Comprehensive dustproof technology of fully mechanized excavation face based on dust segregation

A technology for working face and dust, applied in the directions of dust prevention, fire prevention, safety devices, etc., can solve problems such as affecting the health and safety of workers, poor dust prevention effect, etc., and achieve the effect of significant dust reduction effect and wide practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

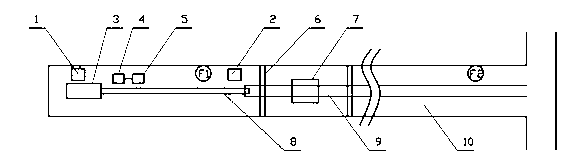

[0013] In the figure, the device based on the dust-isolated comprehensive dust prevention technology for fully mechanized excavation working face includes isolation room a 1, fully mechanized excavation machine 3, high-pressure water supply pump 4, water tank 5, isolation room b 2, water curtain 6, isolation room Explosive water bag 7, second transportation belt 8, rear transportation belt 9, dust concentration sensors F1 and F2, and a closed isolation room a for breathing of workers is set at 10-15 m from the front face in fully mechanized excavation roadway 10 1. Coal seam comprehensive excavator 3, high-pressure water supply pump 4 and water supply tank 5 for spraying coal powder. A dust concentration sensor F1 and a closed isolation room b 2 are installed at 45-50 m from the comprehensive excavator 3. Two or more full-section high-efficiency dust-reducing water curtains 6 with an interval of no more than 5m are set at 40-100 m behind the excavator 3 to fully isolate the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com