Laser lift-off device

A laser peeling and laser technology, applied in laser welding equipment, electrical components, circuits, etc., can solve problems such as poor laser peeling treatment, and achieve the effect of effectively removing dust particles and inhibiting dust particles from flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

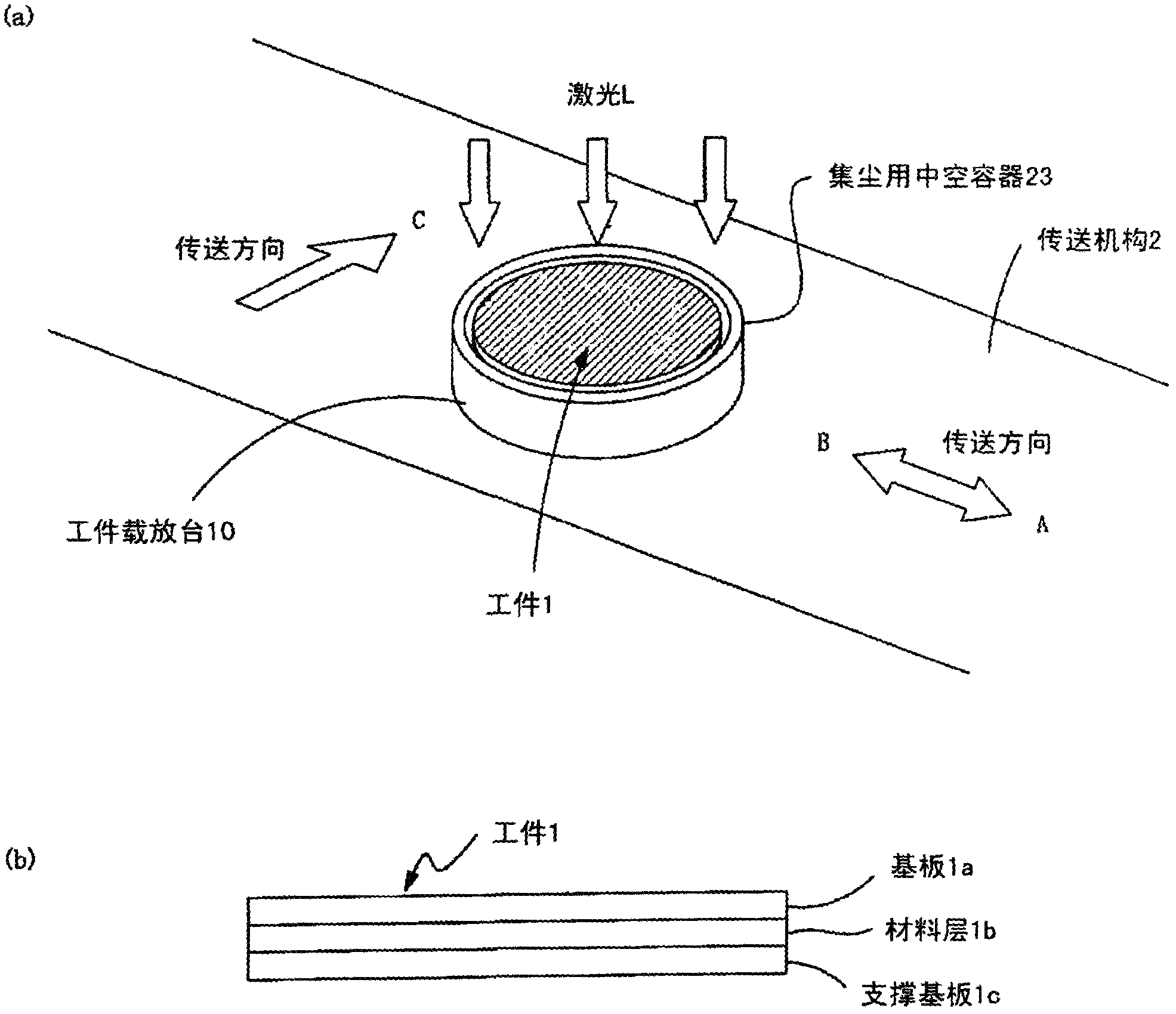

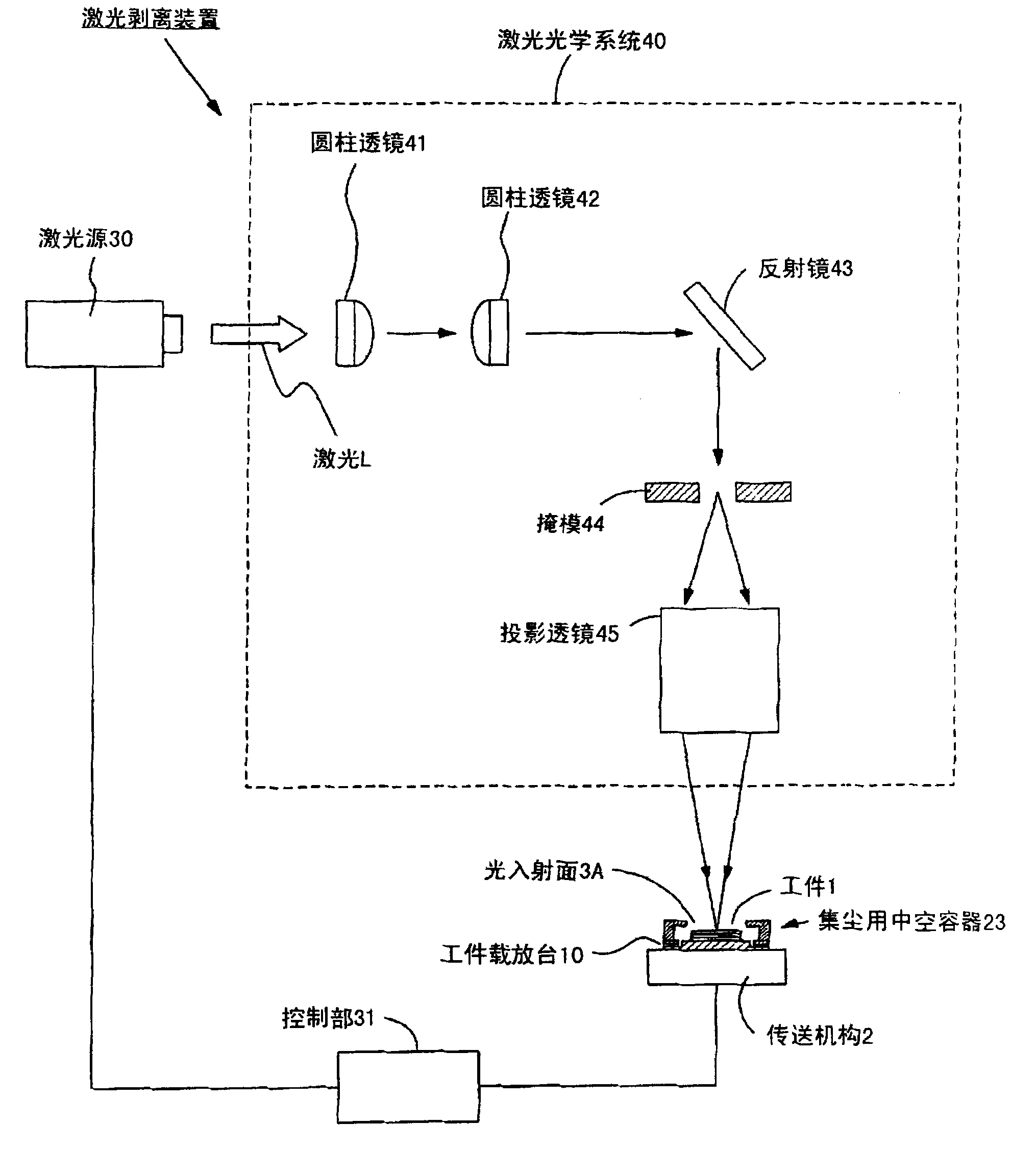

[0073] figure 1 It is a schematic diagram explaining the outline of the laser lift-off process of the Example of this invention.

[0074] In this embodiment, the laser lift-off process is performed as follows.

[0075] figure 1 (b) shows the workpiece 1 formed by stacking the laser-transmitting substrate 1a, the material layer 1b and the supporting substrate 1c, such as figure 1 As shown in (a), it is placed on the workpiece placement table 10 . The workpiece 1 is placed on the workpiece mounting table 10 so that the substrate 1 a is located above.

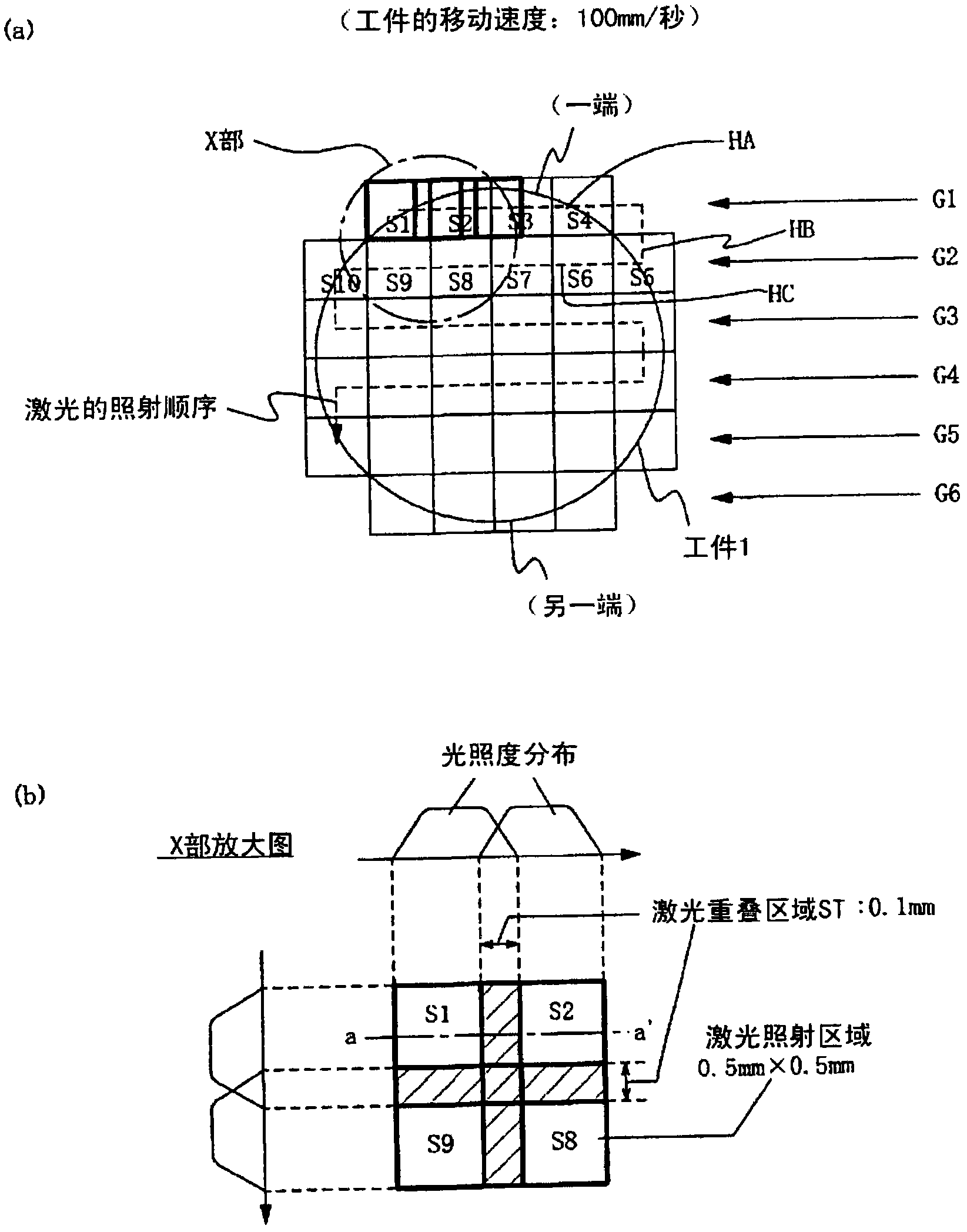

[0076] The workpiece table 10 on which the workpiece 1 is placed is placed on a conveying mechanism 2 such as a conveyor belt, and is conveyed at a predetermined speed by the conveying mechanism 2 . The workpiece 1 is transported in the arrow direction AB in the figure together with the workpiece stage 10 , and penetrates the substrate to be irradiated with pulsed laser light L emitted from a pulsed laser source not shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com