Water-in-oil type nano-emulsion, nano-emulsion composite response type variable-viscosity acid thickening agent and preparation methods of water-in-oil type nano-emulsion and nano-emulsion composite response type variable-viscosity acid thickening agent

A nano-emulsion, water-in-oil technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of weak viscosity-increasing ability, poor temperature and acid resistance stability, and poor shear resistance of thickeners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

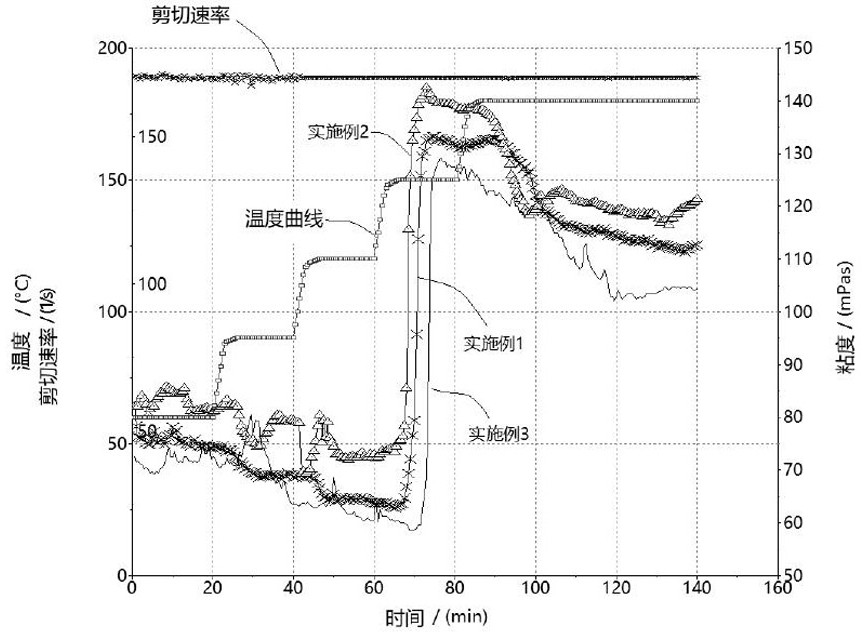

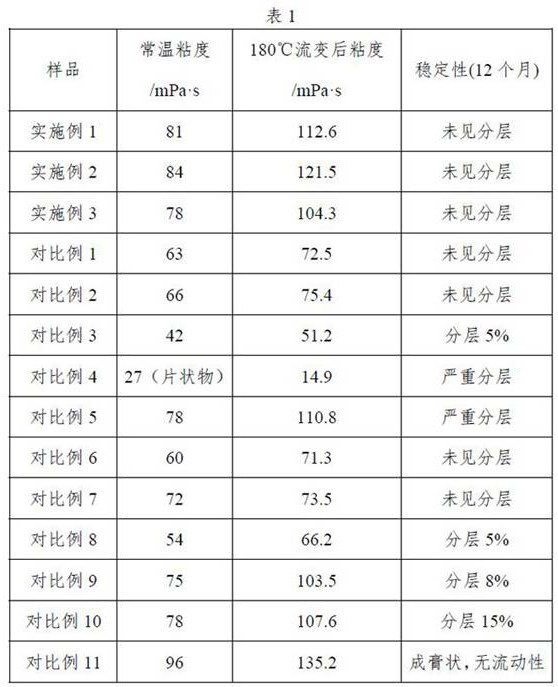

[0060] In this example, a nanoemulsion composite response type viscosity-changing acid thickener is prepared through the following steps

[0061] (1) Preparation of ultrafine powder of thickener

[0062] The preparation of the thickener consists of the following raw materials in parts by weight: 10 parts of acrylamide, 40 parts of acryloyl morpholine, 120 parts of methacryloyloxyethyltrimethylammonium chloride, N , N - 50 parts of dimethylacrylamide, 0.5 part of trimethylolpropane triacrylate, 0.5 part of dodecyl mercaptan, 0.1 part of azobisisobutyronitrile, 0.1 part of potassium persulfate, 0.2 part of sodium bisulfite , 750 parts of water; the preparation method is: acrylamide, acryloylmorpholine, methacryloyloxyethyltrimethylammonium chloride, N , N -After mixing dimethylacrylamide, trimethylolpropane triacrylate and water thoroughly, adjust the pH value to 4.0, then add dodecylmercaptan, potassium persulfate and azobisisobutyronitrile and stir for 30min , transferred ...

Embodiment 2

[0073] In this example, a nanoemulsion composite response type viscosity-changing acid thickener is prepared through the following steps

[0074] (1) Preparation of ultrafine powder of thickener

[0075] The preparation of the thickener consists of the following raw materials in parts by weight: 20 parts of acrylamide, 60 parts of acryloyl morpholine, 140 parts of methacryloyloxyethyltrimethylammonium chloride, N , N - 70 parts of diethylacrylamide, 0.7 parts of tripropylene glycol diacrylate, 0.7 parts of tert-dodecyl mercaptan, 0.25 parts of azobisisobutyronitrile, 0.15 parts of potassium persulfate, 0.3 parts of sodium bisulfite, water 700 copies;

[0076] The preparation method is: acrylamide, acryloylmorpholine, methacryloyloxyethyltrimethylammonium chloride, N , N - After diethylacrylamide, tripropylene glycol diacrylate and water are fully mixed, adjust the pH value to 4.5, then add tert-dodecylmercaptan, potassium persulfate and azobisisobutyronitrile and stir for ...

Embodiment 3

[0087] In this example, a nanoemulsion composite response type viscosity-changing acid thickener is prepared through the following steps

[0088] (1) Preparation of ultrafine powder of thickener

[0089] The thickener is prepared from the following raw materials in parts by weight: 30 parts of acrylamide, 80 parts of acryloyl morpholine, 160 parts of methacryloyloxyethyltrimethylammonium chloride, N - 90 parts of isopropylacrylamide, 1 part of trimethylolpropane triacrylate, 1 part of dodecyl mercaptan, 0.5 parts of azobisisobutyronitrile, 0.2 parts of potassium persulfate, 0.4 parts of sodium bisulfite , 650 parts of water;

[0090] The preparation method is: acrylamide, acryloylmorpholine, methacryloyloxyethyltrimethylammonium chloride, N -After mixing isopropylacrylamide, trimethylolpropane triacrylate and water well, adjust the pH value to 5.0, then add dodecylmercaptan, potassium persulfate and azobisisobutyronitrile and stir for 30min , transferred to the reaction ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com