Wetting agent capable of inhibiting dust flying

A dusty and wetting agent technology, applied in transportation and packaging, other chemical processes, dissolution, etc., can solve the problems of insignificant dust suppression effect, slow condensation speed, weak moisturizing performance, etc., and achieve good viscosity adjustment and stable texture , the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

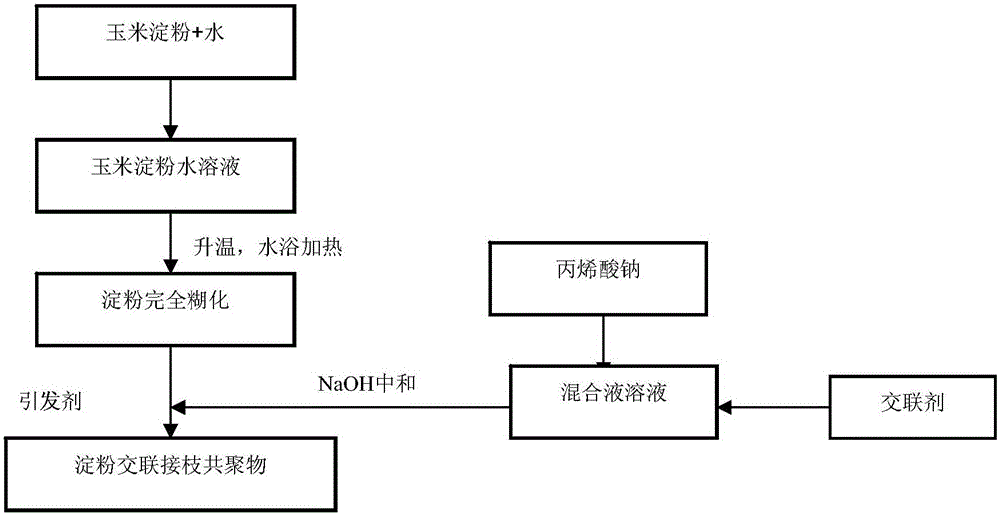

Method used

Image

Examples

Embodiment 1

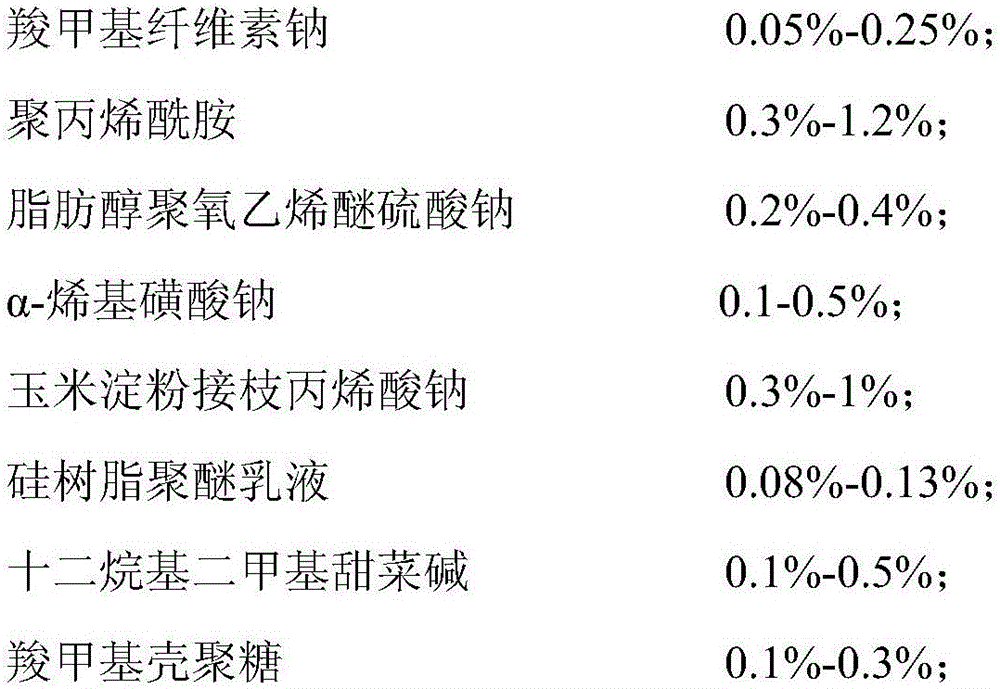

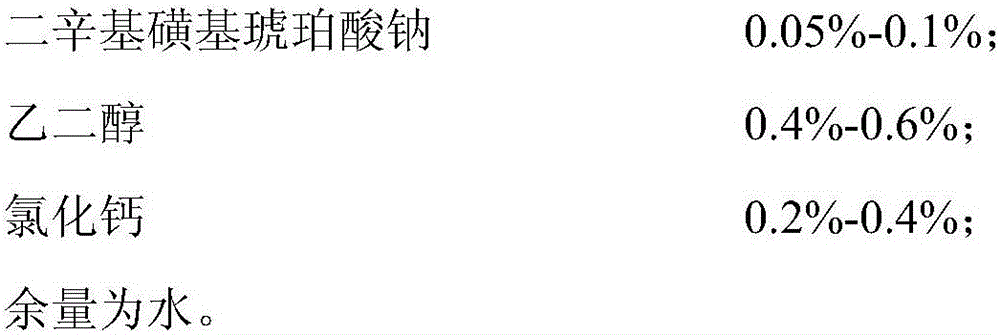

[0026] Weigh respectively according to the following quality standards: sodium carboxymethyl cellulose 1kg, polyacrylamide 6kg, sodium fatty alcohol polyoxyethylene ether sulfate 2.5kg, sodium α-alkenyl sulfonate 2.5kg, cornstarch grafted sodium acrylate 5kg, Silicone resin polyether emulsion 1kg, lauryl dimethyl betaine 2kg, carboxymethyl chitosan 1.5kg, dioctyl sodium sulfosuccinate 0.6kg, ethylene glycol 4.5kg, calcium chloride 2.5kg. Add the above formula raw materials into 970.9kg of clean water, and mix thoroughly to prepare 1000kg of wet dust control wetting agent. The wetting agent with this ratio has good flocculation and water retention performance and excellent dust reduction effect.

[0027] Among them, in this formula, the percentages of various raw materials are: sodium carboxymethyl cellulose 0.1%, polyacrylamide 0.6%, fatty alcohol polyoxyethylene ether sodium sulfate 0.25%, sodium α-olefin sulfonate 0.25% %, Corn Starch Graft Sodium Acrylate 0.5%, Silicone Po...

Embodiment 2

[0029] Weigh respectively according to the following quality standards: sodium carboxymethyl cellulose 2kg, polyacrylamide 9kg, sodium fatty alcohol polyoxyethylene ether sulfate 3.5kg, sodium α-alkenyl sulfonate 3.5kg, cornstarch grafted sodium acrylate 7kg, Silicone resin polyether emulsion 1.2kg, lauryl dimethyl betaine 3kg, carboxymethyl chitosan 2.5kg, dioctyl sodium sulfosuccinate 0.8kg, ethylene glycol 5.5kg, calcium chloride 3.5kg . Add the above formula raw materials into 958.5kg of clean water, mix well and prepare 1000kg of wet dust control wetting agent. The wetting agent with this ratio has uniform texture, moderate foam size and good flocculation effect.

[0030] Among them, in this formula, the percentages of various raw materials are: sodium carboxymethylcellulose 0.2%, polyacrylamide 0.9%, fatty alcohol polyoxyethylene ether sodium sulfate 0.35%, sodium α-olefin sulfonate 0.35% %, corn starch grafted sodium acrylate 0.7%, silicone resin polyether emulsion 0....

Embodiment 3

[0032] Weigh respectively according to the following quality standards: sodium carboxymethylcellulose 1.5kg, polyacrylamide 7kg, sodium fatty alcohol polyoxyethylene ether sulfate 3kg, sodium α-alkenyl sulfonate 3kg, cornstarch grafted sodium acrylate 6kg, silicon Resin polyether emulsion 1.1kg, dodecyl dimethyl betaine 2.5kg, carboxymethyl chitosan 2kg, dioctyl sodium sulfosuccinate 0.7kg, ethylene glycol 5kg, calcium chloride 3kg. Add the above formula raw materials into 965.2kg of clean water, mix thoroughly to prepare 1000kg of wet dust control wetting agent. The wetting agent with this ratio has uniform texture, rich foam, and extremely obvious coagulation-promoting and wetting effects.

[0033]Among them, in this formula, the percentages of various raw materials are: sodium carboxymethylcellulose 0.15%, polyacrylamide 0.7%, fatty alcohol polyoxyethylene ether sodium sulfate 0.3%, sodium α-olefin sulfonate 0.3% %, Corn Starch Graft Sodium Acrylate 0.6%, Silicone Polyethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com