibromobutane is 1:(1.05~1.3):(1~1.2):(0.5~0.6); preferably, the diethylenetriamine, the benzoic acid, the dimethyl carbonate The molar ratio to the 1,4-dibromobutane is 1:1.15:1.05:0.54.

[0030] The ...

Embodiment 1

[0050] An environment-friendly high-temperature acidification corrosion inhibitor, calculated by weight, said environment-friendly high-temperature acidification corrosion inhibitor includes 31 parts of corrosion inhibitor main agent, 8 parts of synergist, 0.8 parts of surfactant, 45 parts of solvent And 6 parts of mercapto acids; the main agent of the corrosion inhibitor includes 8 parts of quinoline quaternary ammonium salts, 7 parts of imidazole type quaternary ammonium salts and 16 parts of Mannich bases; the synergist includes 3 parts of organic acetylenic alcohols and 5 parts plant extracts;

[0051] The surfactant is sodium laurate; the solvent is isopropanol; the mercapto acid is thioglycolic acid; the organic alkynyl alcohol is propynyl alcohol; A mixture of Sophora japonica extract and Rosa roxburghii extract; the weight ratio of the extract of Fangji, the extract of Corydalis Corydalis, the extract of Sophora japonica and the extract of Rosa roxburghii is 1:0.3:0.3:...

Embodiment 2

[0065] An environment-friendly high-temperature acidification corrosion inhibitor, calculated by weight, said environment-friendly high-temperature acidification corrosion inhibitor includes 31 parts of corrosion inhibitor main agent, 8 parts of synergist, 0.8 parts of surfactant, 45 parts of solvent And 6 parts of mercapto acids; the main agent of the corrosion inhibitor includes 8 parts of quinoline quaternary ammonium salts, 7 parts of imidazole type quaternary ammonium salts and 16 parts of Mannich bases; the synergist includes 3 parts of organic acetylenic alcohols and 5 parts plant extracts;

[0066] The raw materials for the preparation of the quinoline quaternary ammonium salt in the main agent of the corrosion inhibitor include quinoline, benzyl chloride, polyoxyethylene fatty alcohol ether and ethanol, the quinoline and the benzyl chloride, the polyoxygen The molar ratio of ethylene fatty alcohol ether to the ethanol is 1:1.2:0.1:1.1;

[0067] The raw materials for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com