Compound foaming agent used for depositing dust and preparation method thereof

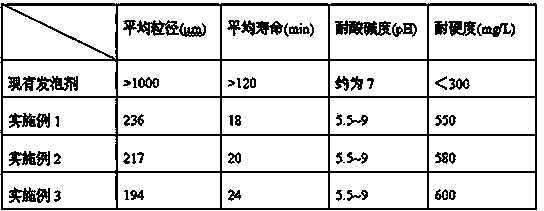

A compound type and foaming agent technology, applied in chemical instruments and methods, dust prevention, mining equipment, etc., can solve problems such as weak acid and alkali resistance and hard water resistance, large average particle size of bubbles, and low foaming rate , to achieve the effects of enhancing hard water resistance, enhancing acid and alkali resistance, and good foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A composite blowing agent for dust reduction, consisting of the following parts by weight:

[0027] Alkyl polyglucoside: 5 kg;

[0028] Fatty alcohol polyoxyethylene ether: 20 kg;

[0029] Fatty alcohol polyoxyethylene ether sodium sulfate: 9 kg;

[0030] Sodium 2-ethylhexyl succinate: 1 kg;

[0031] Water: 65 kg.

[0032] The method for preparing this composite blowing agent may further comprise the steps:

[0033] a. Add 65 kg of water to the mixer in parts by weight, heat and control the temperature to 40°C;

[0034] b. Slowly add 5 kg of alkyl polyglucoside, 20 kg of fatty alcohol polyoxyethylene ether, and 1 kg of sodium 2-ethylhexyl succinate sulfonate into the mixer slowly and stir for 1 hour to make alkyl glucoside and fatty alcohol Oxyethylene ether and sodium 2-ethylhexyl succinate sulfonate quickly dissolve and mix well;

[0035] c. Stop stirring, let it stand for 10 minutes and control the temperature to 35°C;

[0036] d. Slowly add 9 kg of fatty alco...

Embodiment 2

[0038] A composite blowing agent for dust reduction, consisting of the following parts by weight:

[0039] Alkyl polyglucoside: 7 kg;

[0040] Fatty alcohol polyoxyethylene ether: 23 kg;

[0041] Fatty alcohol polyoxyethylene ether sodium sulfate: 11 kg;

[0042] Sodium 2-ethylhexyl succinate: 1 kg;

[0043] Water: 58 kg.

[0044] The method for preparing this composite blowing agent may further comprise the steps:

[0045] a. Add 58 kg of water to the mixer in parts by weight, heat and control the temperature to 42°C;

[0046] b. Slowly add 7 kg of alkyl polyglucoside, 23 kg of fatty alcohol polyoxyethylene ether, and 1 kg of sodium 2-ethylhexyl succinate sulfonate into the mixer slowly and stir for 1 hour to make alkyl glucoside and fatty alcohol Oxyethylene ether and sodium 2-ethylhexyl succinate sulfonate quickly dissolve and mix well;

[0047] c. Stop stirring, let it stand for 15 minutes and control the temperature to 37°C;

[0048] d. Slowly add 11 kg of fatty al...

Embodiment 3

[0050] A composite blowing agent for dust reduction, consisting of the following parts by weight:

[0051] Alkyl polyglucoside: 8 kg;

[0052] Fatty alcohol polyoxyethylene ether: 25 kg;

[0053] Fatty alcohol polyoxyethylene ether sodium sulfate: 14 kg;

[0054] Sodium 2-ethylhexyl succinate: 2 kg;

[0055]Water: 51 kg.

[0056] The method for preparing this composite blowing agent may further comprise the steps:

[0057] a. Add 51 kg of water to the mixer in parts by weight, heat and control the temperature to 45°C;

[0058] b. Slowly add 8 kg of alkyl polyglucoside, 25 kg of fatty alcohol polyoxyethylene ether, and 2 kg of sodium 2-ethylhexyl succinate sulfonate into the mixer and stir for 1 hour to make alkyl glucoside and fatty alcohol Oxyethylene ether and sodium 2-ethylhexyl succinate sulfonate quickly dissolve and mix well;

[0059] c. Stop stirring, let it stand for 20 minutes and control the temperature to 40°C;

[0060] d. Slowly add 14 kg of fatty alcohol po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com