Specific-proportion bi-component fluid output device

An output device, two-component technology, applied in the direction of spraying device, etc., can solve the problems of long processing cycle, low mixing ratio accuracy of two-component spraying equipment, short production cycle, etc., to improve the proportioning accuracy, flexible and convenient switching , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

proportion 2

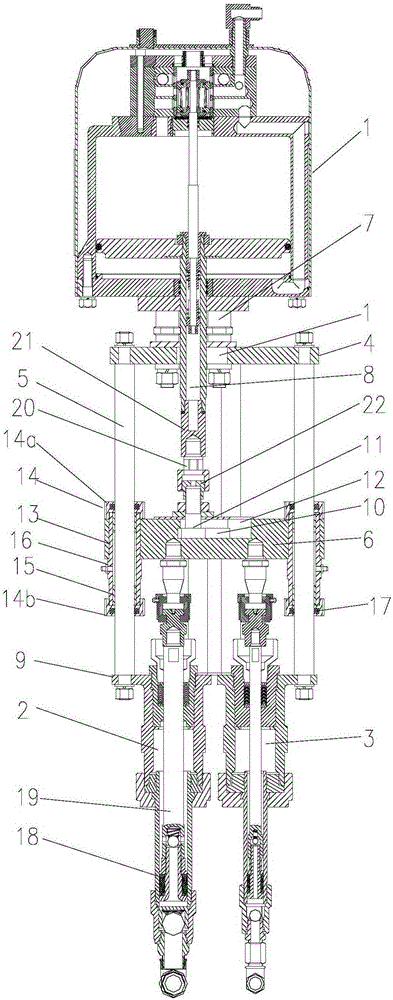

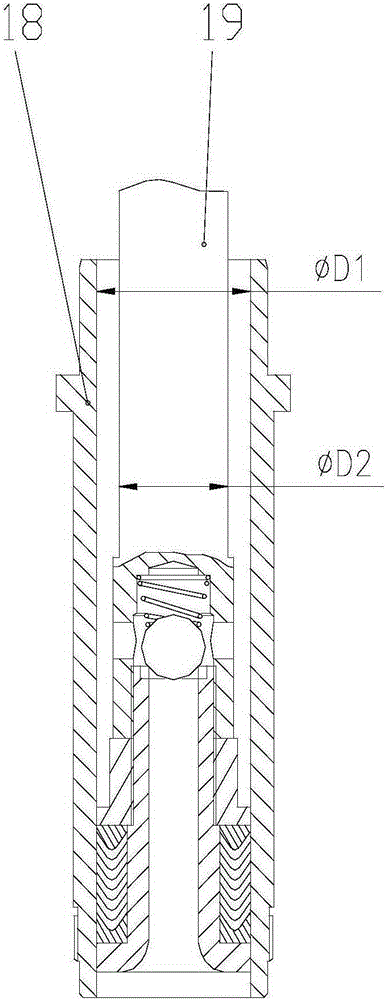

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the high-pressure cylinder assembly in the present invention. As shown in the figure, the specific proportion of the two-component fluid output device in this embodiment includes a power unit 1, a transmission ratio mechanism and a high-pressure cylinder assembly. The high-pressure cylinder assembly At least three types are included. The transmission adjustment mechanism is provided with two power output ends and a high-pressure cylinder assembly is respectively installed (two high-pressure cylinder assemblies are installed, including a high-pressure cylinder assembly 2 and a high-pressure cylinder assembly 3). The mechanism is used to balance the input power of the power plant 1 and output it to the high-pressure cylinder assembly 2 and the high-pressure cylinder assembly 3. Each high-pressure cylinder assembly includes a cylinder body 18 and a pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com