Tension type screen and production technology

A production process, tensioning technology, applied in the field of chemical rubber and plastics, can solve the problems of insufficient understanding of the importance of the screen, low equipment operation efficiency, poor comprehensive economic efficiency, etc., to reduce the probability of tinnitus in workers, and light weight. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

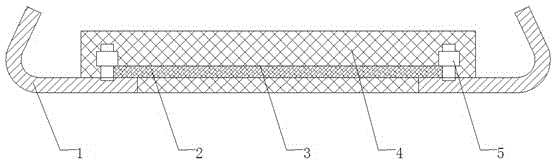

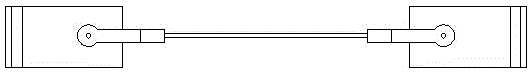

[0023] A tensioned screen comprising a tensioning hook 1, a steel wire rope 2, a cold-drawn steel wire 3, polyurethane 4, and a screw 5. There are tensioning hooks 1 at both ends of the tensioning screen, the steel wire rope 2 and the tensioning hook 1 Connect with screws 5 to form the skeleton layer of the polyurethane screen. The steel wire rope 2 is embedded perpendicular to the tension hook 1. The cold-drawn steel wire 3 is vertically arranged between the steel wire rope 2. After the skeleton is processed, the polyurethane material liquid is poured. A polyurethane mesh layer is formed to make a tensioned screen.

[0024] A production process of a tensioned screen comprising the following steps:

[0025] (1). Fabrication of the skeleton. The skeleton includes tension hooks, steel wire ropes, cold-drawn steel wires, and screws. The manufacturing steps include the following:

[0026] .Prepare the tensioning hook, cut it into the required length with metal lath, bend one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com