Patents

Literature

103results about How to "Suppress flying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Humidity control and ventilation system

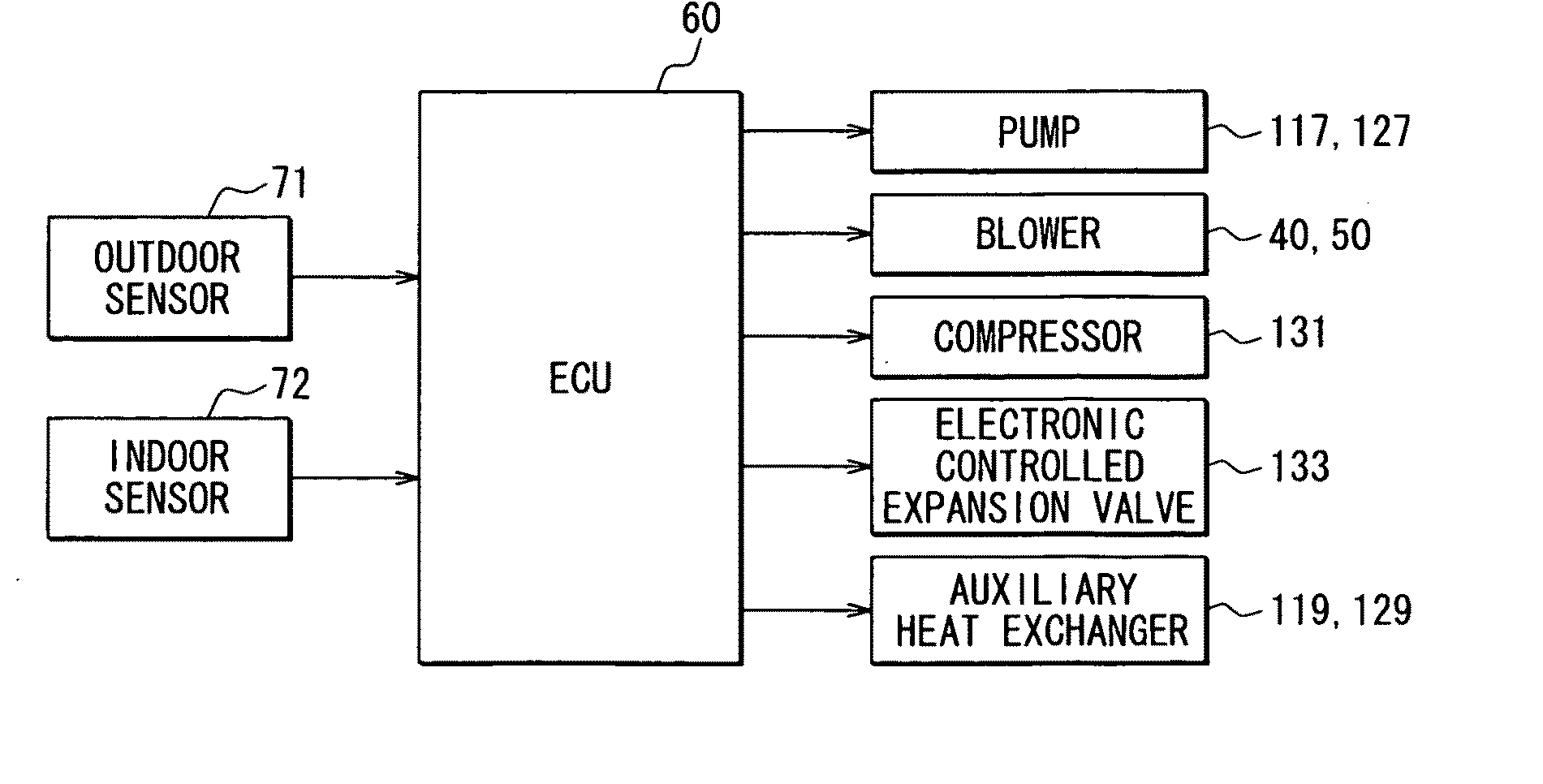

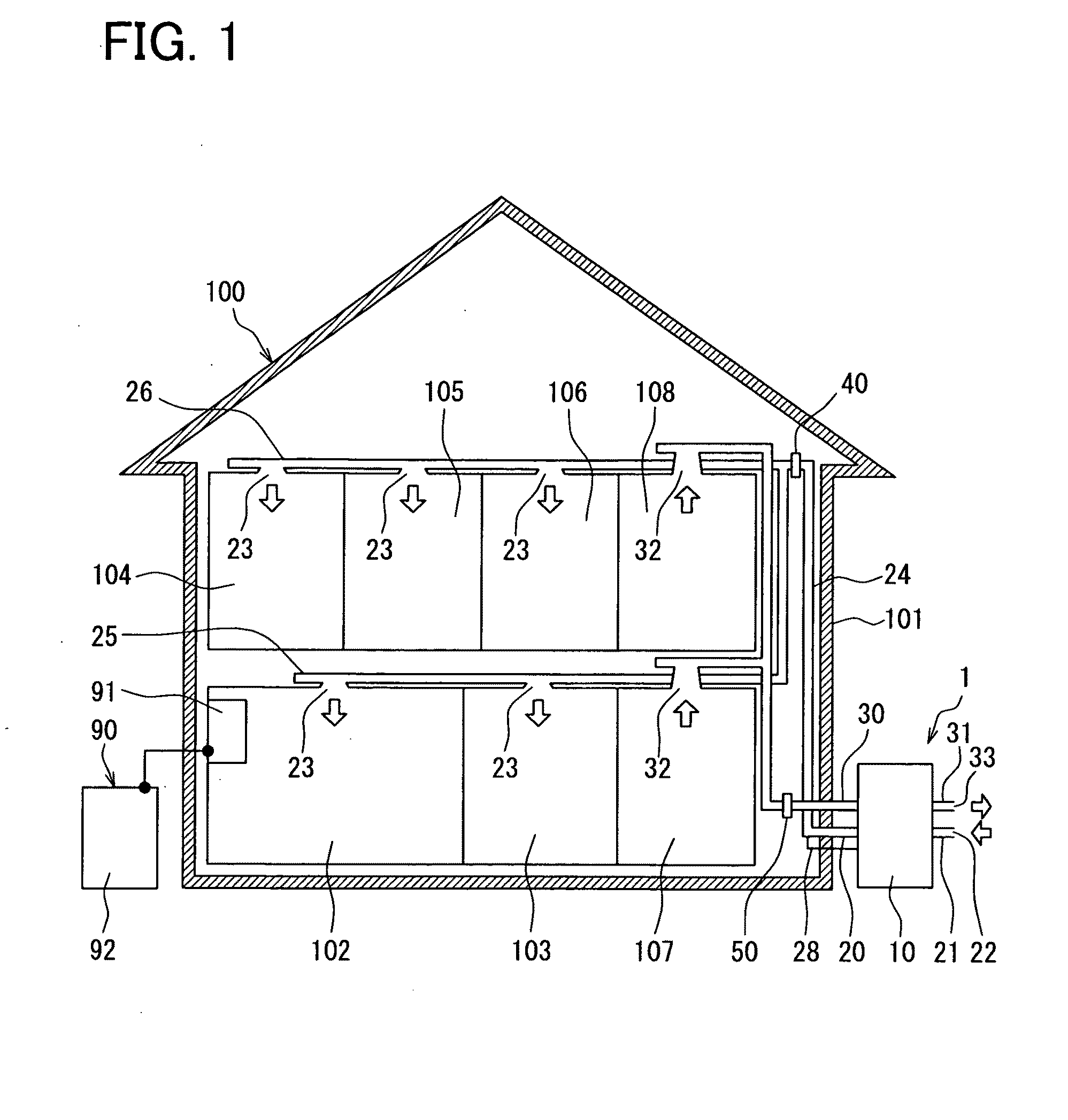

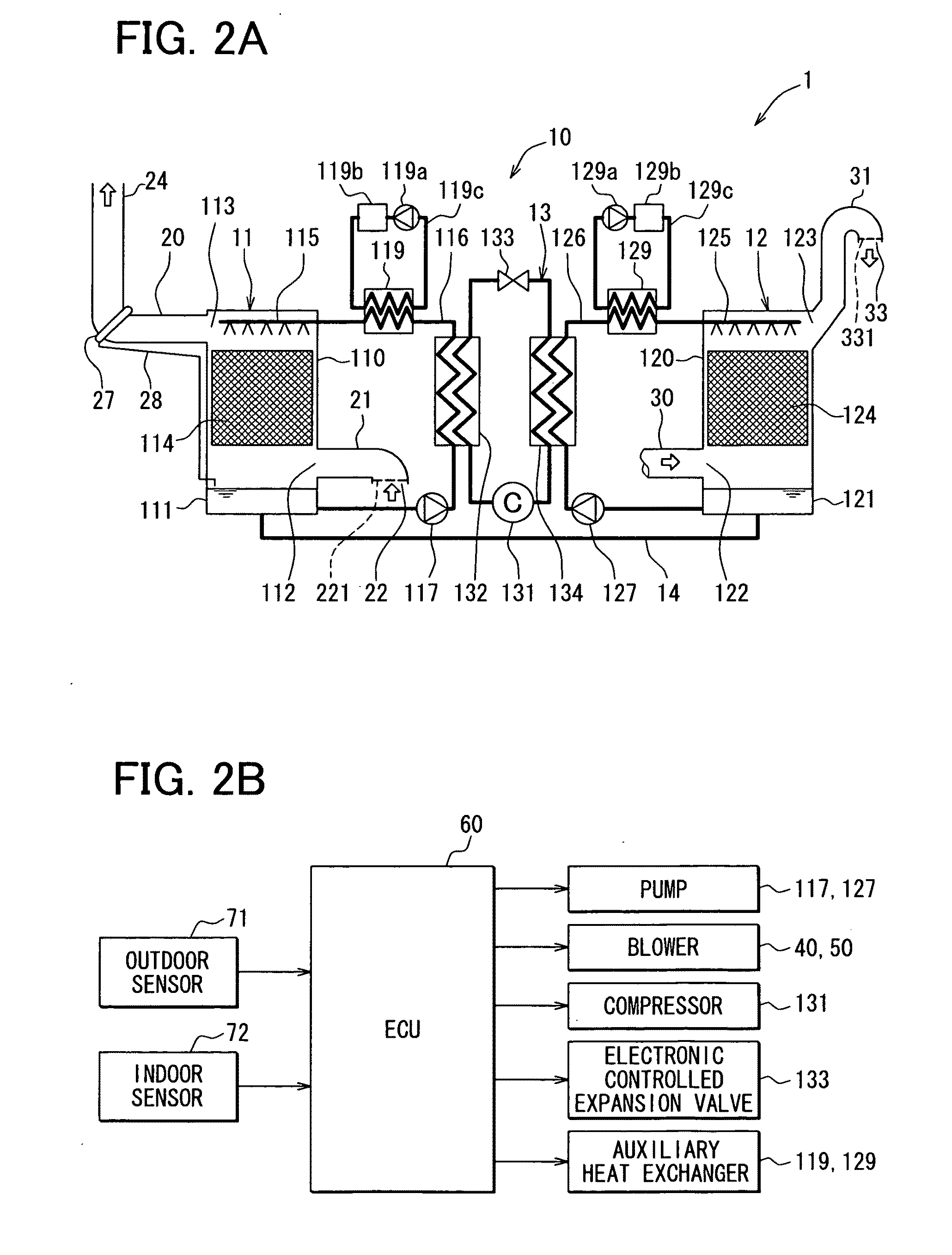

InactiveUS20110056384A1Simple configurationComplex configurationCombination devicesAuxillary pretreatmentHumidityBreathing

A humidity control and ventilation system for a building with an absorption-type humidity controller includes an air supply passage, air discharge passage and a processing unit. The air supply passage is configured to conduct intake air from an exterior inlet port, which is located at an outside of the building, to an interior outlet port, which is located at an inside of the building. The processing unit is inserted in the air supply passage. The air supply passage includes an intake duct that is located between the processing unit and the interior outlet port, and the intake duct includes a vertically extending section, which extends in a vertical direction to create an upflow of the intake air conducted from the processing unit toward the interior outlet port.

Owner:DENSO CORP

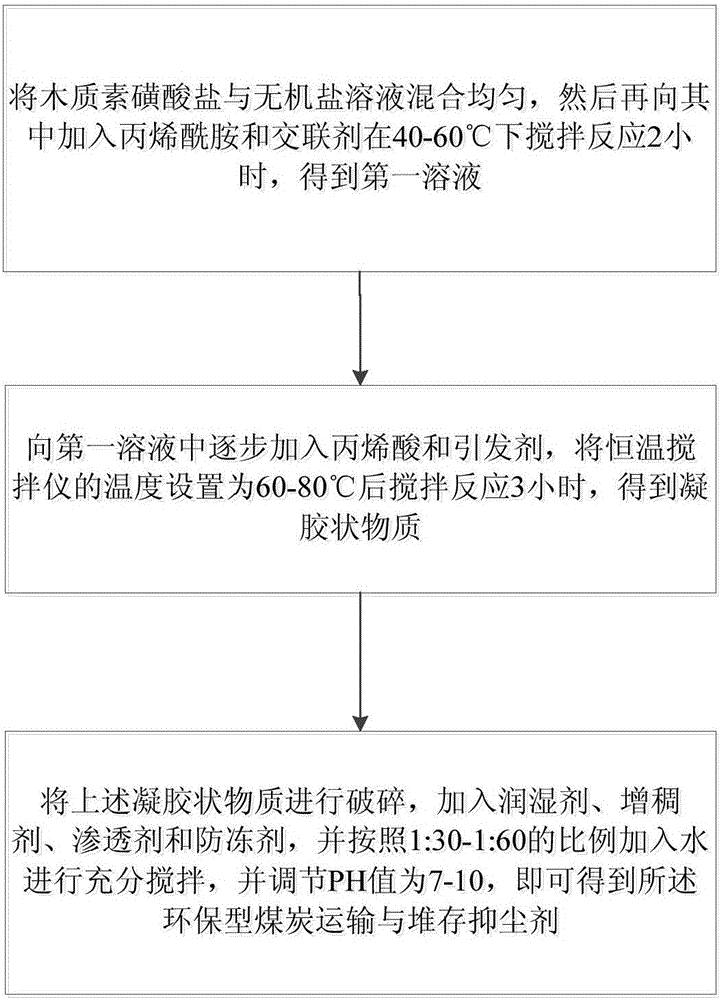

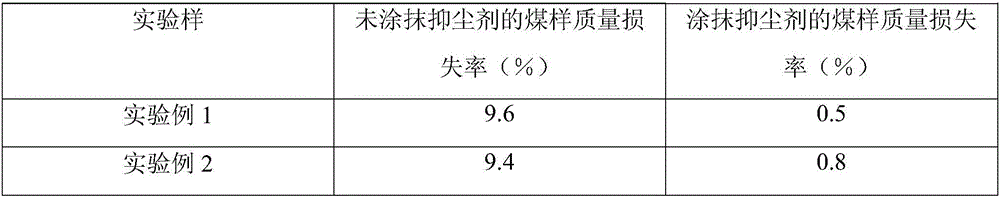

Environmentally-friendly coal transporting and stockpiling dust inhibitor and preparation method thereof

ActiveCN105950116ASuppress flyingImprove wettabilityOther chemical processesInorganic saltsLignosulfonates

The invention discloses an environmentally-friendly coal transporting and stockpiling dust inhibitor and a preparation method thereof. The dust inhibitor comprises, by mass, 5-10% of lignosulfonate, 5-10% of acrylamide, 10-15% of acrylic acid, 0.5-1.4% of a wetting agent, 0.4-0.9% of a thickener, 0.3-0.5% of an osmotic agent, 0.2-0.5% of an antifreeze agent, 0.05-0.1% of an initiator, 0.5-0.8% of a cross-linking agent, 0.2-0.5% of an inorganic salt, and the balance of water. A finally generated gel state substance has an obviously better coal wrapping effect than spraying, and can form a stable protection layer after the gel state substance is sprayed on the surface of coal. The dust inhibitor has the advantages of good wetting effect, fast solidification speed, and large hardness and obvious dust inhibiting effect of the formed protection layer.

Owner:SHANDONG UNIV OF SCI & TECH

Road dust inhibitor and preparation method thereof

InactiveCN104449579AWith moisturizing functionWith bonding functionOther chemical processesCarrying capacityAnti freezing

The invention discloses a road dust inhibitor and a preparation method thereof. The road dust inhibitor is characterized in that the raw materials of the road dust inhibitor comprises surface active agents, stabilizers, hydrophilic agents, thickeners, anti-freezing auxiliaries, antibacterial agents and water. The preparation method comprises, firstly, adding an appropriate amount of water into a reactor; secondly, adding the surface active agents and the stabilizers in; thirdly, after the surface active agents and the stabilizers are fully dissolved, slowly adding the hydrophilic agents and the thickeners in and stirring to achieve dissolution; fourthly, adding the anti-freezing auxiliaries and the antibacterial agents in; lastly, adding the residue water in until reaching a designated concentration. By means of the surface active agent, the road dust inhibitor can form a layer of isolating film on the contact surface between dust and air, and the isolating film has high water carry capacities and adhesive performance; by adding a small amount of salt, the road dust inhibitor obtain certain anti-freezing and antibacterial effects.

Owner:HEFEI UNIV OF TECH

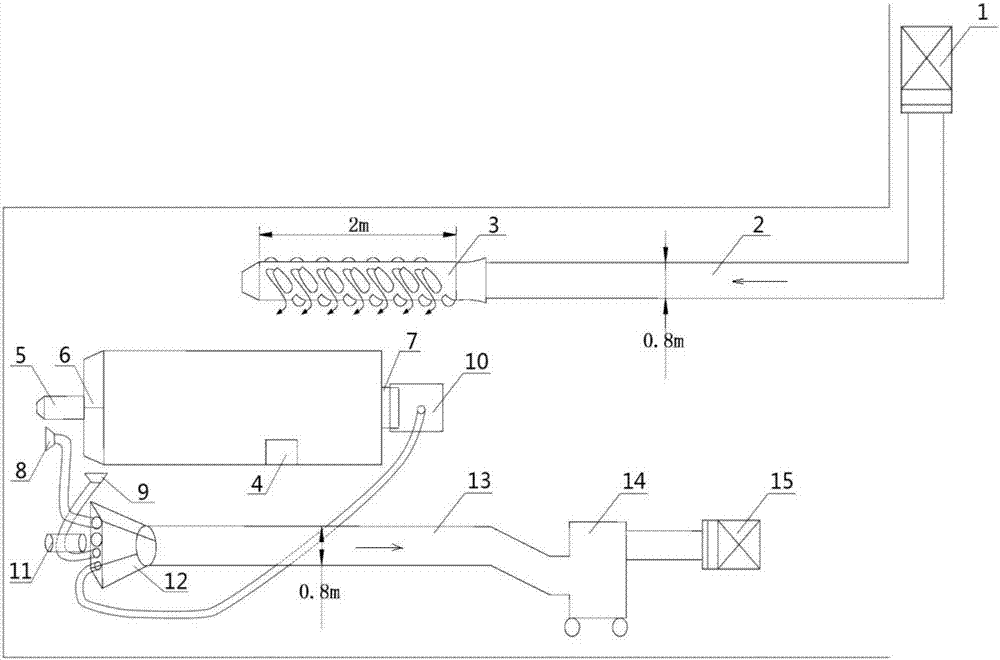

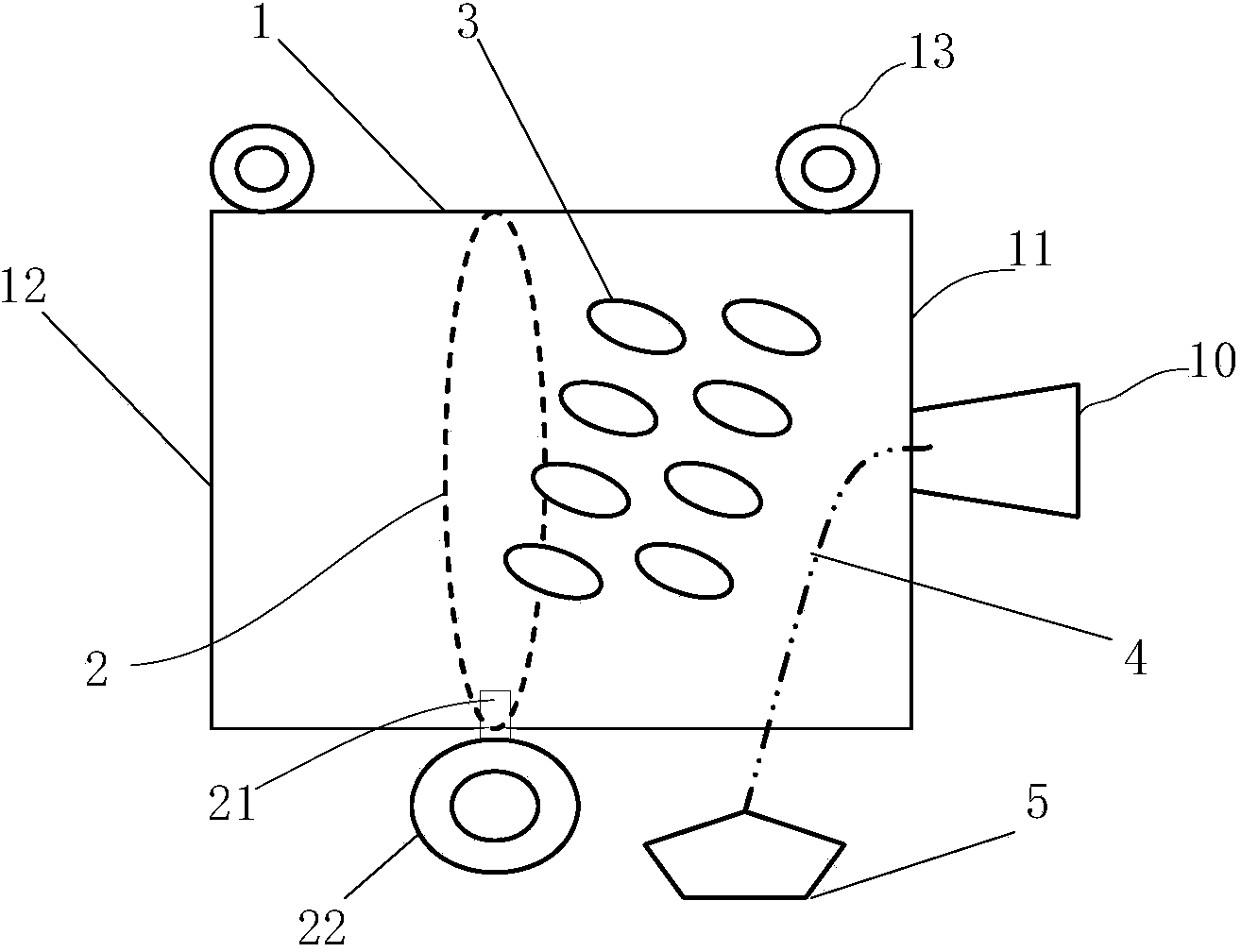

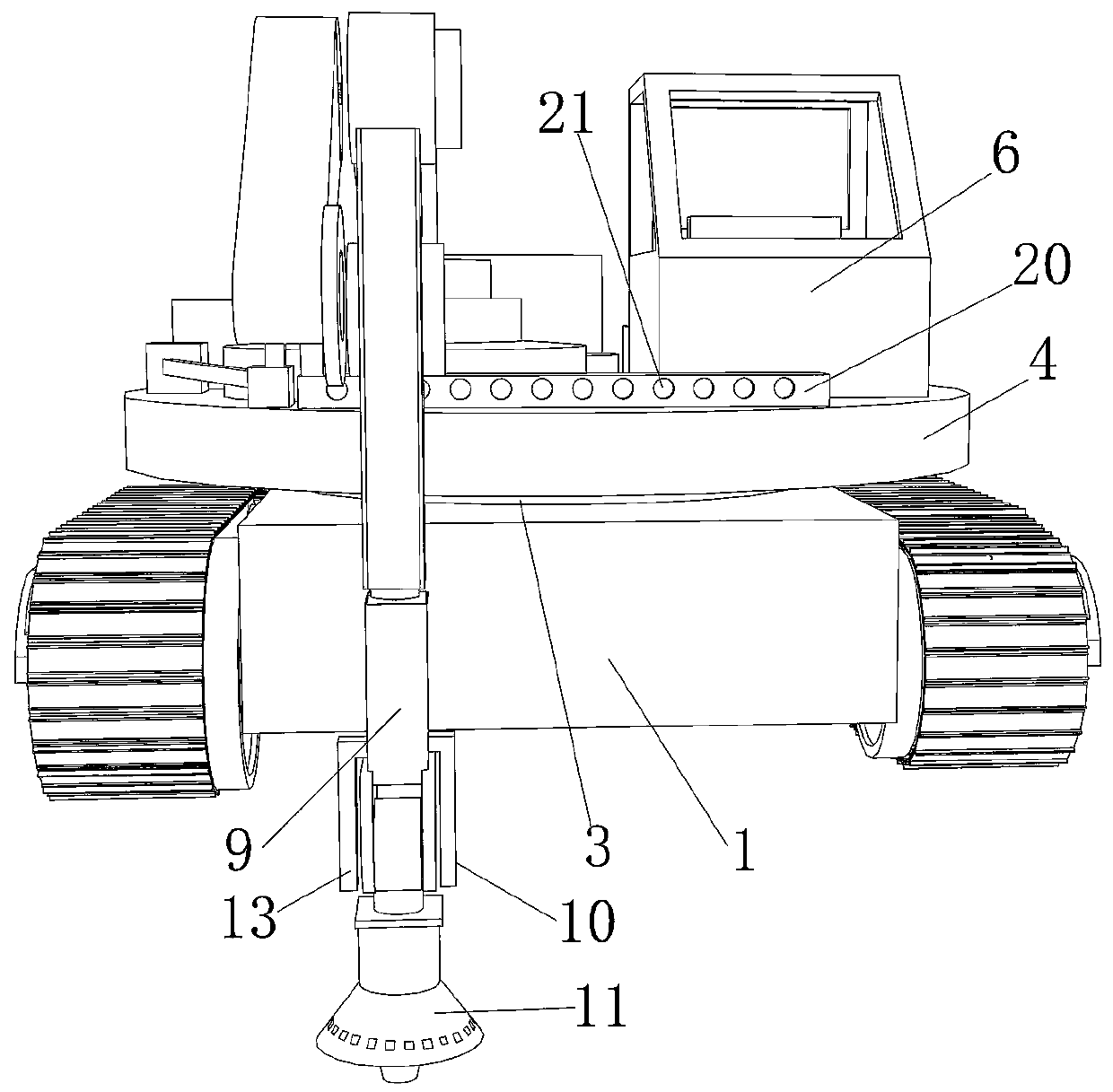

Dust removing system for fully-mechanized coal mining workface

PendingCN107218074AImprove working environmentReduce dust concentrationDust removalFire preventionMining engineeringDust control

The invention discloses a dust removing system for a fully-mechanized coal mining workface. The system includes a dust control system installed on one side of a roadheader, a dust suction system and a dust collecting system installed on the other side of the roadheader, wherein the dust control system comprises a press-in type fan, a press-in type air duct and a wall-attached air duct which are connected with each other in turns; the dust suction system comprises a first suction hood for sucking dust on the cutting head position of the roadheader, a second suction hood for sucking dust on the insertion board position of the roadheader, a third suction hood for sucking dust on the break-of-bulk-point position of a scraper conveyor and belt conveyor, a dust suction air duct and a suction hood assembly box, and the first suction hood, the second suction hood, the third suction hood and the dust suction air duct are all connected to the suction hood assembly box; the dust collecting system comprises an extraction type air duct, a dust remover and an extraction type fan which are connected with each other in turns, and the extraction type air duct is connected to the suction hood assembly box. The dust removing system for the fully-mechanized coal mining workface can effectively control diffusing and spreading of dust in underground roadways, has a good dust suction effect and high dust collecting efficiency, and can greatly reduce the dust concentration of the fully-mechanized coal mining workface.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

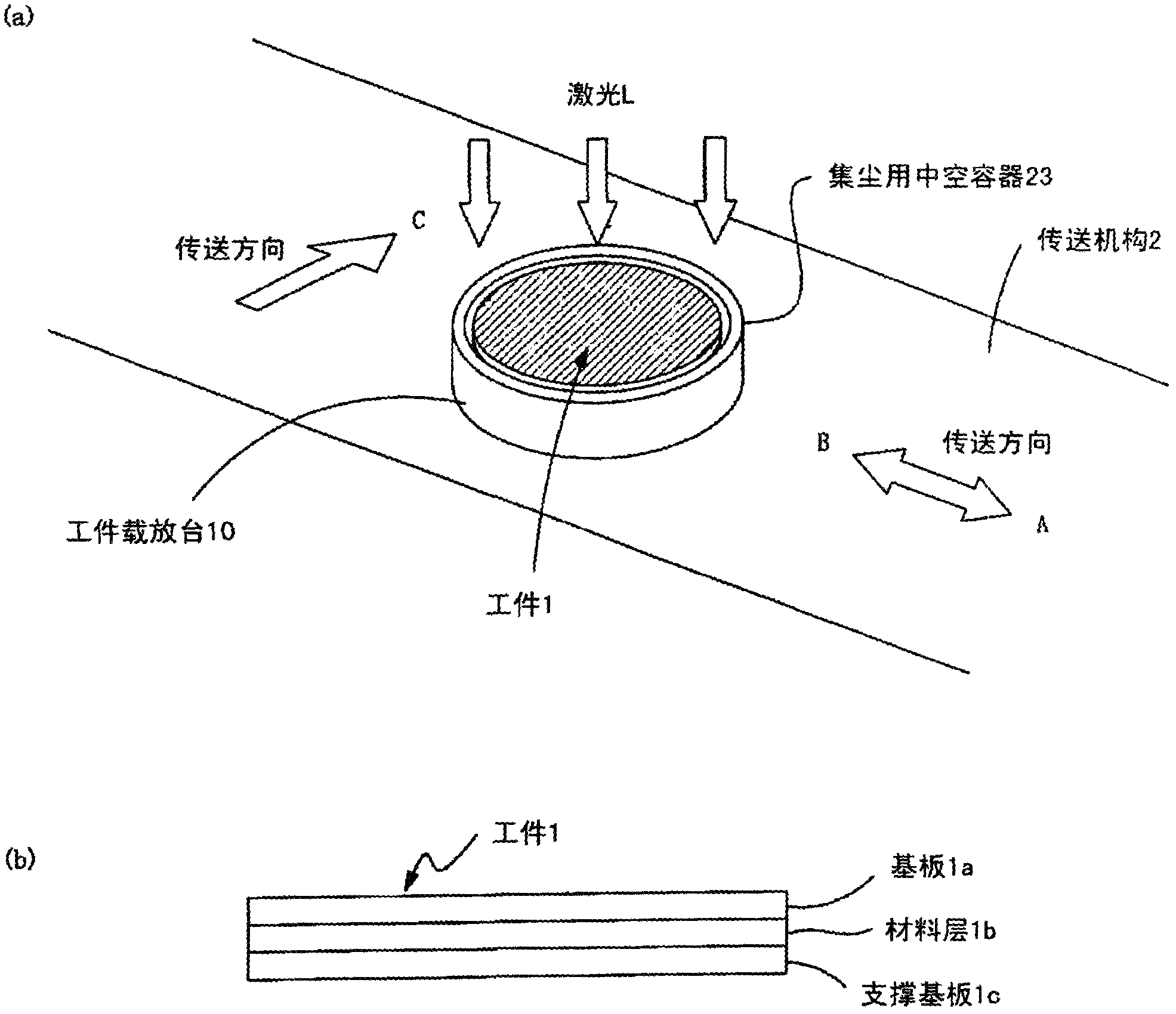

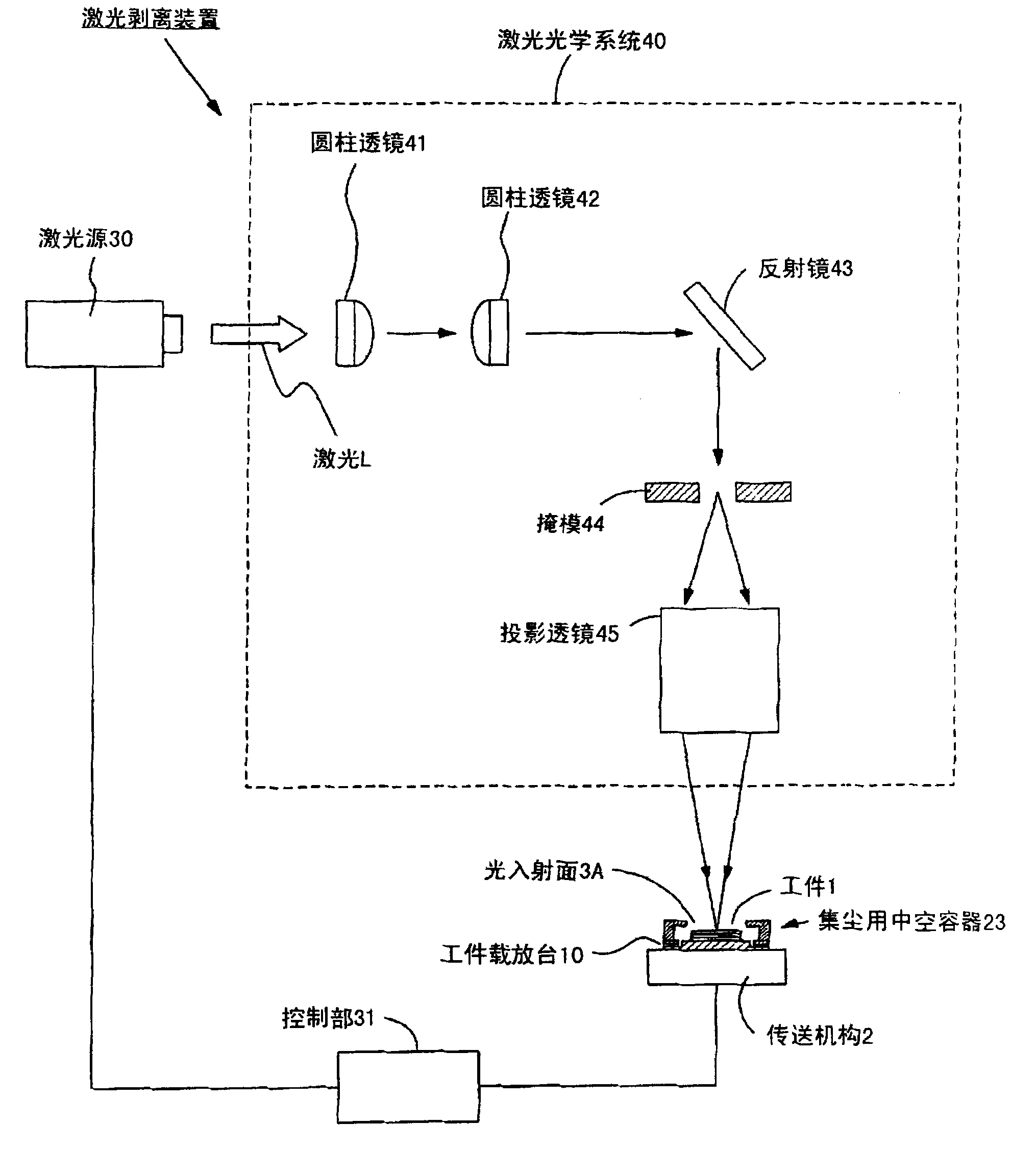

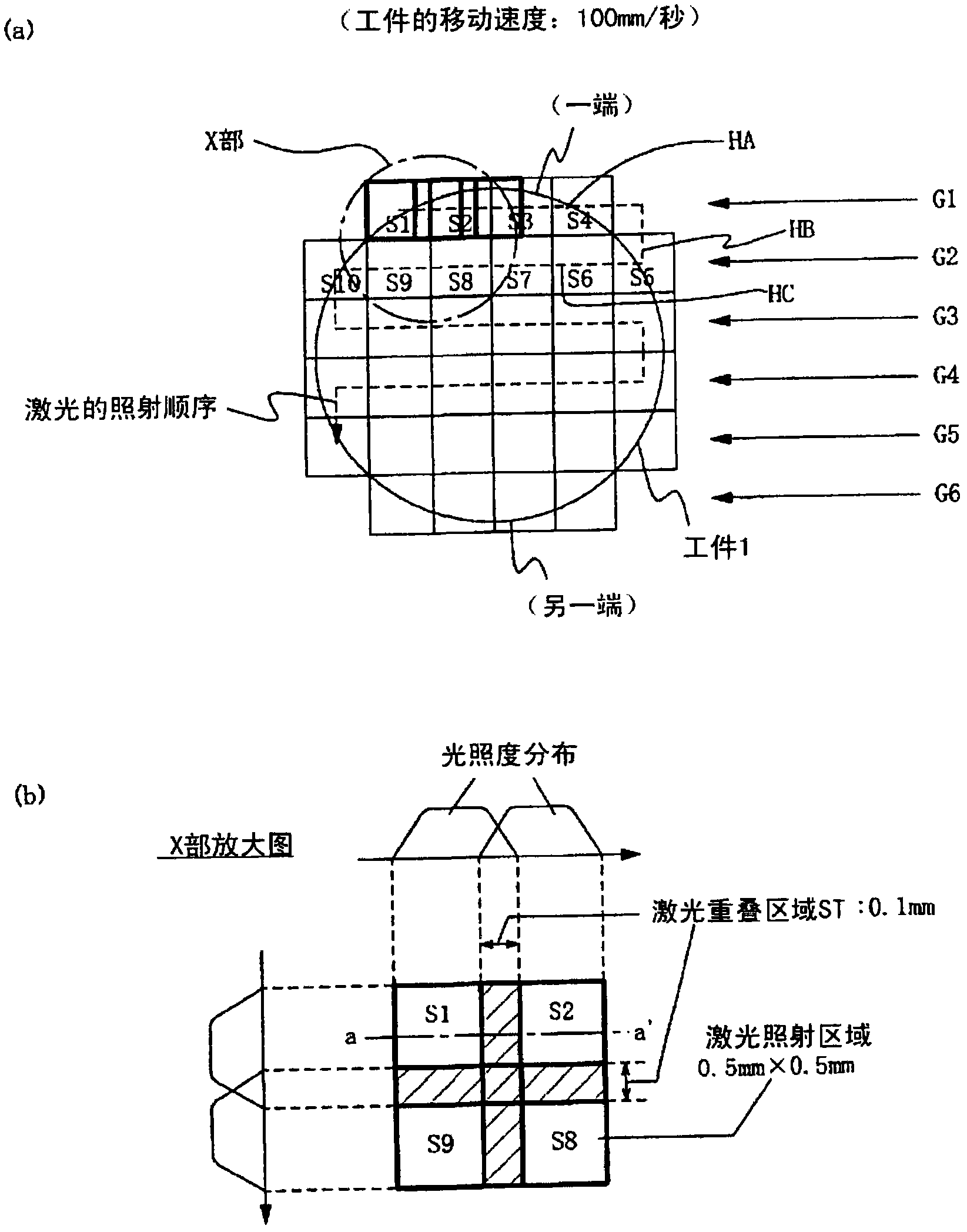

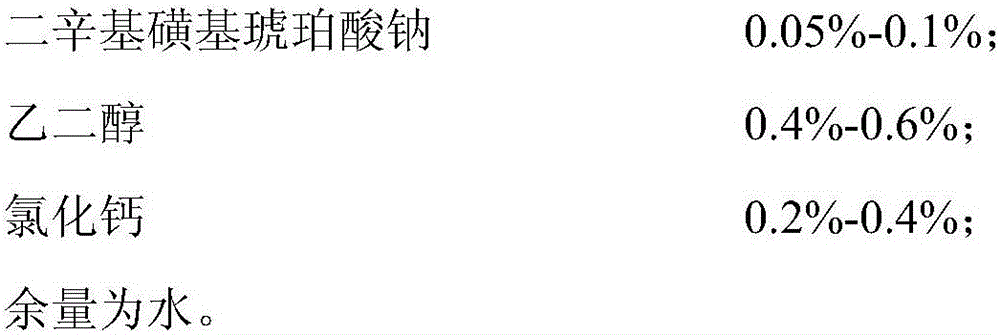

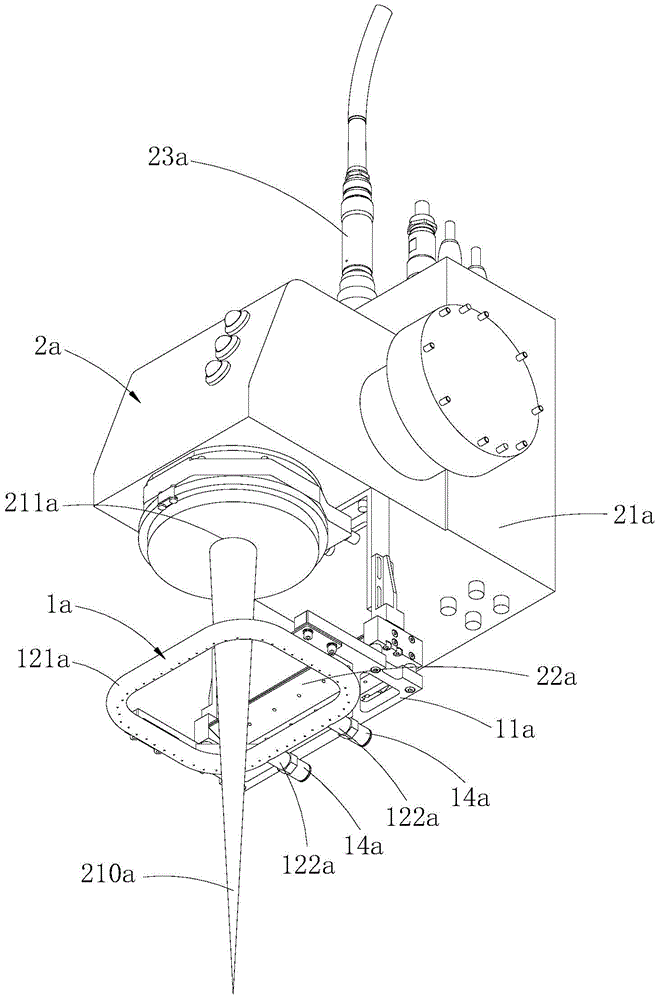

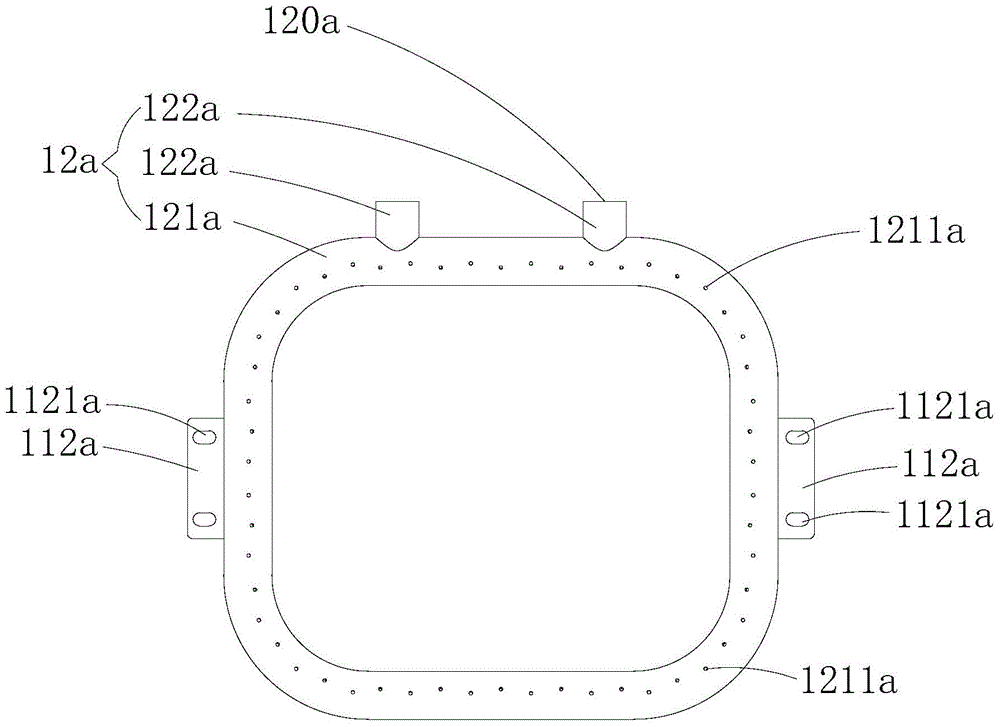

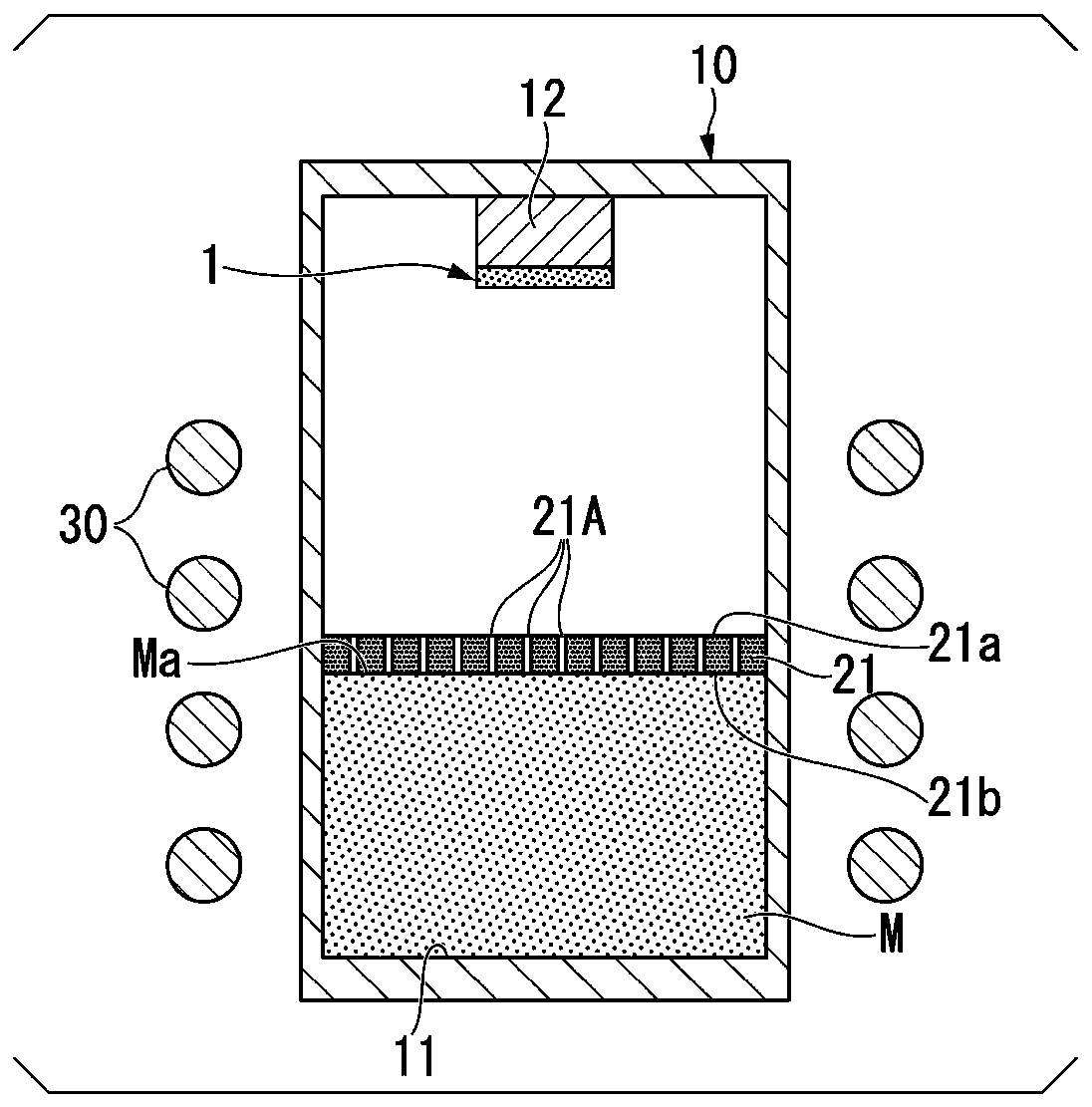

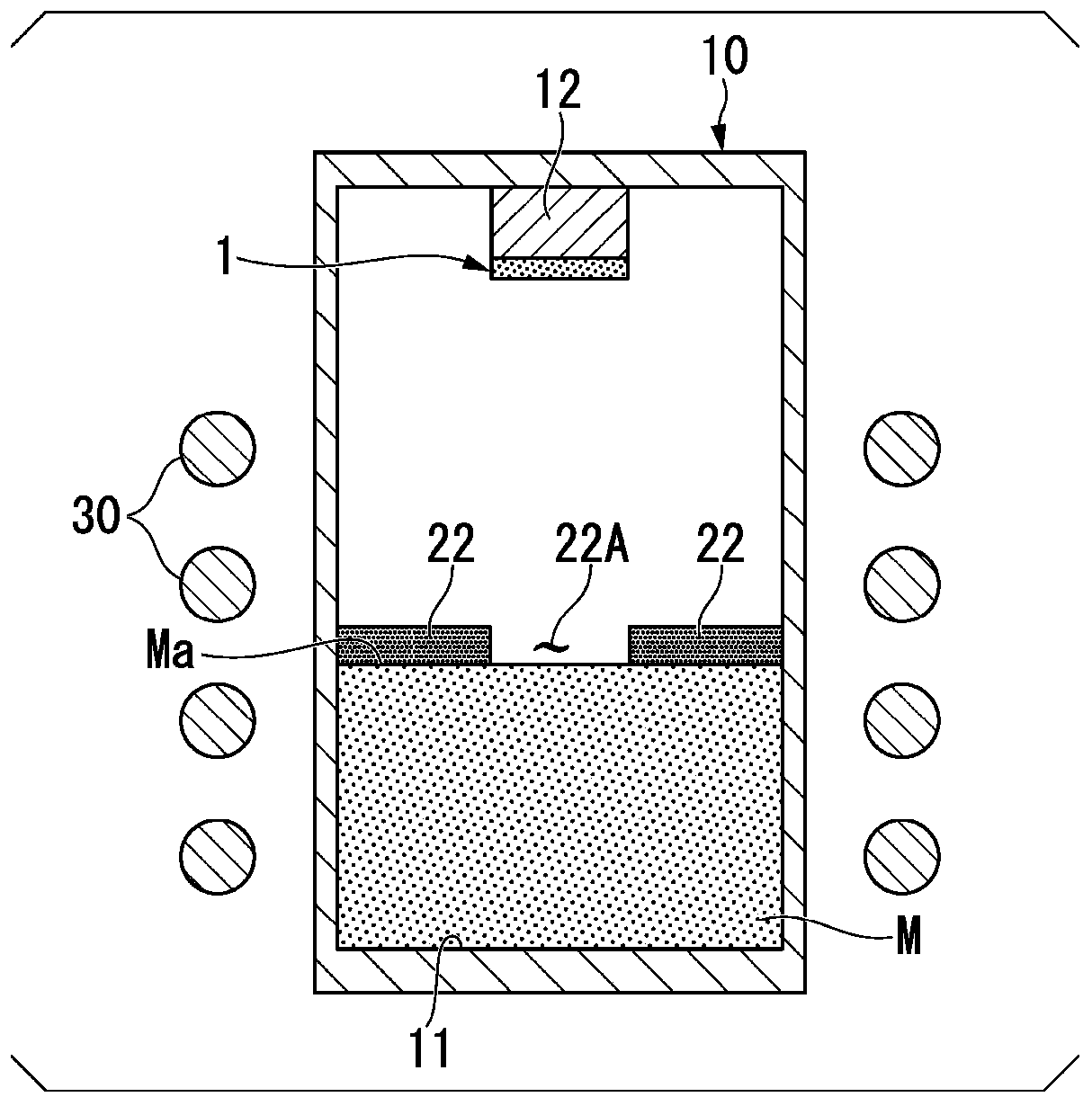

Laser lift-off device

InactiveCN102683248AEfficient collectionEliminate problems like unexploded partsSemiconductor/solid-state device manufacturingLaser beam welding apparatusEngineeringIrradiation

A laser lift-off device eliminates baneful influence of various dust particles generated from a workpiece due to laser irradiation for the workpiece. A periphery of a carrier platform part (11) of a workpiece carrier platform (10) is provided with an annular wall part (21) consisting of an annular outer wall part (21b) and a top wall part (21a). The carrier platform part (11) is provided with outlets (12) used for connecting with exhaust mechanisms at a plurality of positions. The outlets (12) absorb the air in the annular wall part (21) through tubings connected with the exhaust mechanisms such as pumps, fans, and so on. By using the laser to radiate a workpiece (1), the dust particles ejected along with gas from an edge part of the workpiece (1) towards inner spaces (A) divided by the annular outer wall part (21b) and the top wall part (21a) are discharged from the outlets (12) provided on the carrier platform part (11) through flow of fluid towards the outlets (12).

Owner:USHIO DENKI KK

Water-based dust depressor and preparation method thereof

InactiveCN104693339AImprove securityAvoid the decrease of wind erosion resistanceOther chemical processesWater basedAqueous solution

The invention provides a water-based dust depressor and a preparation method thereof. The dust depressor is prepared through water solution copolymerization, the dust depressor comprises 6-25 parts of unsaturated acid; 2-10 parts of unsaturated esters; 0.1-0.5 part of cross-linking agent; 0.1-2.0 parts of initiating agent and 100 parts of water; the raw materials further comprise antalkali, and the quantity of the antalkali adjusts the pH value of a reaction system to 6.0-9.0. The dust depressor is prepared by the unsaturated acid and the unsaturated esters through the water solution copolymerization technology, a shell layer can be formed on the surface of a dust particle, a good moisturizing function and a dust depressing function are achieved, and an obtained product contains neither volatile low-molecular compounds nor corrosive high valence metal ions. The prepared chemical dust depressor can be used by being diluted with water and sprayed, the comprehensive performance is good, and the safety and environmental protection are achieved.

Owner:HEBEI UNIV OF TECH

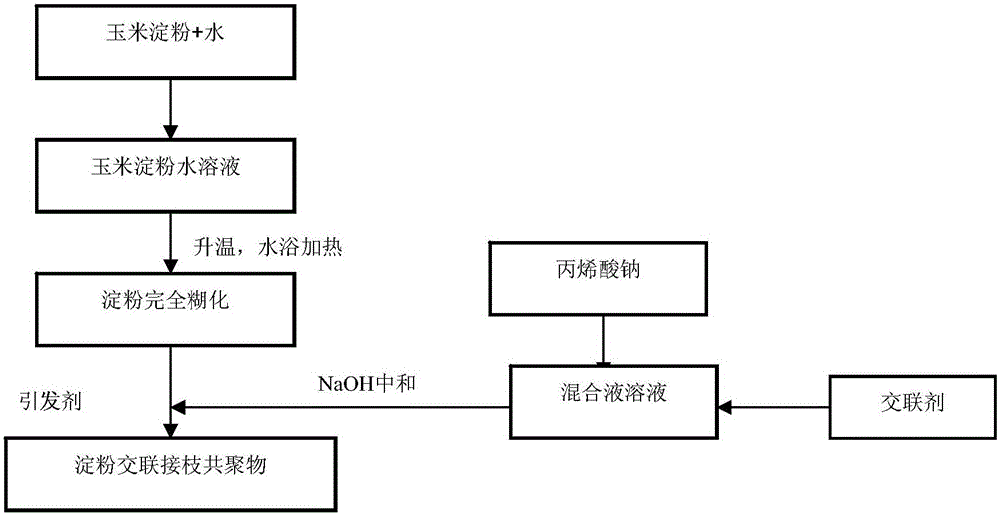

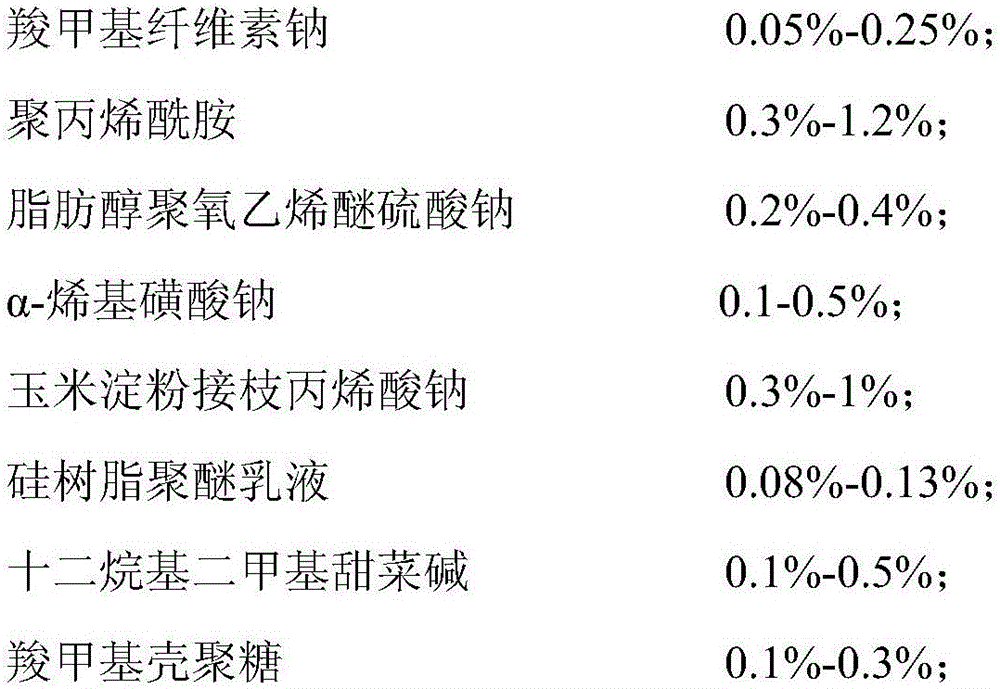

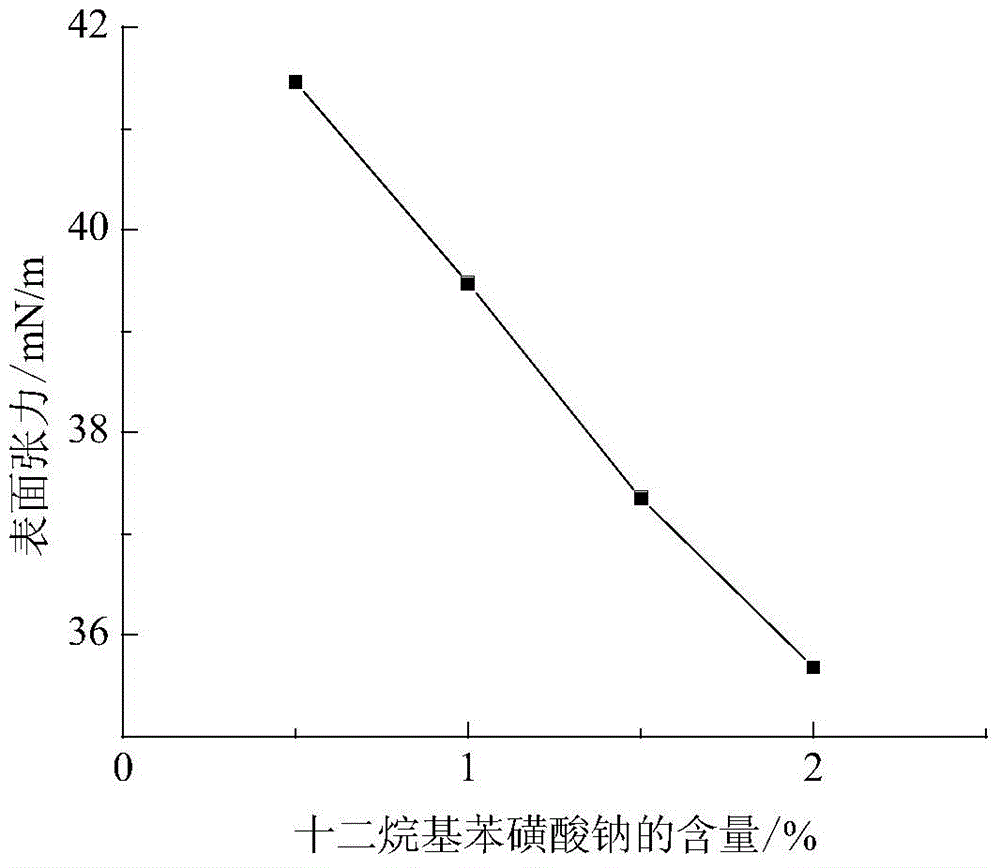

Wetting agent capable of inhibiting dust flying

ActiveCN105860933AReduce surface tensionImprove wettabilityOther chemical processesTransportation and packagingCorn starchSodium carboxymethylcellulose

The invention discloses a wetting agent capable of inhibiting dust flying. The wetting agent comprises 0.05-0.25% of sodium carboxymethyl cellulose, 0.3-1.2% of polyacrylamide, 0.2-0.4% of polyoxyethylene fatty alcohol sodium sulfate, 0.1-0.5% of sodium alpha-alkenylsulfonate, 0.3-1% of corn starch grafted sodium acrylate, 0.08-0.13% of silicone resin polyether emulsion, 0.1-0.5% of dodecyldimethylbetaine, 0.1-0.3% of carboxymethyl chitosan, 0.05-0.1% of dioctyl sodium sulphosuccinate, 0.4-0.6% of ethanediol, 0.2-0.4% of calcium chloride and the balance of water. The sprayed fog drops can quickly capture and wrap the dust particles, thereby increasing the particle settling speed. The sprayed fog drops can be covered on the dust on the coal rock surface and ground surface to prevent secondary flying dust, thereby enhancing the dust removal efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

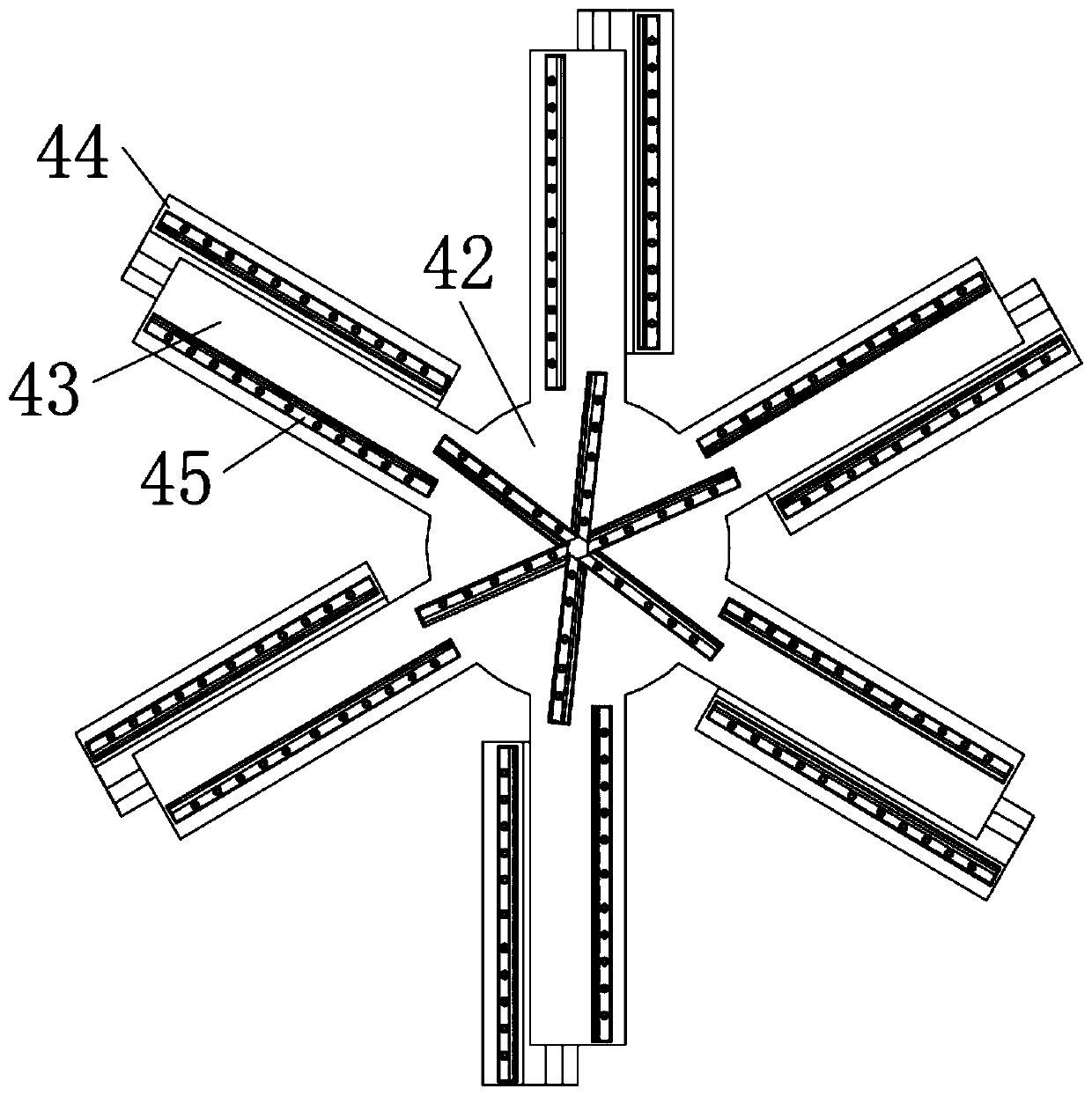

Composite hygroscopic and moisture-retention type inhibitor for small-particle-size flying dust and preparation method of composite hygroscopic and moisture-retention type inhibitor

InactiveCN106479101AGood moisturizing effectSuppresses flying dustOther chemical processesMoisture retentionDouble bond

The invention discloses a composite hygroscopic and moisture-retention type inhibitor for small-particle-size flying dust and a preparation method of the composite hygroscopic and moisture-retention type inhibitor. The composite hygroscopic and moisture-retention type inhibitor comprises 20-30% of high-molecular polymers, 1-5% of hygroscopic agent, 5-15% of xylogen additives and 50-60% of water. The preparation method includes the steps of heating water and a telomere to about 80 DEG C, dropping unsaturated double bond contained vinyl monomers and an initiator respectively with continuous stirring, refluxing for 0.5-1 hour, adding the xylogen additives, the hygroscopic agent and the like, stirring for 20-40 minutes, cooling, and aging to obtain uniform liquid inhibitor. The composite dust inhibitor is high in hygroscopicity, moisture retention property and water solubility and capable of improving air quality and living environment remarkably by effectively inhibiting particles of different sizes on the ground from entering into air.

Owner:NANJING UNIV OF SCI & TECH

Variable-focus laser welding equipment, blowing protecting device thereof and blowing protecting method

ActiveCN104942436AQuality improvementImprove efficiencyLaser beam welding apparatusOptoelectronicsExhaust pipe

The invention is applicable to the technical field of laser welding, and discloses a variable-focus laser welding blowing protecting method, a variable-focus laser welding blowing protecting device and variable-focus laser welding equipment with the blowing protecting device. The variable-focus laser welding blowing protecting device is arranged on a side with a focusing lens of a variable-focus laser welding head, is used for restraining smoke and plasmas from flying towards the side with the focusing lens in a variable-focus laser welding process and comprises a connecting support, an exhaust pipe and a gas supplying component for delivering gas to the inside of the exhaust pipe; the exhaust pipe is provided with a hollow inner cavity, a gas inlet and a plurality of exhaust holes; and the exhaust holes are formed in a wall surface, which backs on to the variable-focus laser welding head, of the exhaust pipe. The technical problem that smoke and plasmas which are generated when a variable-focus laser welding technology is applied to work pieces with complex surface structures such as sheet metal parts of a body in white of an automobile affect laser welding quality and welding efficiency greatly is solved.

Owner:HANS LASER TECH IND GRP CO LTD

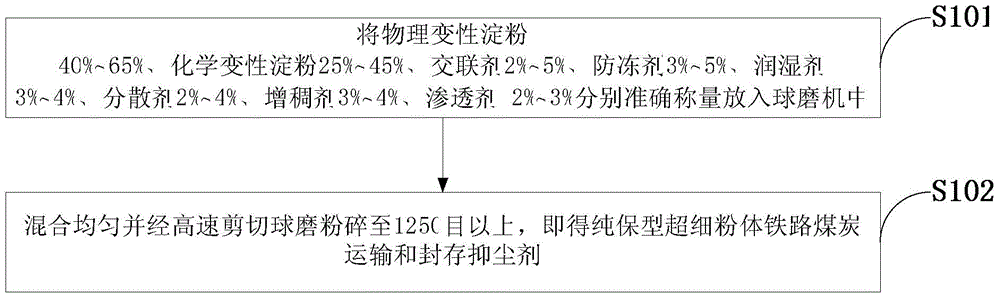

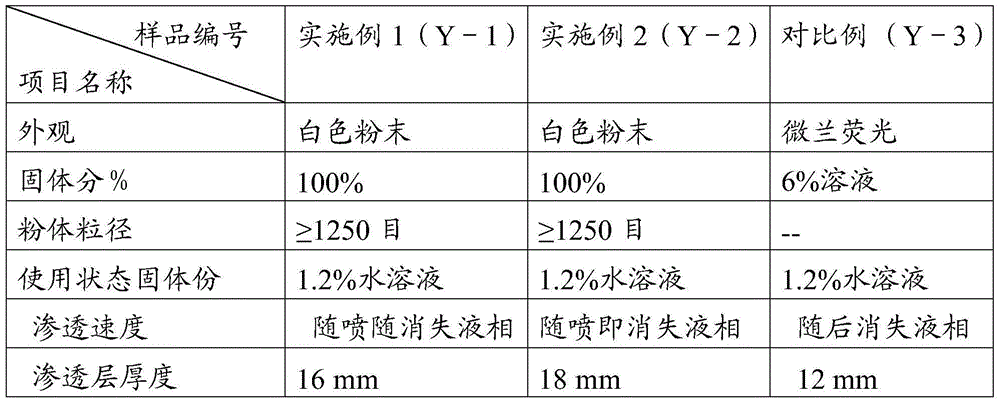

Environment-friendly superfine powder railway coal transportation and storage dust suppressant and preparation method

InactiveCN103980860ASuppress flyingImprove wettabilityOther chemical processesAnti freezingCross linker

The invention discloses an environment-friendly superfine powder dust suppressant for railway coal transportation and storage and a preparation method. The environment-friendly superfine powder dust suppressant for railway coal transportation and storage comprises the following components in percentage by weight: 40-65% of physical modified starch, 25-45% of chemical modified starch, 2-5% of cross linker, 3-5% of anti-freezing agent, 3-4% of wetting agent, 2-4% of dispersant, 3-4% of thickener and 2-3% of penetrating agent. The preparation method for the environment-friendly superfine powder dust suppressant for railway coal transportation and storage comprises: weighing the components of the dust suppressant in percentage by weight respectively and putting the components into a ball mill; and mixing uniformly and performing high-speed shear ball milling to above 1,250 meshes, thus obtaining the environment-friendly superfine powder dust suppressant for railway coal transportation and storage. The superfine powder material is prepared by compounding the physical modified starch and the chemical modified starch, adding an inorganic gel material and adding multiple aids, and has the construction effects of good coal bed wetting effect, thick pervious bed, high curing speed, large setting strength of the pervious bed and good dust suppression effect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

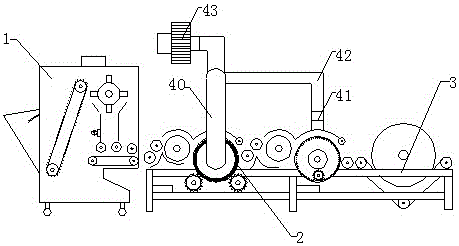

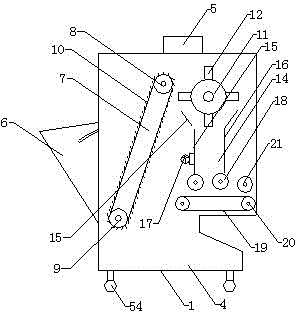

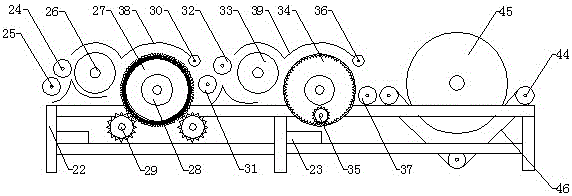

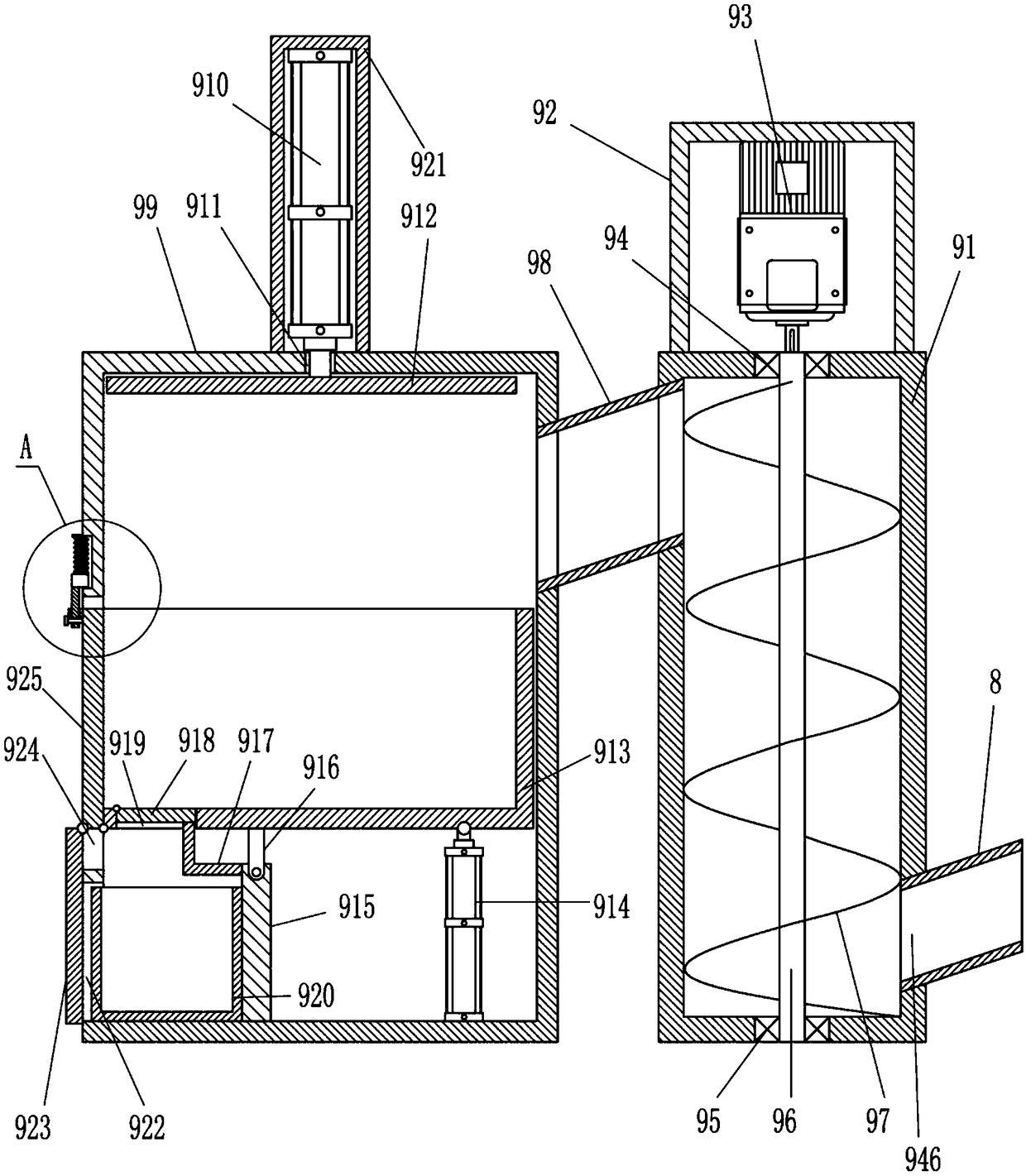

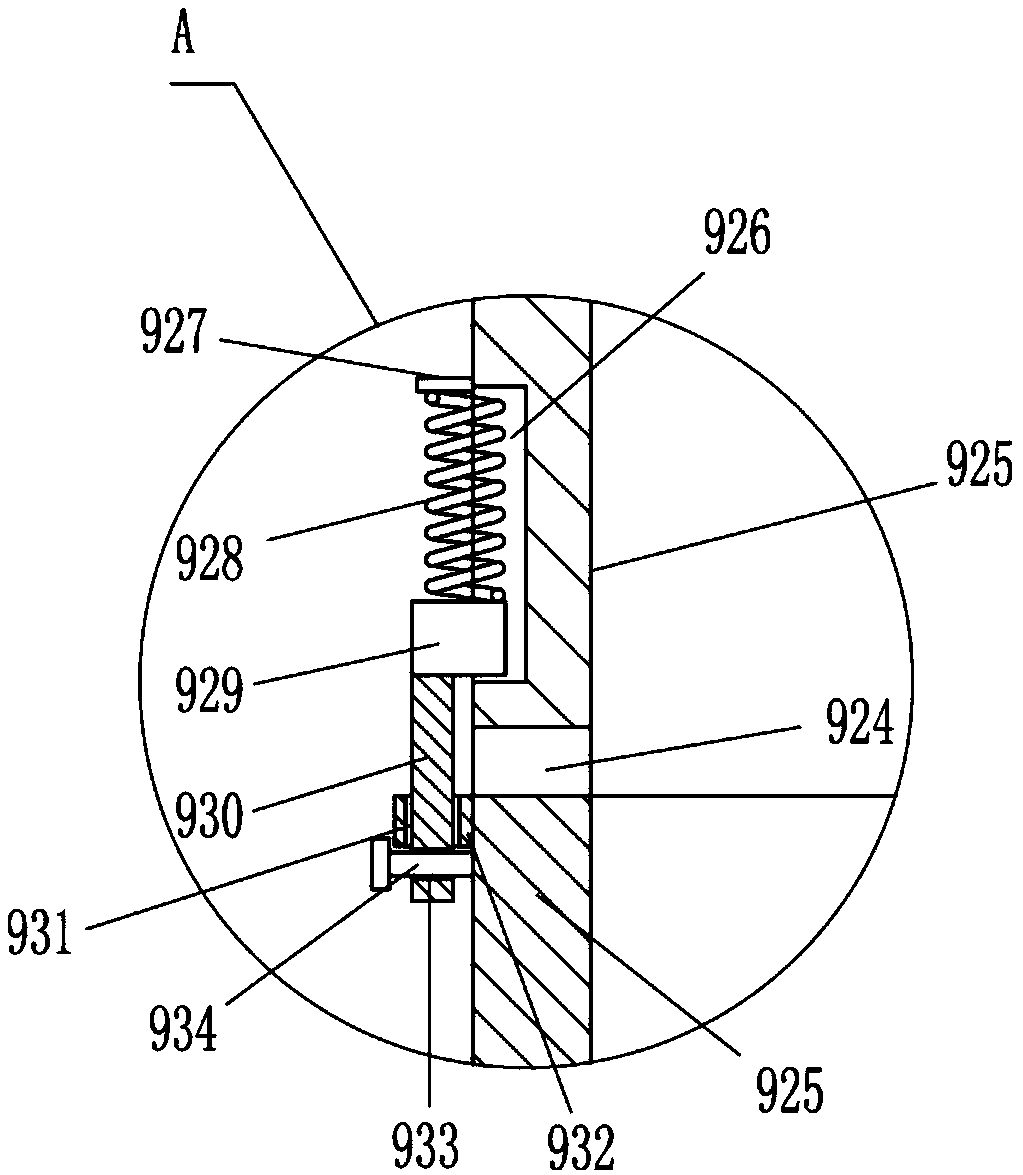

Highly-efficient cotton fluffer

InactiveCN105040169AGuaranteed cleanlinessEnsure cleanlinessFibre cleaning/opening by toothed membersFibre cleaning/opening machinesAgricultural engineeringAgricultural science

The invention belongs to the technical field of textile equipment and relates to a highly-efficient cotton fluffer. The highly-efficient cotton fluffer comprises an automatic cotton-feeding device, a cotton-carding device and a cotton-collecting device. Compared with a conventional cotton-feeding device, the automatic cotton-feeding device is more mechanized so that input of manual power is greatly reduced and helps to ensure personal safety of operators and achieve automated cotton-feeding with great safety factor. The automatic cotton-feeding device is connected with the cotton-carding device in order to realize synchronous drive. Double licker-in roller devices and double dust cage devices are employed by the cotton-carding device and used for carding cotton and dedusting twice in one process in order to satisfy requirements for high quality and high cleanliness. The cotton-collecting device located at the tail end adopts a cotton-accumulating drum to automatically collect cotton under drive of a driving belt so that cotton collection without manual labor is realized, thereby greatly saving manpower of a company. Additionally, cost of production and manufacture of the company is decreased. As a whole, the highly-efficient cotton fluffer is advantaged by being reasonable in structure layout, high in working efficiency, great in safety factor of manufacture and production and in cotton cleanliness and few in input of manpower.

Owner:HENAN XINPUFENG COTTON GIN TECH CO LTD

Modified gelatin dust suppressant and preparation method thereof

A modified gelatin dust suppressant and a preparation method thereof relate to a dust suppressant and a preparation method thereof; the dust suppressant comprises the following raw materials by weight percent: 2%-10% of industrial gelatin, 60-99% of water, 2%-10% of inorganic acid, 0-10% of surfactant, 0-10% of crosslinking agent, 0.01%-5% of sodium hydroxide and 0-5% of emulsifier. The preparation method comprises the following steps: adopting inorganic acid to degrade industrial gelatin at 20-80 DEG C for 2-15h, then using sodium hydroxide to neutralize the product and obtaining the finished product. According to different dust compositions and properties in different places, the degraded gelatin is used for wetting and penetrating tests and surfactant is added to increase the wetting and penetrating effect to different dusts. The dust suppressant of the invention is applicable to road surfaces, parks, construction site, scattered stock ground, mineral fields, coal dumps, ports and other operational areas which are easy to generate dust; after being dissolved in water and sprayed out, the dust suppressant can increase the coagulation of dust and inhibit the dispersion and movement of dust particles.

Owner:SHENYANG JIANZHU UNIVERSITY

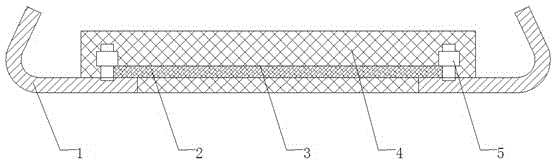

Tension type screen and production technology

A tension type screen comprises tension hooks, a steel wire rope, cold-drawn steel wires, polyurethane and screws. A production technology of the tension type screen comprises the steps of skeleton fabrication, treatment of abrasive blasting, degreasing and coating on a skeleton, mold preparation, detection and correction of a formula, screen pouring, demolding, repairing, inspection and finished product packing. The tension type screen has the advantages of being resistant to abrasion, oil, aging, tear and impact, high in elasticity, strong in shock absorption, large in load support capacity and the like; compared with a metal screen, a polyurethane screen is light in weight, high in screening efficiency, not prone to hole blocking, resistant to abrasion, impact and tear, long in service life, low in noise, convenient to install and high in comprehensive benefits.

Owner:ANHUI LONGCHUAN RUBBER & PLASTIC TECH CO LTD

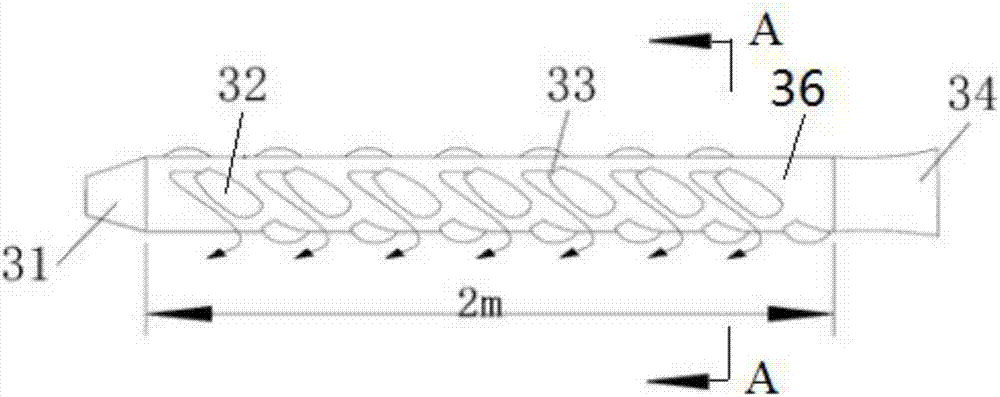

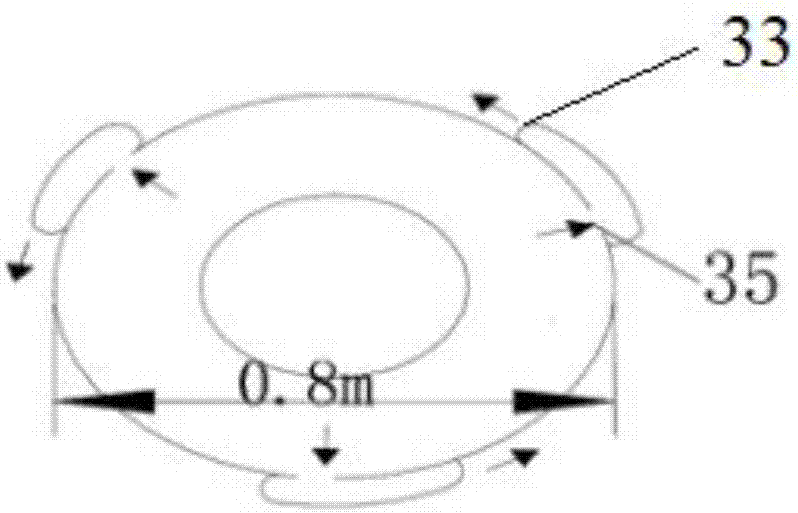

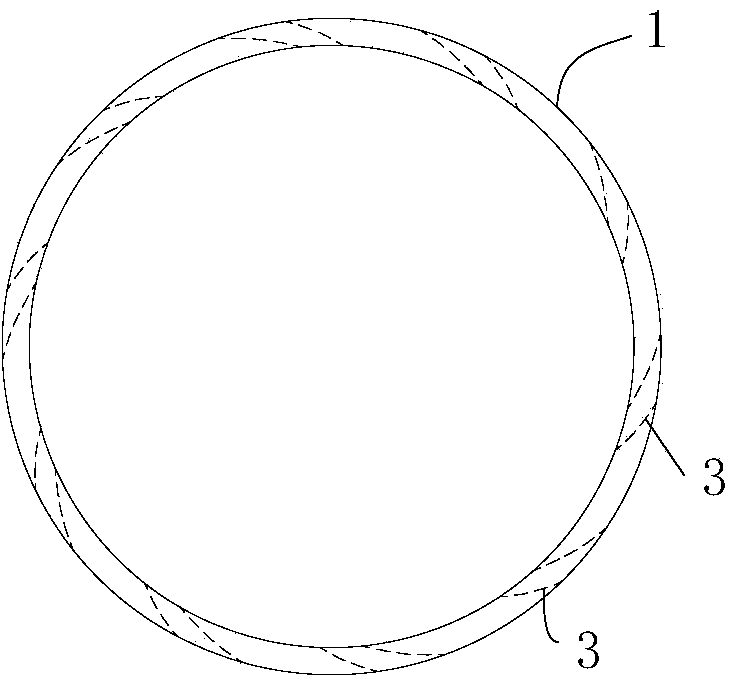

Wall-attached air duct

ActiveCN103912300ASuppress flyingStop the spreadTunnel/mines ventillationPulp and paper industryCoal

The invention provides a wall-attached air duct which comprises a duct body. One end of the duct body is an air inlet while the other end of the same is an air outlet, an air retaining plate is arranged in the duct body, and multiple lateral air outlets are arranged on the duct body spirally and all positioned between the air inlet and the air retaining plate. A tunneling working face provided with a press-in-type ventilation system and a foam or spray dedusting system is adopted in a coal mine; by arranging the air retaining plate inside the duct body, when airflow passes through the air retaining plate inside the duct body, a part of the airflow can be diverted to flow towards the lateral air outlets, the airflow becomes spiral airflow through the lateral air outlets which are spirally arranged to blow to the working face at low speed, fresh airflow blows to the working face at low speed to inhibit dust flying, an air curtain is formed around the working face to stop dust-containing airflow of the working face from spreading outwards and effectively prevent gas from gathering, and the air retaining plate can adjust air quantity. The wall-attached air duct is easy to process and convenient to mount.

Owner:HUAINAN MINING IND GRP

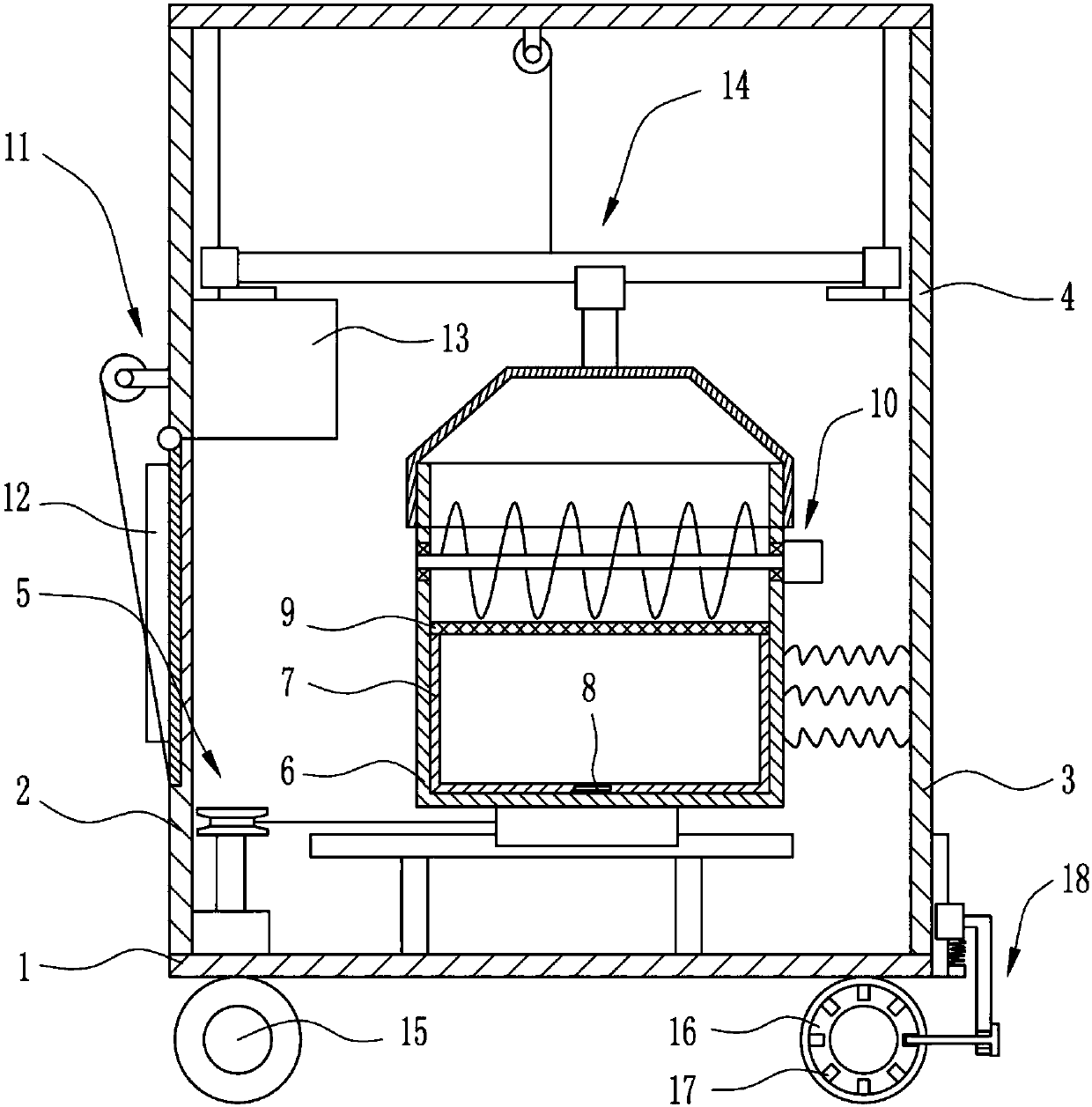

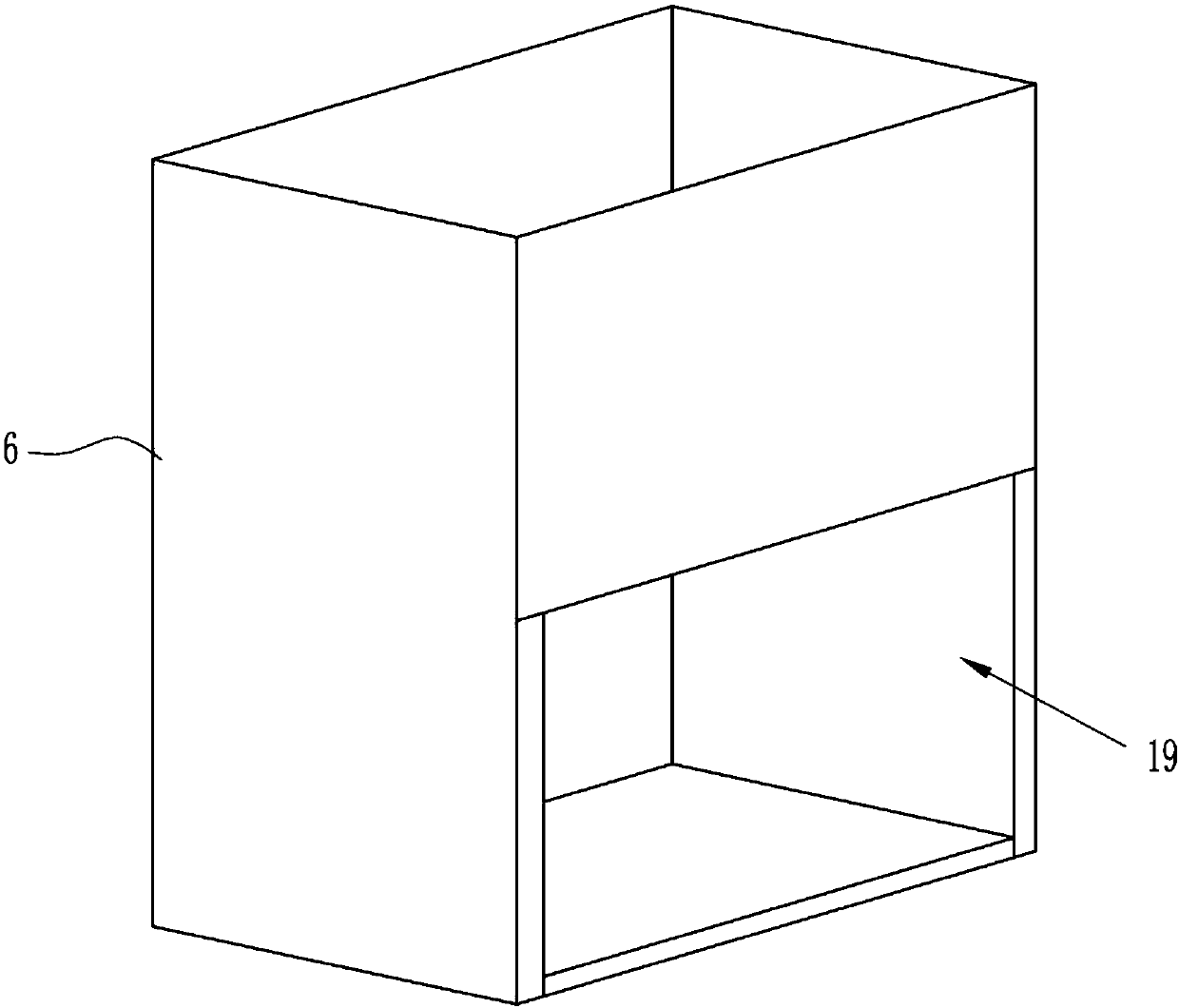

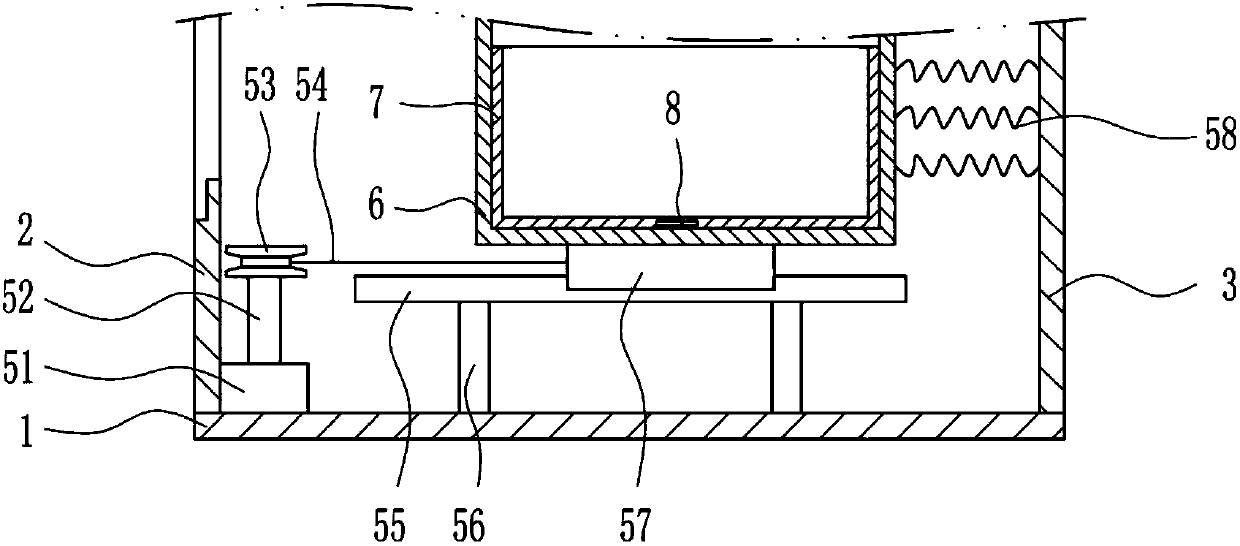

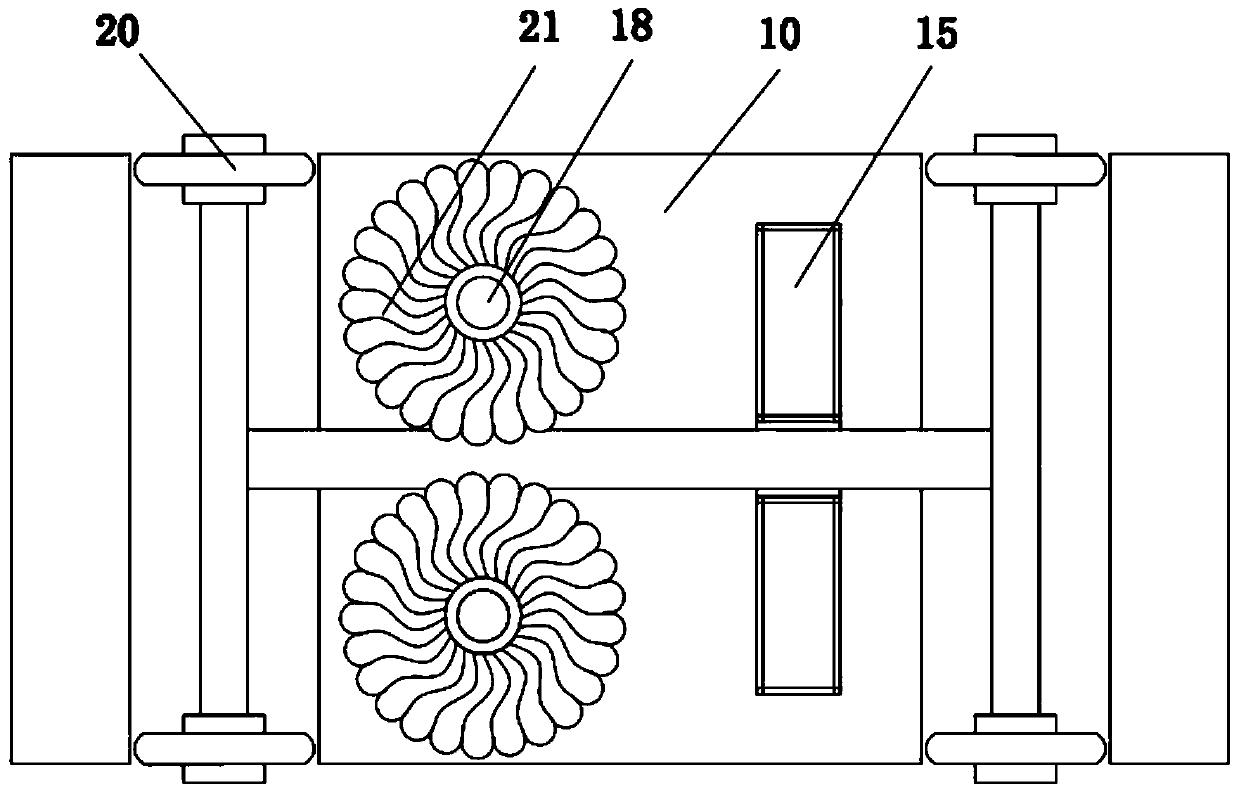

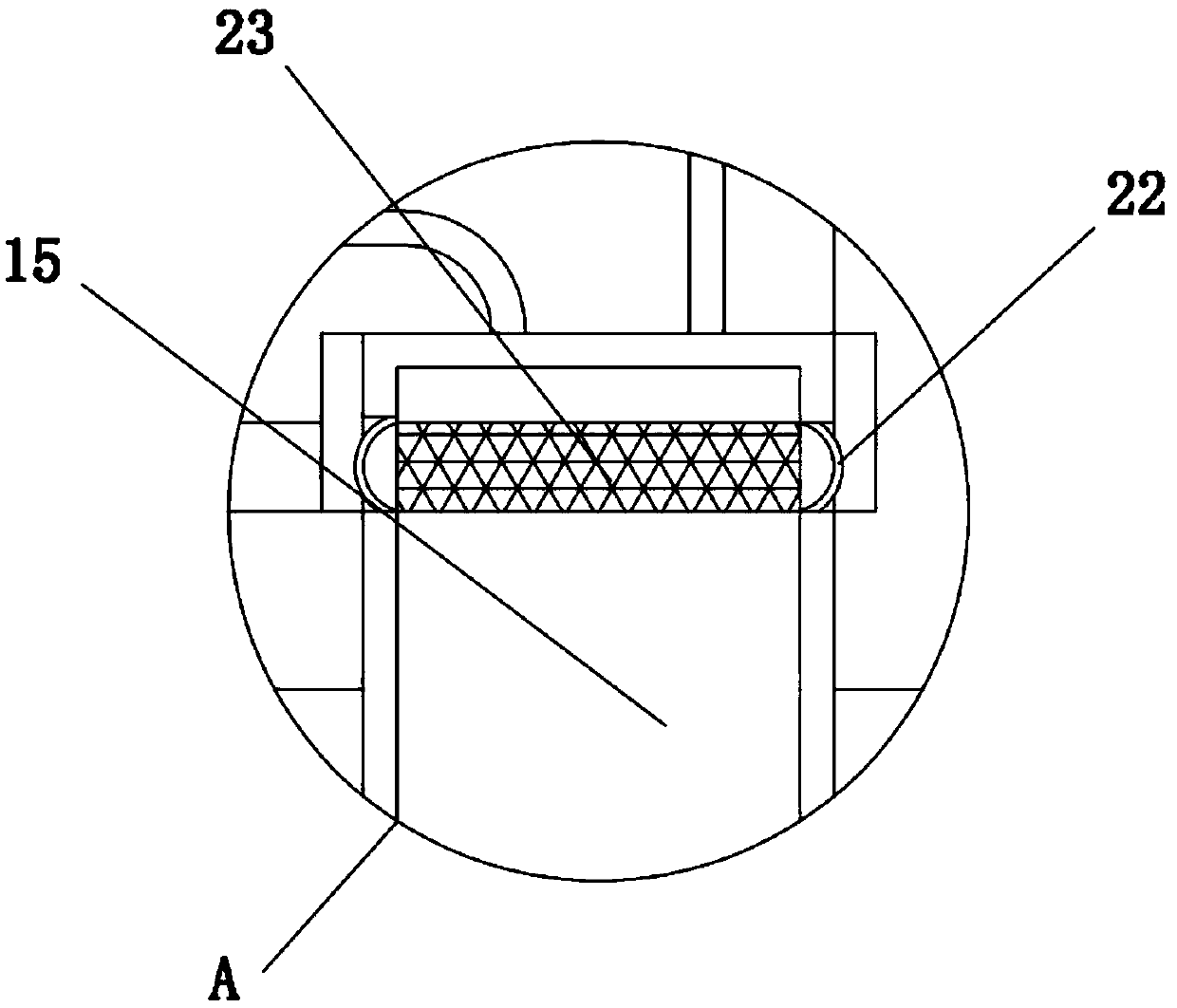

Energy-saving and environment-friendly factory production device

The invention relates to a production device, in particular to an energy-saving and environment-friendly factory production device, and aims at achieving the technical purpose of providing the energy-saving and environment-friendly factory production device capable of restraining flying of powdery products. To achieve the above technical purpose, the energy-saving and environment-friendly factoryproduction device is provided and comprises a first installing plate, a second installing plate, a third installing plate, a fourth installing plate, a vibration mechanism, a containing frame, a collecting frame, a handle, a screen plate, a breaking mechanism, an auxiliary mechanism, a solar panel, a storage battery, a dustproof mechanism, wheels, a circular installing plate and a fixing mechanism, and the second installing plate is fixedly connected to one end of the top of the first installing plate. The energy-saving and environment-friendly factory production device achieves the effect ofrestraining flying of the powdery products.

Owner:JIANGXI MINGHUI ENVIRONMENTAL PROTECTION TECH CO LTD

Integrated cleaning trolley with functions of sprinkling cleaning and drying

InactiveCN109620058AConvenience for later centralized processingEasy to disassemble and operateCarpet cleanersFloor cleanersSuction forceAir blower

The invention relates to an integrated cleaning trolley with functions of sprinkling cleaning and drying. The trolley includes a suction head, a trolley body and wheels. The upper end of the suction head is provided with a dust suction channel, an air pump is fixed at the upper end of the dust suction channel, the trolley body is arranged on the right side of a water tank, the right end of the trolley body is fixedly provided with a handle, and the wheels are installed at the lower end of the trolley body. According to the integrated cleaning trolley with the functions of sprinkling cleaning and drying, when the air pump is in work, large suction force is provided for the suction head, the suction head can absorb dust in a place where the suction head passes through, dust is transferred into a dust removal chamber through the dust suction channel, late concentrated processing is facilitated, an electric wire is clamped in a hot air cavity through a clamp groove, and maintenance and disassembly can be facilitated. When an air blower works, air from the air blower becomes hot after being heated by the electric wire, the hot air can dry the ground below a hot air cavity, and the situation is avoided that water is accumulated on the ground and pedestrians are easy to slip.

Owner:ANHUI UNIV OF SCI & TECH

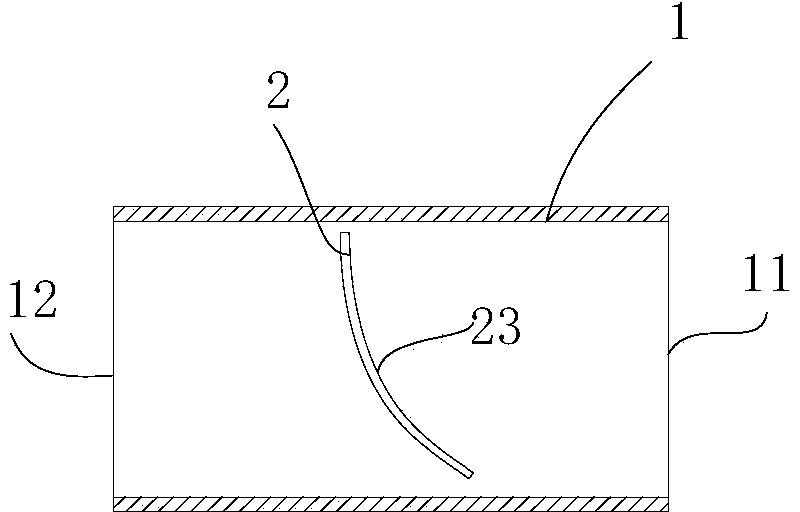

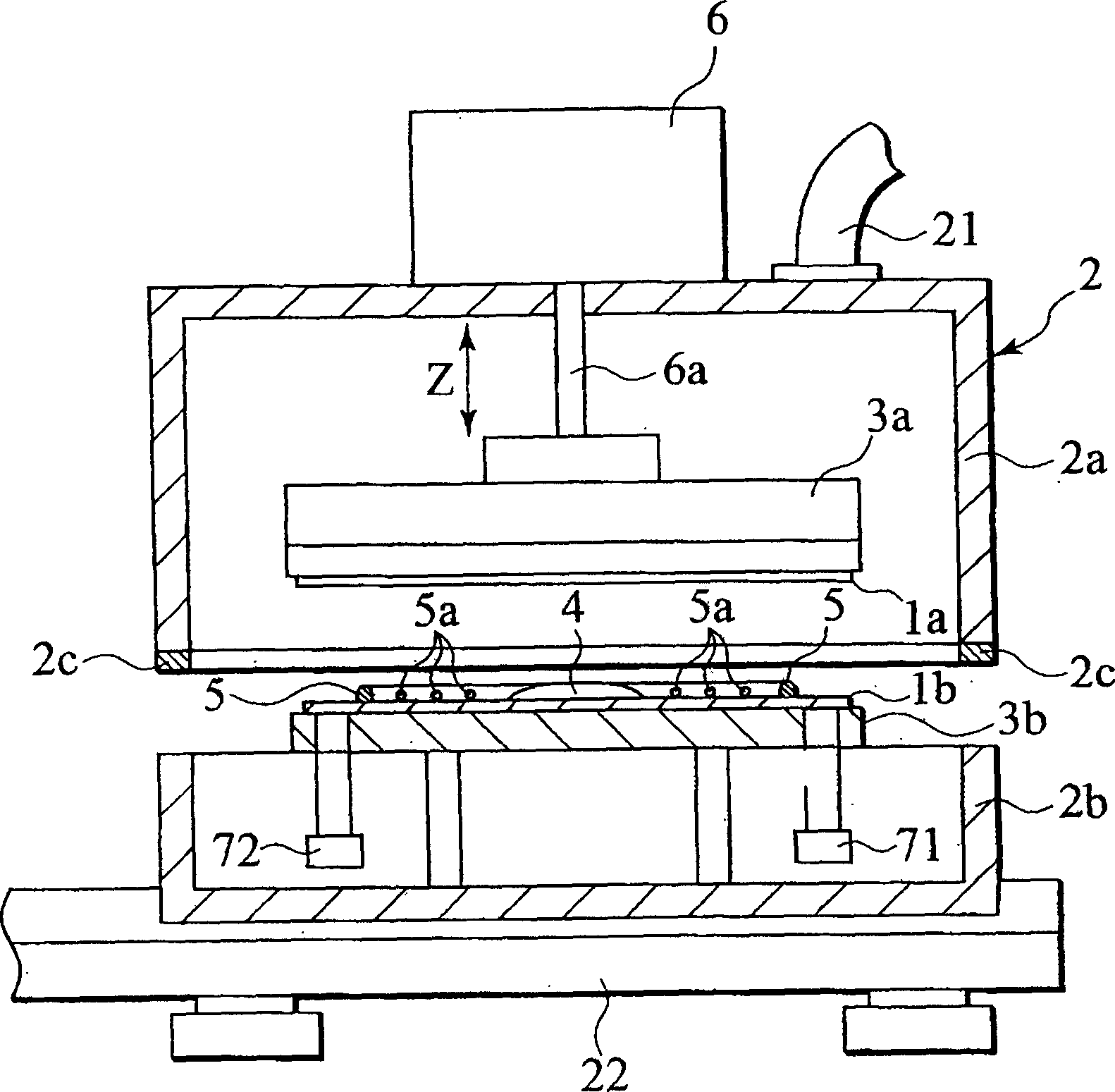

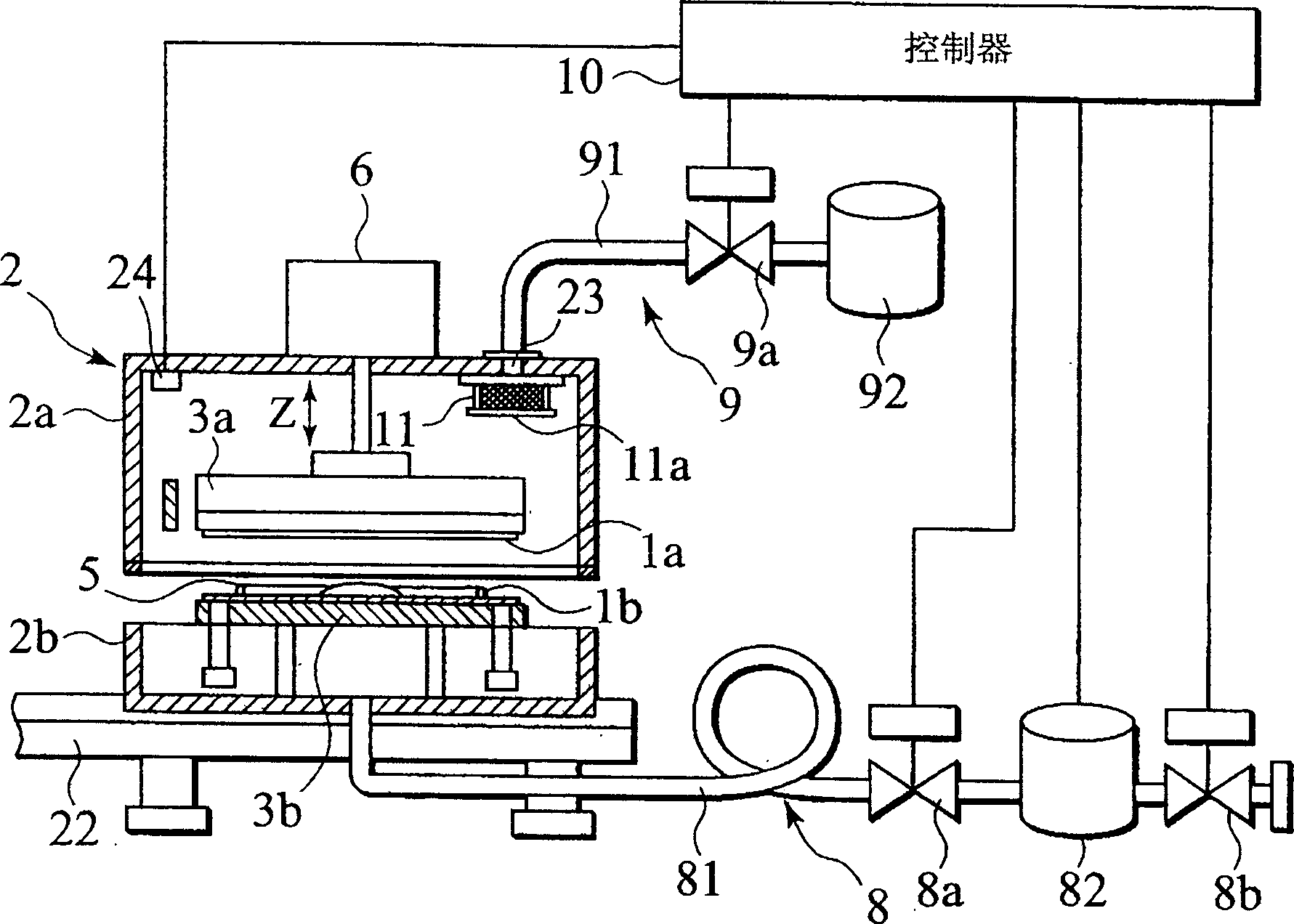

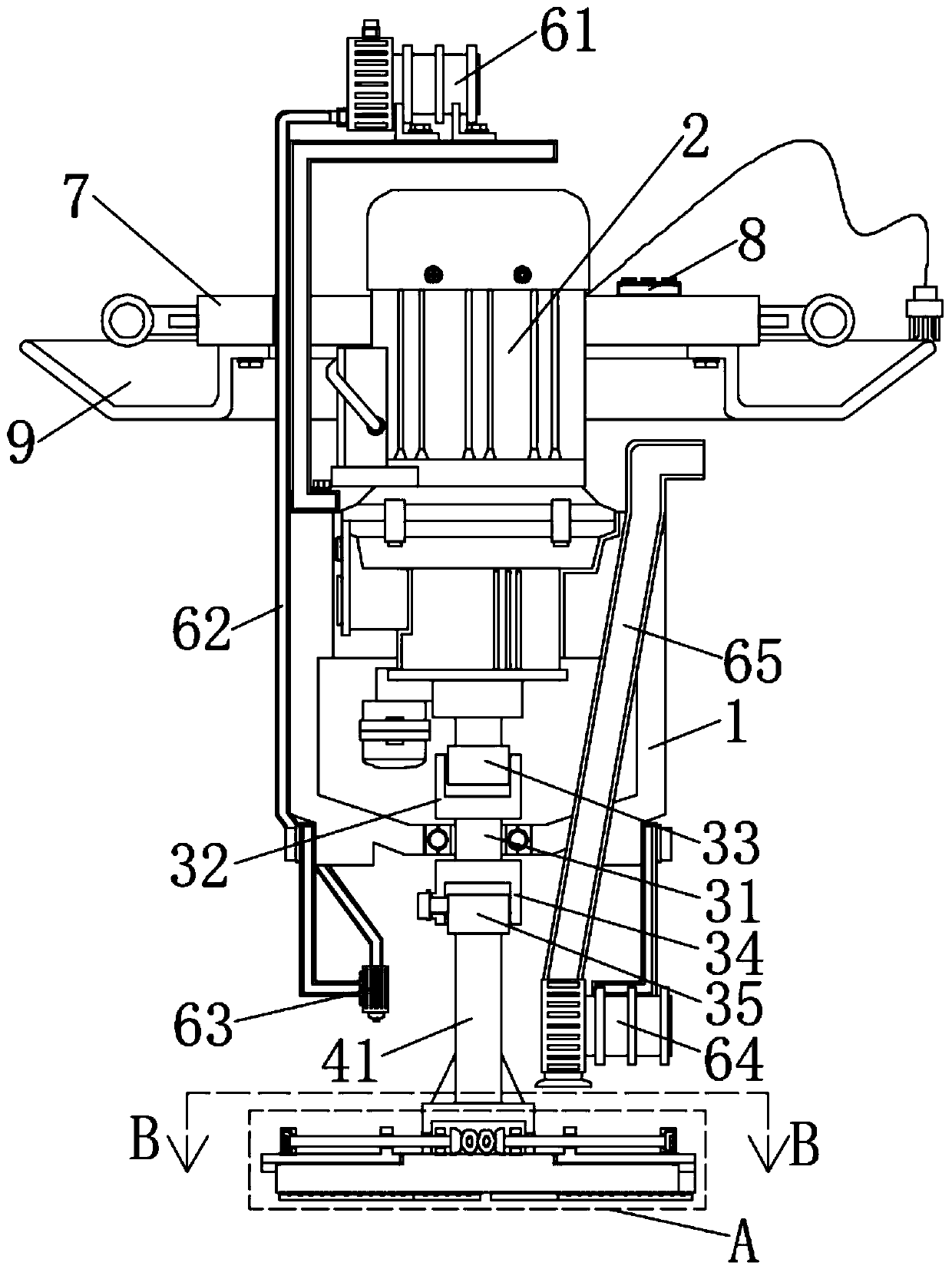

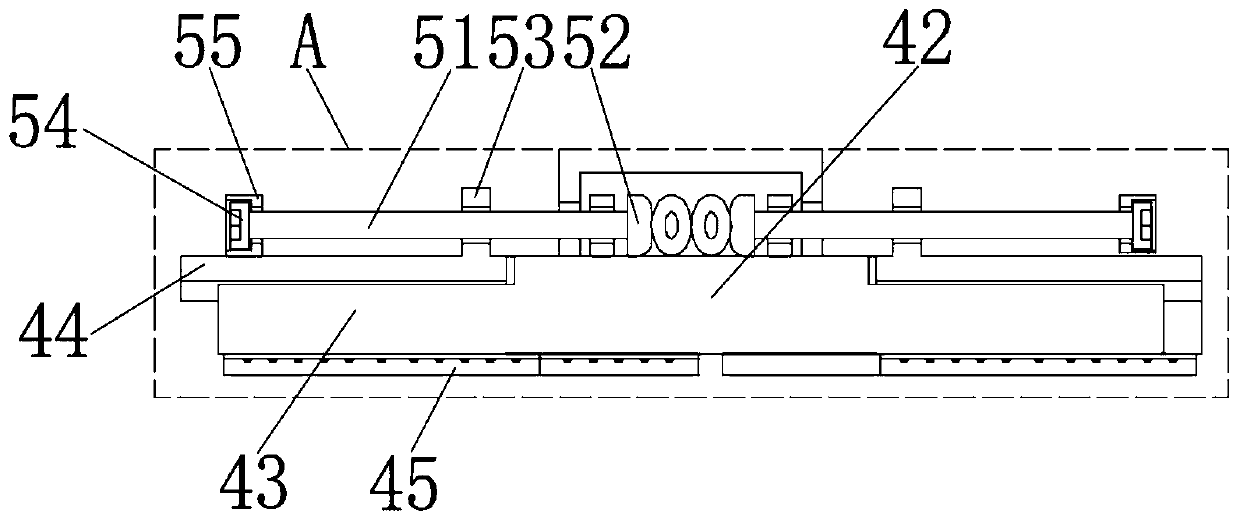

Substrate binding device and method

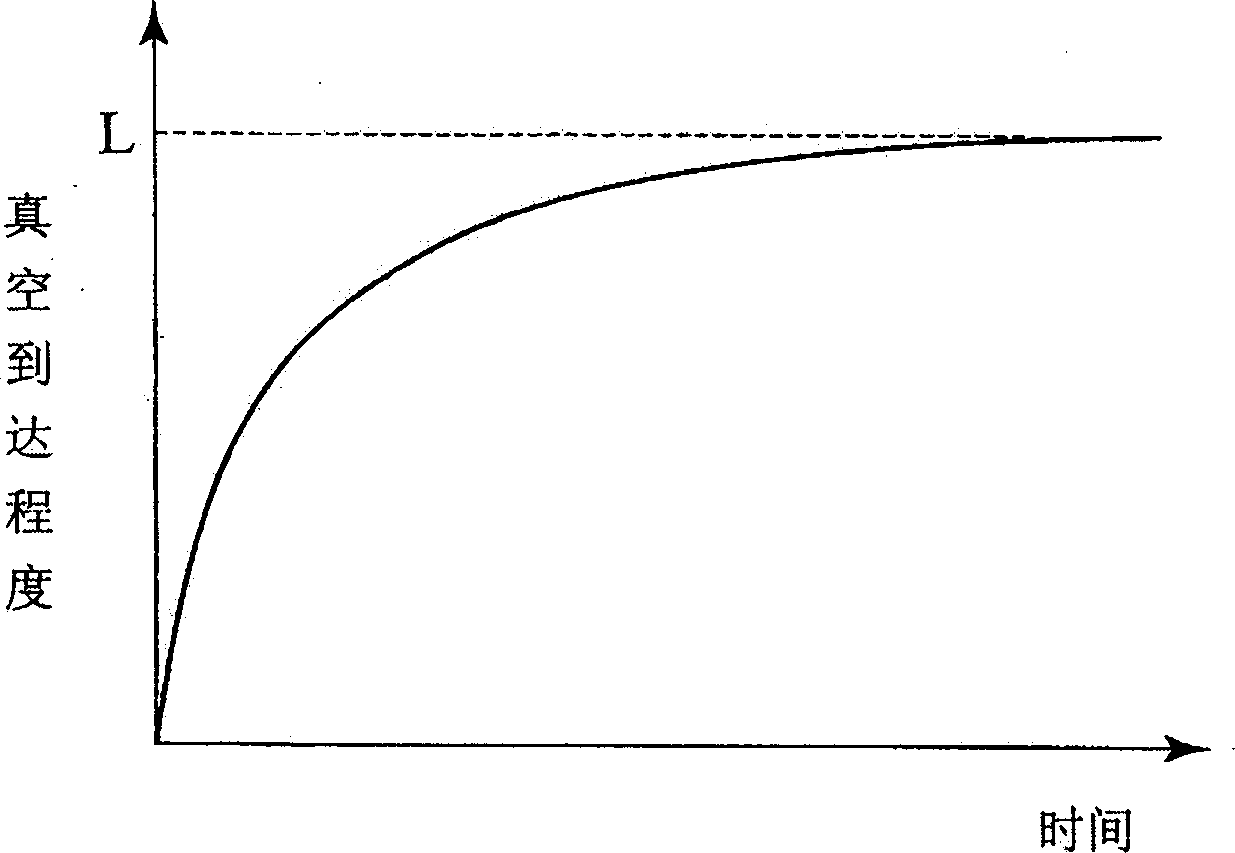

InactiveCN1439919ASuppress flyingSuppress smallStatic indicating devicesNon-linear opticsVacuum pumpingLiquid-crystal display

The present invention relates to an improved excellent substrate laminating apparatus and method, which are good for manufacturing liquid crystal display panel. For the vacuum pumping performing of a chamber (2), the opening of a valve (8a) communicating with a vacuum pump (82) is controlled to change the intake resistance of a pipe (81) from high to low, and to suppress an exhaust air stream occurring when vacuum pumping is started. Furthermore, in the process (vacuum venting) for recovering the atmosphere pressure in the chamber (2), a recovery valve (9a) is controlled to change from high to low, the inflow resistance of a gas introduced into the chamber (2), so that the amount of the gas introduced into the chamber (2) at the beginning of the vacuum venting is reduced. Therefore, since the air stream in the chamber (2) can be moderated during the vacuum pumping and the vacuum venting, the stirring up of dust in the chamber (2) and the attachment of the dust to the substrates can be avoided, and high-quality laminated substrates can be provided at a high manufacturing yield.

Owner:SHIBAURA MECHATRONICS CORP

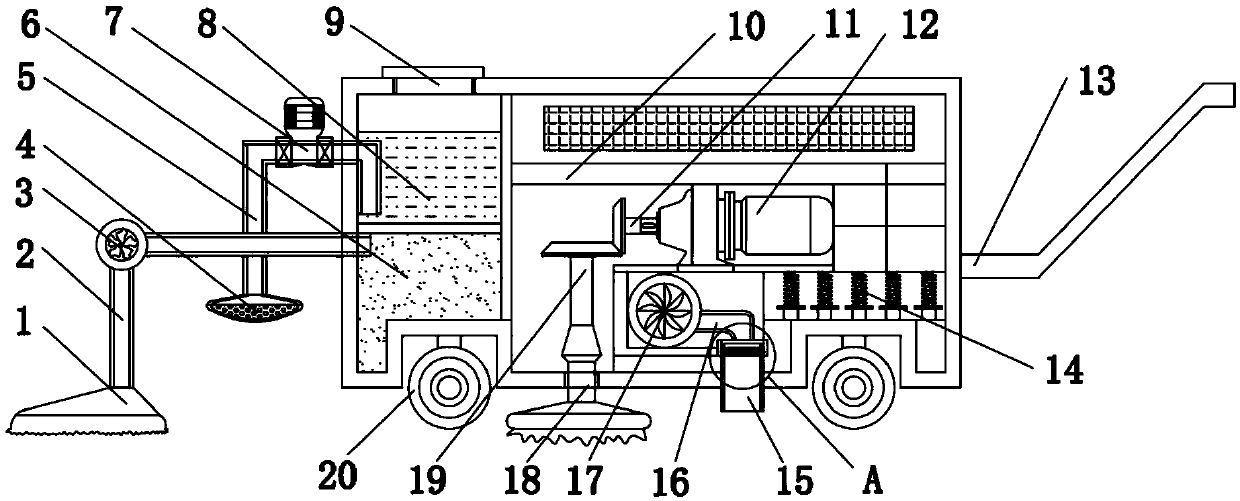

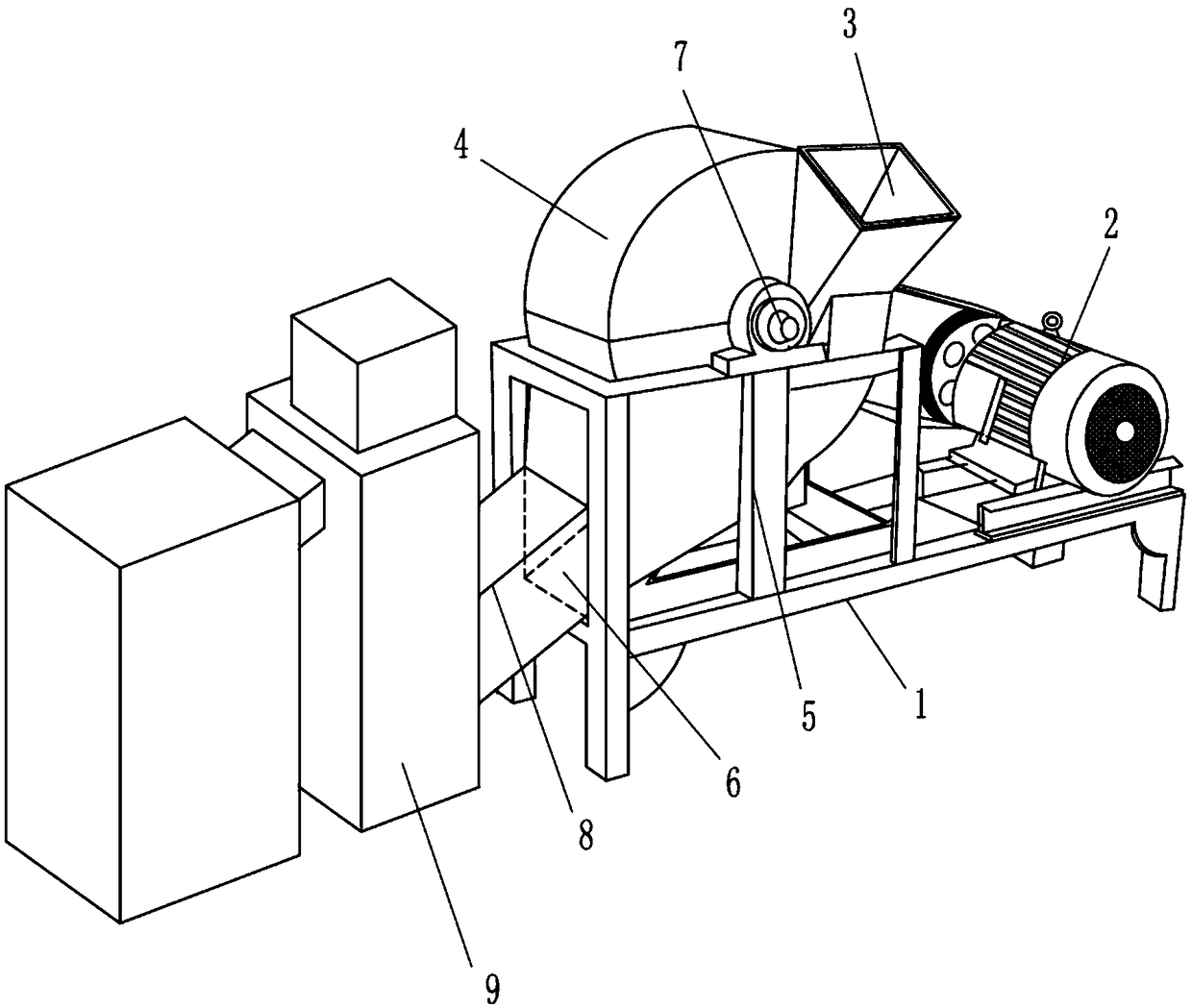

Waste processing device for wood pulverizer

ActiveCN109227865AEasy to cleanSave time and effortWood working apparatusFlat articlesWaste processingWood processing

The invention belongs to the field of wood processing equipment, and particularly relates to a waste processing device for a wood pulverizer. The waste processing device for the wood pulverizer achieves the technical purposes that wood waste can be conveniently cleaned away, wood bits in the wood waste can be restrained from flying, time and labor are saved during wood waste processing, the efficiency is high, and waste is thoroughly processed. The waste processing device for the wood pulverizer comprises a bottom frame, a driving mechanism, a feeding hopper, a pulverizing box, a support, a smashing mechanism, a waste processing device and a first discharging pipe; the driving mechanism is installed at the top of the bottom frame, the pulverizing box is fixedly connected to the top of thebottom frame through the support, the smashing mechanism is installed inside the driving mechanism, and the smashing mechanism is in transmission connection with the output end of the driving mechanism. The device achieves the effects that wood waste can be conveniently cleaned away, wood bits in the wood waste can be restrained from flying, time and labor are saved during wood waste processing, the efficiency is high, and waste is thoroughly processed.

Owner:浙江久安绿色智能家居有限公司

Construction dust depressor and preparation method thereof

ActiveCN106008851ANo secondary pollutionImprove securityOther chemical processesCarboxylic acidAqueous solution

The invention discloses a construction dust depressor and a preparation method thereof. According to the dust depressor, unsaturated carboxylic acid, unsaturated sulfonic acid and unsaturated polyether are adopted as monomer raw materials, a neutralizer and an initiator are adopted as auxiliary raw materials, and the dust depressor is prepared through an aqueous solution copolymerization technology. Ionic stability of the dust depressor is improved through the non-ionicity of unsaturated polyether monomers, the adaptability of the dust depressor to cement, concrete and residue soil dust is improved, and the prepared dust depressor can be diluted with water to be sprayed and used and is good in comprehensive performance, safe and environmentally friendly.

Owner:加翎加(天津)环境科技有限公司

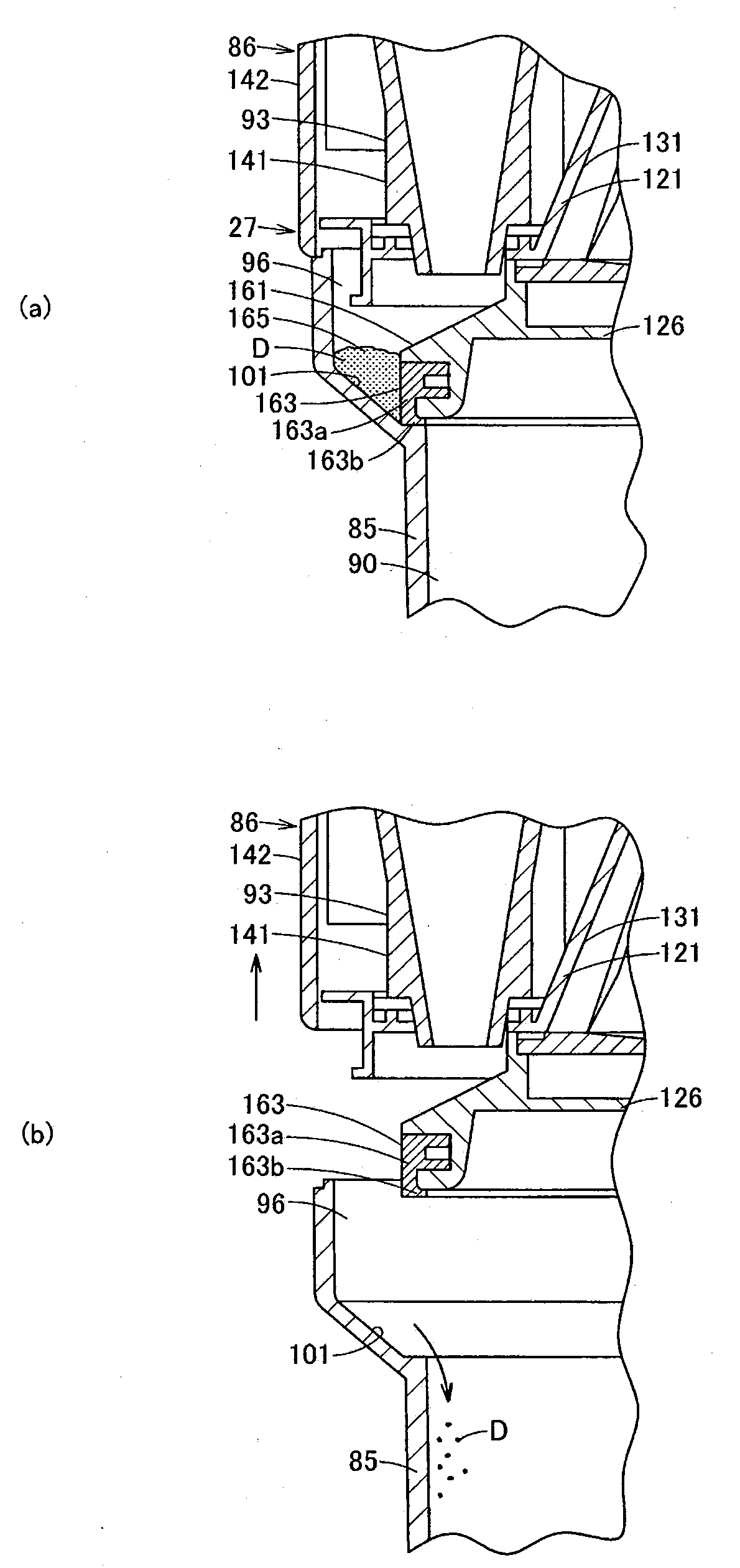

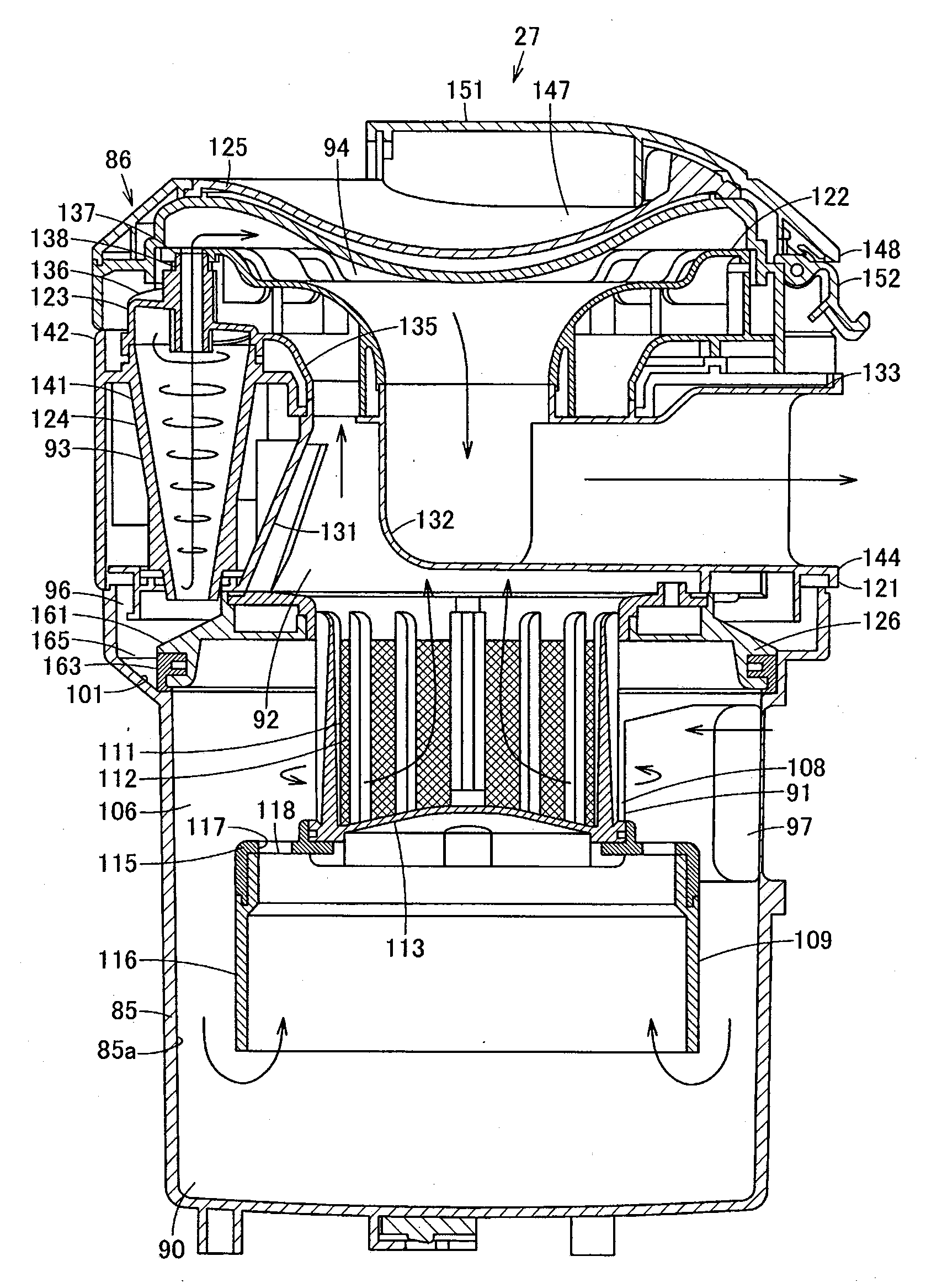

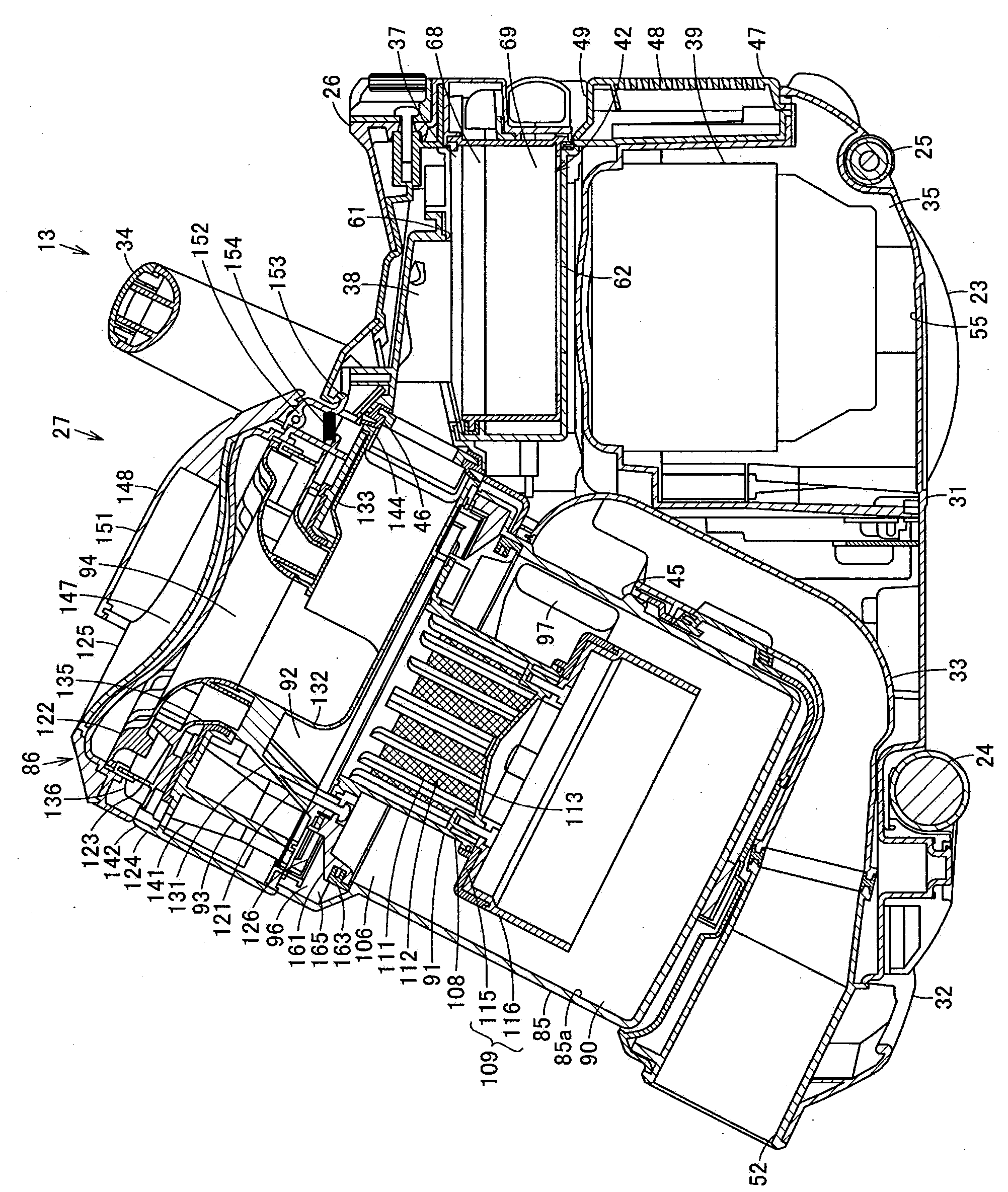

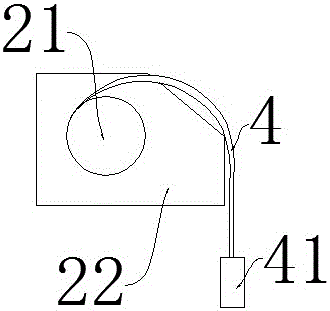

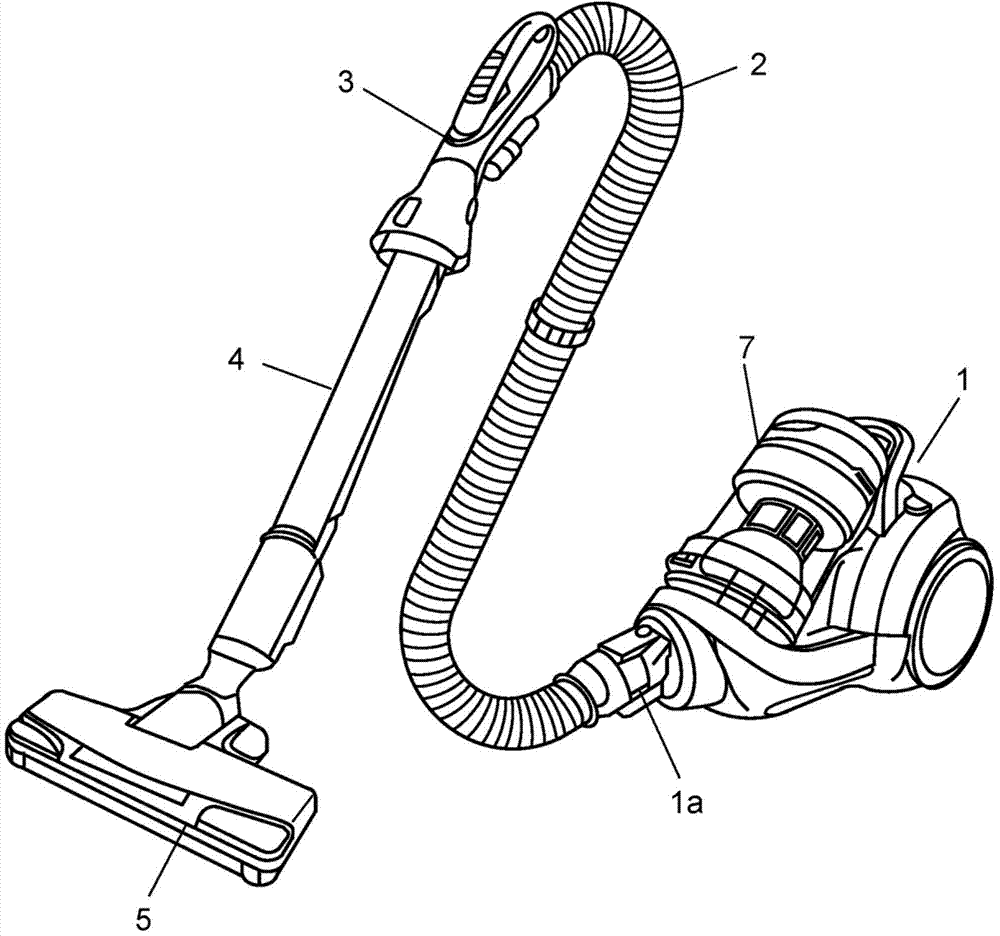

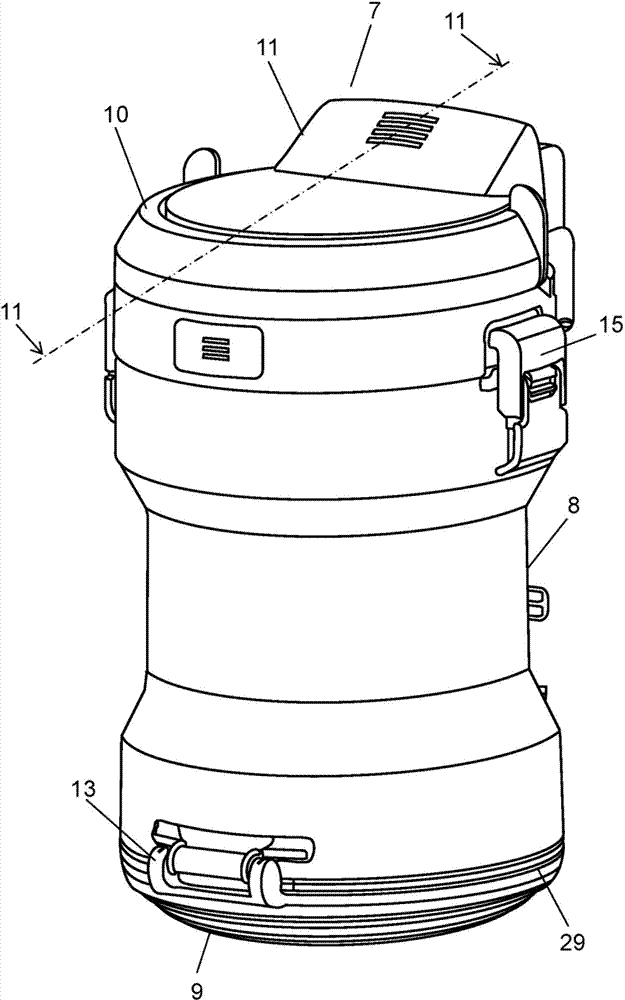

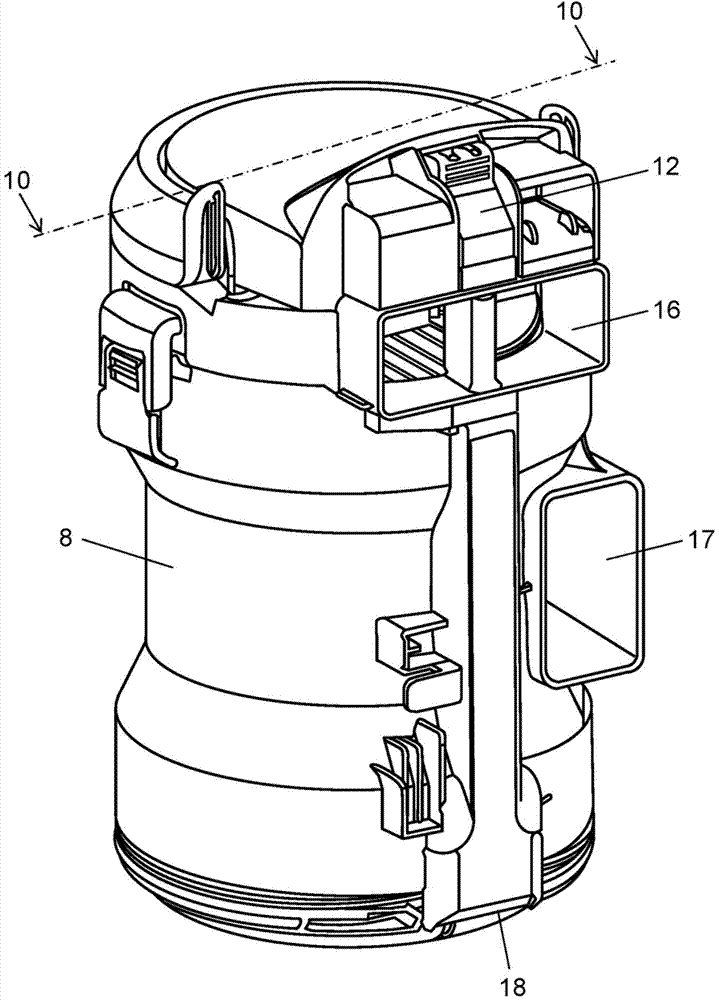

Dust collecting device and electric cleaner with the same

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

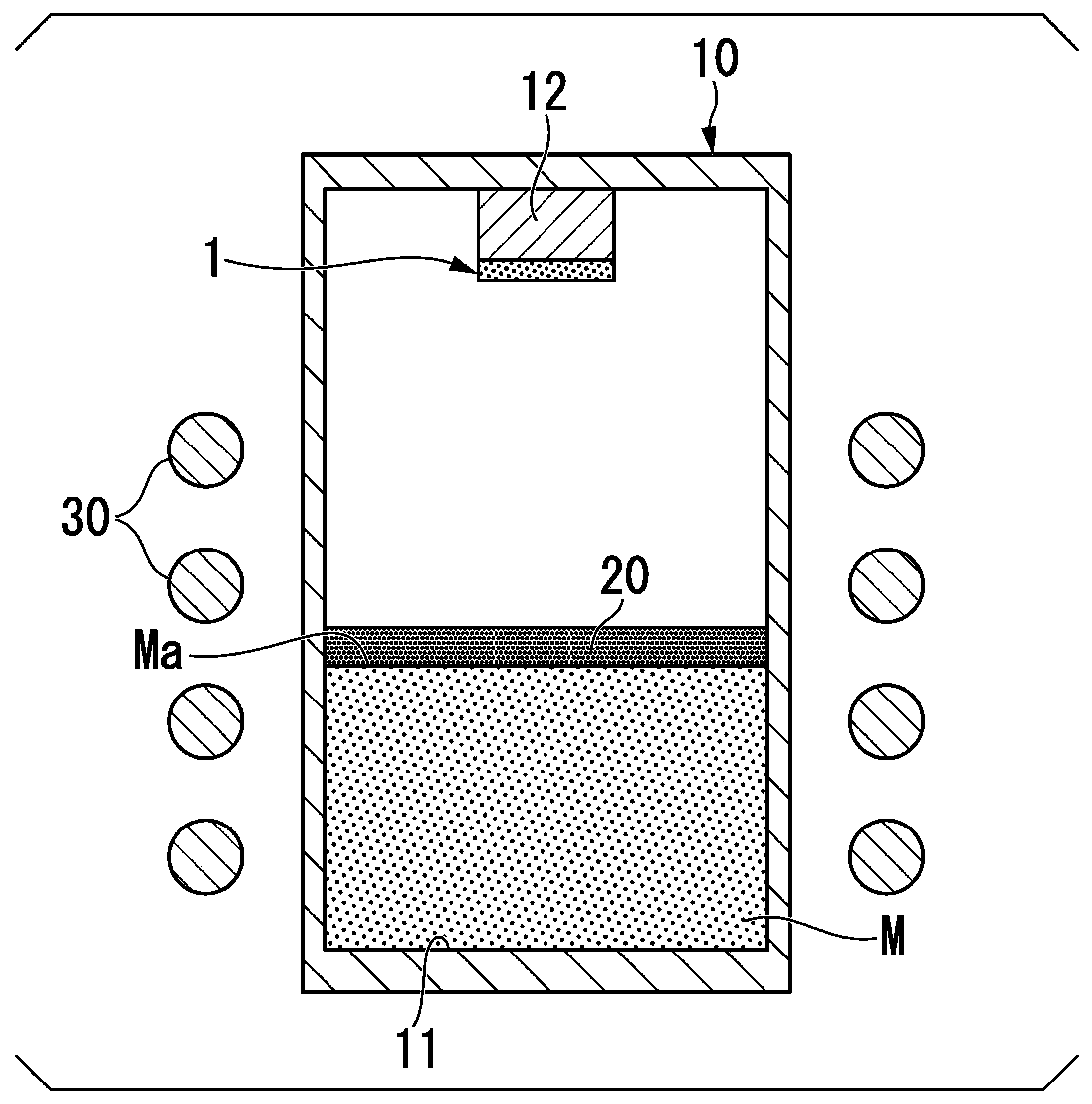

METHOD OF MANUFACTURING SiC SINGLE CRYSTAL AND COVERING MEMBER

InactiveCN110878424ASuppress flyingPolycrystalline material growthFrom condensed vaporsCrucibleCarbide

The present invention provides a method of manufacturing a SiC single crystal and a covering member. The method of manufacturing a SiC single crystal includes: a storing step of storing a SiC source,which is a powder, in an inner bottom part of a crucible, wherein the crucible is configured to store the SiC source and to attach a seed crystal to a position of the crucible which faces the SiC source; a placing step of placing a porous material on at least a portion of a first surface of the SiC source, wherein the first surface is positioned on a side of the seed crystal; and a crystal growthstep of sublimating the SiC source by heating to grow a crystal on the seed crystal, in which the porous material is formed of carbon or a carbide, and the hole diameter of the porous material is smaller than the average particle diameter of the SiC source.

Owner:RESONAC HOLDINGS CORPORATION

Environment-friendly blackboard preventing dust pollution

ActiveCN106004184ASuppress flyingKeep healthyBoard cleaning devicesWriting boardsElectricityPhysical health

The invention discloses an environment-friendly blackboard preventing dust pollution. The environment-friendly blackboard preventing the dust pollution comprises a blackboard body and a motor. The upper portion of the blackboard body is fixedly connected with an electrostatic type eraser. The lower portion of the blackboard body is fixedly connected with a dust containing box. The electrostatic type eraser comprises a dust box. A rotating shaft is arranged in the dust box and connected with a piece of eraser cloth. One end of the eraser cloth is connected with the rotating shaft, and the other end of the eraser cloth is connected with a plastic plate. The eraser cloth is a piece of conductive cloth and electrically connected with an electrostatic generator. The rotating shaft is electrically connected with the motor. A touch-pressure switch is arranged on the plastic plate and is in signal connection with the electrostatic generator. According to the environment-friendly blackboard preventing the dust pollution, the physical character that an electrified body attracts tiny objects is utilized, and chalk dust is restrained from flying by controlling the electricity capacity of the eraser; and therefore, the physical health of teachers and students is effectively protected, and the teachers and the students are protected against dust hazards. The environment-friendly blackboard preventing the dust pollution is simple in structure and convenient to operate; and meanwhile, existing blackboards made from various materials can be refitted to be the environment-friendly blackboards preventing the dust pollution, and therefore application and popularization are benefited.

Owner:裴萌

Preparation method of liquid dust suppressant capable of rapidly forming film

InactiveCN106117444AHave water absorptionPossession of penetrationOther chemical processesCelluloseRoad surface

The invention discloses a preparation method of a liquid dust suppressant capable of rapidly forming a film and belongs to the field of dust suppressants. Sodium alginate and kelp cellulose are extracted from kelp respectively, kelp cellulose is grafted with acrylic acid and dimethyl diallylammonium chloride, reactants of sodium alginate and polyvinyl alcohol are compounded after grafting, a surfactant is added after compounding, and the dust suppressant can be obtained. The prepared dust suppressant has the effects of water absorption, permeation and bonding and is mixed with water and then sprayed to a pavement, water molecules in air can be absorbed, a wet and nonvolatile water retention film is formed on the pavement rapidly, the film forming time is 20-50 s, the purpose of dust flying inhibition is achieved, the rapidly formed continuous and complete film can resist wind and rainwater and can have a protection function on the pavement, raw materials of the dust suppressant are environment-friendly and easy to degrade, and no secondary pollution is caused.

Owner:河南省九金科技有限公司

Electric dust collector

The invention provides an electric dust collector. A dust-collecting device of the electric dust collector comprises a structure configuring a primary filter (21) configured in the following manner: in the primary filter (21) provided with a plurality of through holes penetrating through an upstream side surface and a downstream side surface of the primary filter (21), a direction of a central axis and a forward direction of an outer side swirling airflow (61) flowing on the upstream side surface of the primary filter (21) form a second inclined angle which is downward inclined opposite to the forward direction. The central axis is a straight line of connecting an opening center of a first etching hole and an opening center of a second etching hole. Therefore, a declining swirling airflow (61) going toward a direction of a dust-collecting chamber (33) can be generated in the inner circumference of the primary filter (21), so that the dust can be prevented from flying; and blockage of the filter can be prevented.

Owner:PANASONIC CORP

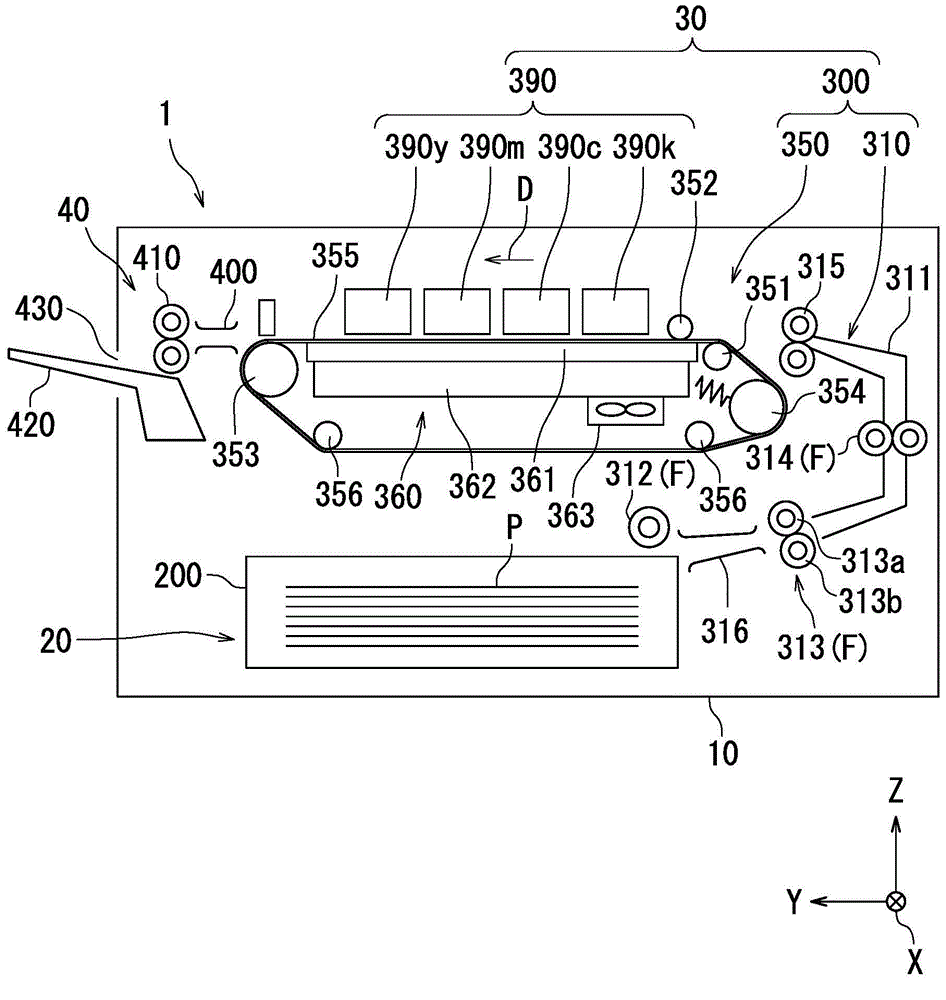

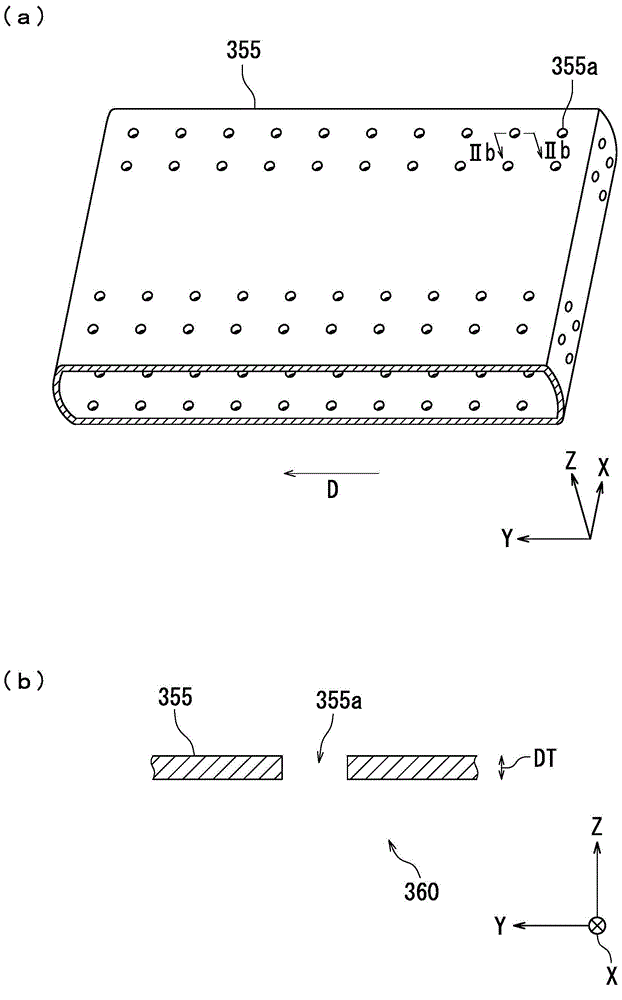

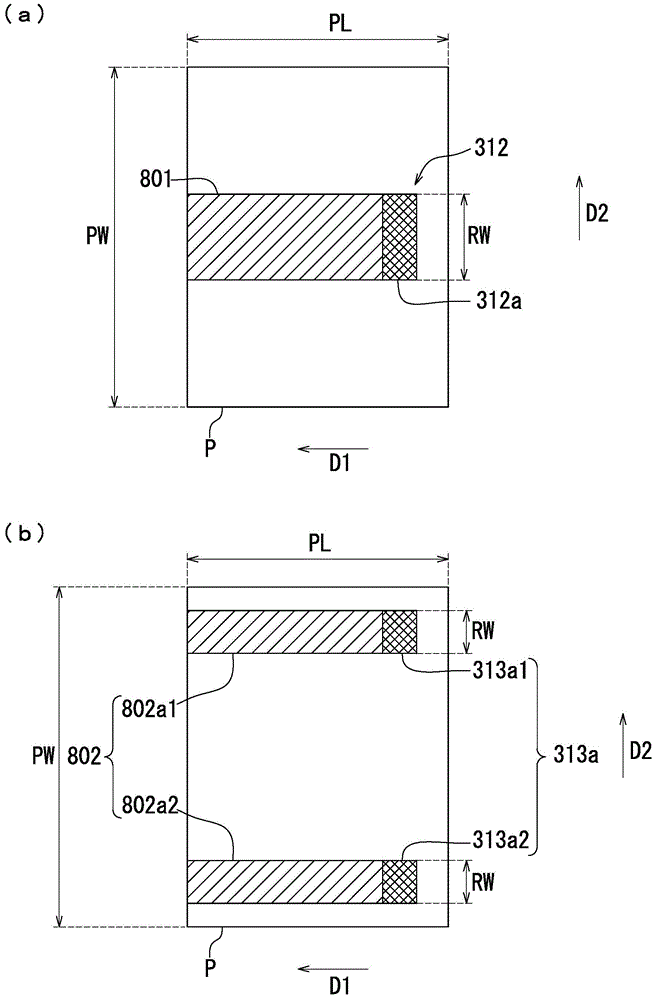

Conveyor device and inkjet recording apparatus

A conveyor device includes a feed member, a conveyor belt, and a suction section. The feed member feeds a recording medium while in contact with a part of the recording medium. The conveyor belt conveys the recording medium having been conveyed by the feed member. The suction section sucks the recording medium onto the conveyor belt. The conveyor belt includes a first region that is to receive the part of the recording medium and a second region adjacent to the first region. The conveyor belt has a plurality of suction holes in communication with the suction section. The suction holes have a lower opening ratio in the first region than in the second region.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

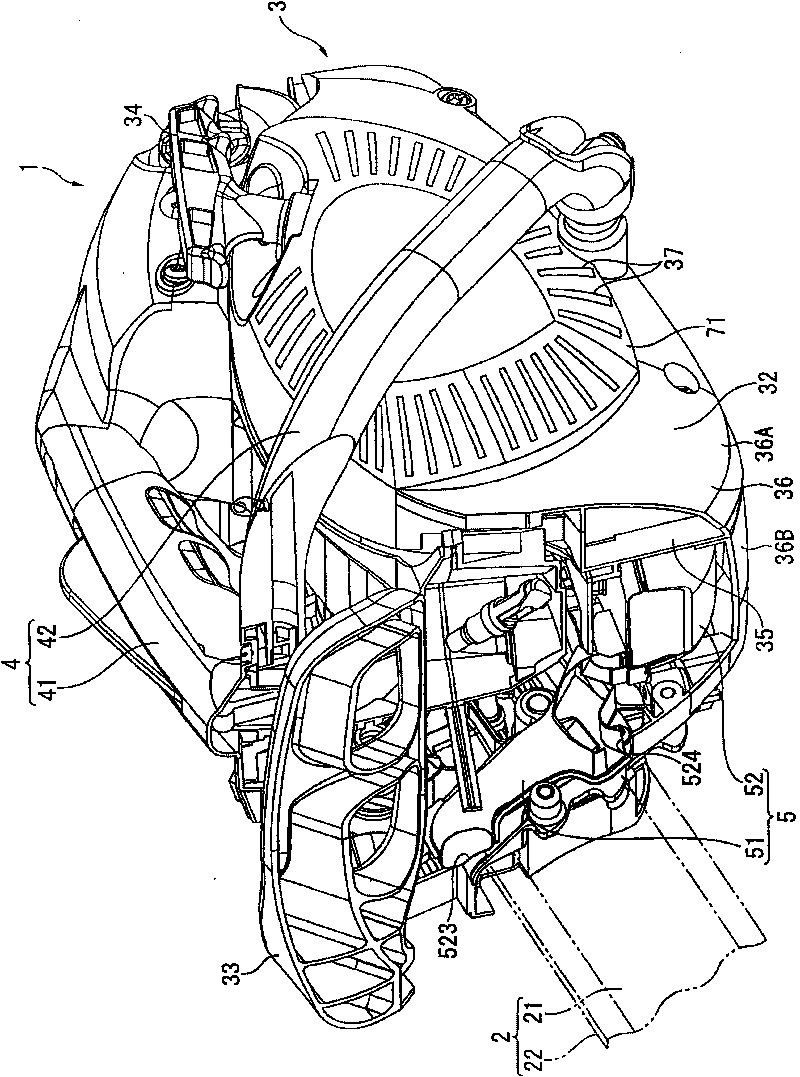

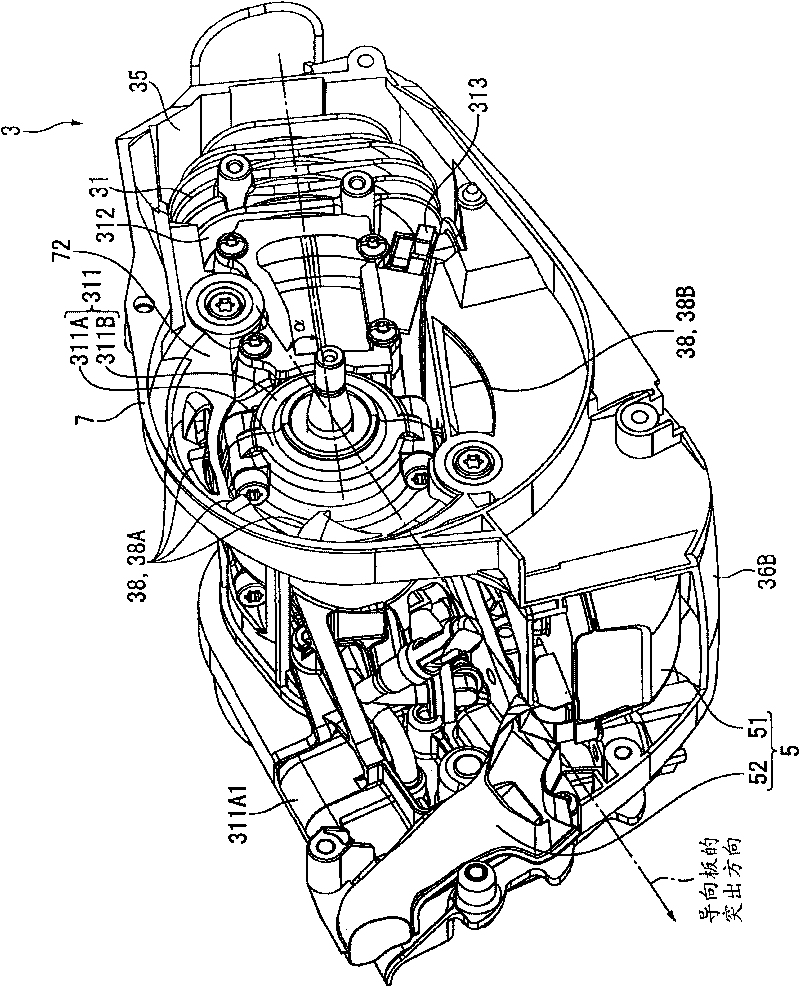

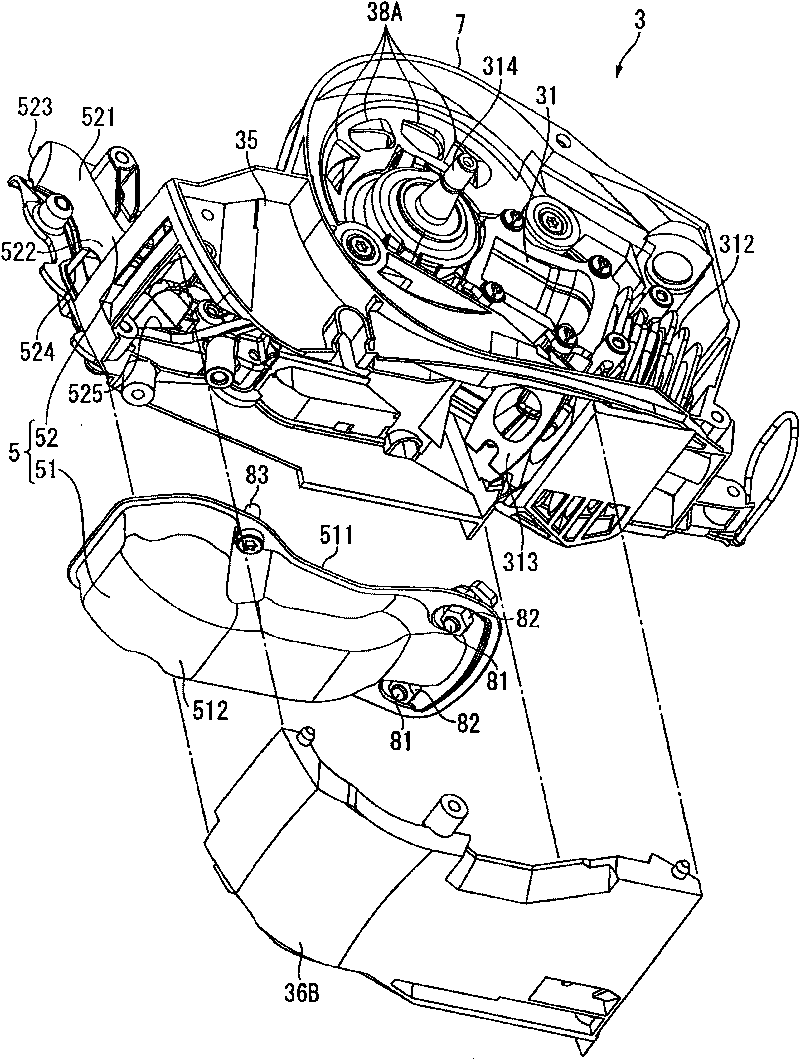

Chain saw

InactiveCN101722534ASuppress flyingGuaranteed exhaust efficiencyChain sawsEngineeringSynthetic resin

The invention provides a chain saw. A muffler (5) structurally comprises a muffler body (51) and a passage part (52), wherein the muffler body (51) is arranged below an engine (31); and the passage part (52) is extended upwards from the muffler body (51) and is provided with openings on the upper side in front of a chain saw body (3). Accordingly, as exhaust air can be discharged towards the front of the chain saw body (3) and exhaust noise can be transmitted forwards, the exhaust noise capable of being heard by an operator is reduced to further improve the operating environment. In addition, the exhaust air is discharged after passing through the longer passage part (52) extending upwards from the muffler body (51) to cool the exhaust air. Therefore, although a shell (32) made of synthetic resin is usually utilized to cover the chain saw body (3) and an exhaust opening is formed at a position in the shell (32) corresponding to the openings (523, 524) of the passage part (52), the color of a marginal part of the exhaust opening can be prevented from being changed due to the heat of the exhaust air.

Owner:HUSQVARNA ZENOAH

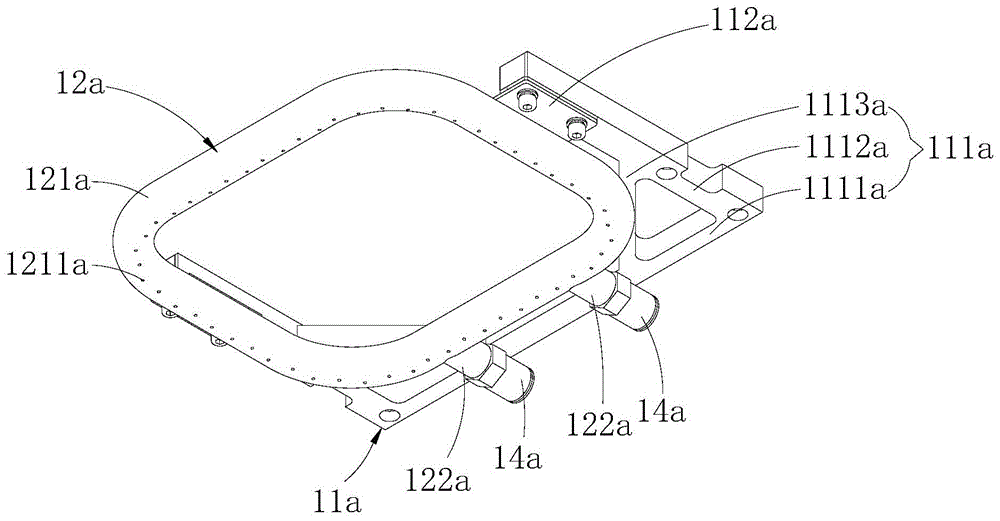

Working method of punching device with protective structure and for bridge construction

ActiveCN110948710AAvoid harmImprove protectionWorking accessoriesStone-like material working toolsElectric machineryDrive motor

The invention discloses a working method of a punching device with a protective structure and for bridge construction. The punching device comprises a device shell, a driving motor, a water pump, a sludge pump and an integrated switch. The driving motor is fixedly installed inside the device shell. A transmission mechanism is installed on the lower portion of the device shell and comprises a rotating rod. The rotating rod is embedded into the middle of the bottom of the device shell through a bearing. A transmission sleeve is fixedly installed on the top of the rotating rod, and a transmissioninsertion block is arranged on the top of the transmission sleeve in an insertion mode. A connecting sleeve is fixedly installed at the bottom of the rotating rod, and a connecting insertion block isarranged at the bottom of the connecting sleeve in an insertion mode. A punching mechanism is installed at the bottom of the connecting insertion block. According to the punching device, due to the fact that polishing and cutting blades are arranged and installed at the bottom of the punching device, the hole forming operation can be conducted by the grinding operation, and the phenomenon that broken blocks generated by drilling splash and cause the harm to constructors is effectively avoided; and transverse fixing beams and transverse moving beams are arranged and can slide to be adjusted, and therefore the hole forming diameter of the device can be flexibly adjusted.

Owner:安徽启源建筑工程有限公司

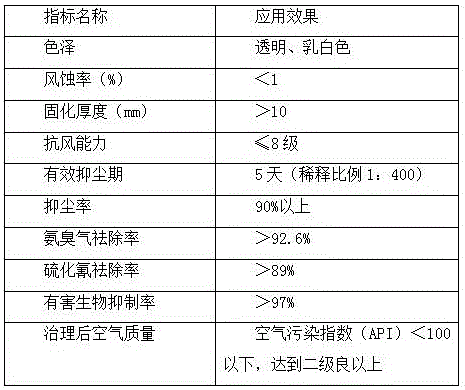

Deodorant dust suppressant and preparation method

ActiveCN106833531ASuppresses flying dustEasy to degradeGas treatmentOther chemical processesGypsumChemistry

The invention relates to a deodorant dust suppressant and a preparation method, belongs to the technical field of dust suppressants, and provides a deodorant dust suppressant capable of effectively suppressing dust flying and removing foul smells and peculiar smells in dust and a preparation method. According to the technical scheme, the deodorant dust suppressant is prepared from, by weight, 50-70 parts of urea, 5-15 parts of high-molecular water-absorbing resin, 5-15 parts of dispersible emulsion powder, 5-15 parts of polyacrylamide, 5-15 parts of gypsum and a deodorant. The preparation method is used for preparing the deodorant dust suppressant.

Owner:山西猫头鹰环保科技股份有限公司

Crushing device for road construction

InactiveCN111519509ASuppress flyingContinuous collection and processingMechanical machines/dredgersDirt cleaningWater storage tankArchitectural engineering

The invention provides a crushing device for road construction. With the crushing device adopted, the problems of incomplete dust suppression, small stone splashing, high noise and poor working environment in an operating room in the working process of a conventional road crushing device are effectively solved. According to the technical schemes of the invention, the crushing device comprises a base; a fixed fluted disc is welded to the outer wall of the top of the base; a rotating disc is fixed on the outer wall of the top of the base through a rotating shaft; a water storage tank is fixed tothe outer wall of the top of the rotating disc through screws; a water pump is fixed to the top outer wall of the rotating disc through screws; a water spraying pipe is fixed to the outer wall of thetop of the rotating disc through screws; spraying holes are formed in the outer wall of one side of the water spraying pipe; the water spraying pipe, the water storage tank and the water pump are connected through guide pipes; a water conveying pipe is fixed to the outer wall of the top of the water spraying pipe through screws and inserted into a mechanical arm; and a water outflow pipe is fixedto the other end of the water spraying pipe through screws.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Flying dust inhibitor for environmental protection and preparation method thereof

The invention discloses a flying dust inhibitor for environmental protection. The flying dust inhibitor comprises the following components (in percentage by mass): 55-60 percent of water; 18-23 percent of a reinforcing agent; 5-10 percent of a coagulant; 7-12 percent of a surfactant; 2-5 percent of a bacteriostatic agent; silicic acid gel is alternately generated through a sodium silicate solutionand a calcium chloride solution; a layer of silicic acid gel film is formed on the surface of the dust in a wet environment to reinforce dust and avoid dust raising phenomenon; bentonite is added into the flying dust inhibitor, the moisture loss of dust can be reduced, moisture is locked in molecules for a long time and the surface of the dust is kept moist so as to achieve the flying dust inhibition function, improve the moisture retention and the adhesion of the flying dust inhibitor, ensure the humidity of the silicic acid gel layer formed on the surface of the dust, improve the adhesion strength of the silicic acid gel layer formed on the surface of the dust, effectively inhibit the flying dust flying, and provide the long-term flying dust flying.

Owner:李骏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com