Apparatus for automatically adding foaming agent

A technology of automatic adding and foaming agent, which is applied in the direction of safety devices, mixers, dust prevention, etc., can solve the problems of inability to reach the mixing ratio range of dust-reducing foam, poor mixing effect, etc., and achieve simple structure, convenient adjustment, and accurate mixing ratio high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

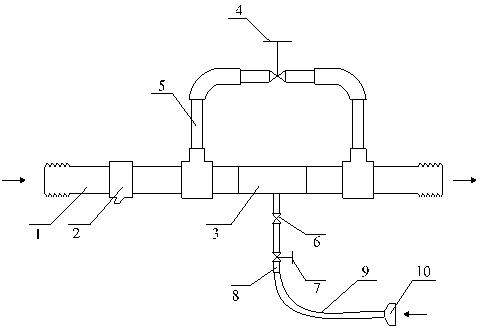

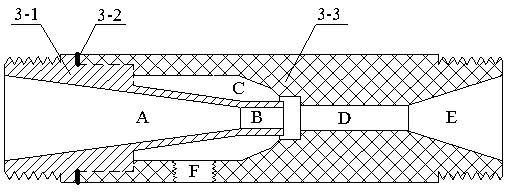

[0012] figure 1 As shown, the foaming agent automatic adding device of the present invention is mainly composed of a main pipe 1, an ejector 3, and a side branch pipe 5. The inlet end of the main pipe 1 is connected with the high-pressure water pipe under the coal mine through a joint, and the outlet end is connected with the foaming pipe through a joint. The injector 3 is connected to the main pipe 1, and the main pipe 1 in front of the inlet channel of the ejector 3 is provided with a filter 2. The main pipe 1 connected before and after the inlet and outlet channels of the ejector 3 is connected with a side branch 5 connected in parallel with the ejector 3, and the side branch 5 is provided with a cut-off valve 4. By adjusting the opening of the stop valve 4, a On the one hand, the flow rate and jet velocity passing through the nozzle 3-1 in the ejector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com