A kind of fibril preparation process and the pet fiber that this process makes

A preparation process and filament technology, which is applied in the field of PET fibers, can solve the problems of finished product color, appearance influence, unfavorable production quality, and influence on product quality, so as to improve quality and appearance aesthetics, reduce human resource expenditure, and improve The effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

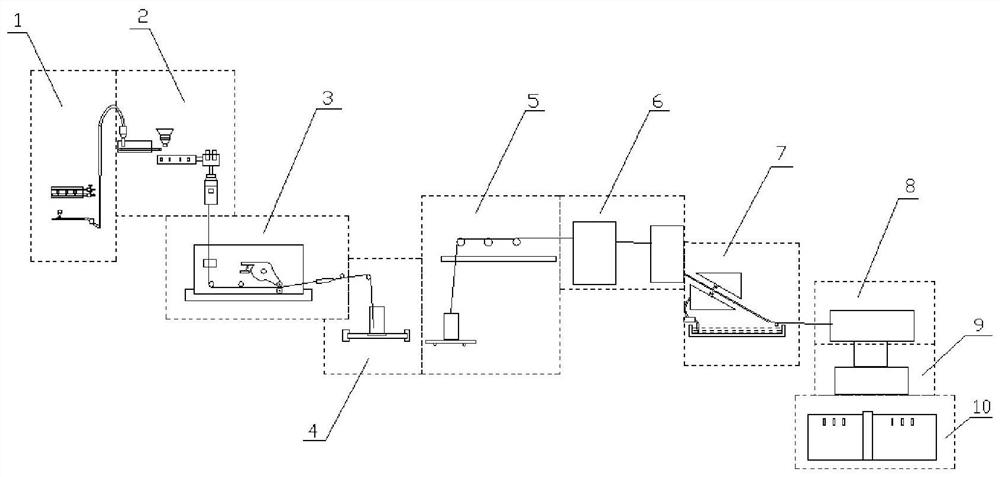

[0091] see Figure 1-25 , a kind of fibril preparation process that the present invention relates to and the PET fiber that this process makes, described process is based on a kind of PET antibacterial fiber production line, and described production line includes mixing mechanism 1, extruding mechanism 2, drawing mechanism 3, Collecting mechanism 4, clustering mechanism 5, extending mechanism 6, crimping and spraying mechanism 7, cutting mechanism 8, unloading mechanism 9 and packing mechanism 10;

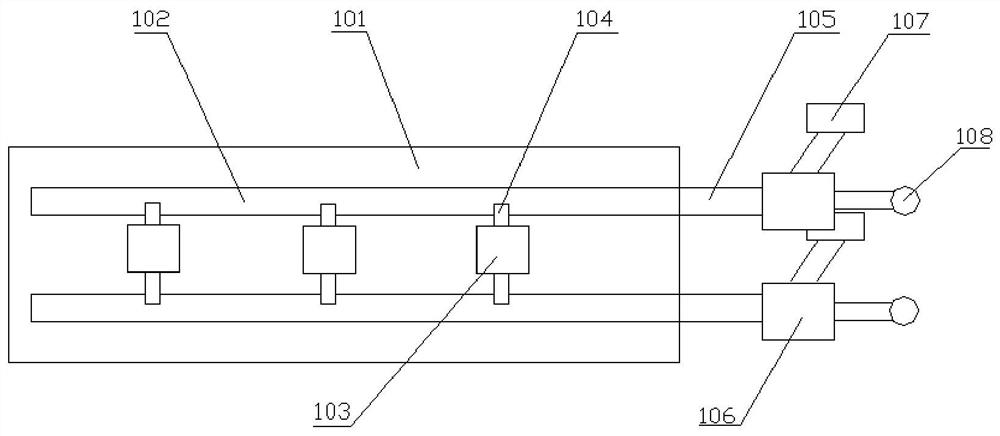

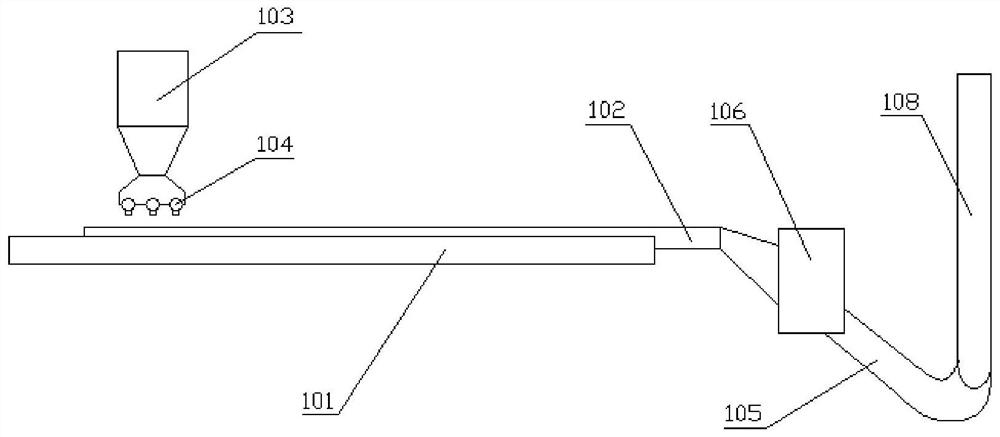

[0092] see figure 2 and image 3 , the mixing mechanism 1 includes a support 101, at least one transmission belt 102 is installed on the support 101, a plurality of collection hoppers 103 are installed above the transmission belt 102, and a plurality of collection hoppers 103 are filled with different Raw materials, the bottom of the collecting hopper 103 is horizontally equipped with a screw extruder 104, the discharge end of the screw extruder 104 is located directly above the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com