Patents

Literature

32results about How to "Complex configuration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

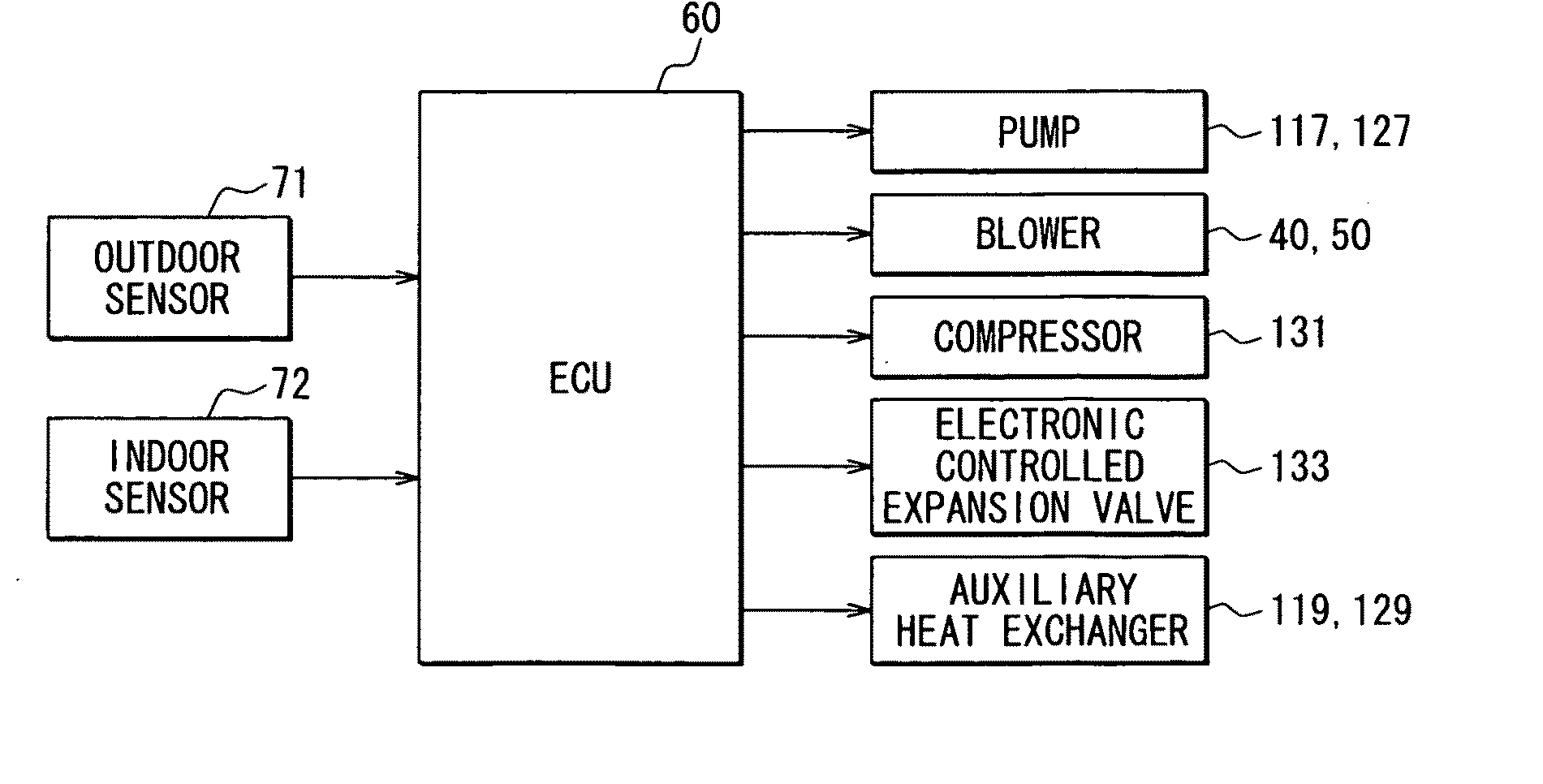

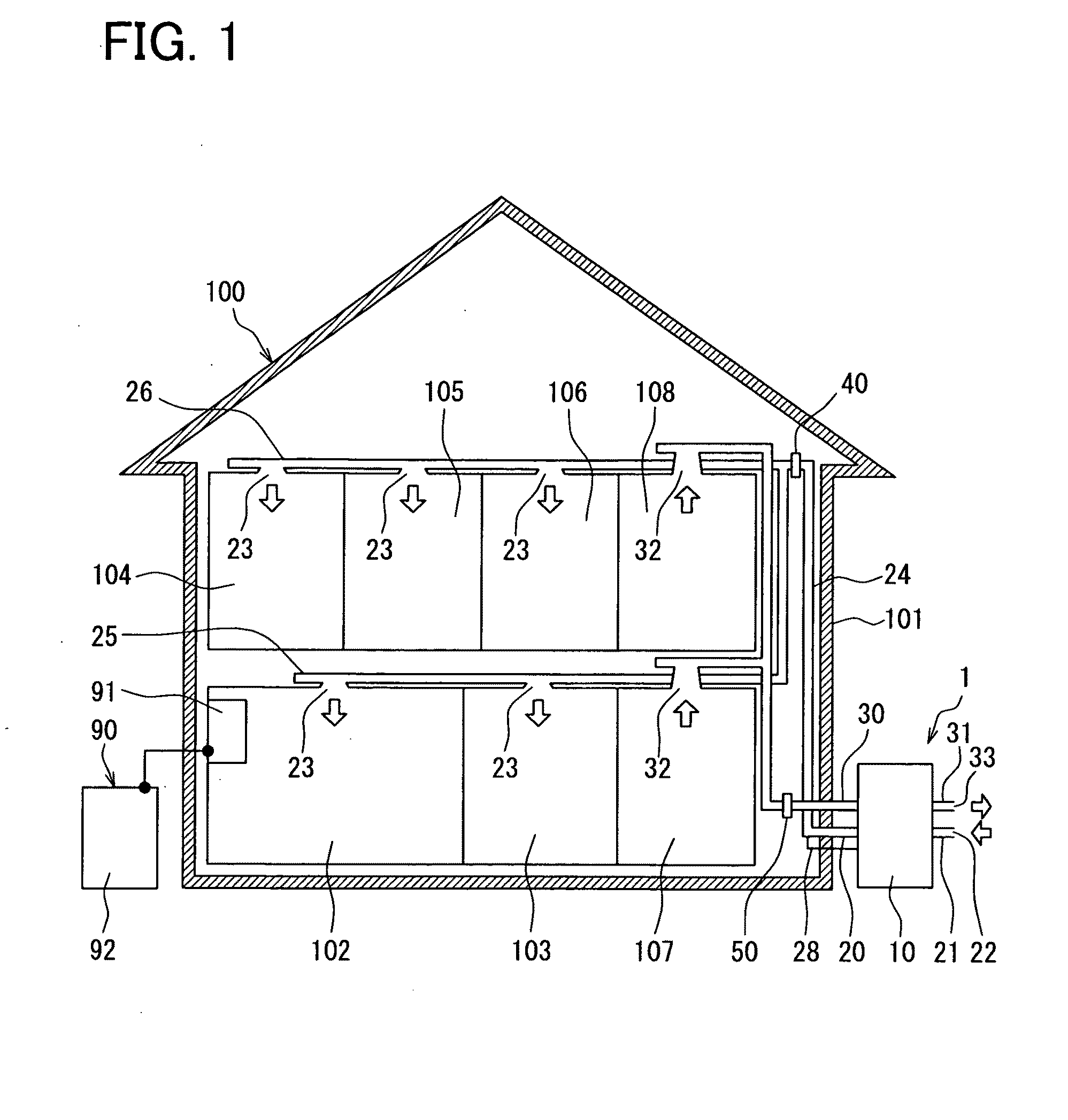

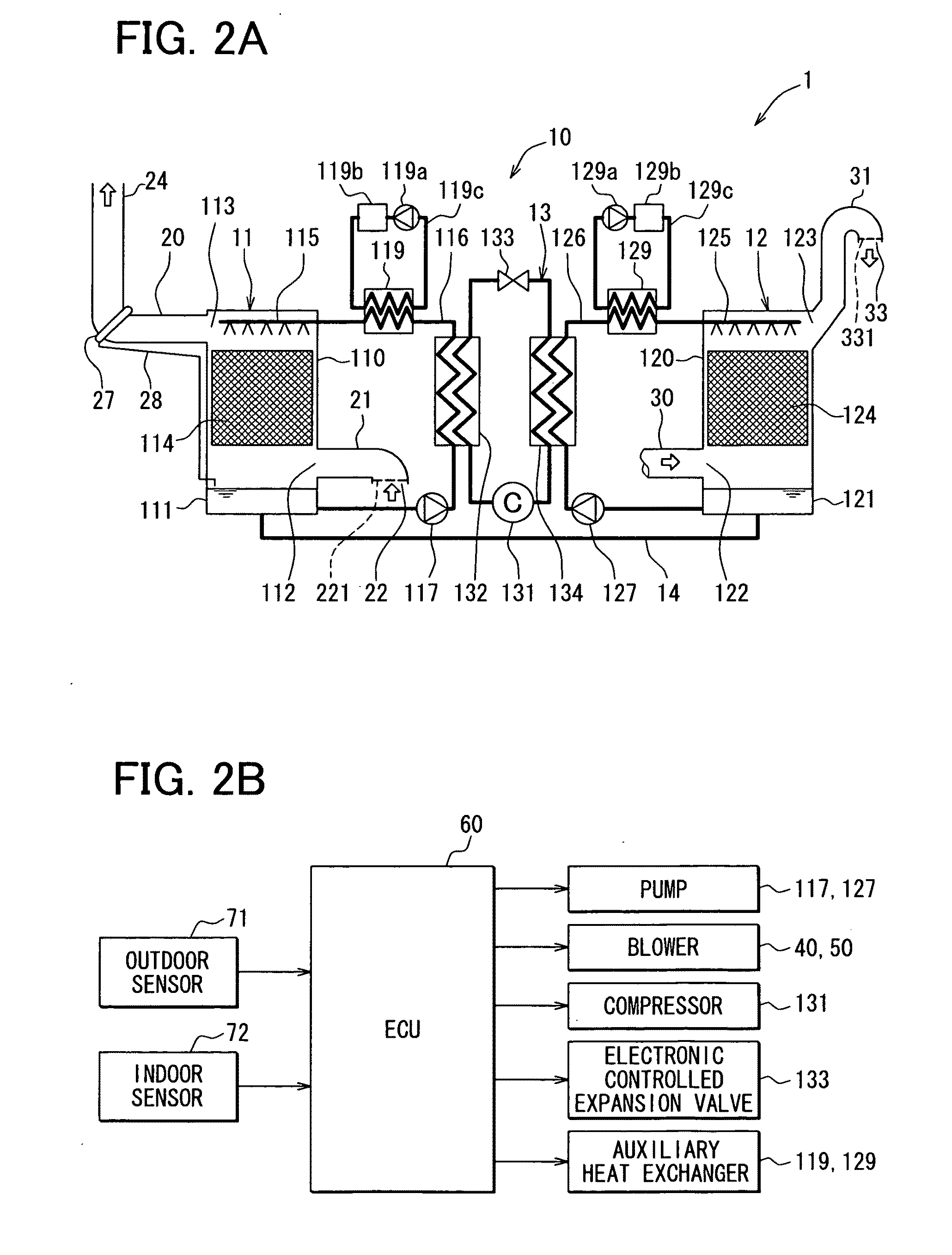

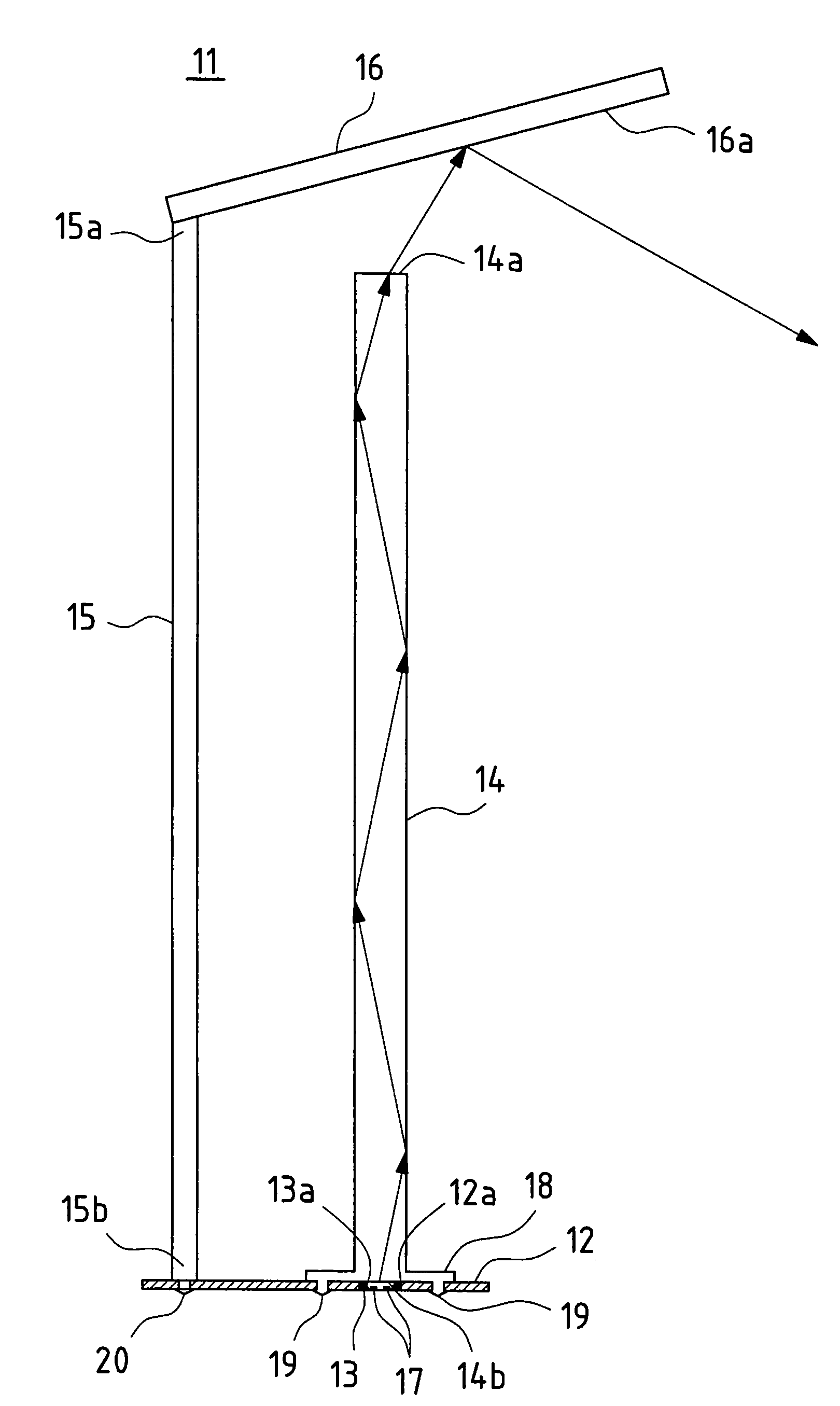

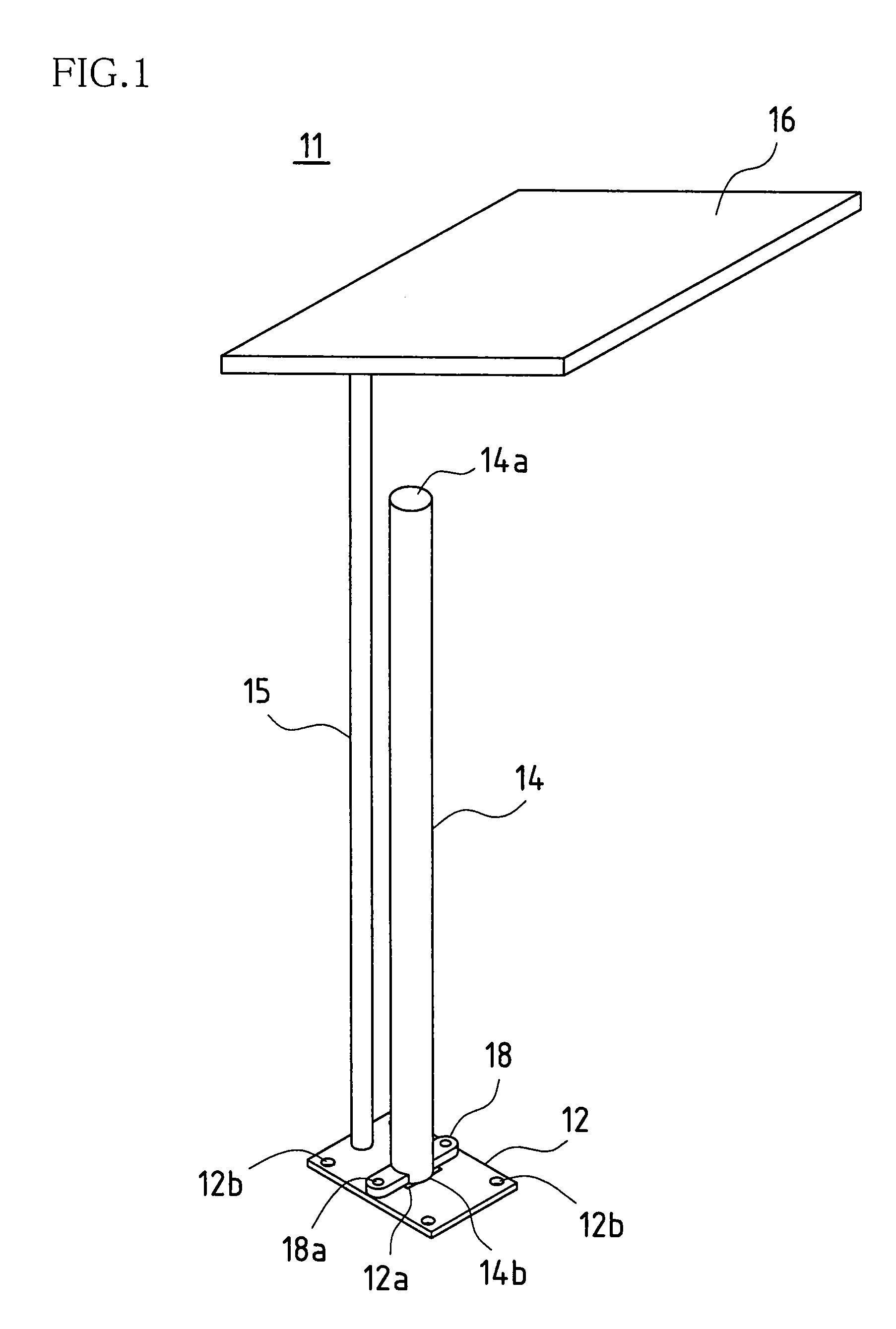

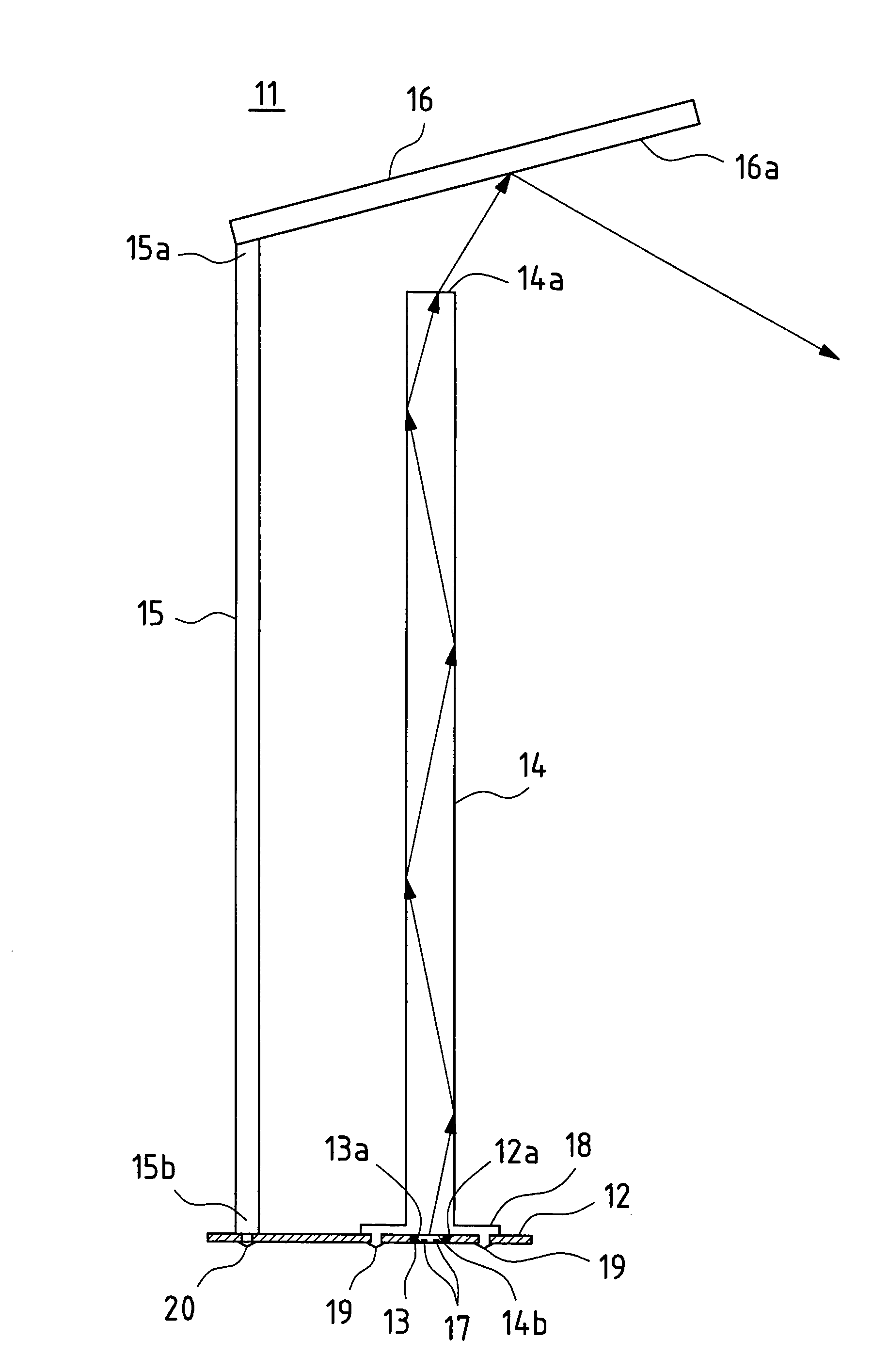

Humidity control and ventilation system

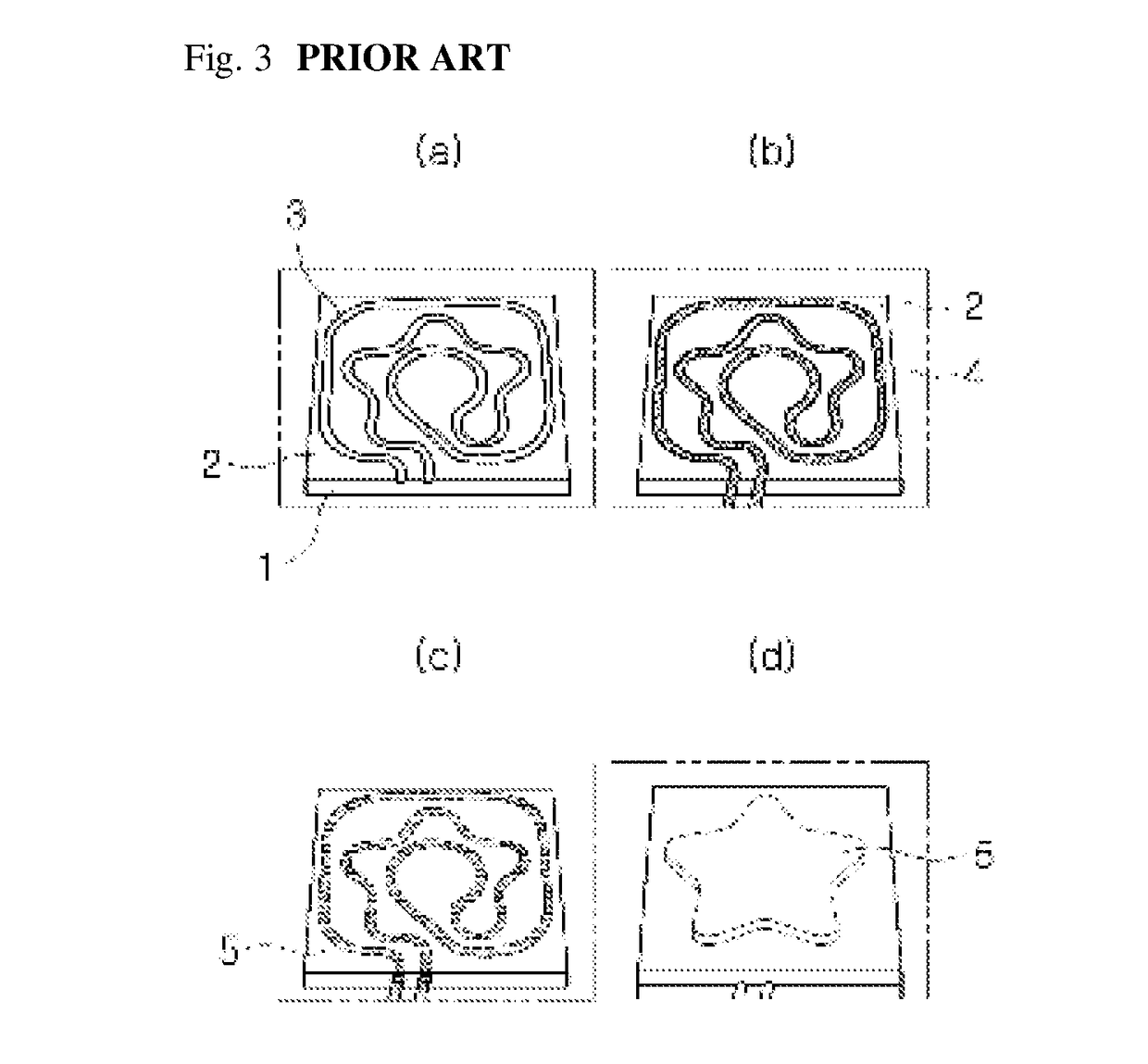

InactiveUS20110056384A1Simple configurationComplex configurationCombination devicesAuxillary pretreatmentHumidityBreathing

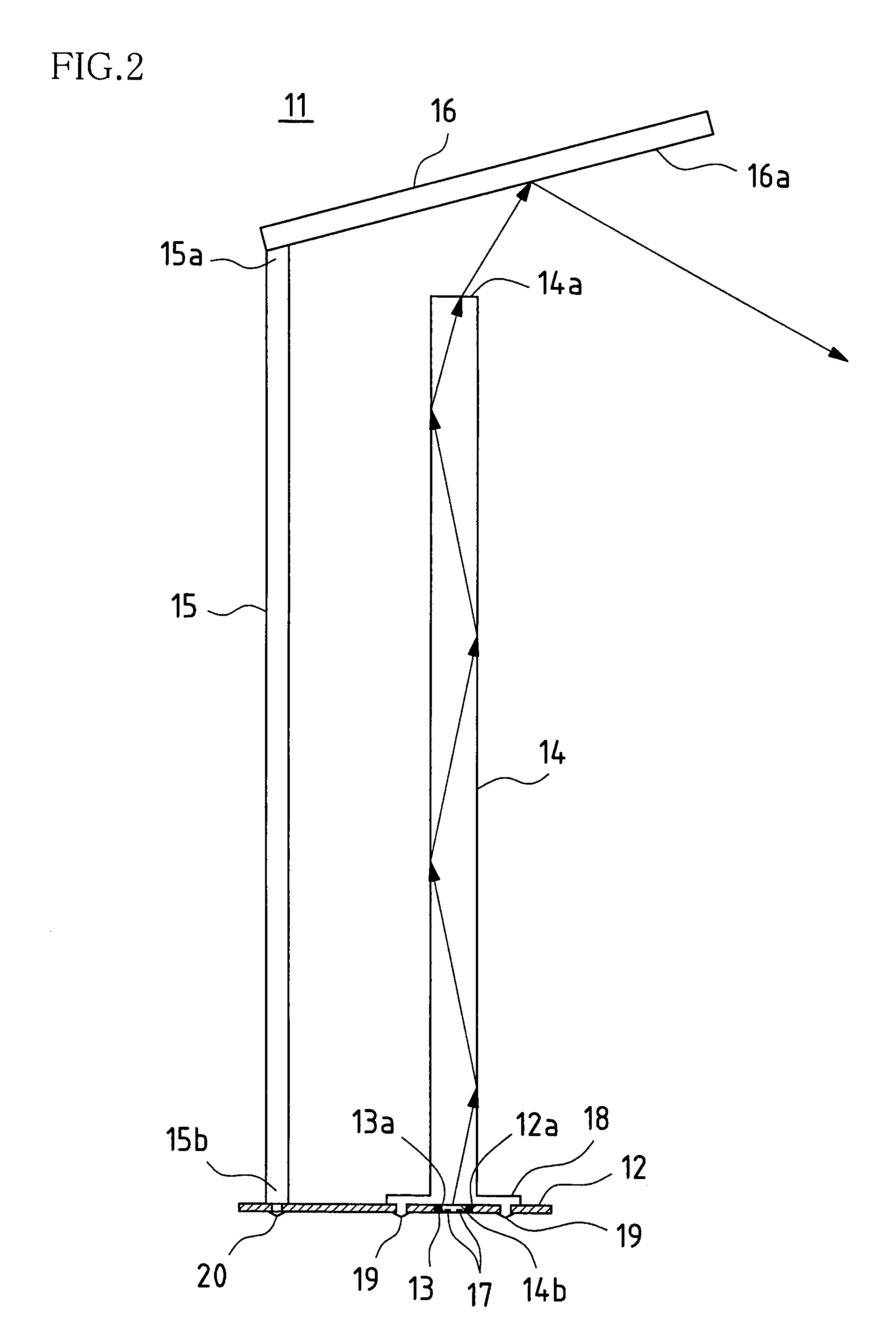

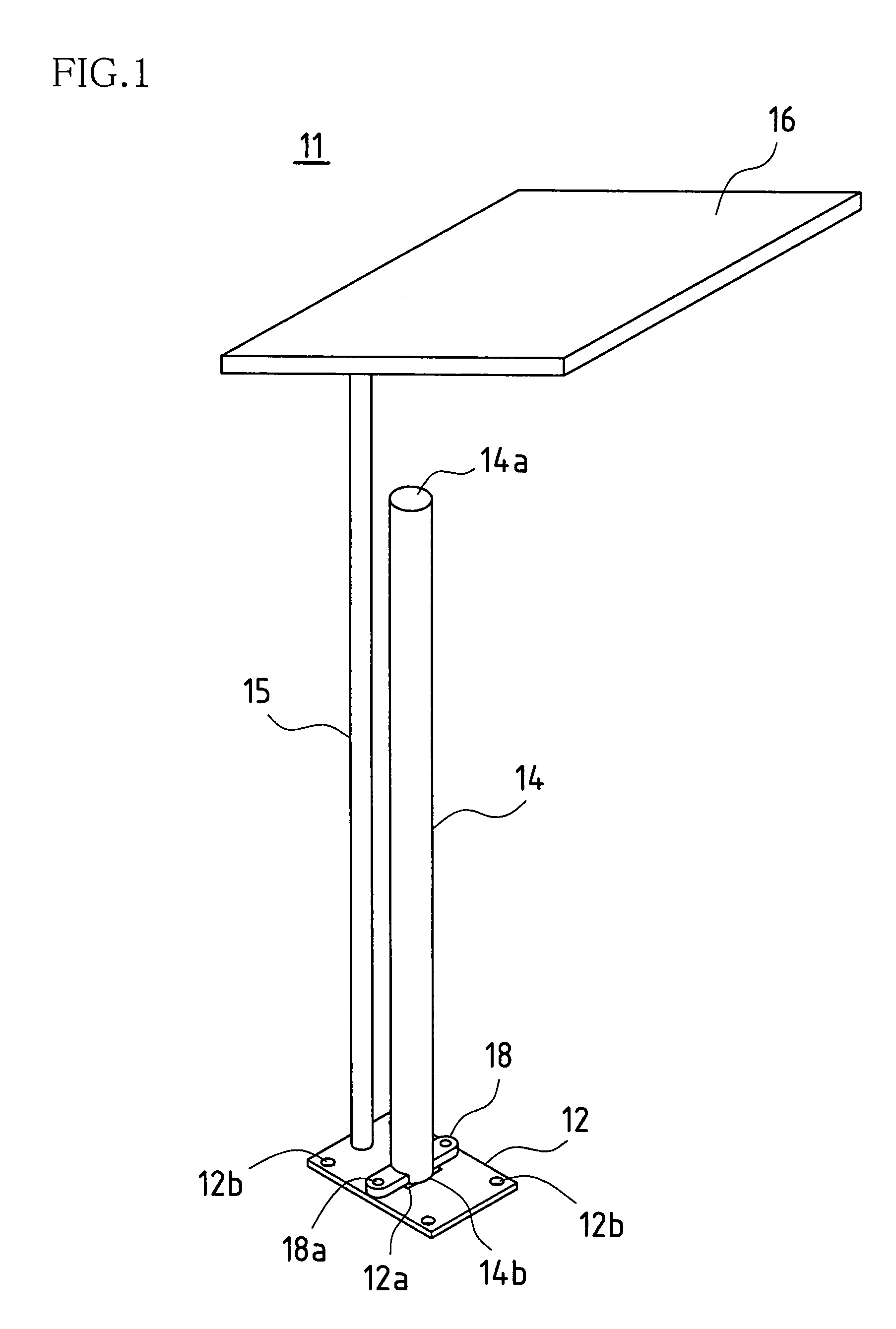

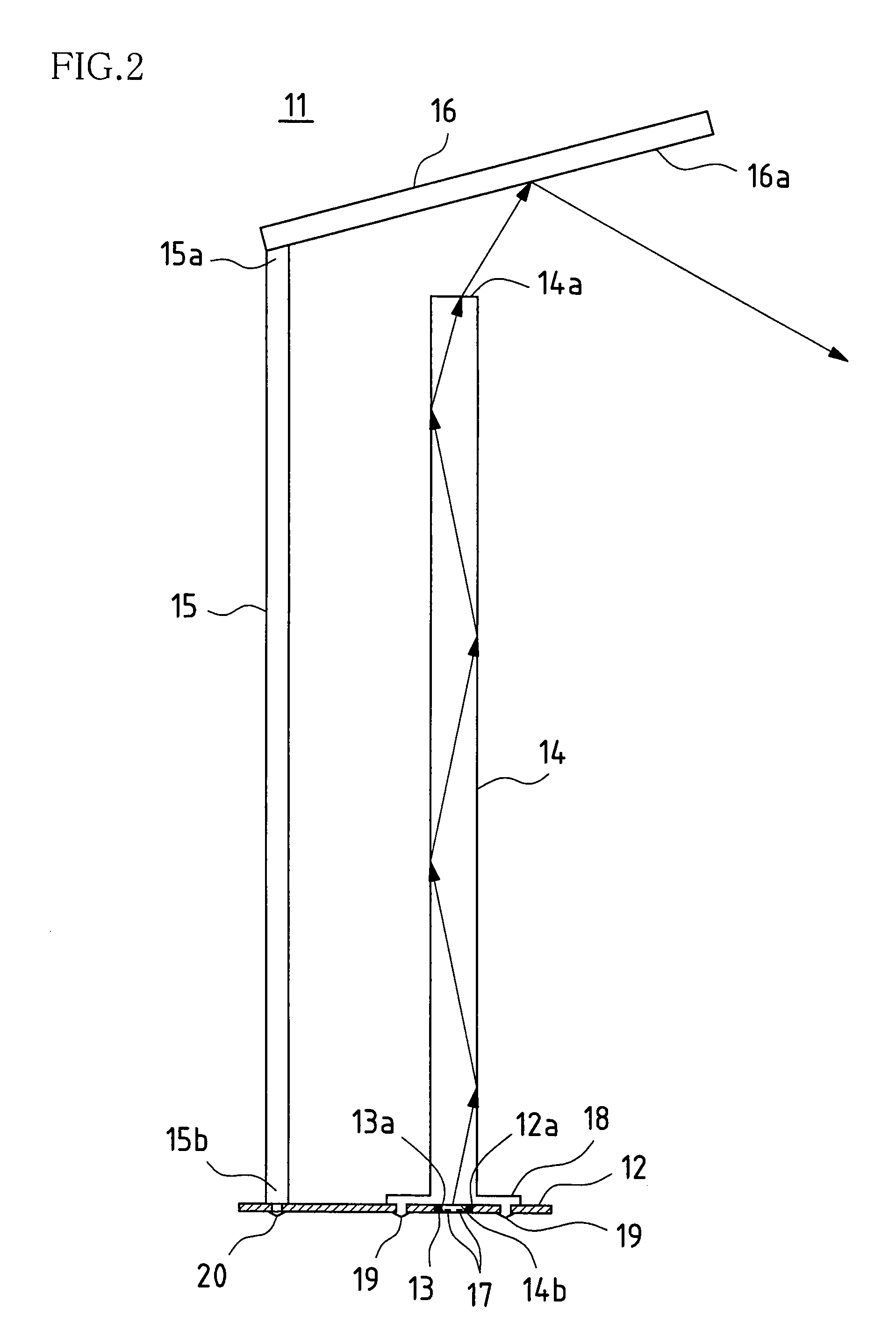

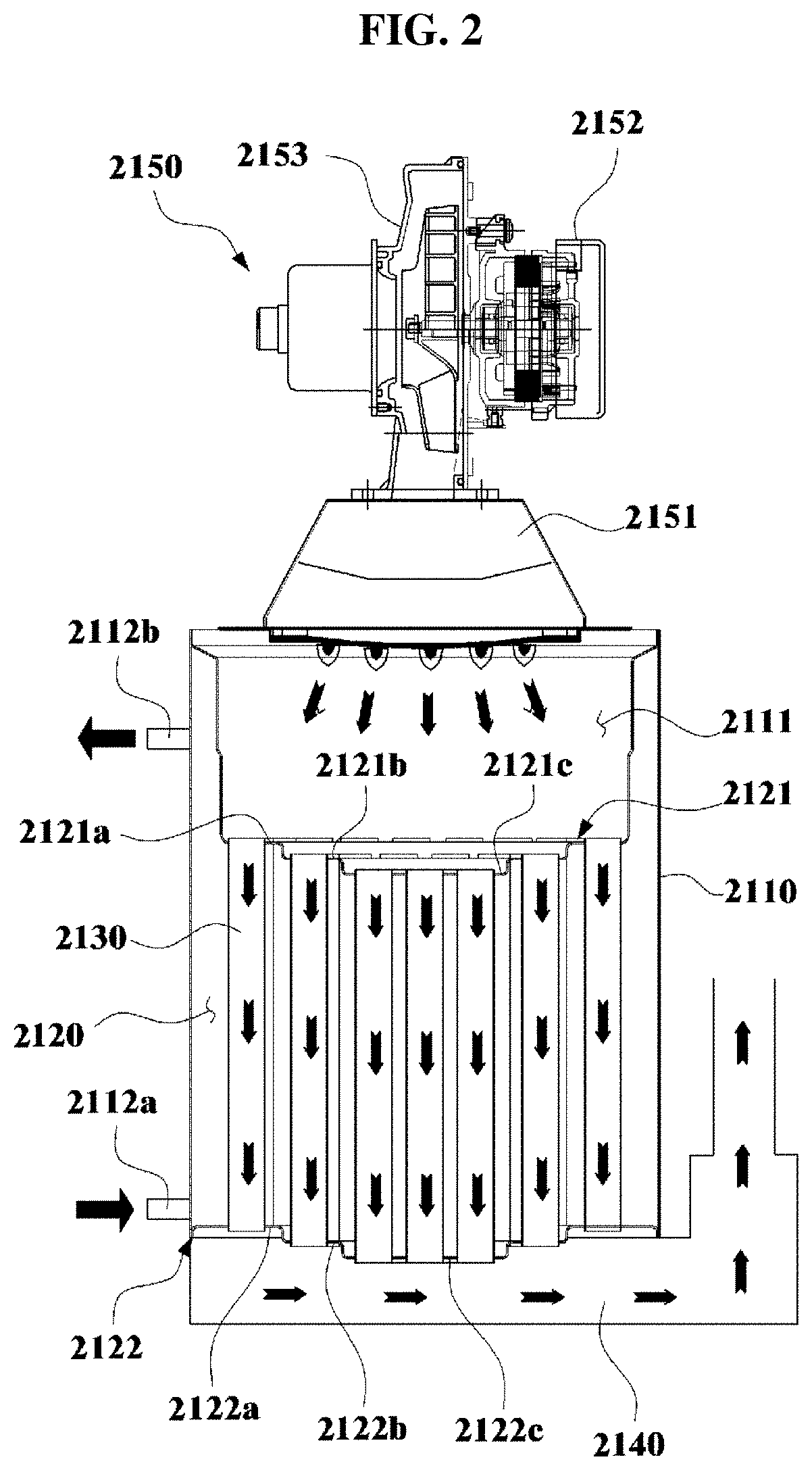

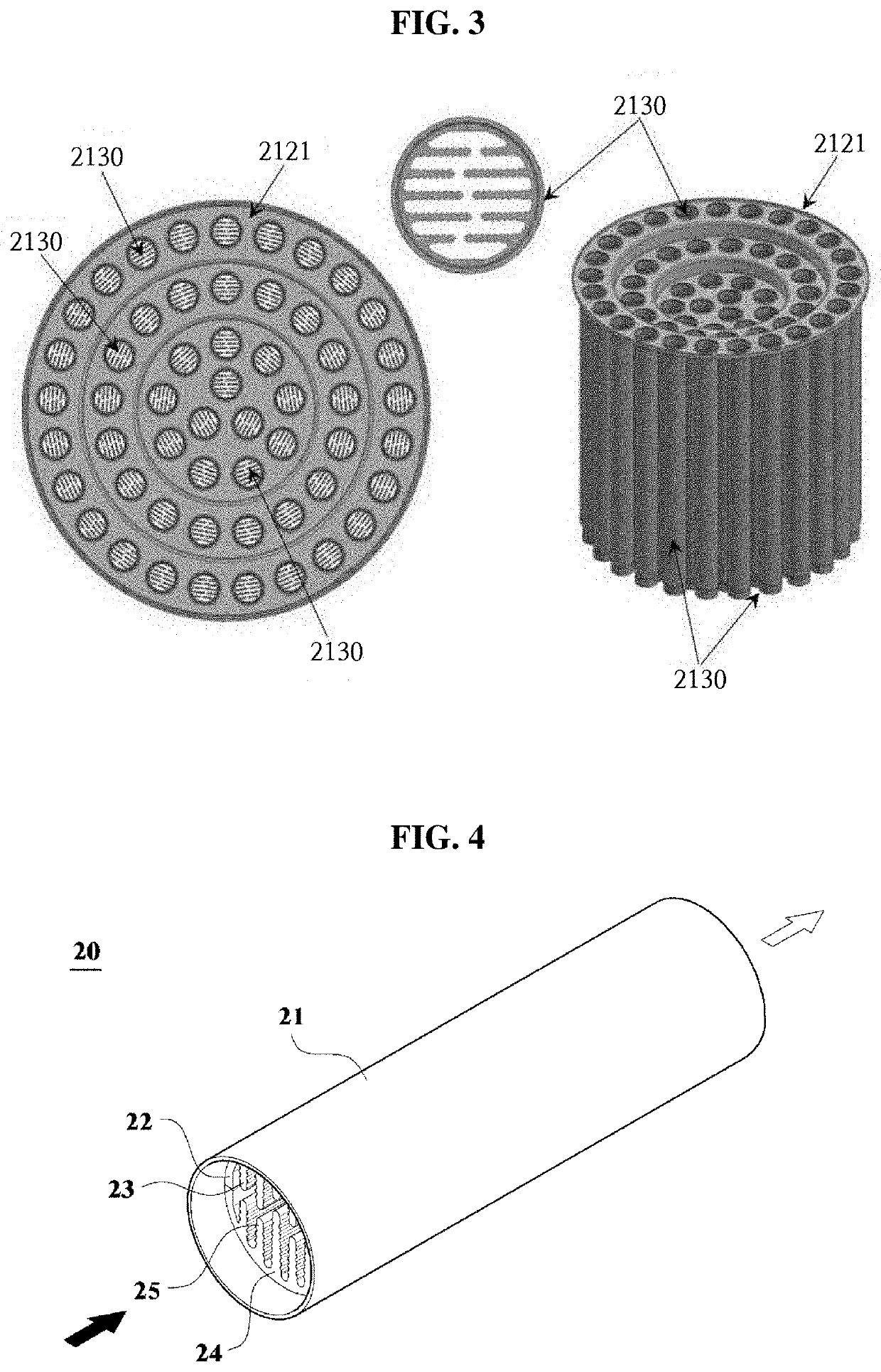

A humidity control and ventilation system for a building with an absorption-type humidity controller includes an air supply passage, air discharge passage and a processing unit. The air supply passage is configured to conduct intake air from an exterior inlet port, which is located at an outside of the building, to an interior outlet port, which is located at an inside of the building. The processing unit is inserted in the air supply passage. The air supply passage includes an intake duct that is located between the processing unit and the interior outlet port, and the intake duct includes a vertically extending section, which extends in a vertical direction to create an upflow of the intake air conducted from the processing unit toward the interior outlet port.

Owner:DENSO CORP

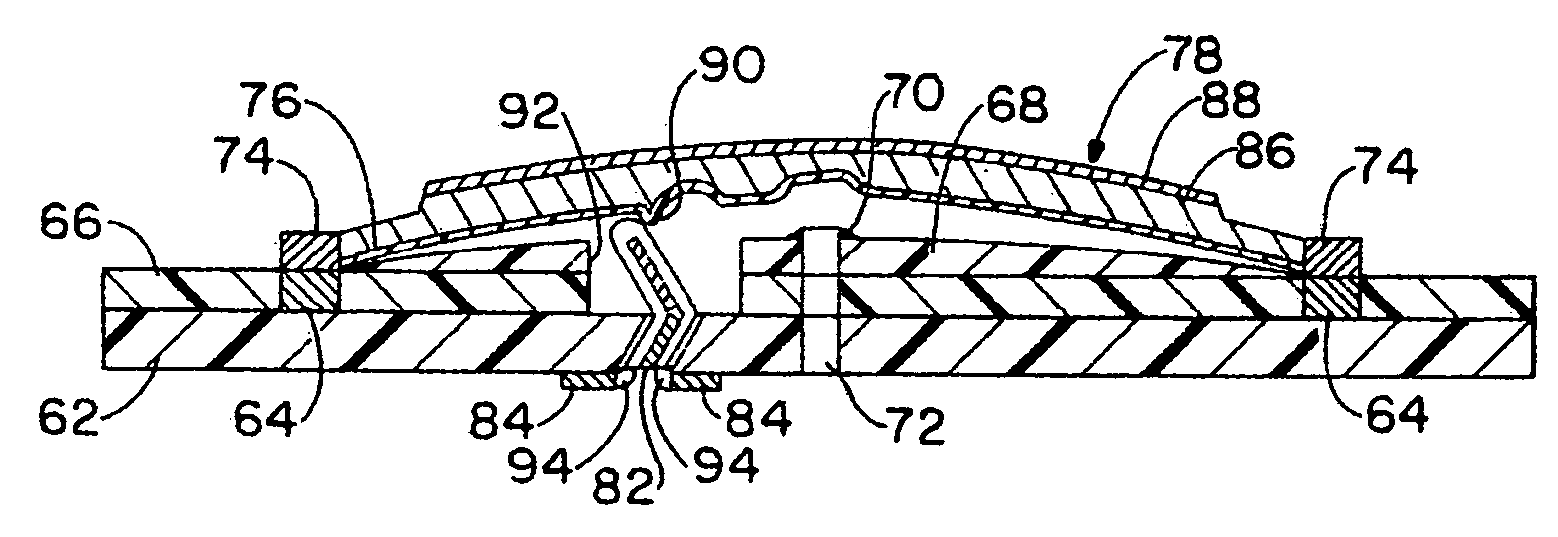

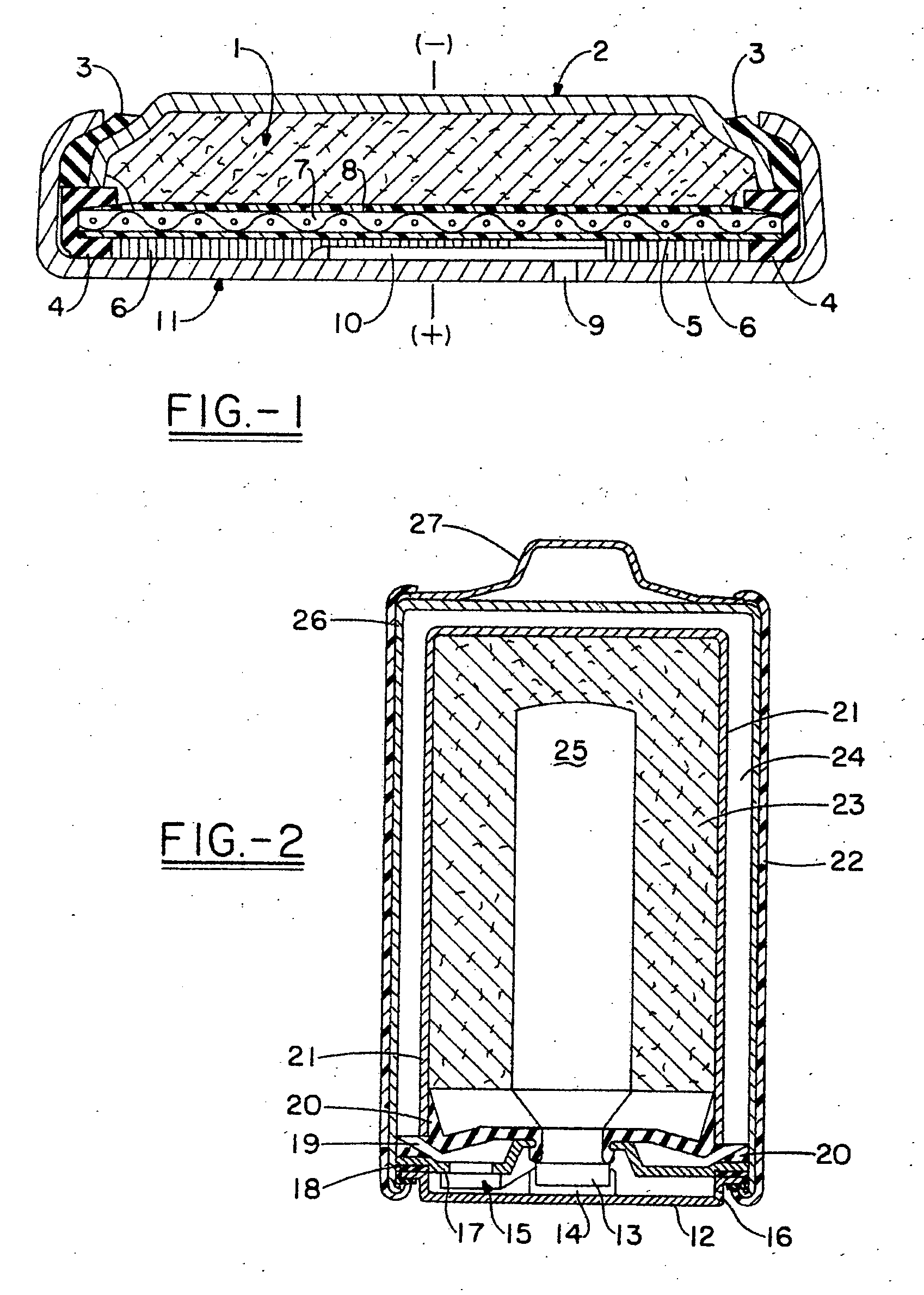

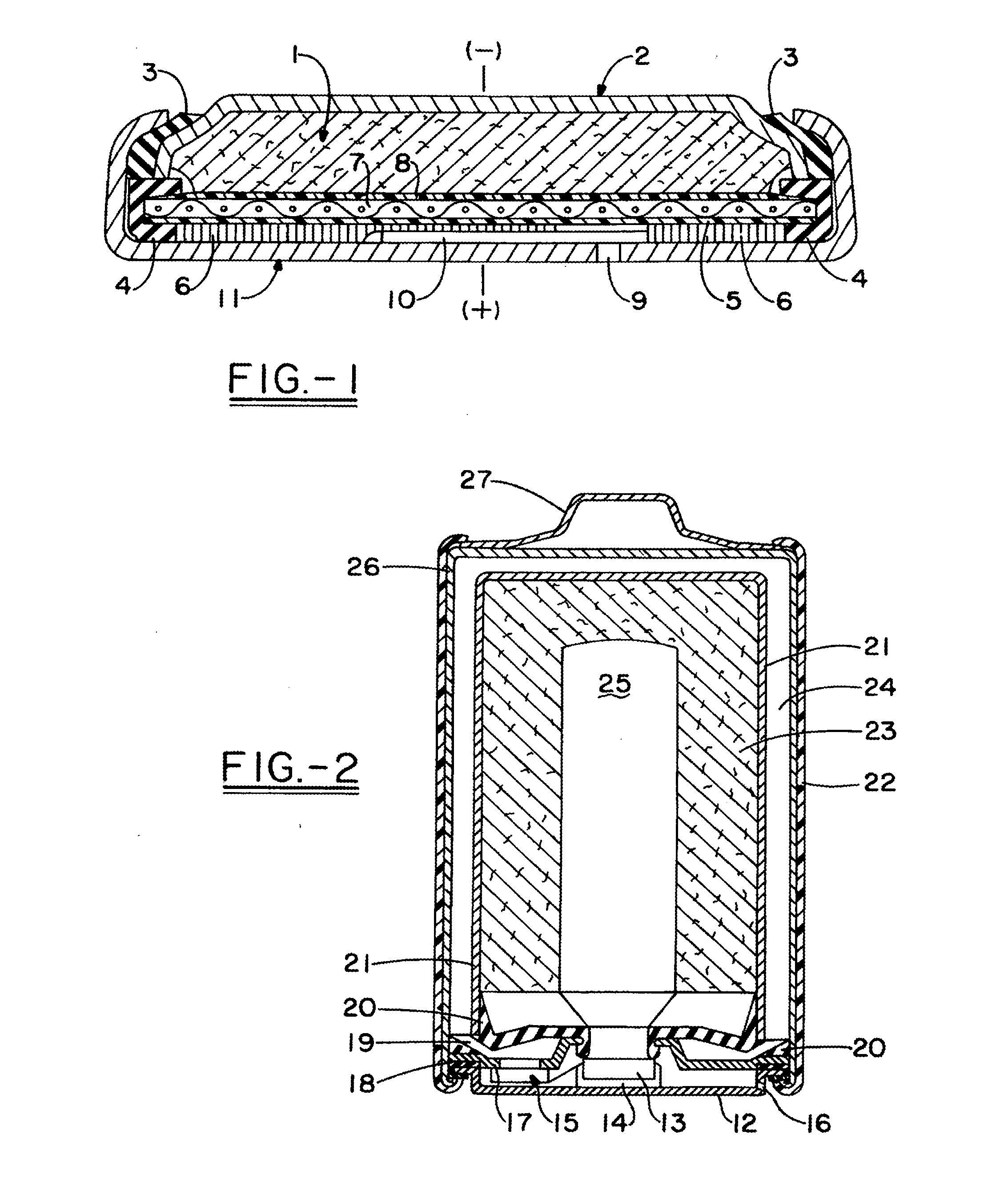

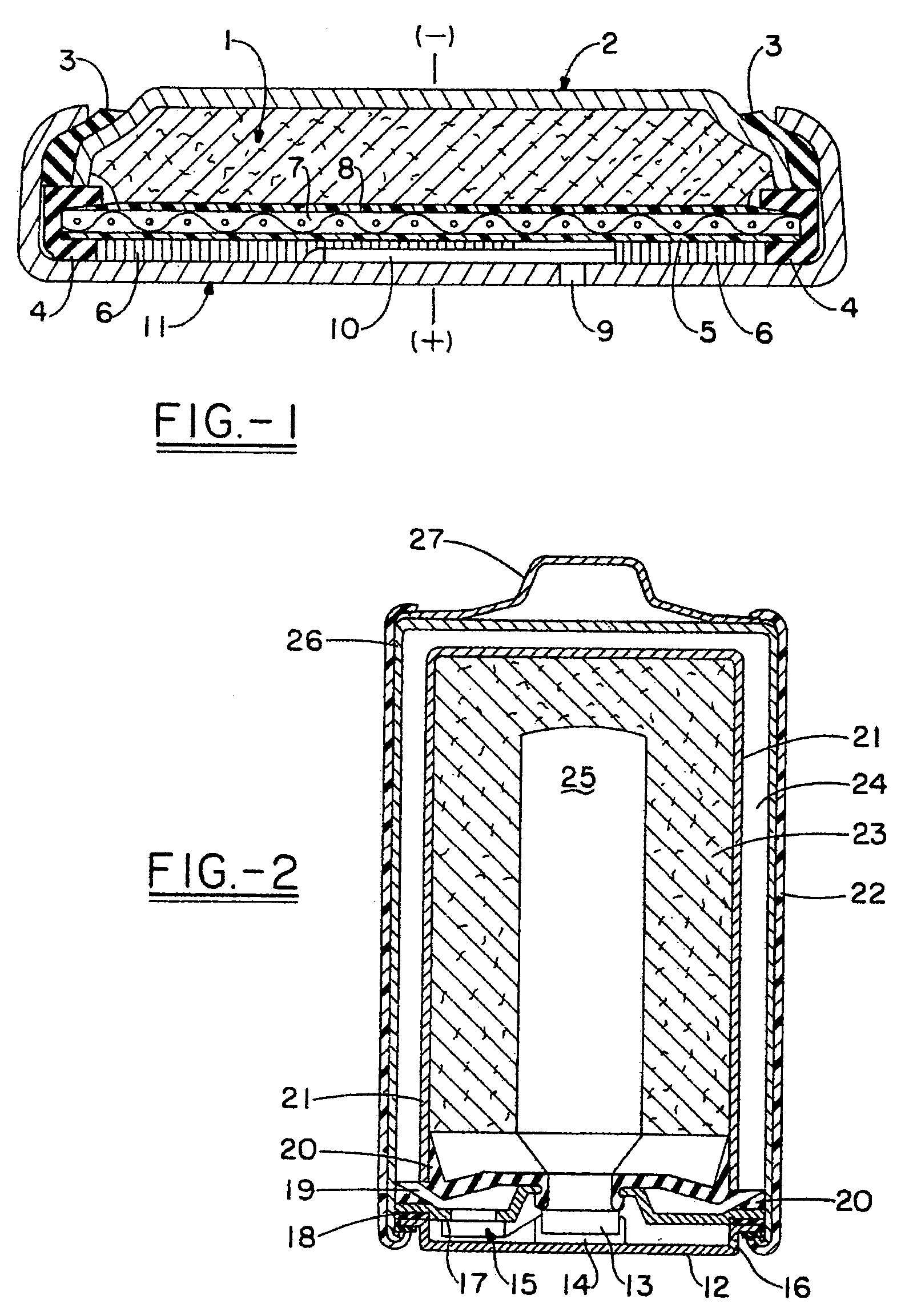

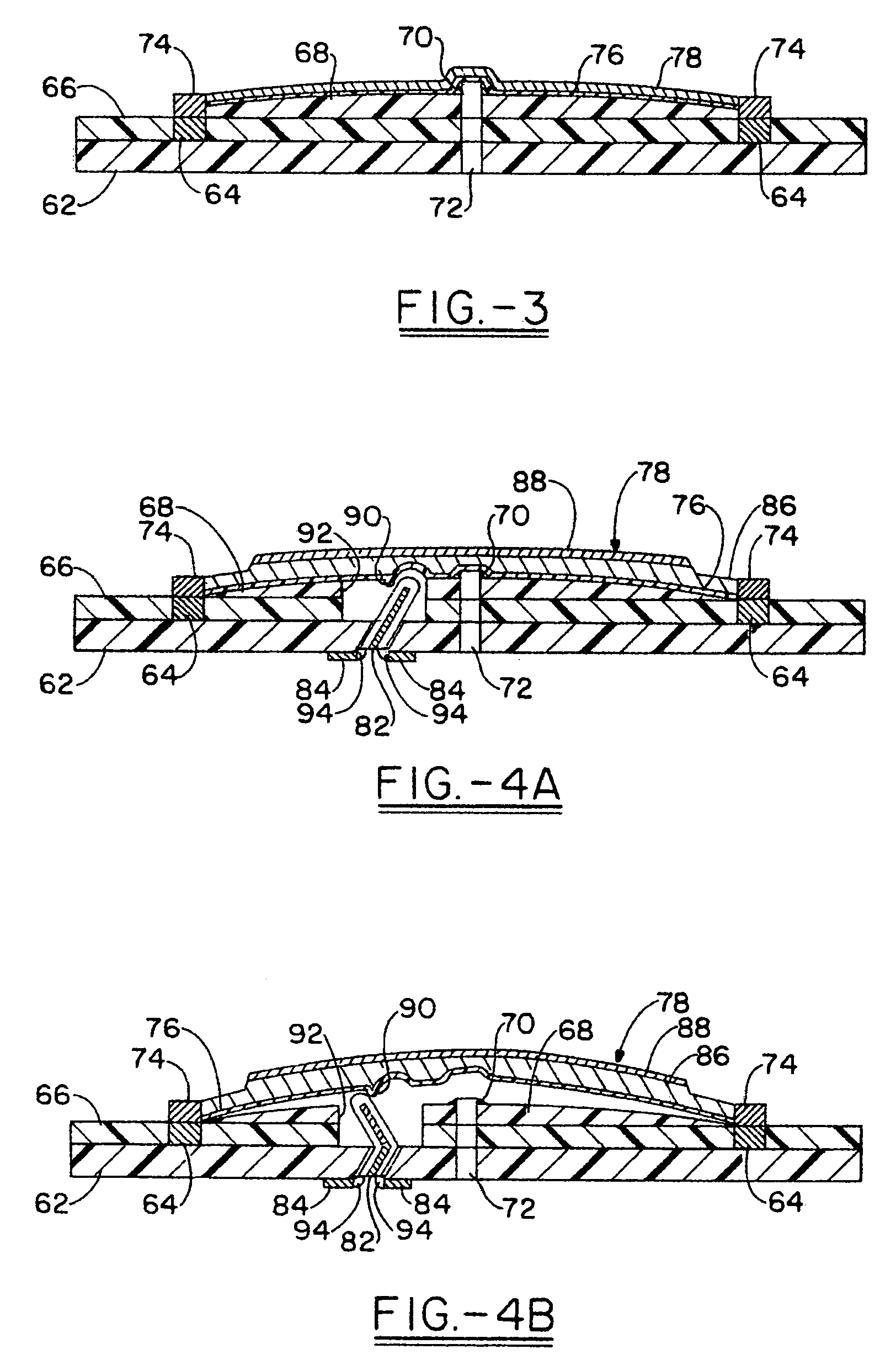

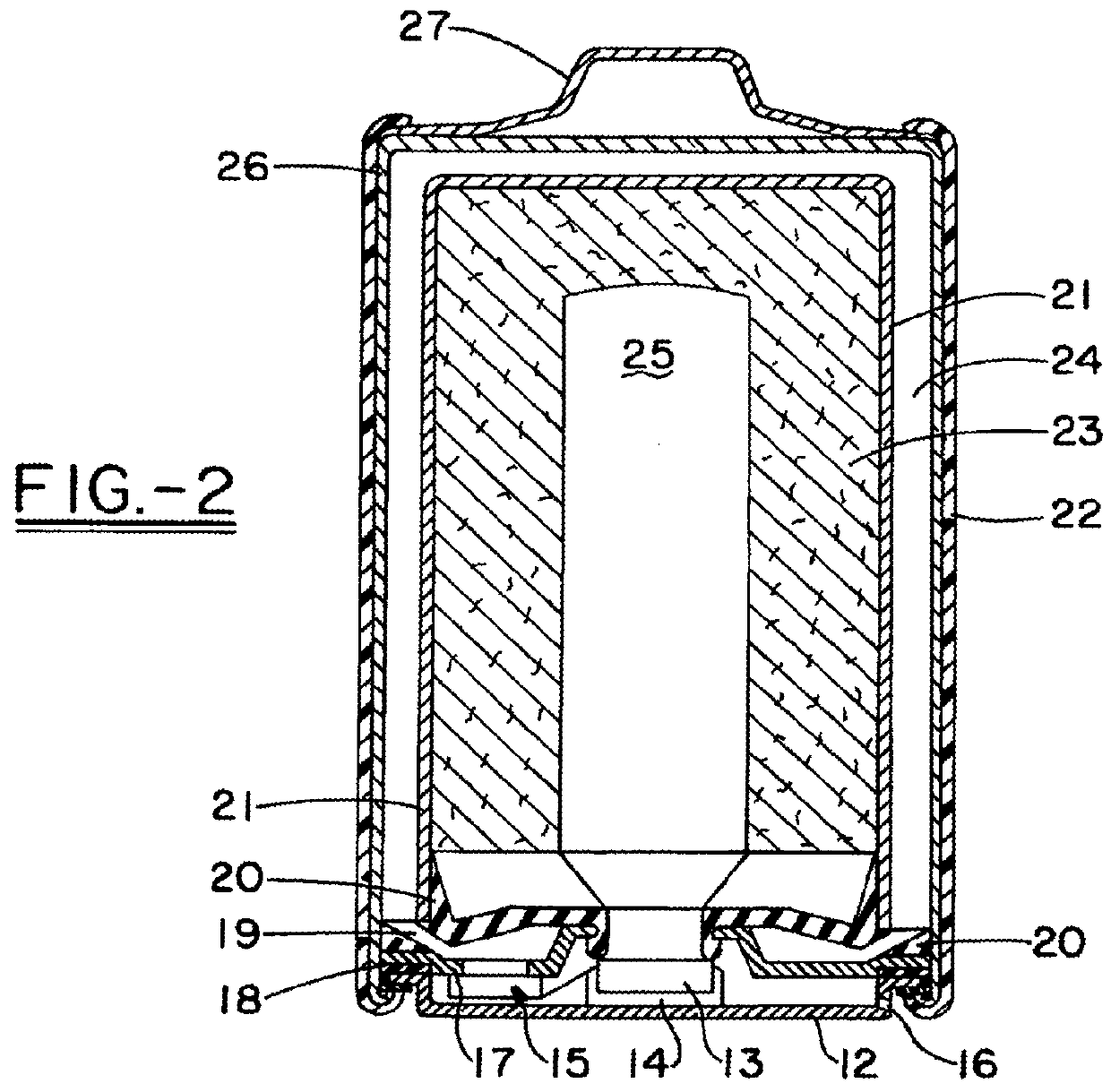

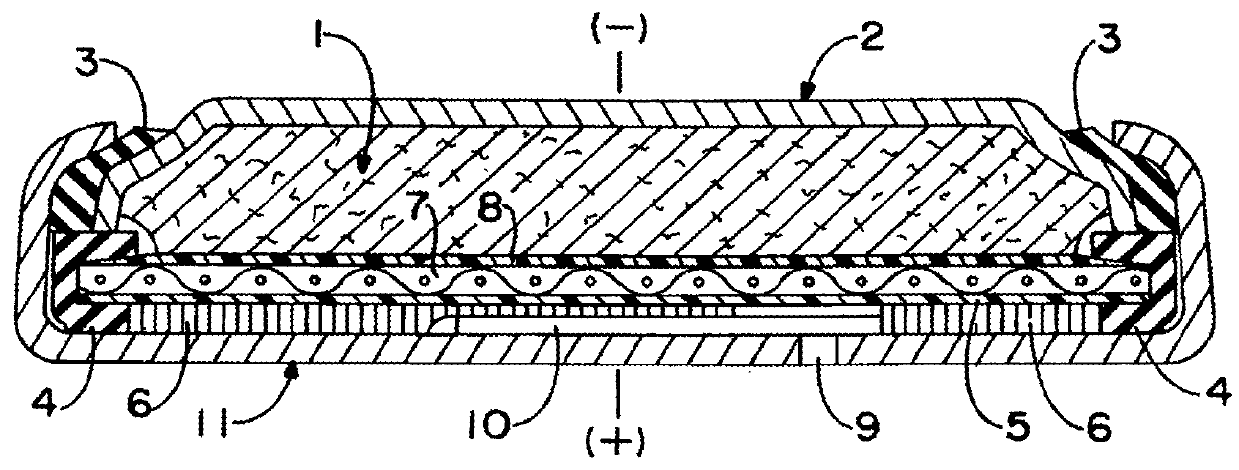

Fluid regulating microvalve assembly for fluid consuming cells

InactiveUS20060257701A1Low costInexpensive and straightforward to produceFuel and primary cellsReactant parameters controlElectrochemical cellBiomedical engineering

A fluid regulating microvalve assembly for use to control fluid flow to a fluid consuming electrode, such as an oxygen reduction electrode, in an electrochemical cell. The microvalve assembly includes a stationary valve body having an aperture and a microactuator movable from a first position where the microvalve body aperture is closed to fluid flow to at least a second position where fluid is able to pass through the microvalve body aperture. The fluid regulating microvalve assembly can utilize cell potential or a separate source to open and close the microvalve. The fluid regulating microvalve assembly can be located outside the cell housing or inside the cell housing, for example between one or more fluid inlet apertures and the fluid consuming electrode. The invention includes a method of making a multilayer microvalve assembly, particularly one for use in a fluid depolarized battery, using a printing process to deposit at least one of the layers.

Owner:SCHUMM BROOKE JR +3

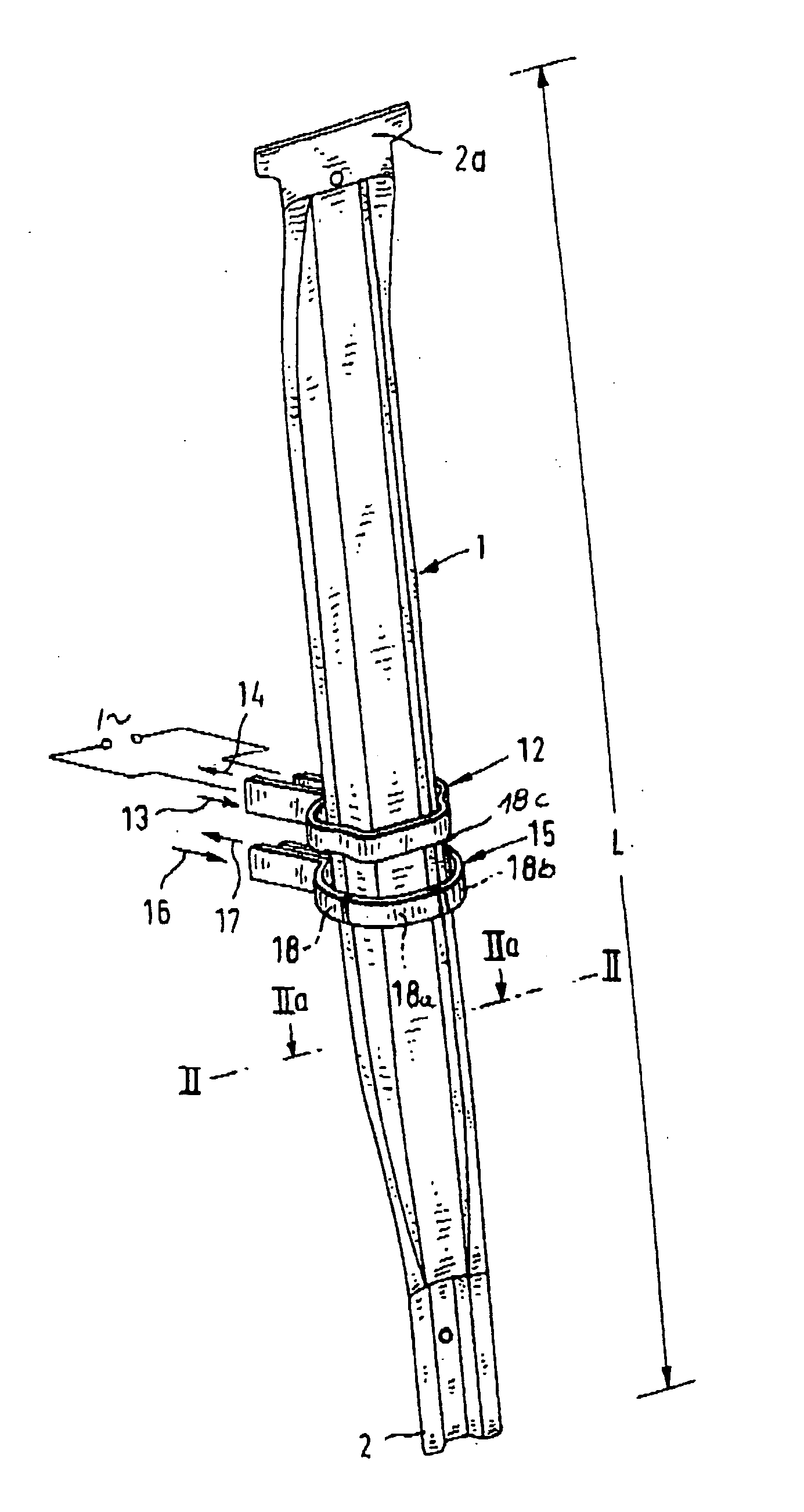

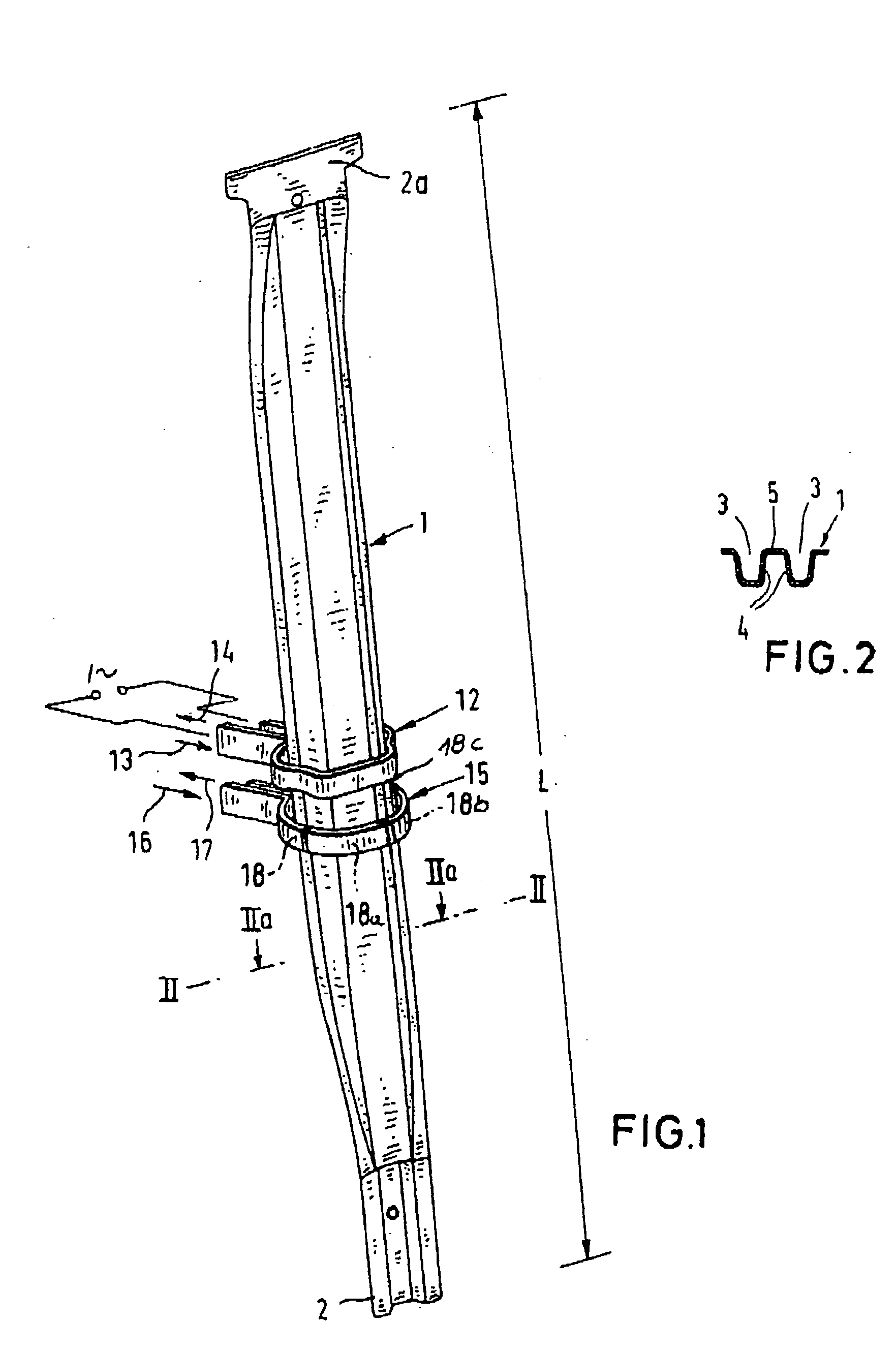

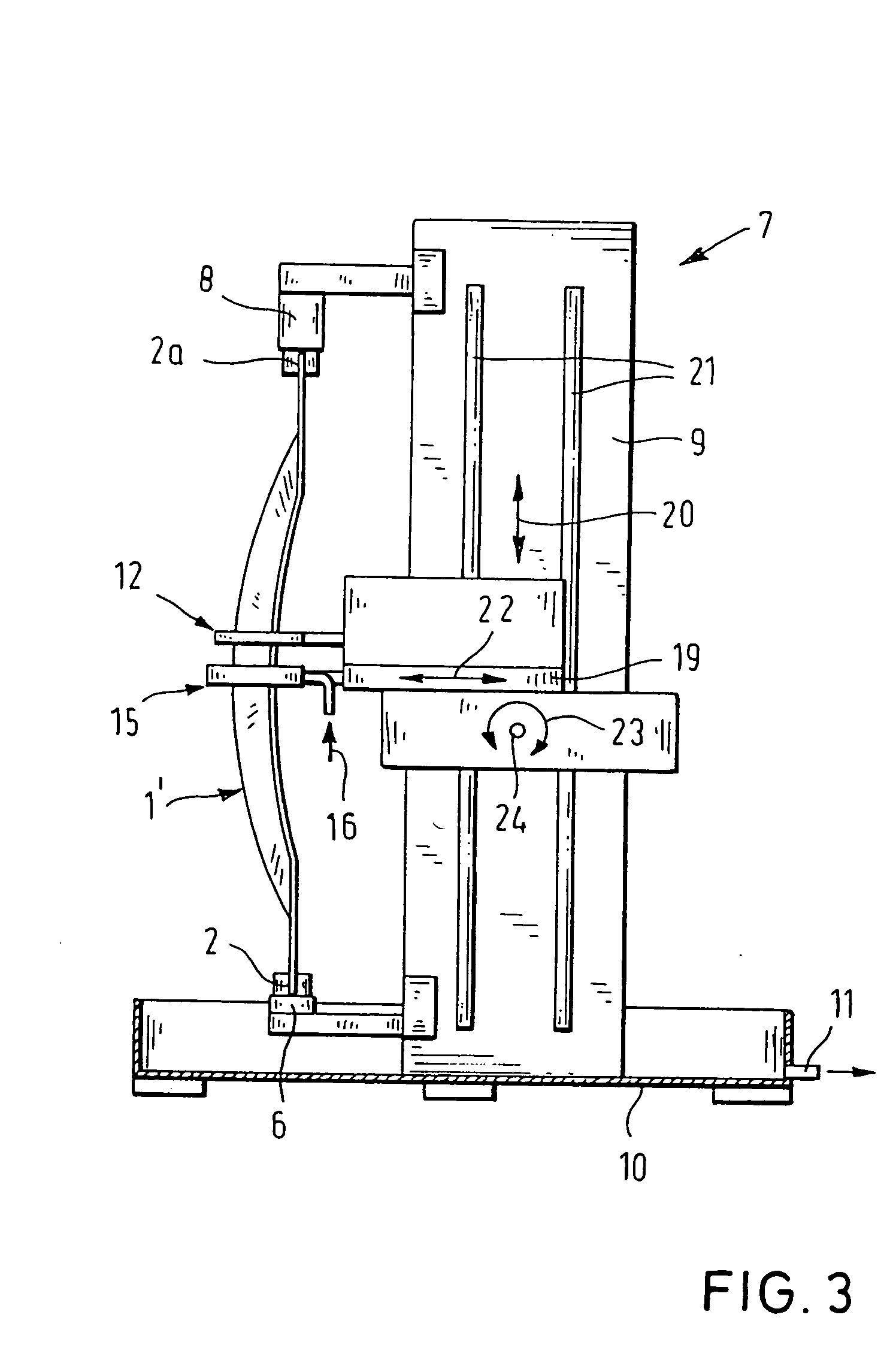

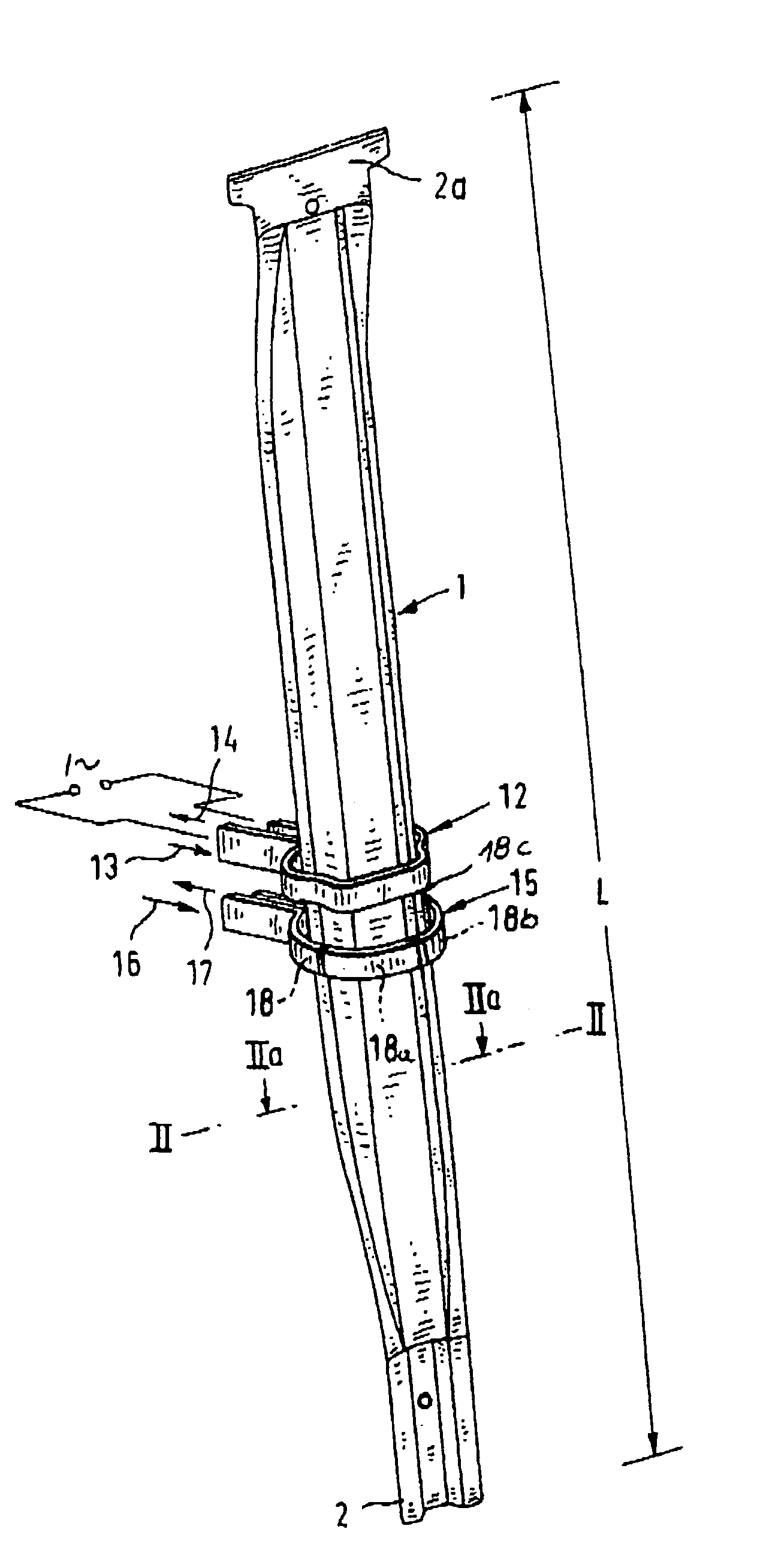

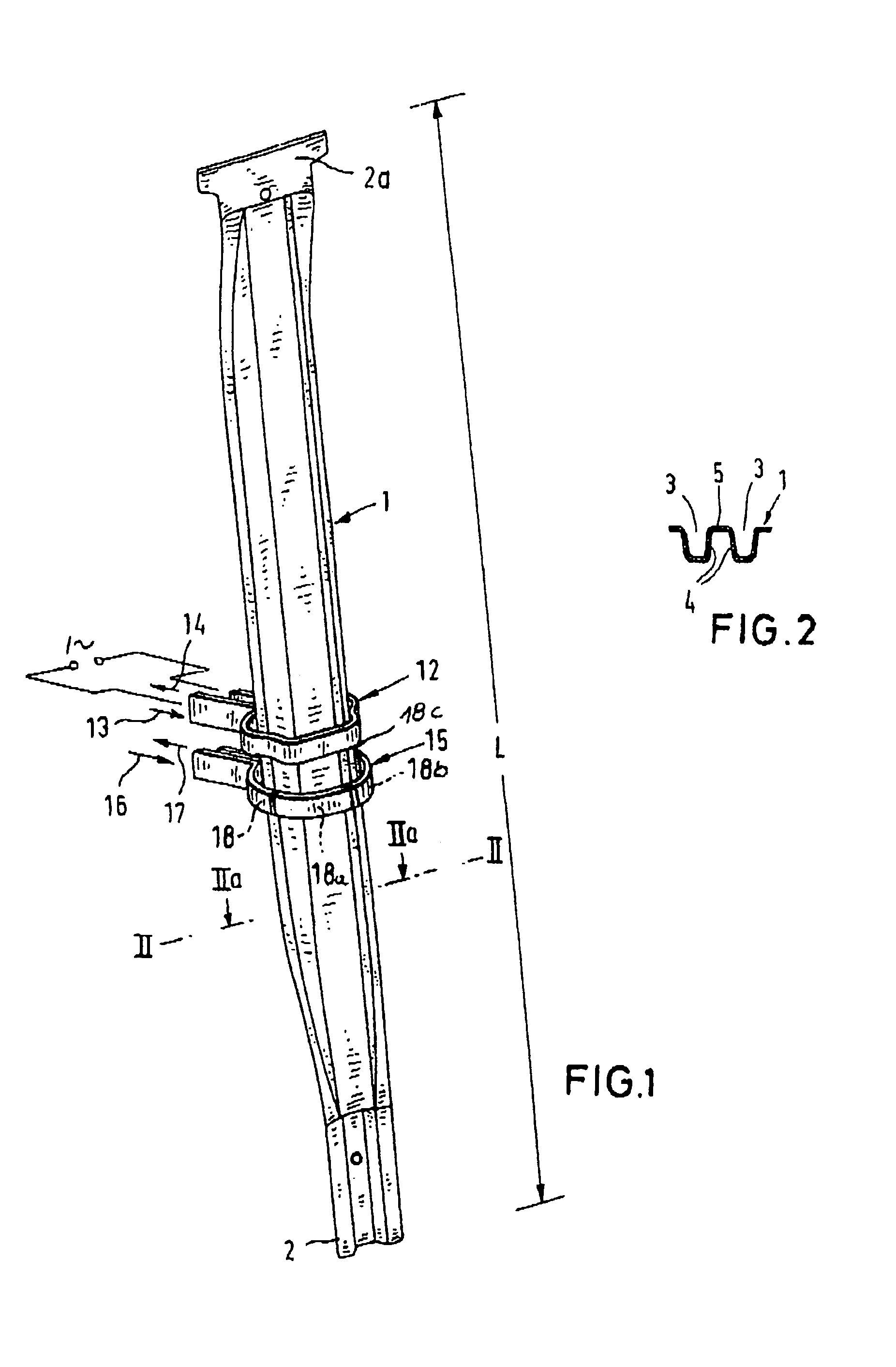

Apparatus for heat treatment of structural body parts in the automobile industry

InactiveUS20050006828A1Reduce maintenanceReduce wearFurnace typesIncreasing energy efficiencySheet steelHorizontal axis

Apparatus for heat-treating an elongate structural body part made from a blank compressed while being soft or from steel strip of hardenable 22 Mn B5 mod. steel sheet with a thickness of 1 mm to 3 mm, includes an apparatus for positioning the structural body part in substantially upright disposition. Placed in surrounding relationship to the structural body part is an induction element which can move from bottom to top, thereby being able to follow a contour of the structural body part and allowing to at least partially heat the structural body part to an austenitizing temperature suitable for hardening. Disposed adjacent to the induction element is a cooling unit which follows the induction element in movement direction. The induction element and the cooling unit are moveable relative to one another and connected to a tool carriage which is mounted to a column for movement in a vertical direction, in a transverse direction to the column and about a horizontal axis.

Owner:BENTELER AKTIENGES

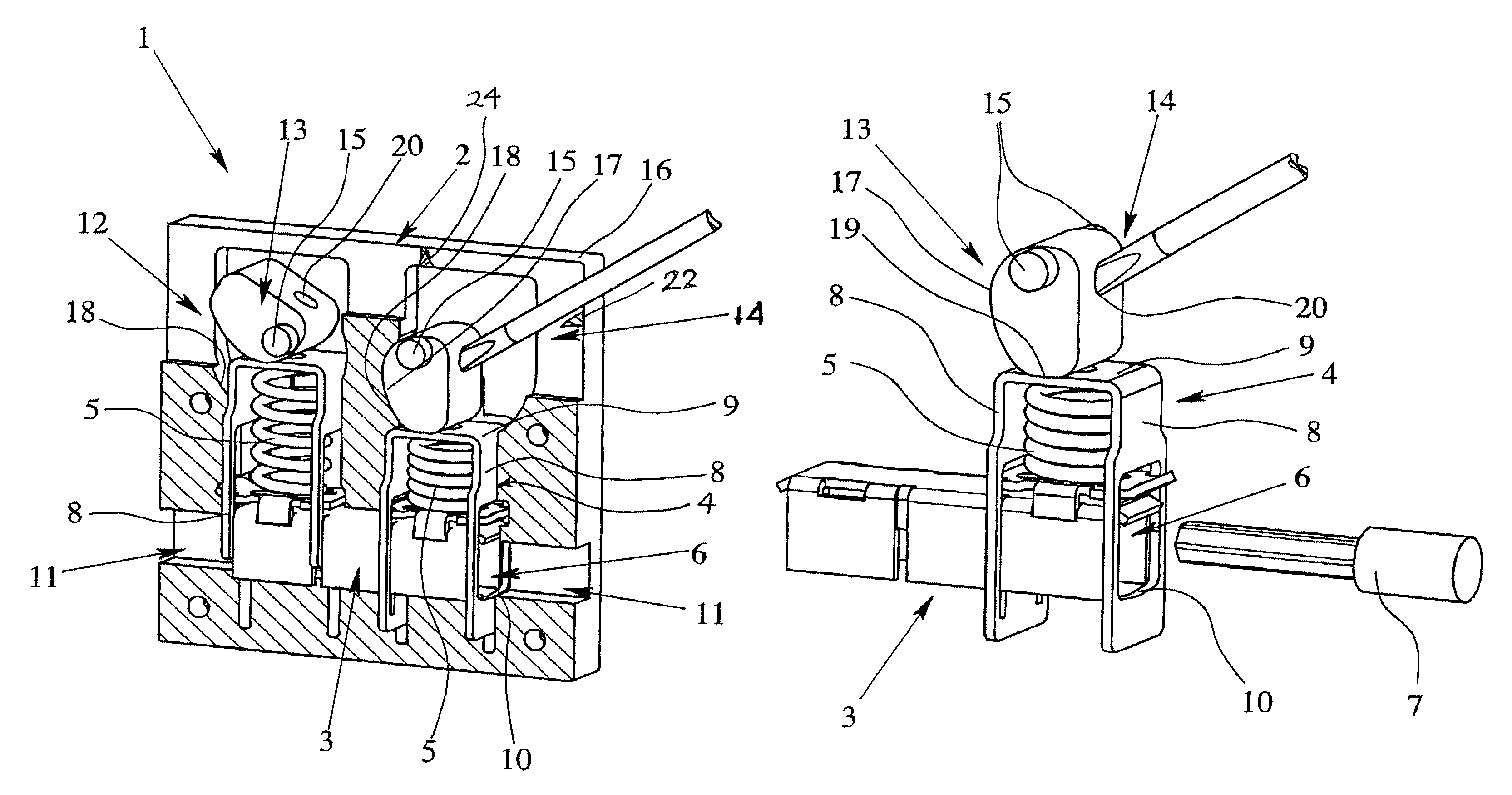

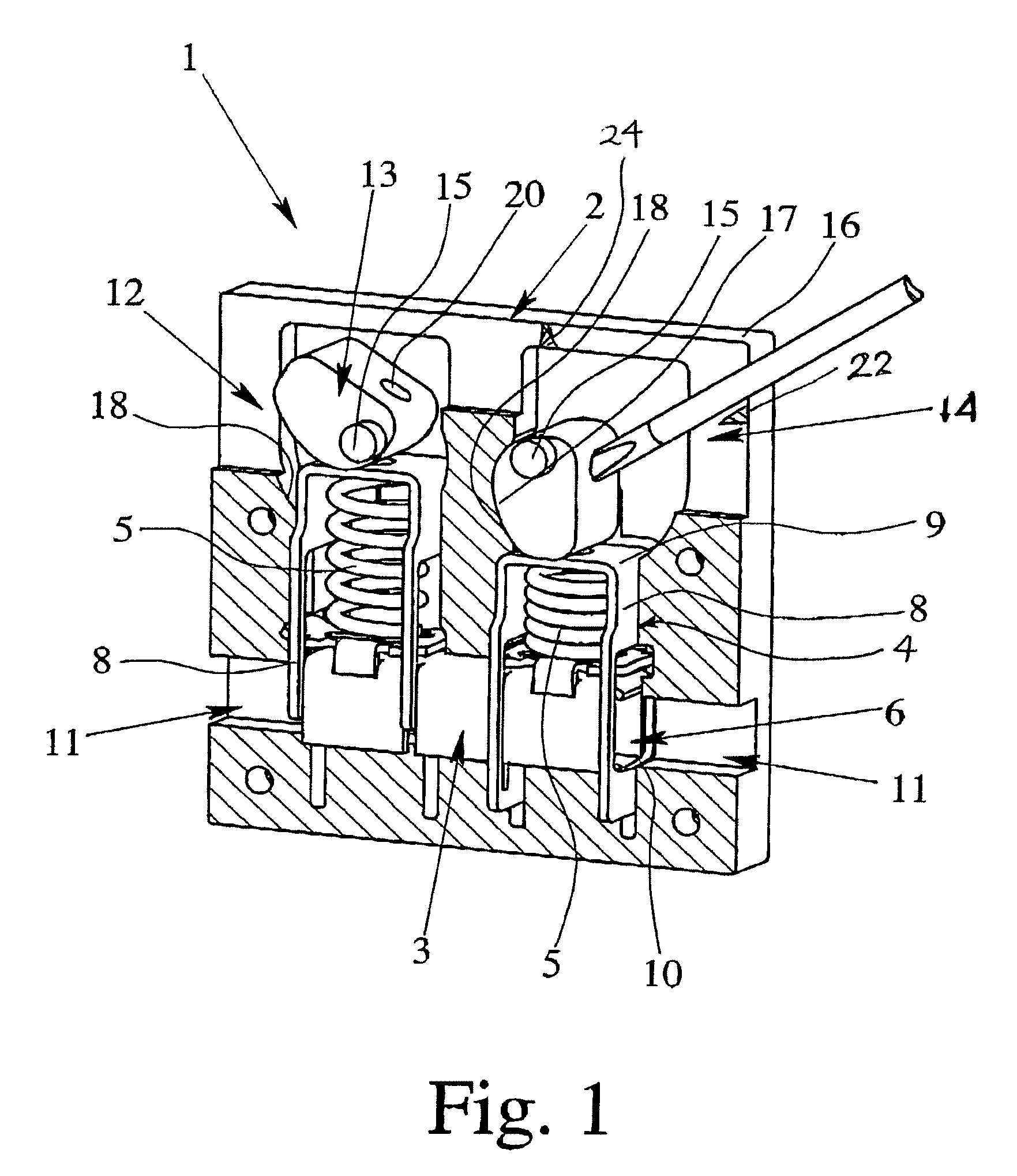

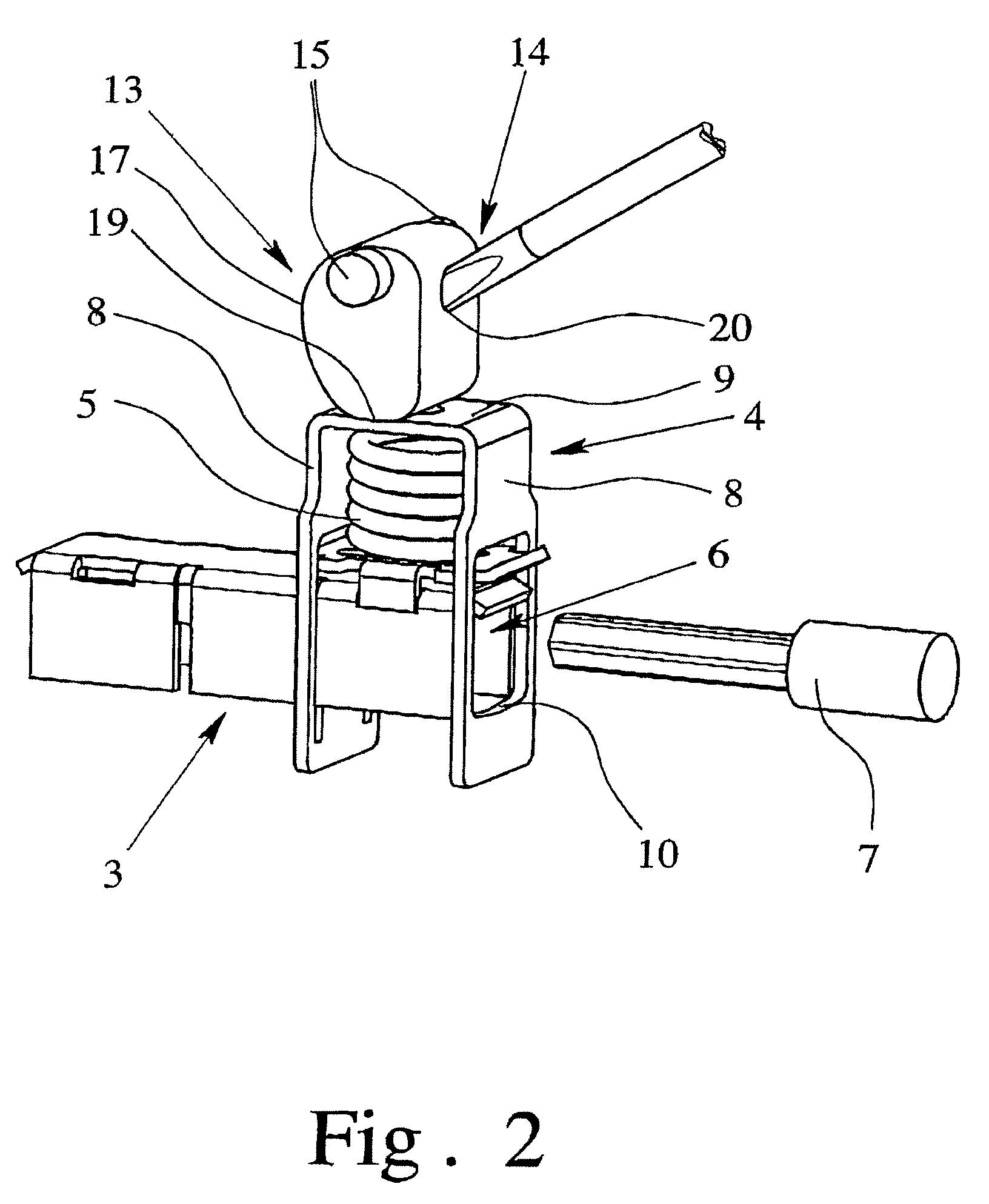

Electrical terminal

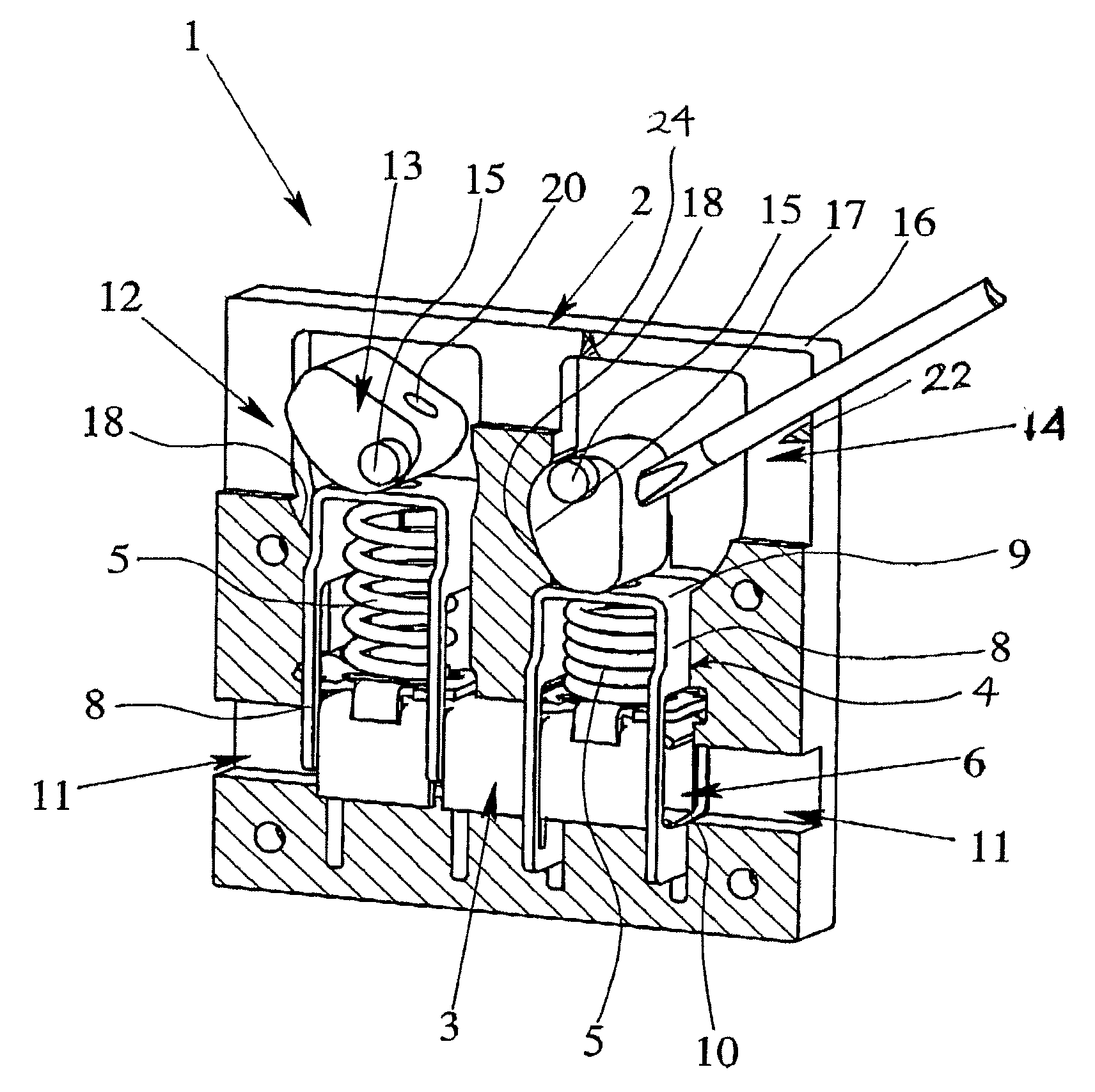

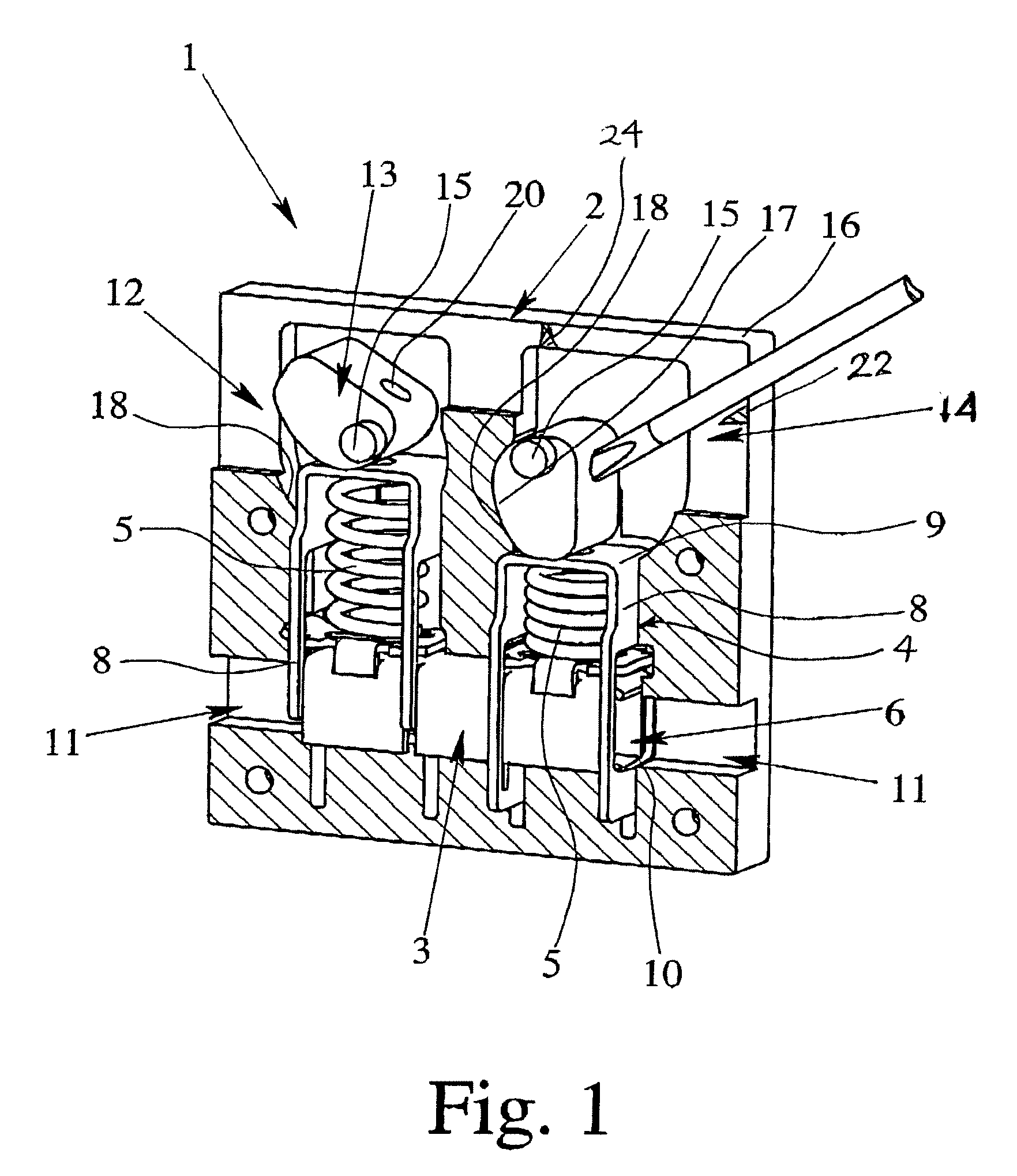

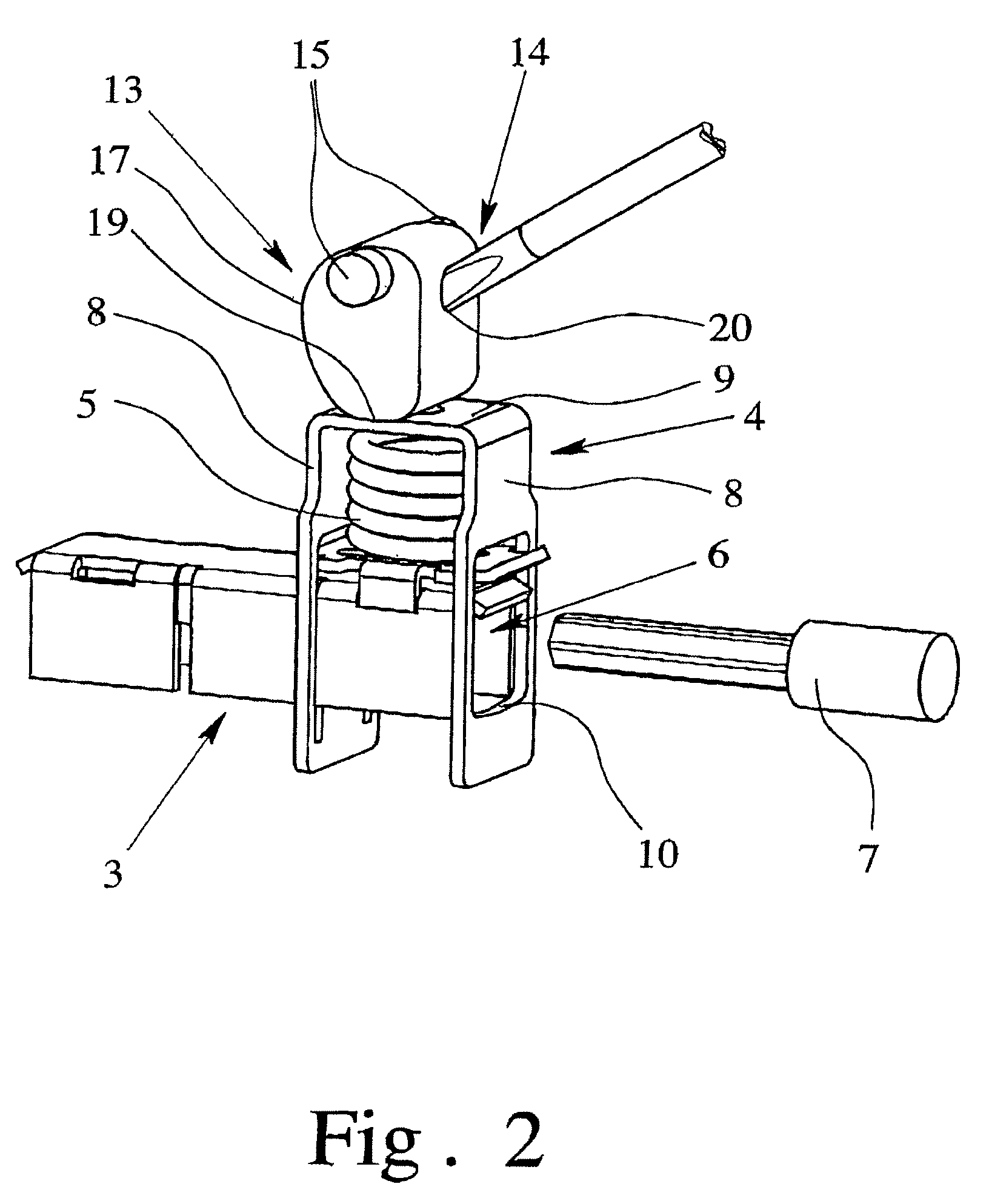

InactiveUS7354319B2Simple manual opening of the clamping siteLarge sectionContact members penetrating/cutting insulation/cable strandsClamped/spring connectionsEngineeringCam

An electrical terminal includes an insulating housing, a conductor bar, strain-relief clamp connections and actuating elements located in the insulating housing for opening and closing the strain-relief clamp connections. The electrical terminal enables simple manual opening of the clamping site even when the strain-relief clamp connection is designed for leads with large cross section since the actuation element is made as an actuating cam that is eccentrically supported in the insulating housing. The actuating cam can be pivoted by an actuating tool out of a first position in which the strain-relief clamp connection is closed into a second position in which the strain-relief clamp connection is opened so that an electric lead can be inserted between the conductor bar and a through opening in the strain relief clamp connection.

Owner:PHOENIX CONTACT GMBH & CO KG

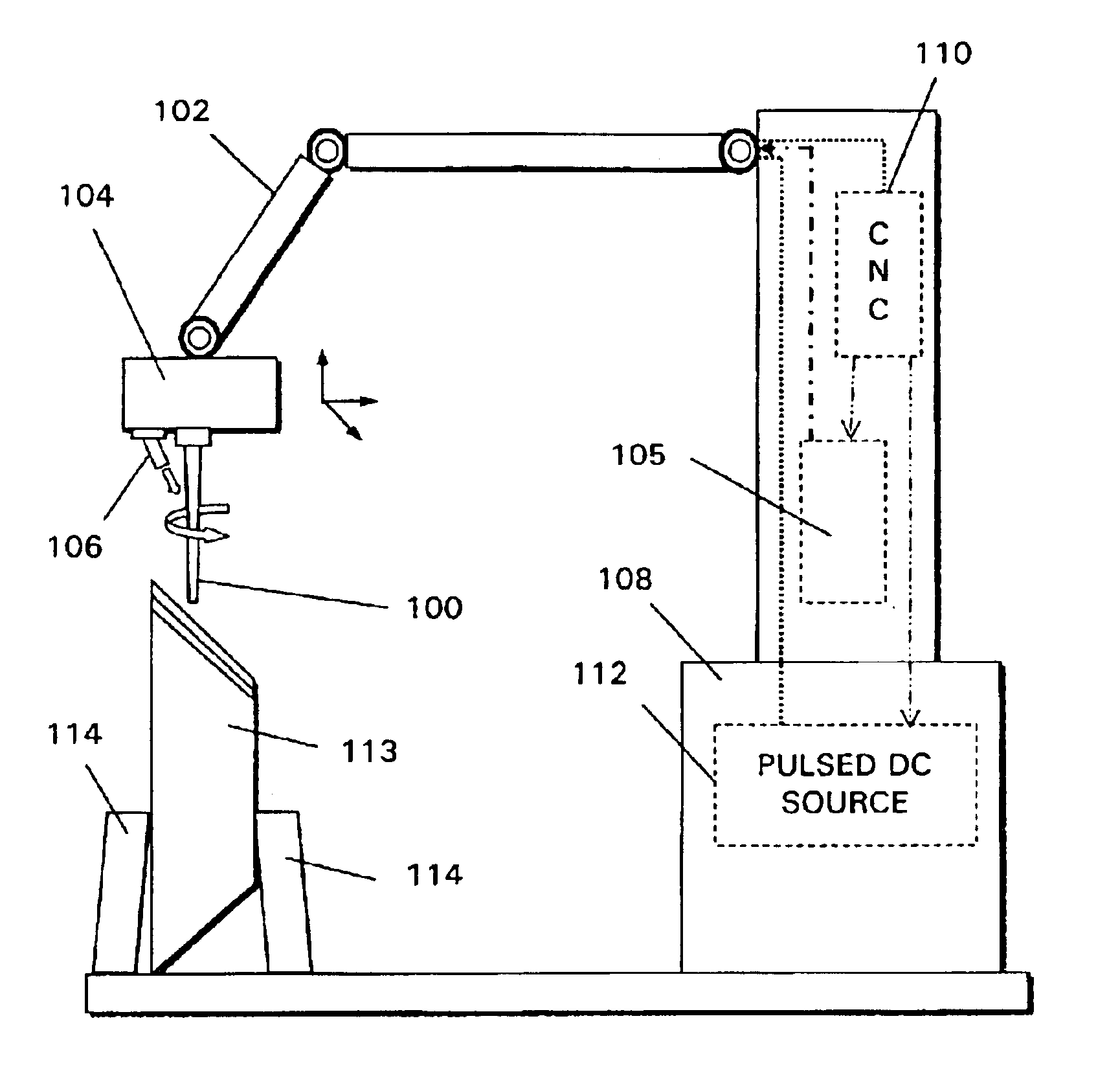

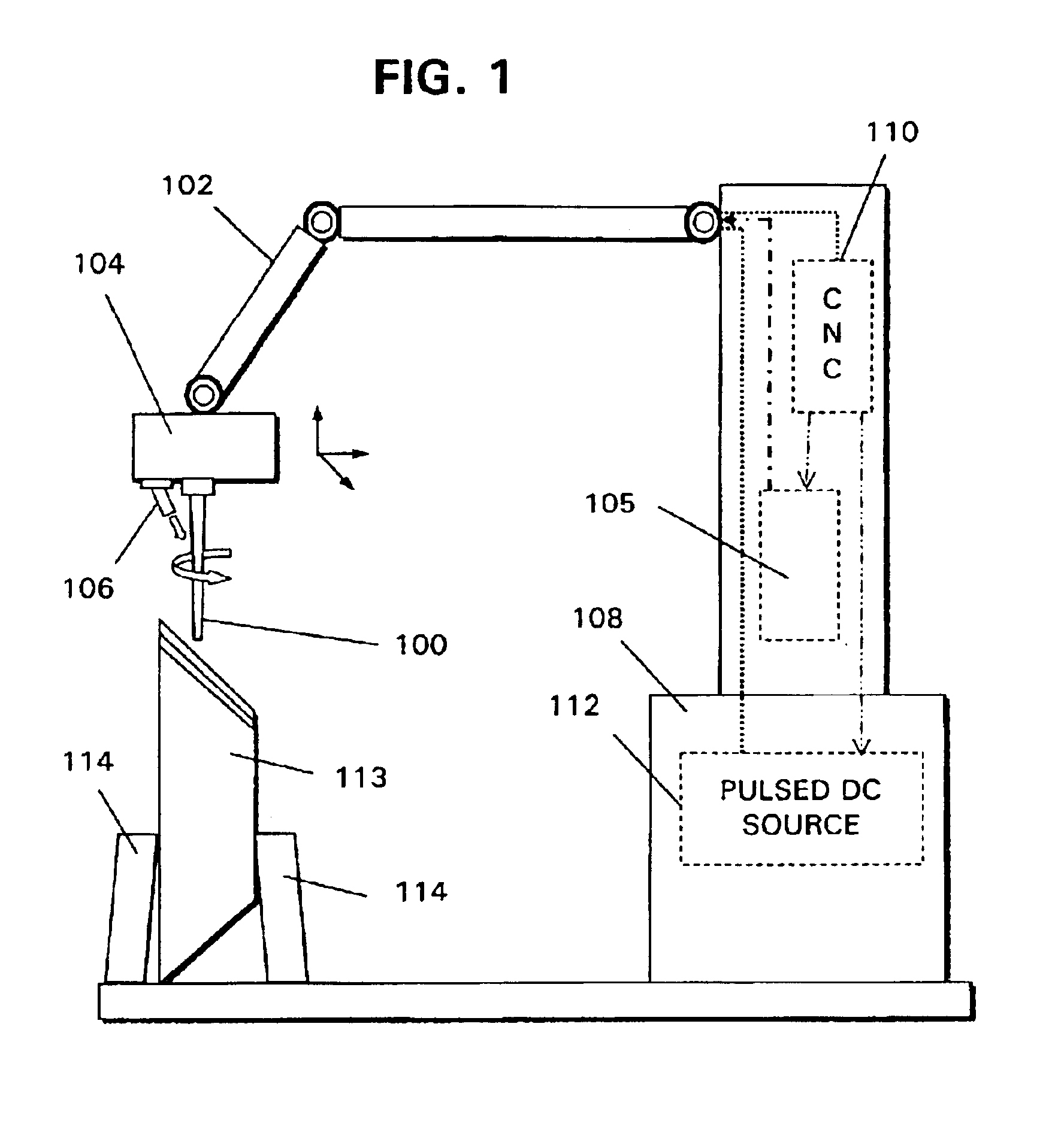

Multi-axis numerical control electromachining of bladed disks

InactiveUS6858125B2High metal erosionComplex configurationAutomatic control devicesElectrolysis componentsNumerical controlControl manner

A multi-axis machine, with numerical control on each axis, is used to drive the tool and workpiece movements necessary to machining complex airfoil geometry. Tooling is typically made of a metal such as brass or other low cost material and rotates during machining. The tooling may be any shape(cylindrical, conical) and size depending on application. A DC power (continuous or pulsed) is used to provide voltage across the tool and workpiece. A medium such as water, de-ionized water, or electrolyte (such as sodium nitrite) is provided between the tool and workpiece. Workpiece metal is removed in a controlled manner by high intensity thermal erosion.

Owner:GENERAL ELECTRIC CO

LED lighting apparatus

InactiveUS20080239725A1Irradiation range can be expandedBrighter illuminationPoint-like light sourceMeasurement apparatus componentsLight guideEffect light

Owner:SHARP KK

Electrical terminal

InactiveUS20070141910A1Produced simply and economicallyLarge sectionContact members penetrating/cutting insulation/cable strandsClamped/spring connectionsStrain reliefConnection design

An electrical terminal includes an insulating housing, a conductor bar, strain-relief clamp connections and actuating elements located in the insulating housing for opening and closing the strain-relief clamp connections. The electrical terminal enables simple manual opening of the clamping site even when the strain-relief clamp connection is designed for leads with large cross section since the actuation element is made as an actuating cam that is eccentrically supported in the insulating housing. The actuating cam can be pivoted by an actuating tool out of a first position in which the strain-relief clamp connection is closed into a second position in which the strain-relief clamp connection is opened so that an electric lead can be inserted between the conductor bar and a through opening in the strain relief clamp connection.

Owner:PHOENIX CONTACT GMBH & CO KG

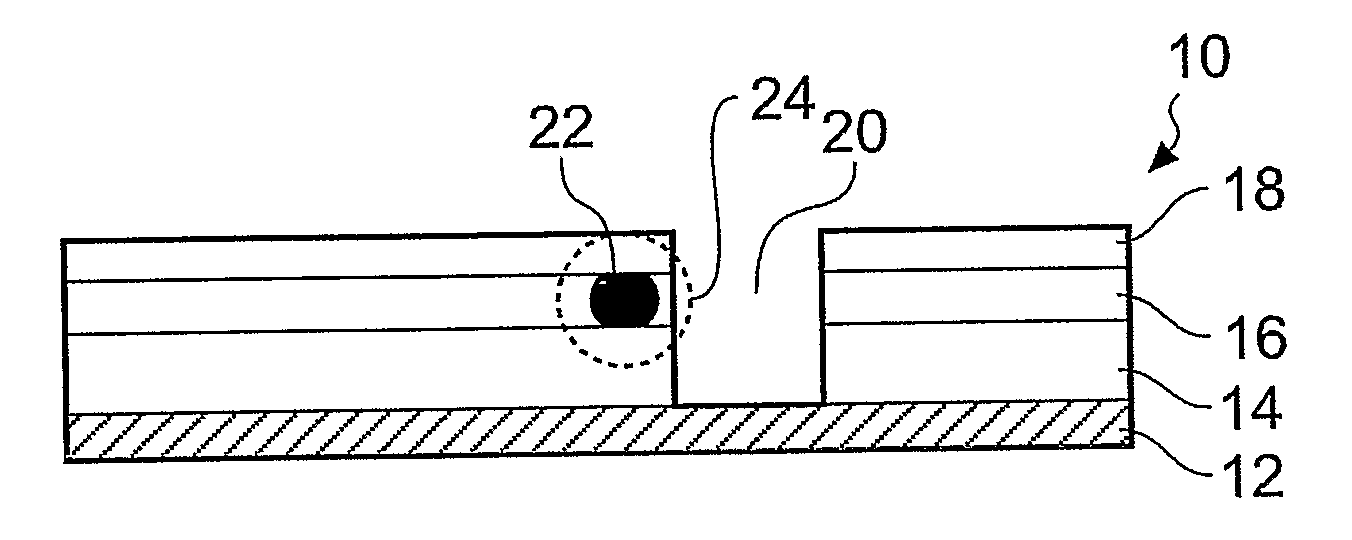

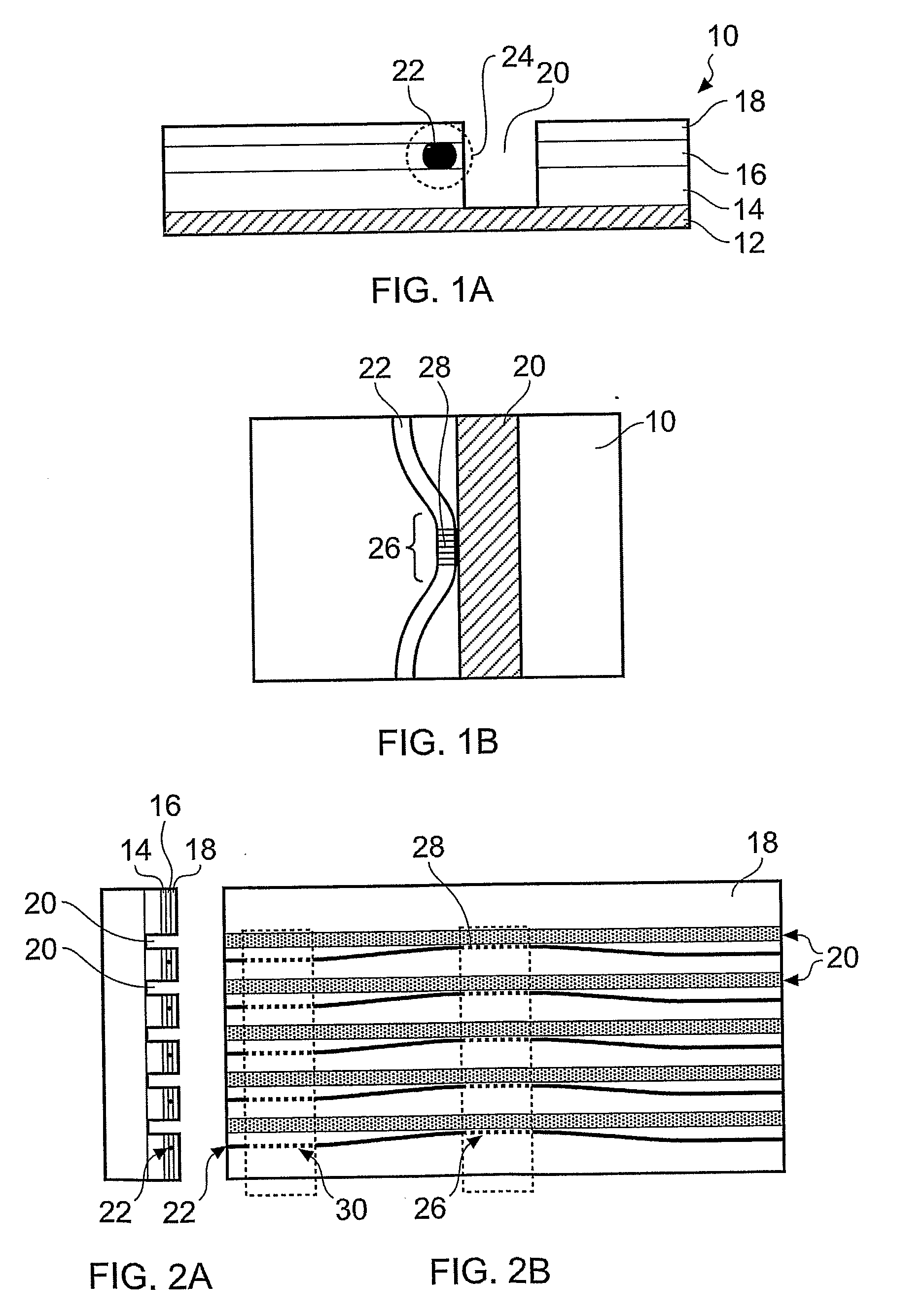

Waveguide devices using evanescent coupling between waveguides and grooves

InactiveUS20100172610A1Smoothly brought into proximity with grooveGood flexibilityLaser using scattering effectsOptical articlesGratingCoupling

An optical waveguide device (10) comprises a planar substrate with a lower cladding layer (14), a core layer (16) and an upper cladding layer (18), a groove (20) in the substrate that extends at least into the core layer (16), and a waveguiding channel (22) in the core layer (16), wherein at least a part of the waveguiding channel (22), which may contain a Bragg grating, is sufficiently proximate to the groove (20) in the plane of the substrate for an evanescent field of light propagating in the waveguiding channel (22) to extend laterally into the groove (20). Material contained in the groove modifies the properties of the waveguiding channel, so that a sample of material can be analysed or an active material can be used to modulate the propagating light. The groove (20) can be made before the waveguide (22). The groove (20) can be made by cutting into the substrate with a saw and the waveguide (22) can be made by direct writing in the core layer (16) with an ultraviolet beam.

Owner:UNIV OF SOUTHAMPTON

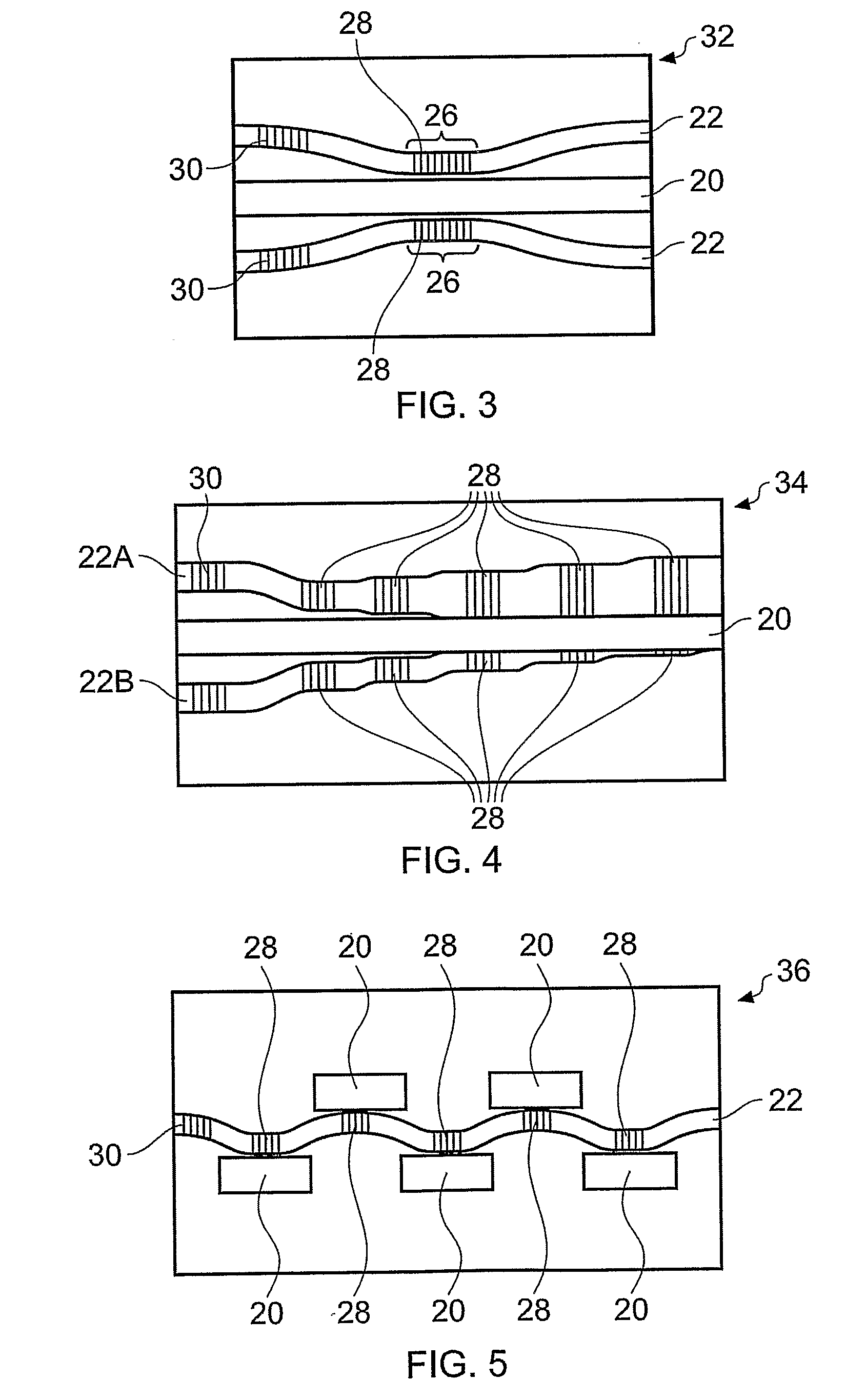

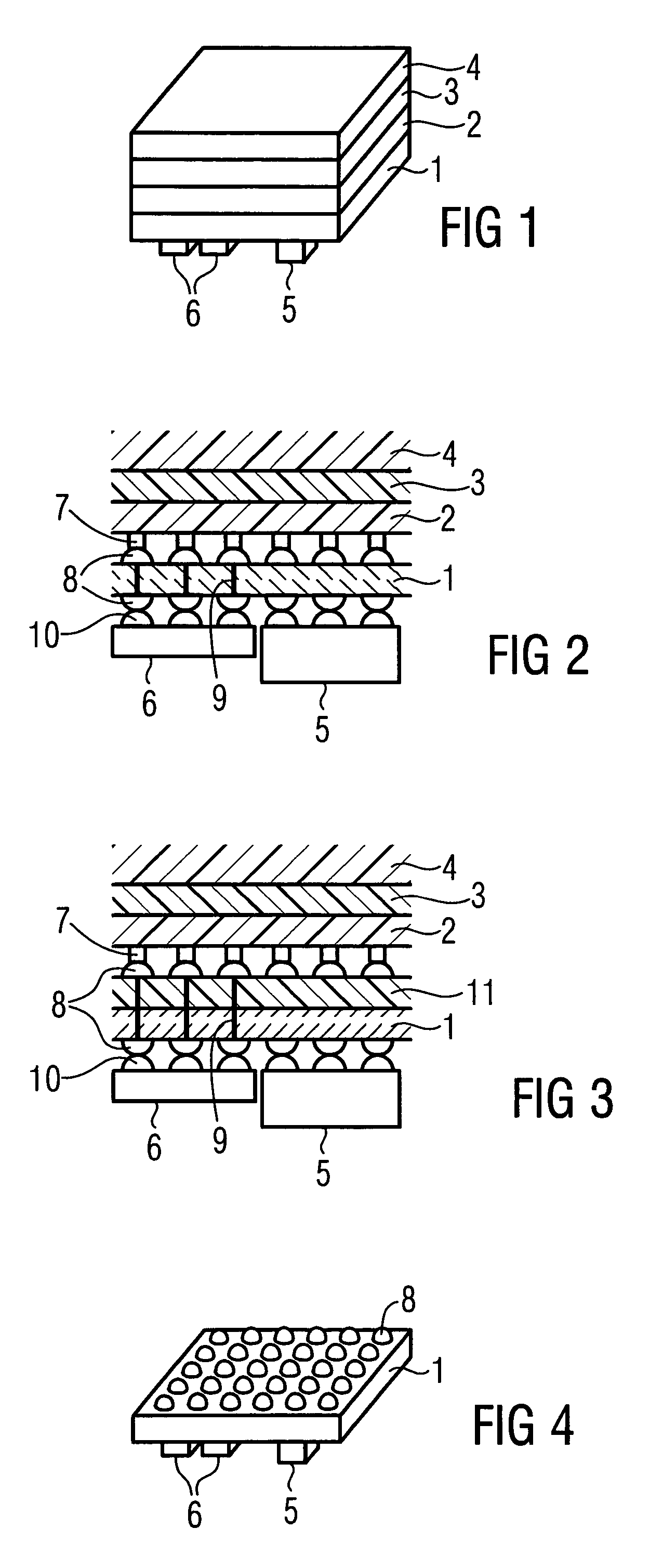

Image detector for x-ray devices with rear-contact organic image sensors

InactiveUS7148486B2Improve fill factorHigh detection sensitivitySolid-state devicesMaterial analysis by optical meansContact image sensorSoft x ray

An image detector for an x-ray device includes photosensors which have at least two contacts on which an electrical signal occurs when x-rays are detected. In each case, at least one contact of the photosensors is arranged on its rear side, facing away from the image source. Further, the material used for the photosensors is an organic photodiode material.

Owner:SIEMENS HEALTHCARE GMBH

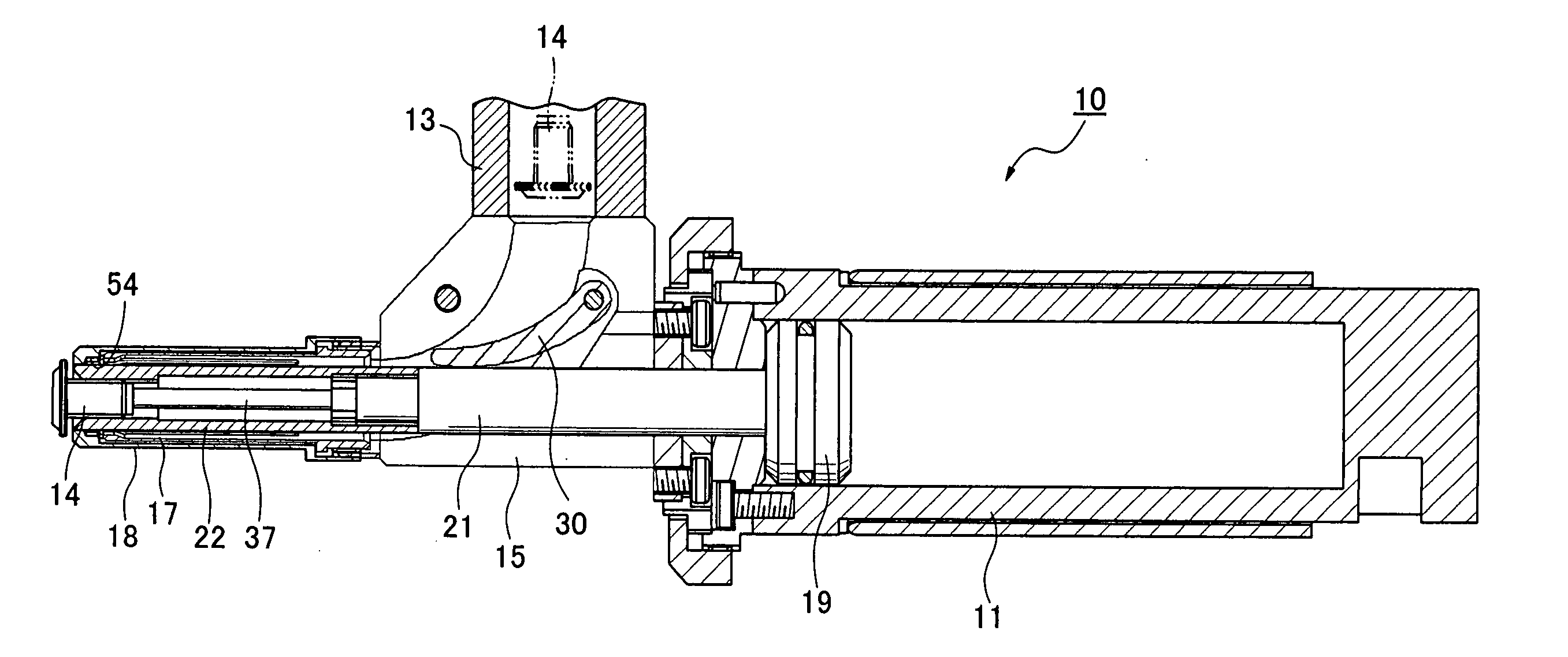

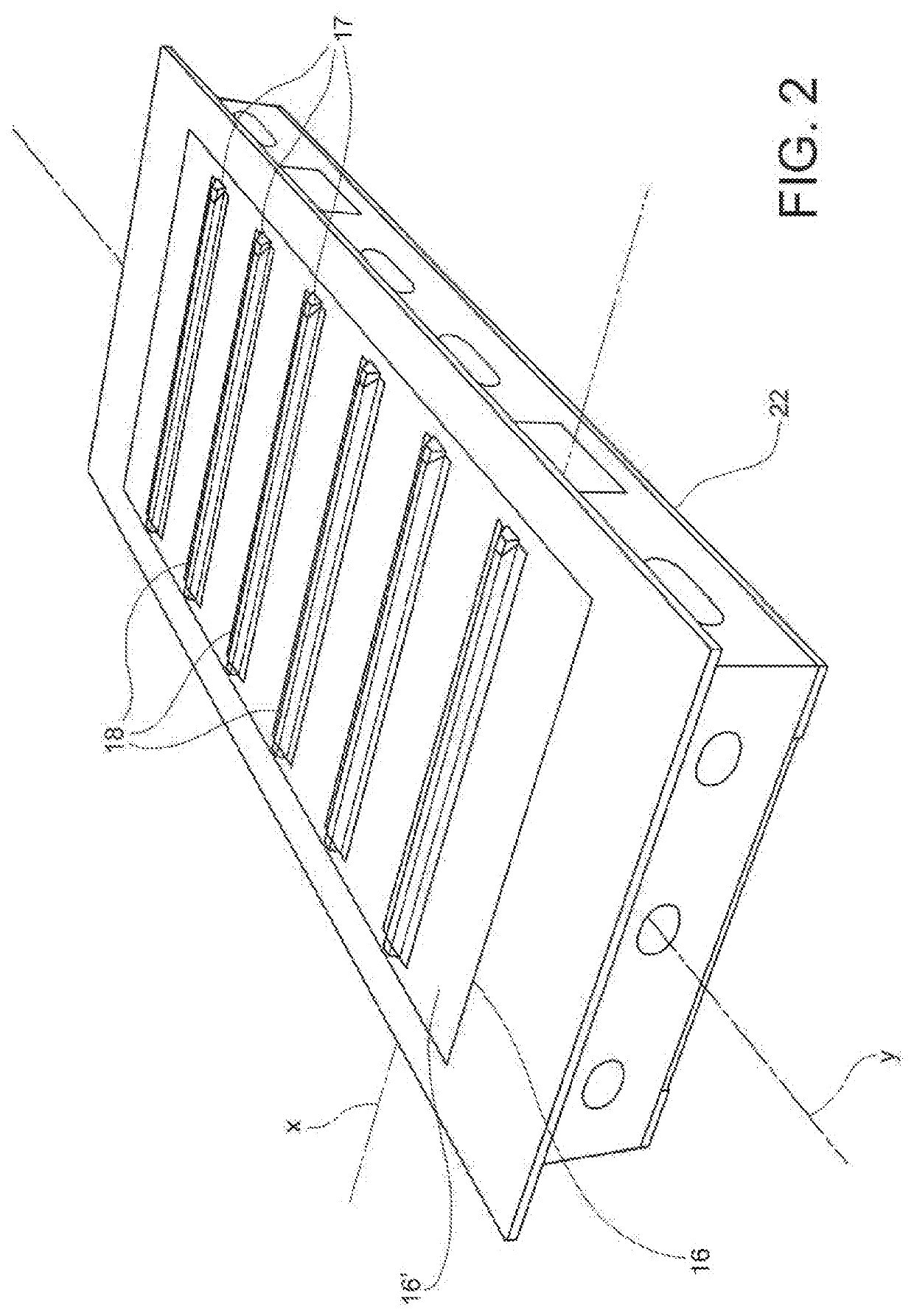

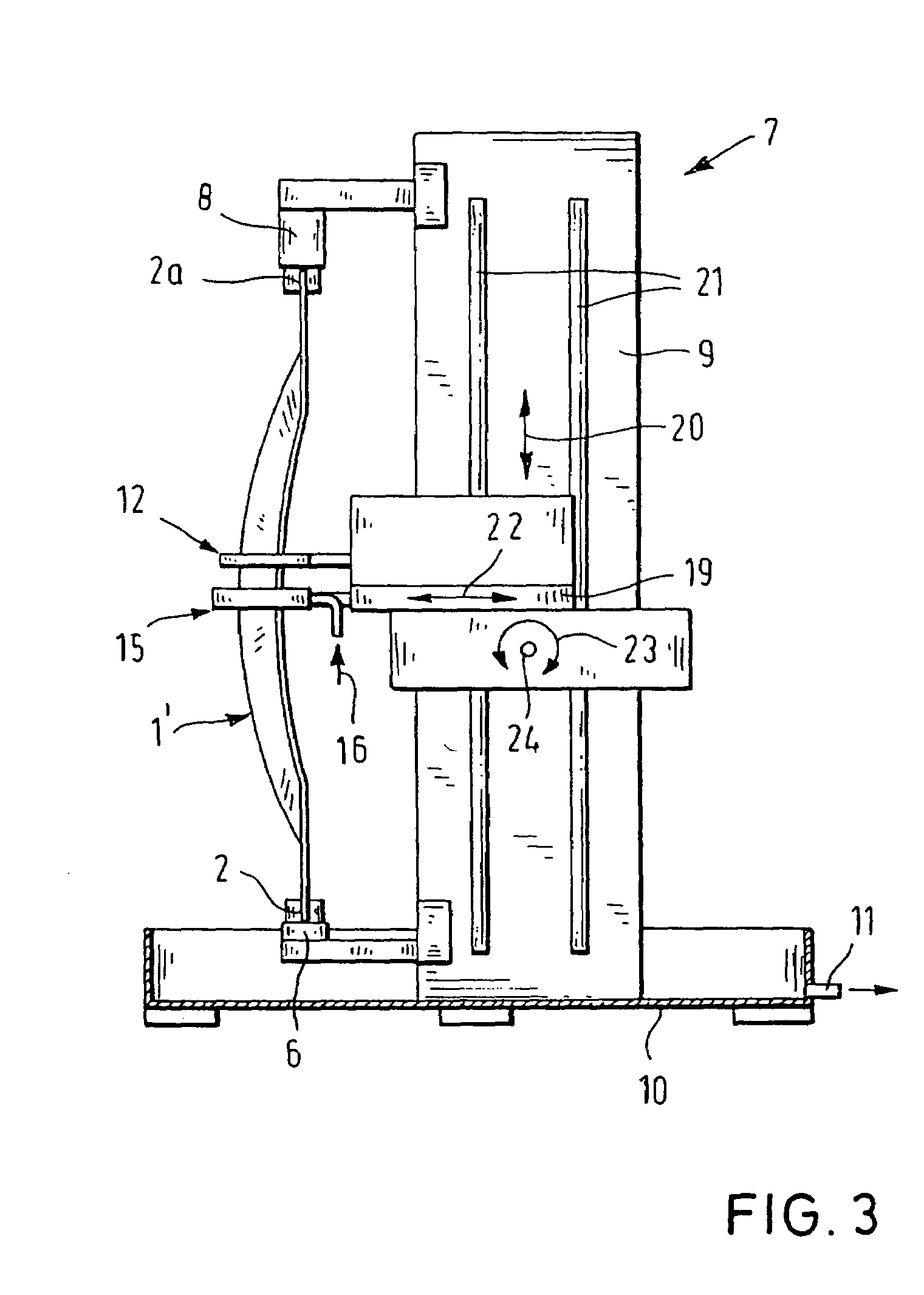

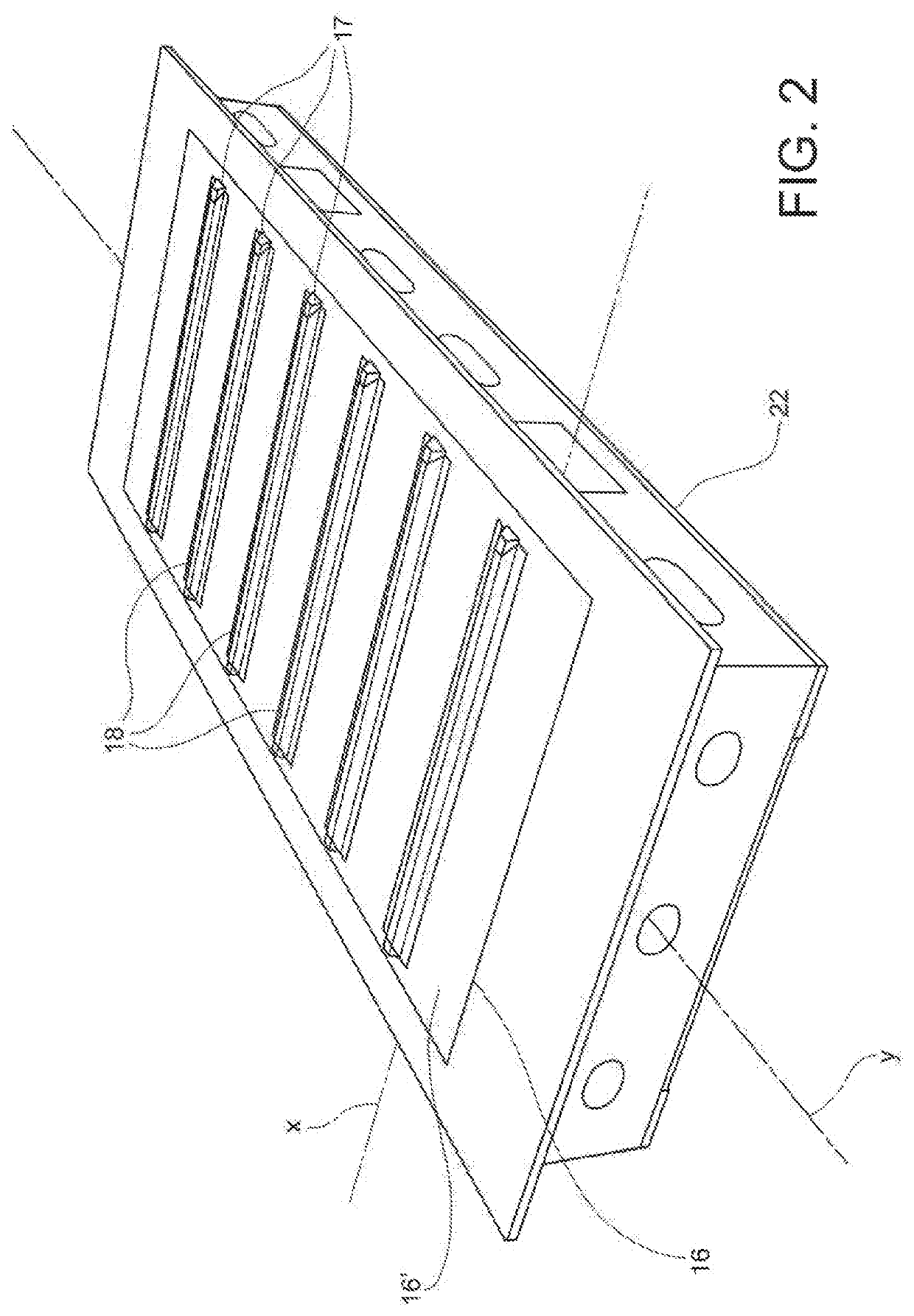

Stud welding apparatus

InactiveUS20050023252A1Prevent rollingShorten the lengthArc welding apparatusResistance welding apparatusEngineeringStud welding

A welding gun 10 has a collet for holding a stud with a flange and a shank at the tip of the welding gun. The collet comprises a tubular first collet member 17, secured to the tip, which elastically opens to a larger diameter than the stud flange, for holding the flange at the tip, and a tubular second collet member 22, secured to the tip of a piston rod 21 which extends from an air cylinder 11 provided in the aft portion thereof toward the first collet member, for, by the movement of the piston, picking up, accommodating, and holding the shank of a stud fed with its flange to the fore inside the first collet member 17. A collet cover 18 is provided for enclosing the exterior of the first collet member 17, from the tip end thereof, with the tip of the collet cover 18 and the tip of the first collet member forming a flange edge carrying space 54 for accommodating and holding the edge of the stud flange and holding the end of the stud shank in an attitude such that it floats free from the inner wall of the first collet member.

Owner:NEWFREY

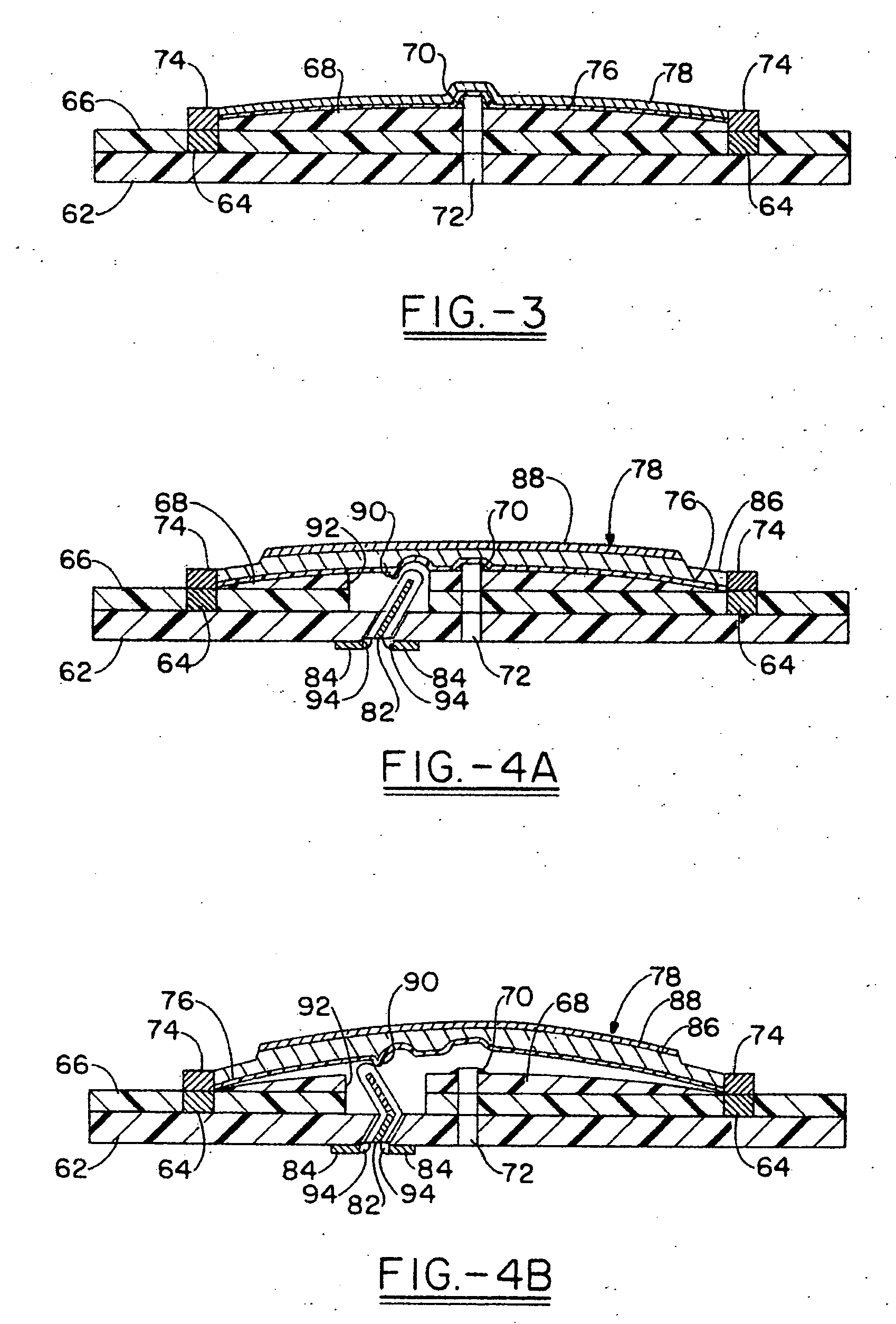

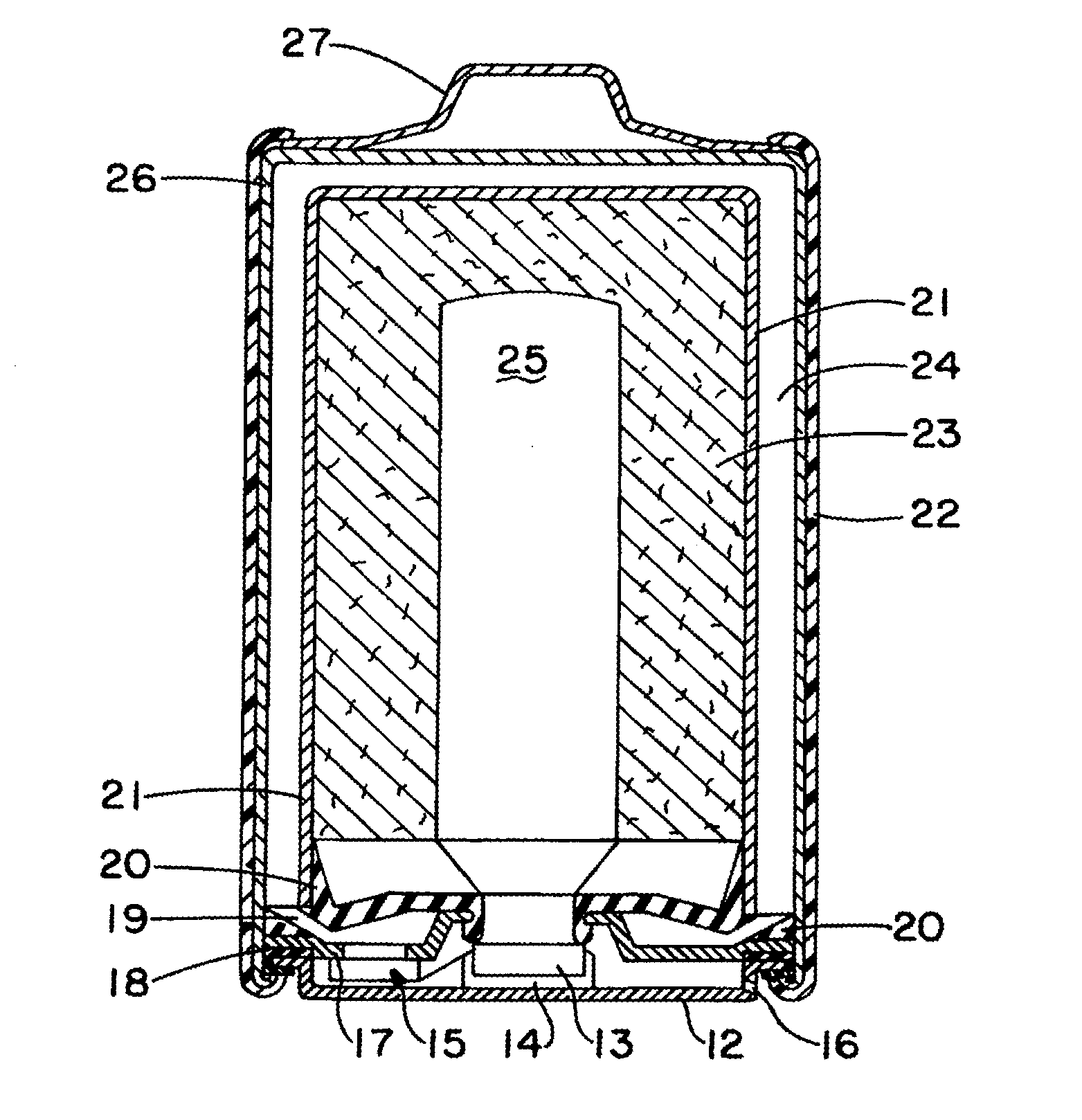

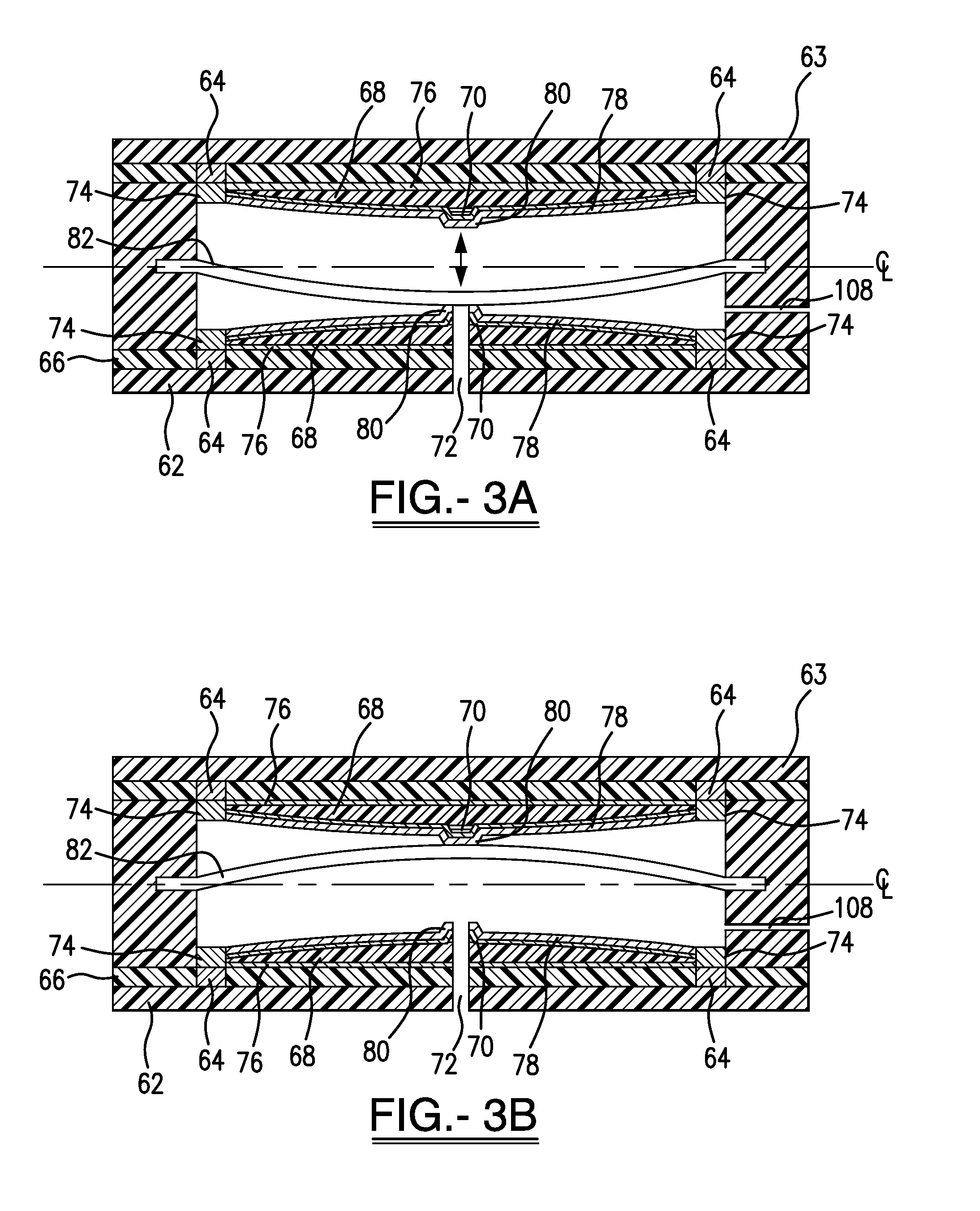

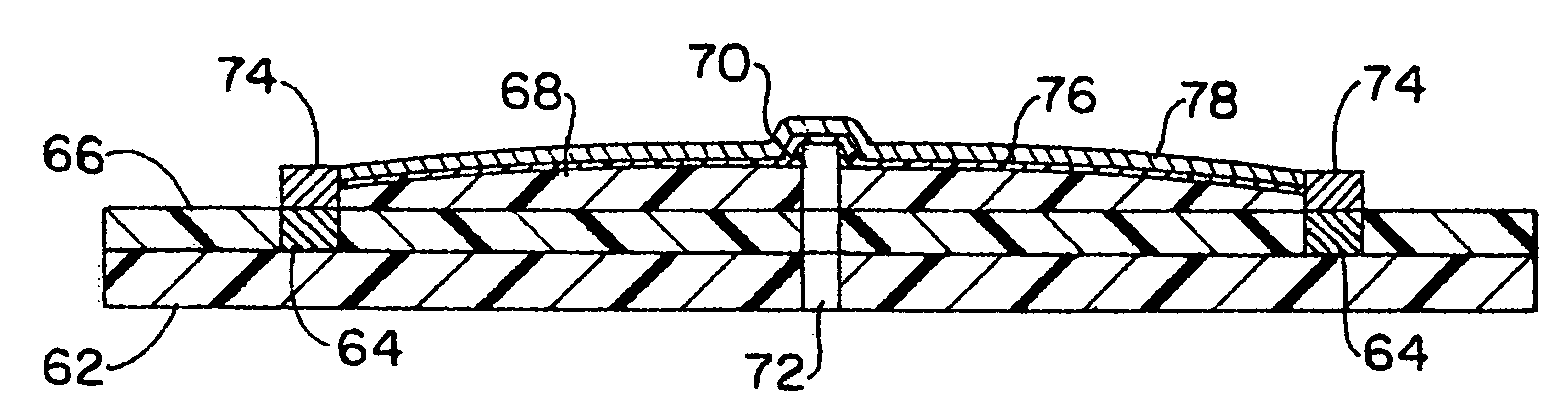

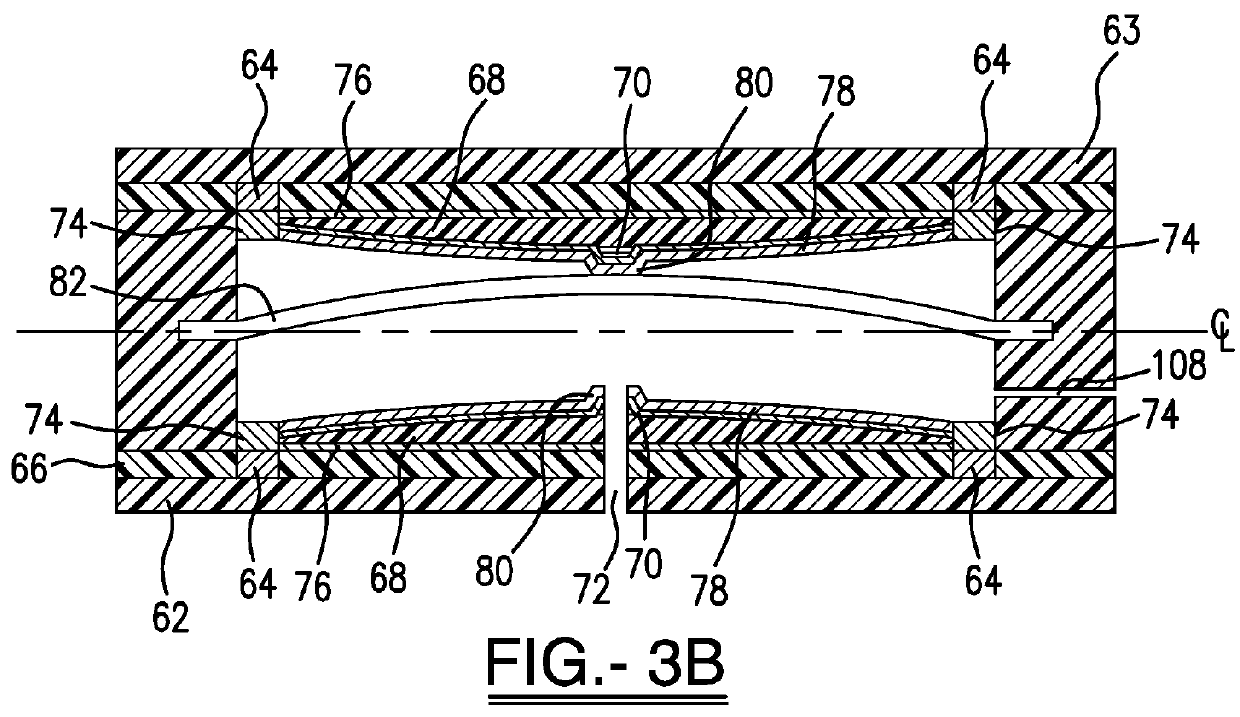

Fluid regulating microvalve assembly for fluid consuming cells with spring-like shape-retaining aperture cover

ActiveUS20120208102A1Inexpensive and straightforward to produceLow costFuel and primary cellsValve arrangementsElectrochemical cellBiomedical engineering

A fluid regulating microvalve assembly for use to control fluid flow to a fluid consuming electrode, such as an oxygen reduction electrode, in an electrochemical cell is proposed. The microvalve assembly includes a stationary valve body having an aperture and microactuators movable from a first closed aperture position to at least a second position where fluid is able to pass through the microvalve body aperture. These microactuators control the movement of spring-like shape-retaining interior aperture covers, which covers can be belleville springs or flat springs. The fluid regulating microvalve assembly can utilize cell potential or a separate source. The latter assembly can be located outside or inside the cell housing, for example between a fluid inlet aperture and the fluid consuming electrode. Using a printing process to deposit at least one of the layers is proposed for making the multilayer microvalve assembly for a fluid depolarized battery.

Owner:SCHUMM JR BROOKE

LED lighting apparatus

InactiveUS7513666B2Efficient illuminationComplex configurationPoint-like light sourceMeasurement apparatus componentsLight guideEffect light

Owner:SHARP KK

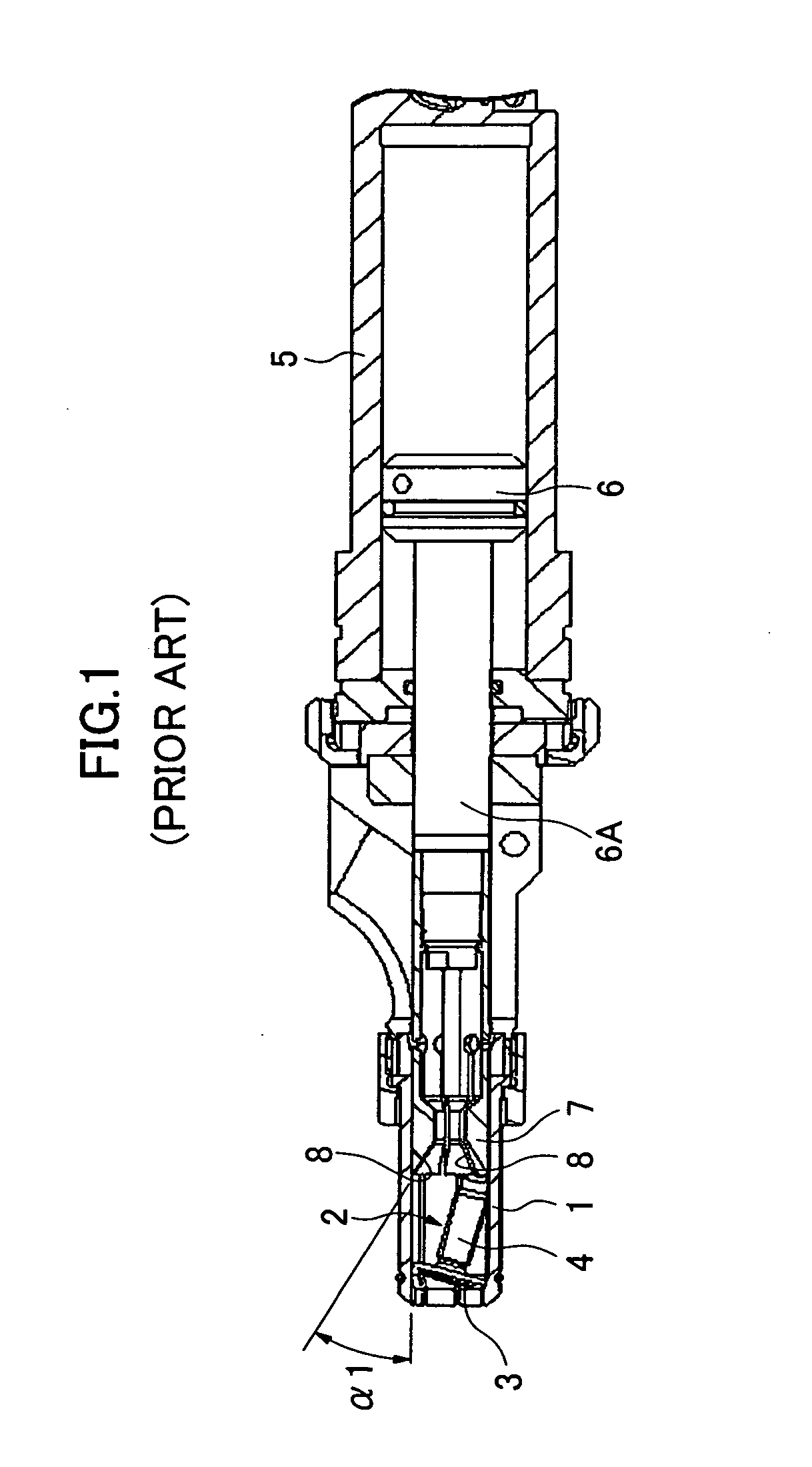

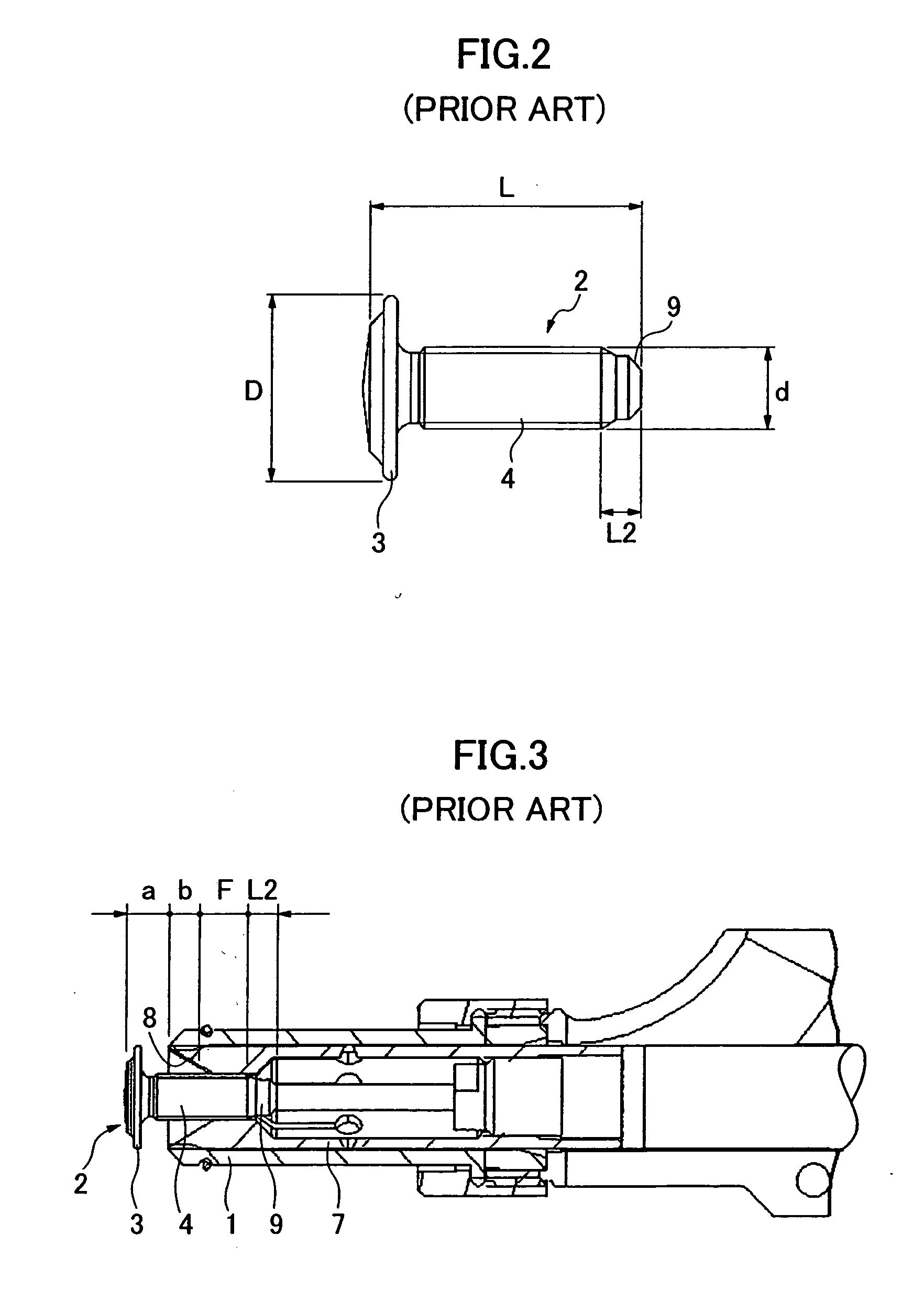

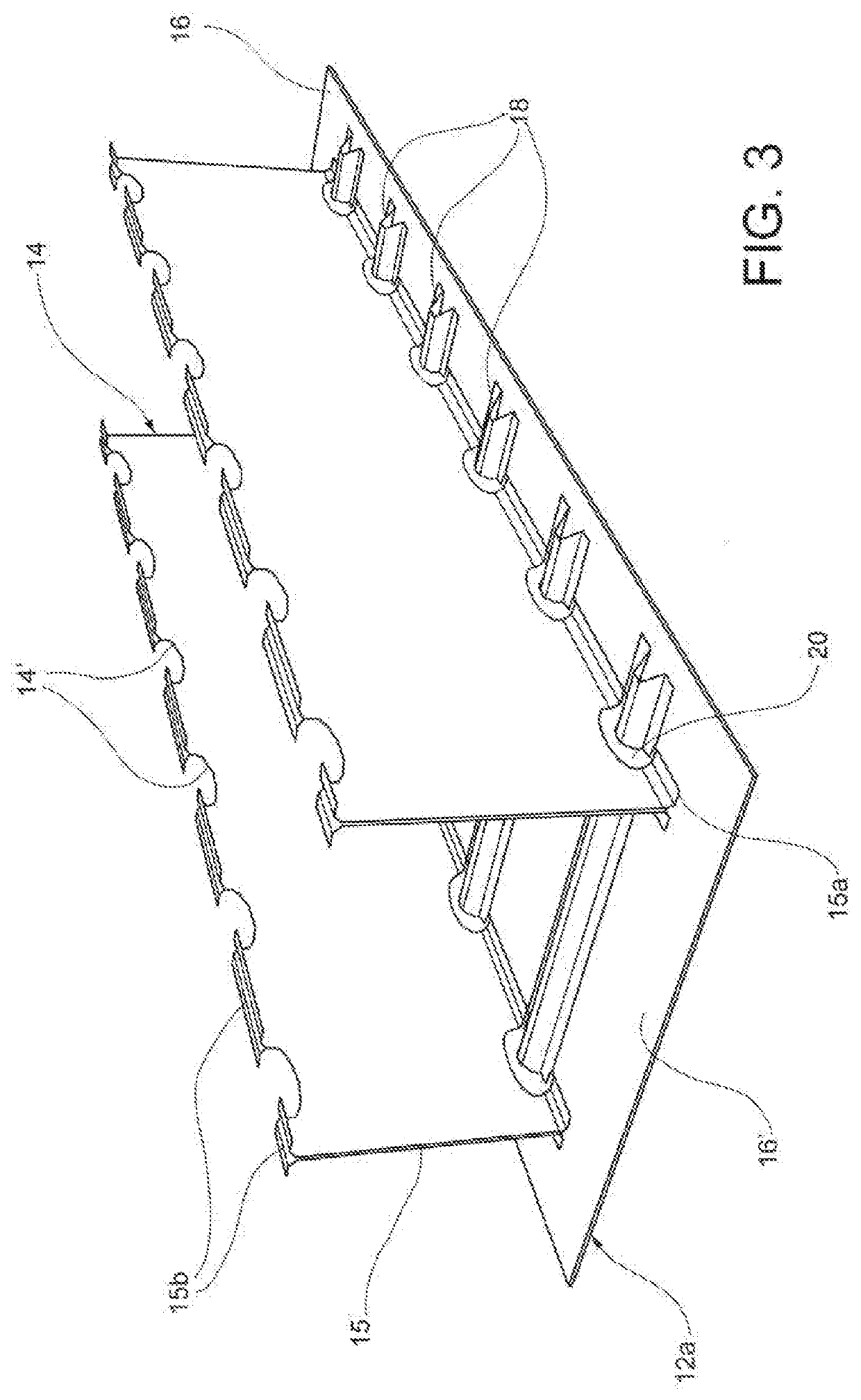

Acetabular reamer

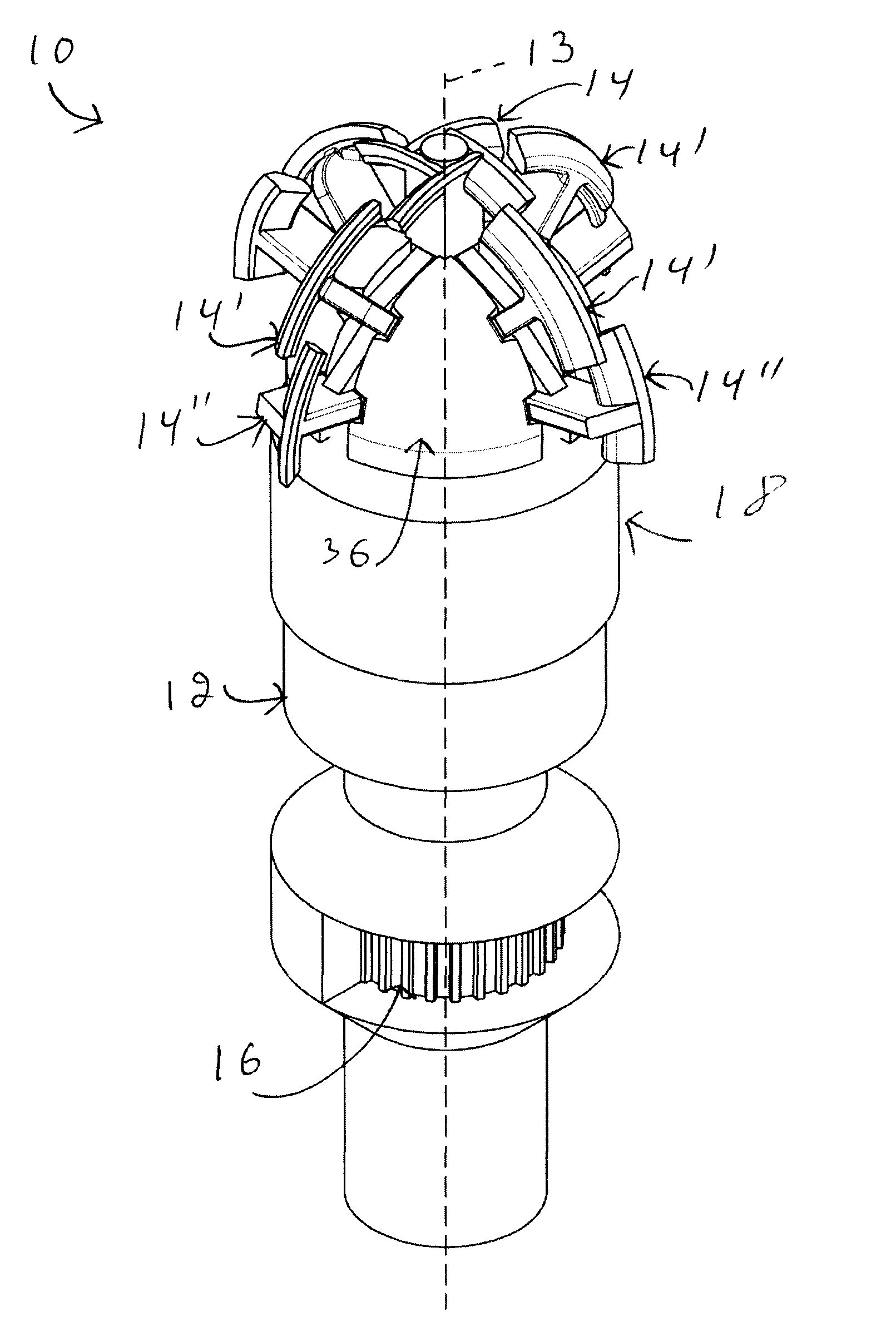

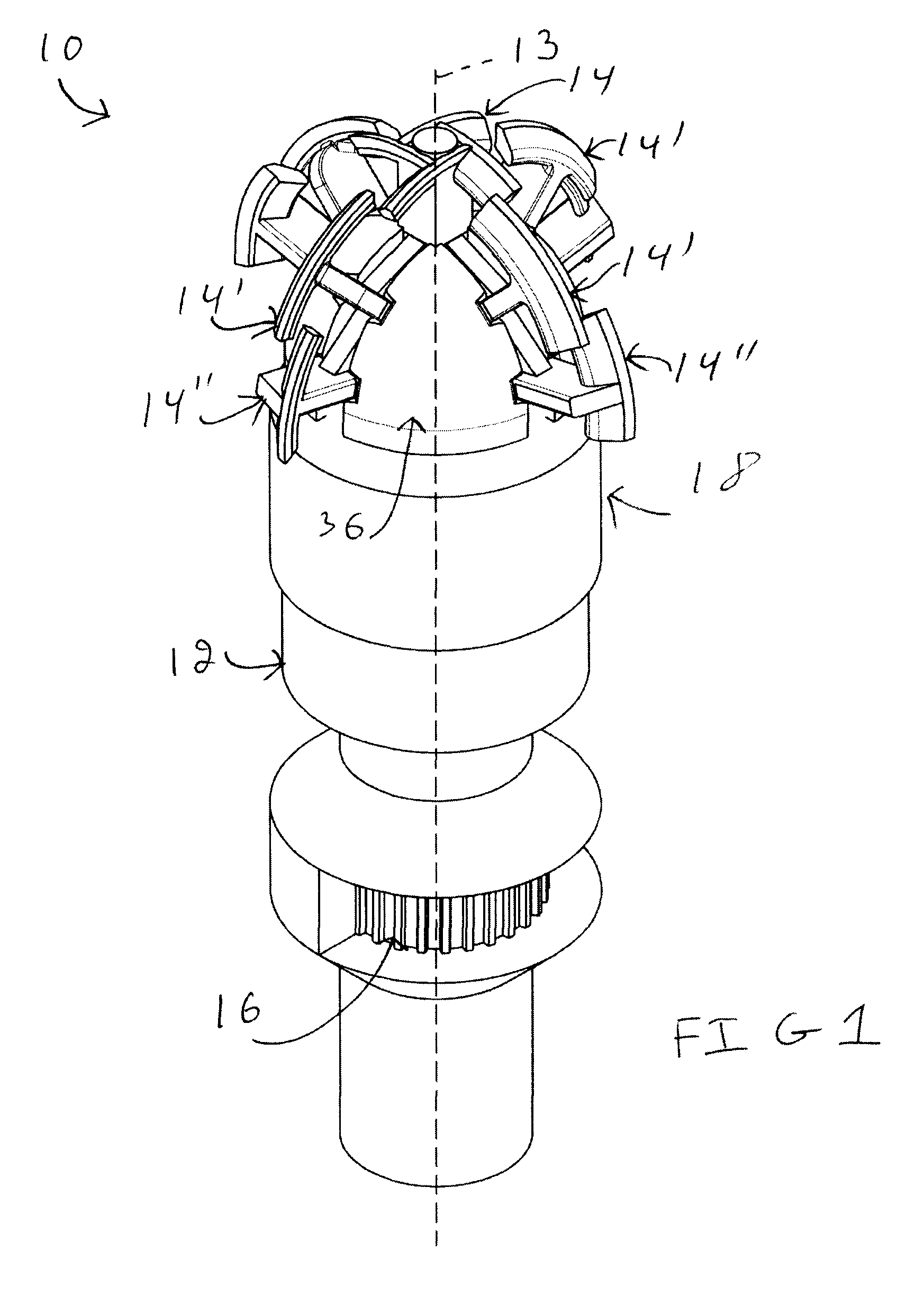

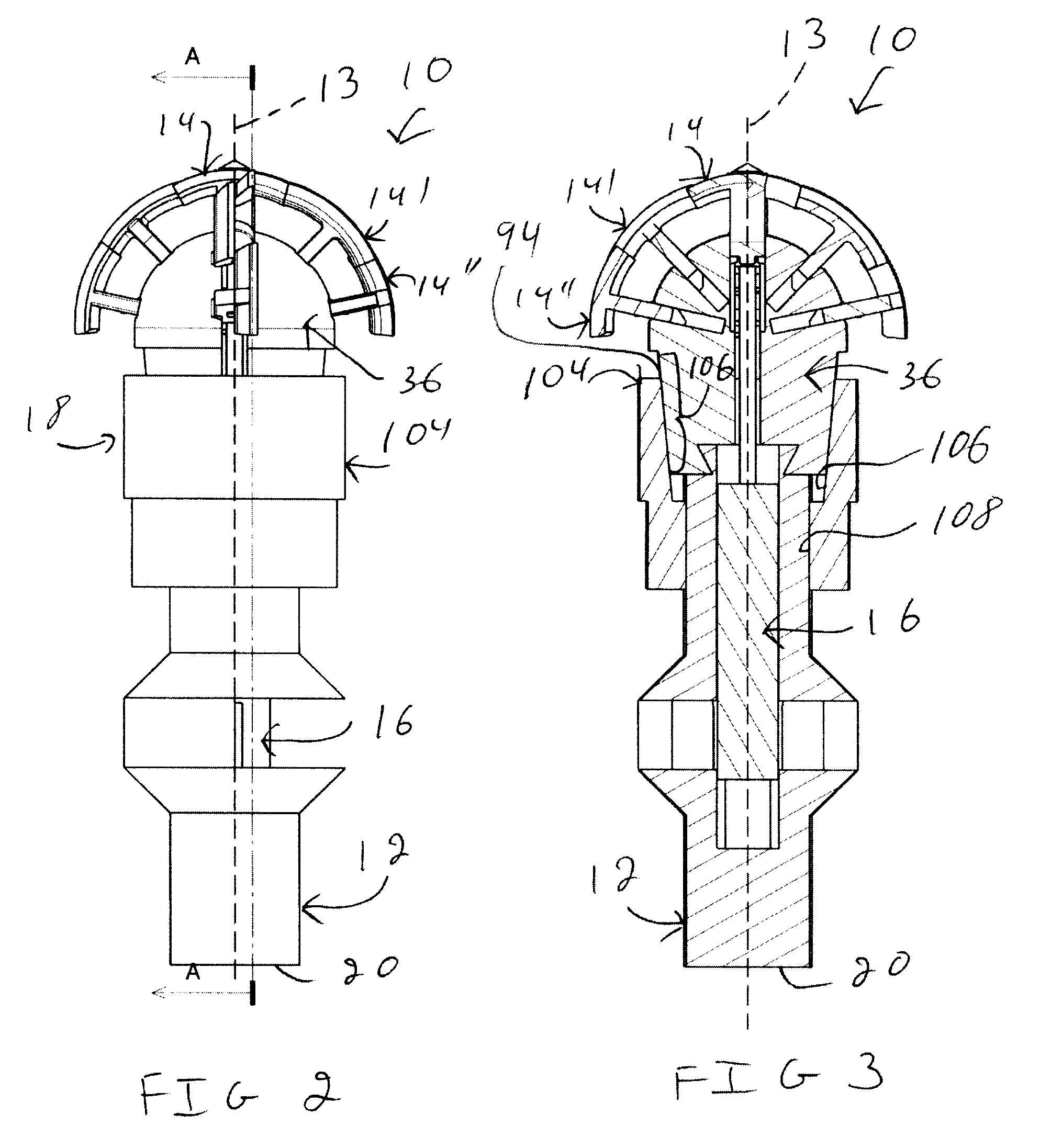

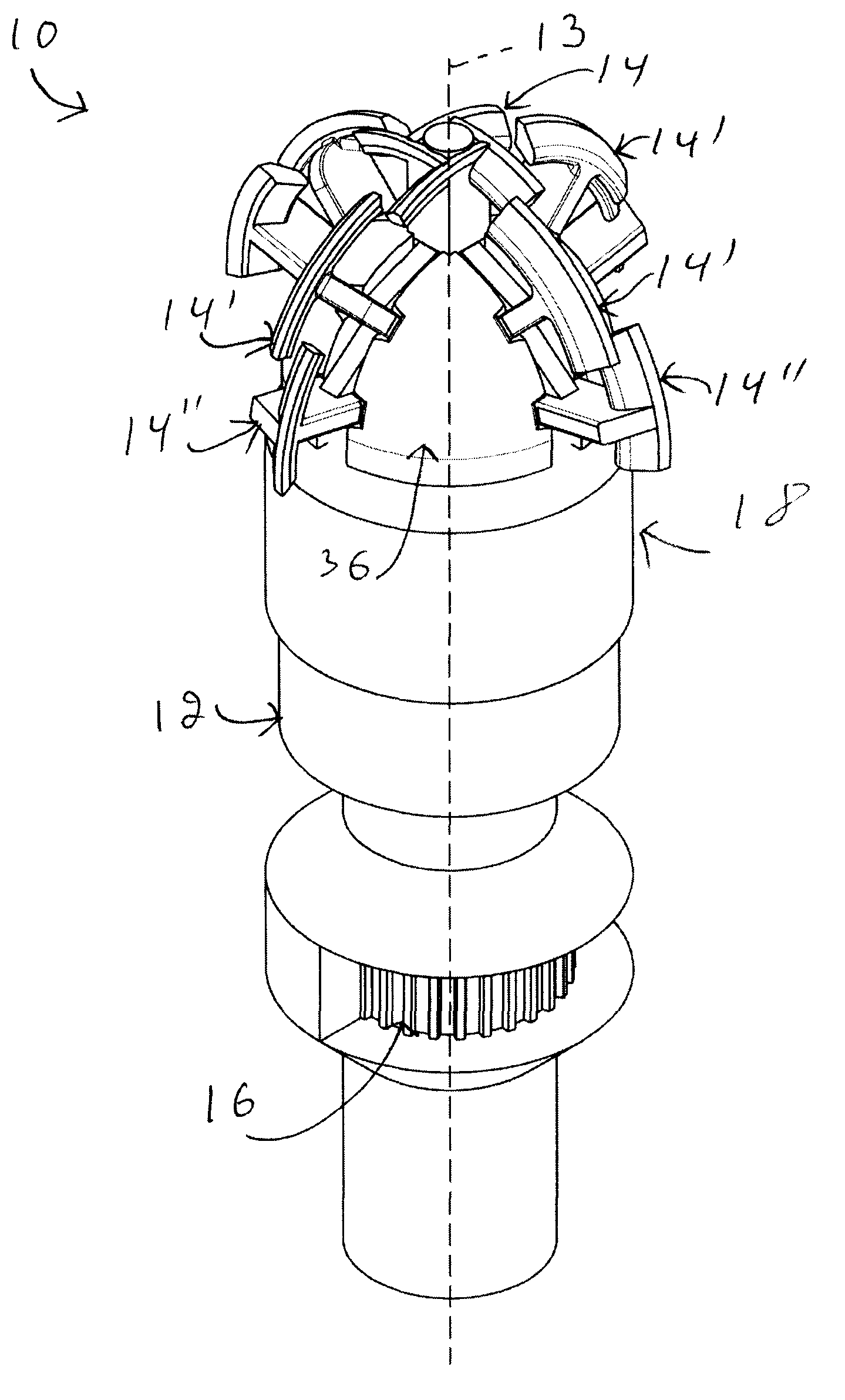

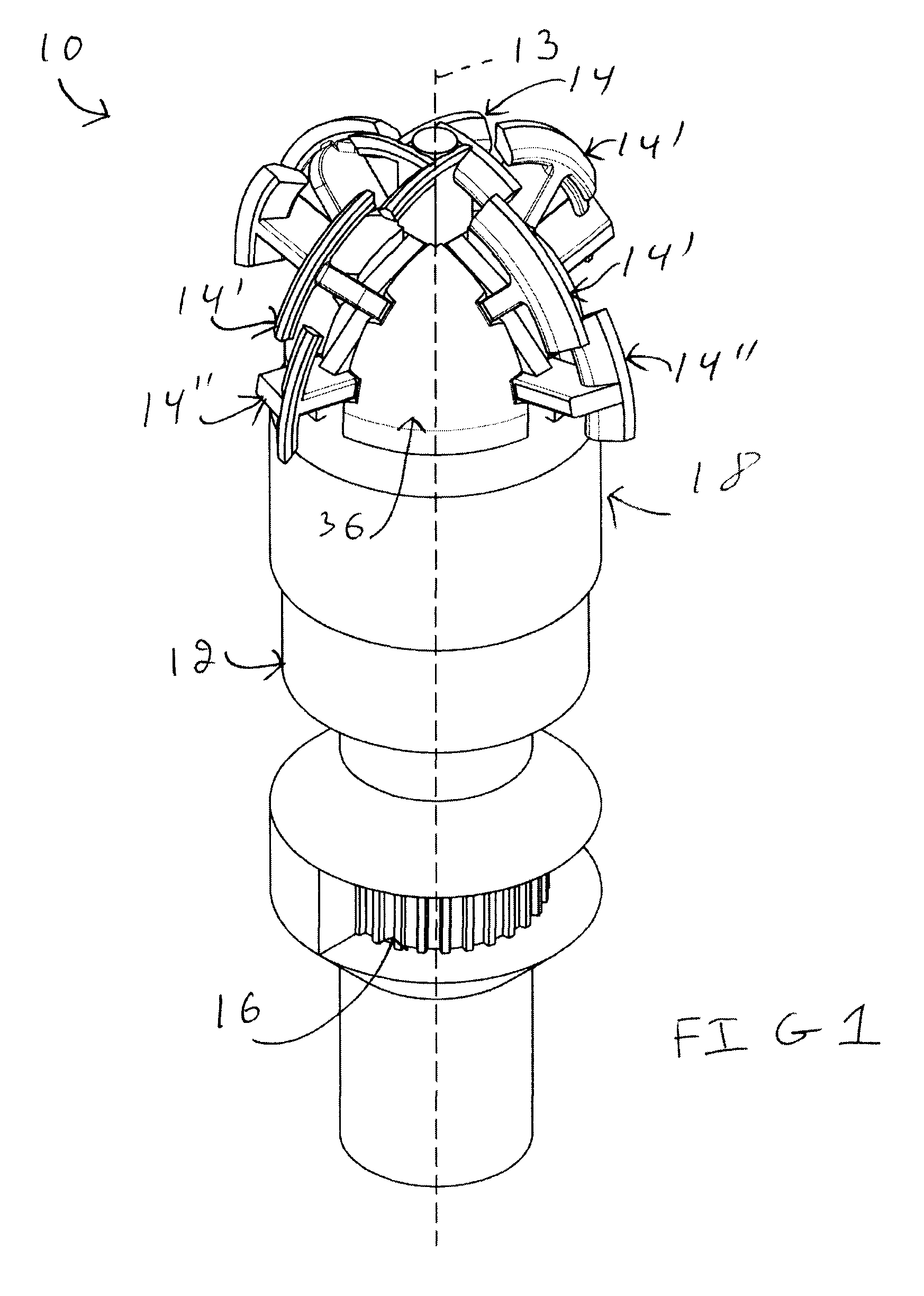

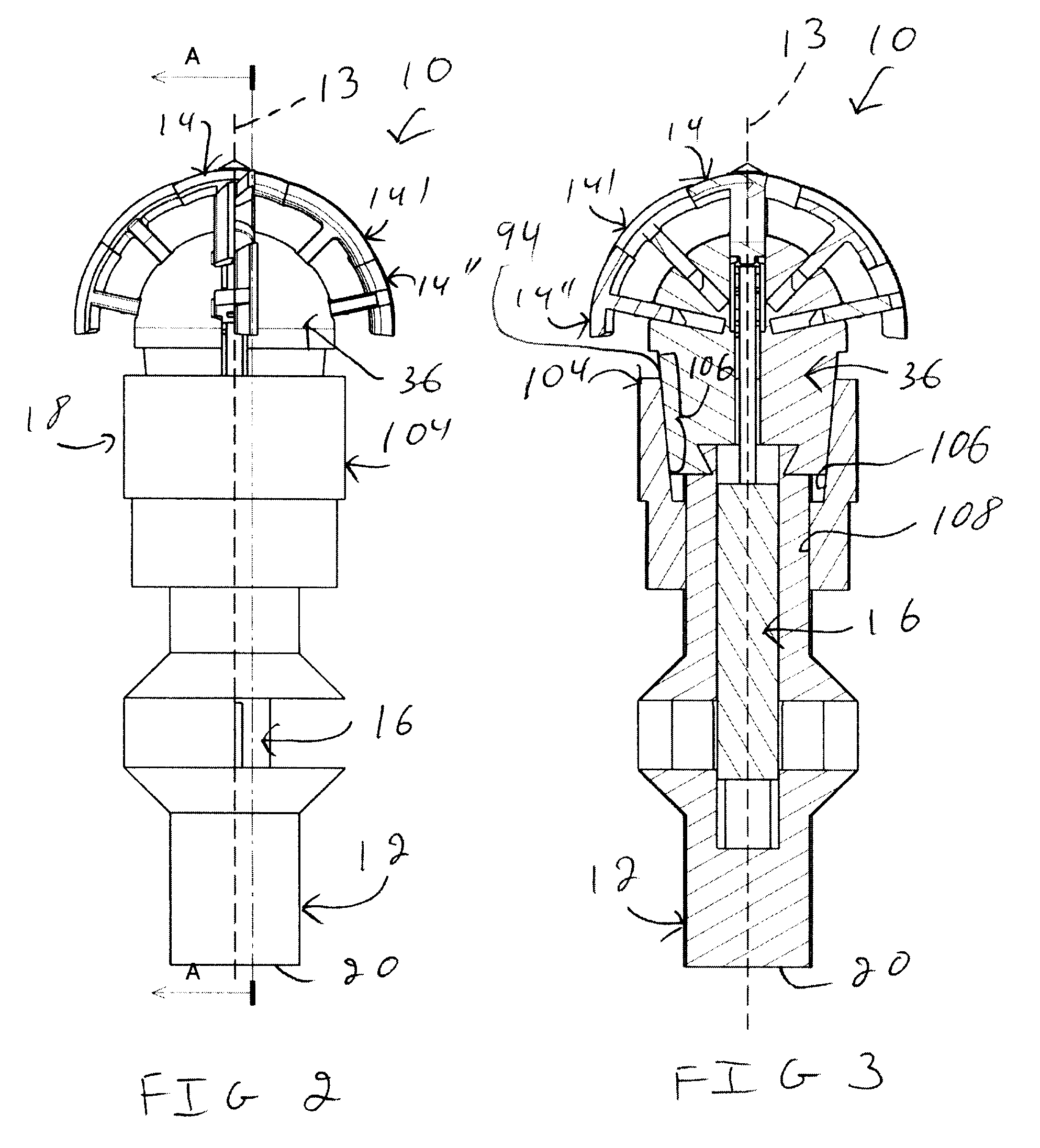

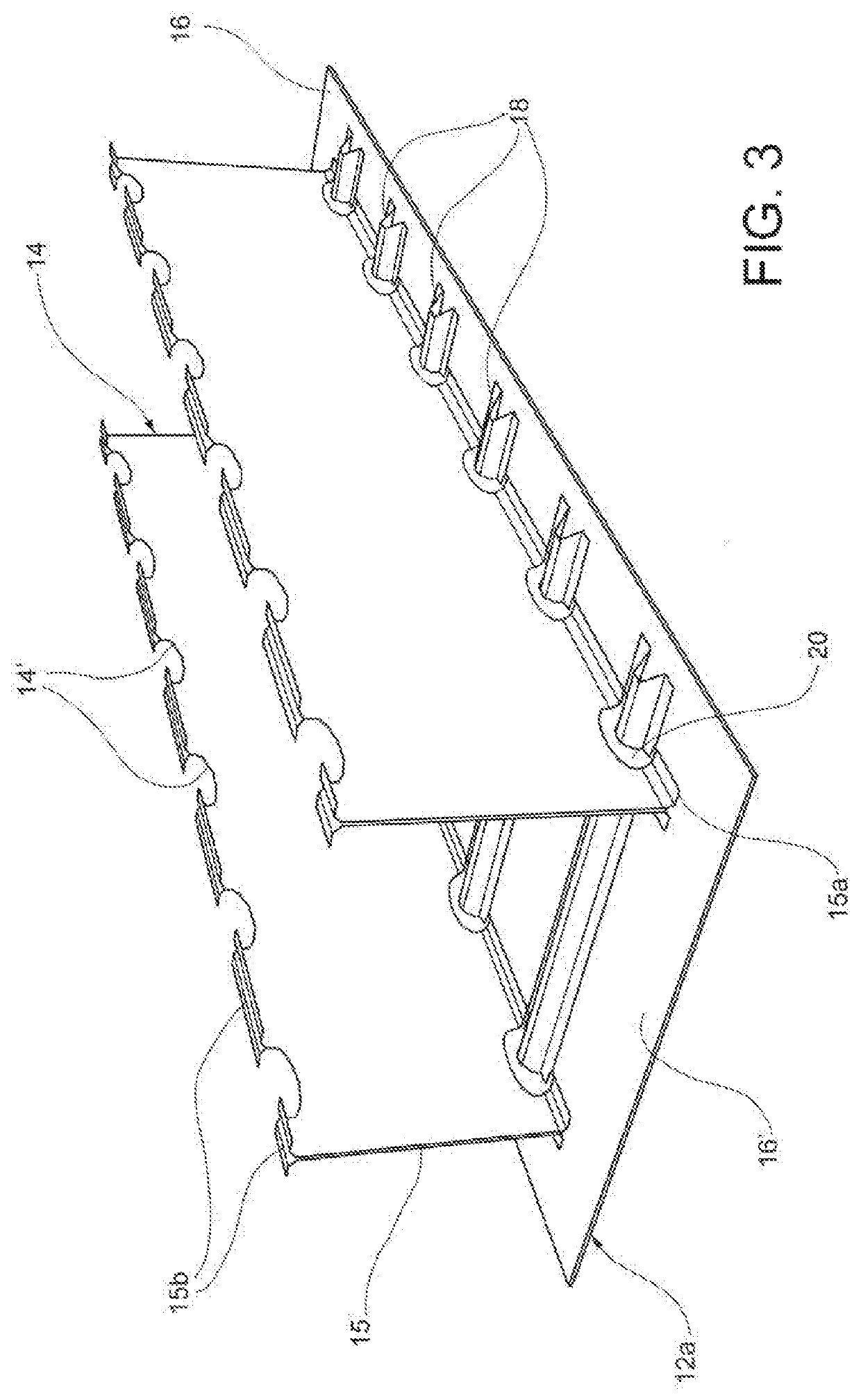

An acetabular reamer comprising: a body defining a rotation axis about which the acetabular reamer is rotatable; a reaming element movable between a reaming element inner position and a reaming element outer position relative to the body; an actuator for moving the reaming element between the reaming element inner and outer positions; and a reaming element lock configurable between a locked configuration and an unlocked configuration. In the unlocked configuration, the reaming element is freely movable by the actuator between the reaming element inner and outer positions. In the locked configuration, the reaming element lock prevents the reaming element from moving relative to the body. In use, when the reaming element lock is in the locked configuration and reaction forces are exerted onto the reaming element, a larger portion of the reaction forces is transmitted to the body than to the actuator.

Owner:ECOLE DE TECH SUPERIEURE

Acetabular reamer

A acetabular reamer (10) for reaming an acetabulum, reaction forces being exerted onto the acetabular reamer by the acetabulum when the acetabulum is reamed, the acetabular reamer comprising: a body (12), the body (12) defining a rotation axis (13) about which the acetabular reamer (10) is rotatable; a reaming element (14, 14′, 14″) operatively coupled to the body (12) so as to be movable between a reaming element inner position and a reaming element outer position relatively thereto, the reaming element (14, 14′, 14″) being positioned further away from the rotation axis in the reaming element outer position than in the reaming element inner position; an actuator (16) operatively coupled to the reaming element (14, 14′, 14″) for moving the reaming element (14, 14′, 14″) between the reaming element inner and outer positions; and a reaming element lock (18) configurable between a locked configuration and an unlocked configuration, the reaming element lock (18) being operatively coupled to the reaming element (14, 14′, 14″) in a manner such that when the reaming element lock (18) is in the unlocked configuration, the reaming element (14, 14′, 14″) is substantially freely movable by the actuator (16) between the reaming element inner and outer positions, and when the reaming element lock (18) is in the locked configuration, the reaming element lock (18) substantially prevents the reaming element (14, 14′, 14″) from moving relatively to the body (12); the reaming element lock (18) being configured, sized and operatively coupled to the reaming element (14, 14′, 14″) and the body (12) in a manner such that when the reaming element lock (18) is in the locked configuration and the reaction forces are exerted onto the reaming element (14, 14′, 14″), a larger portion of the reaction forces is transmitted to the body (12) than to the actuator (16).

Owner:ECOLE DE TECH SUPERIEURE

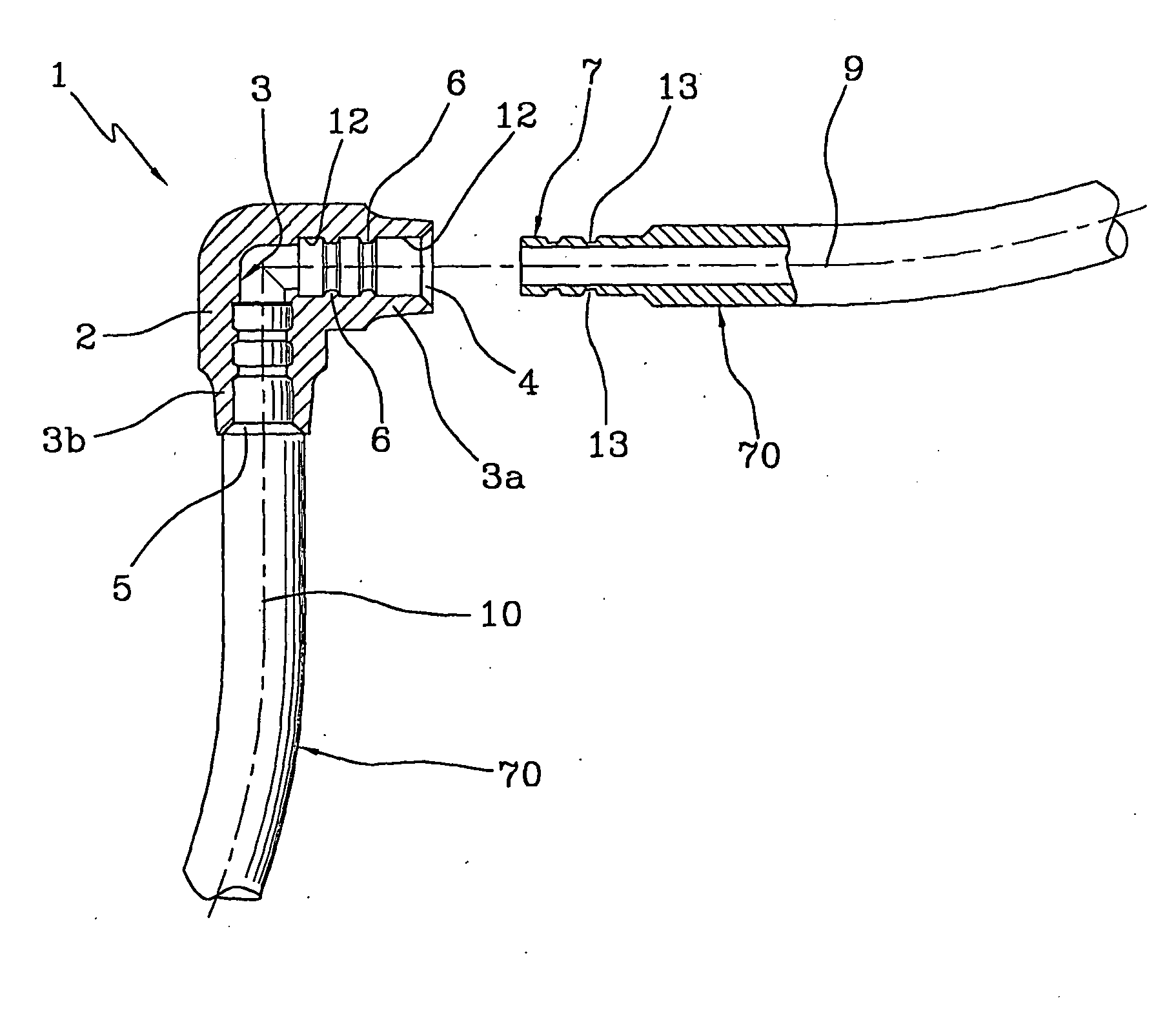

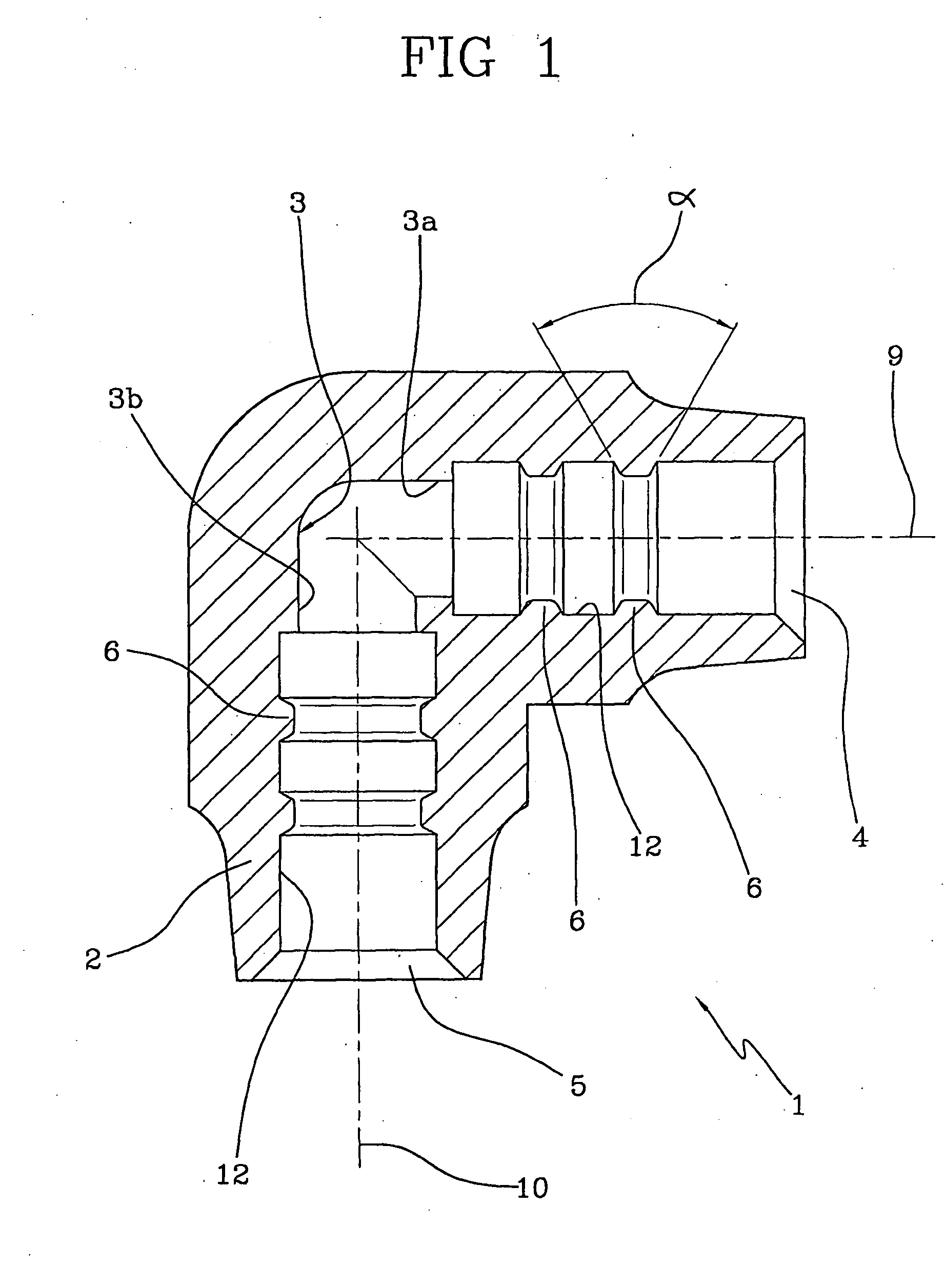

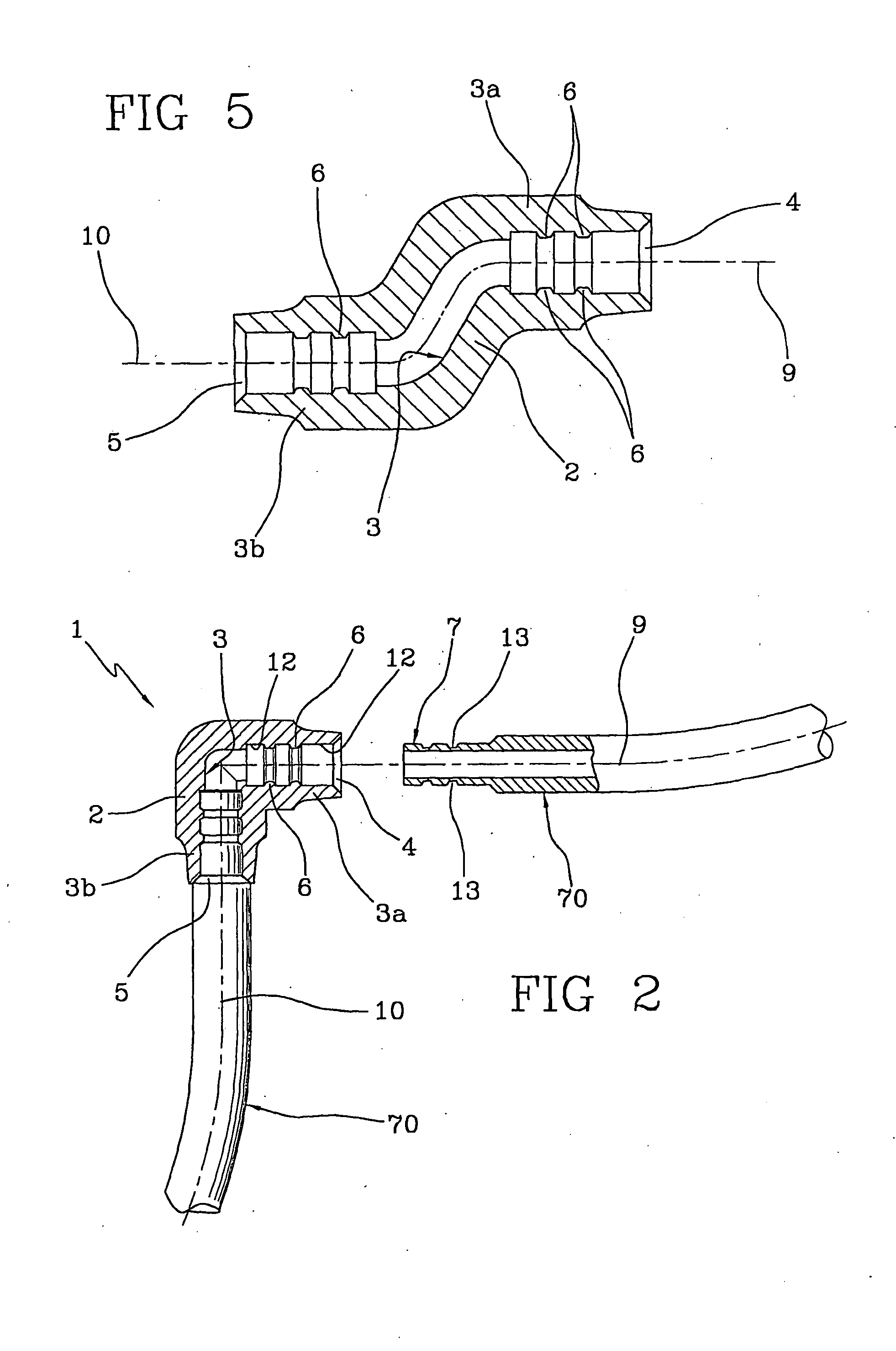

Hydraulic Connector and a Hydraulic Circuit Incorporating the Connector

ActiveUS20090001718A1Losing anchoring efficiencyLosing seal efficiencyCouplingsTube connectorsBlood treatmentsMedicine

A hydraulic connector made entirely of an elastomeric material connects tubes or other hydraulic circuit components used in machines for extracorporeal blood treatment. The hydraulic connector comprises a main body (2), which defines a conduit (3), and a predetermined number of protuberances (6) fashioned to enable a stable engagement of the connector to an end of a tubular port (7) of tubing or other hydraulic component. The conduit (3) exhibits a first longitudinal portion (3a) directed along a first development axis (9) and a second longitudinal portion (3a) directed along a second development axis (10); the axes (9, 10) do not coincide.

Owner:GAMBRO LUNDIA AB

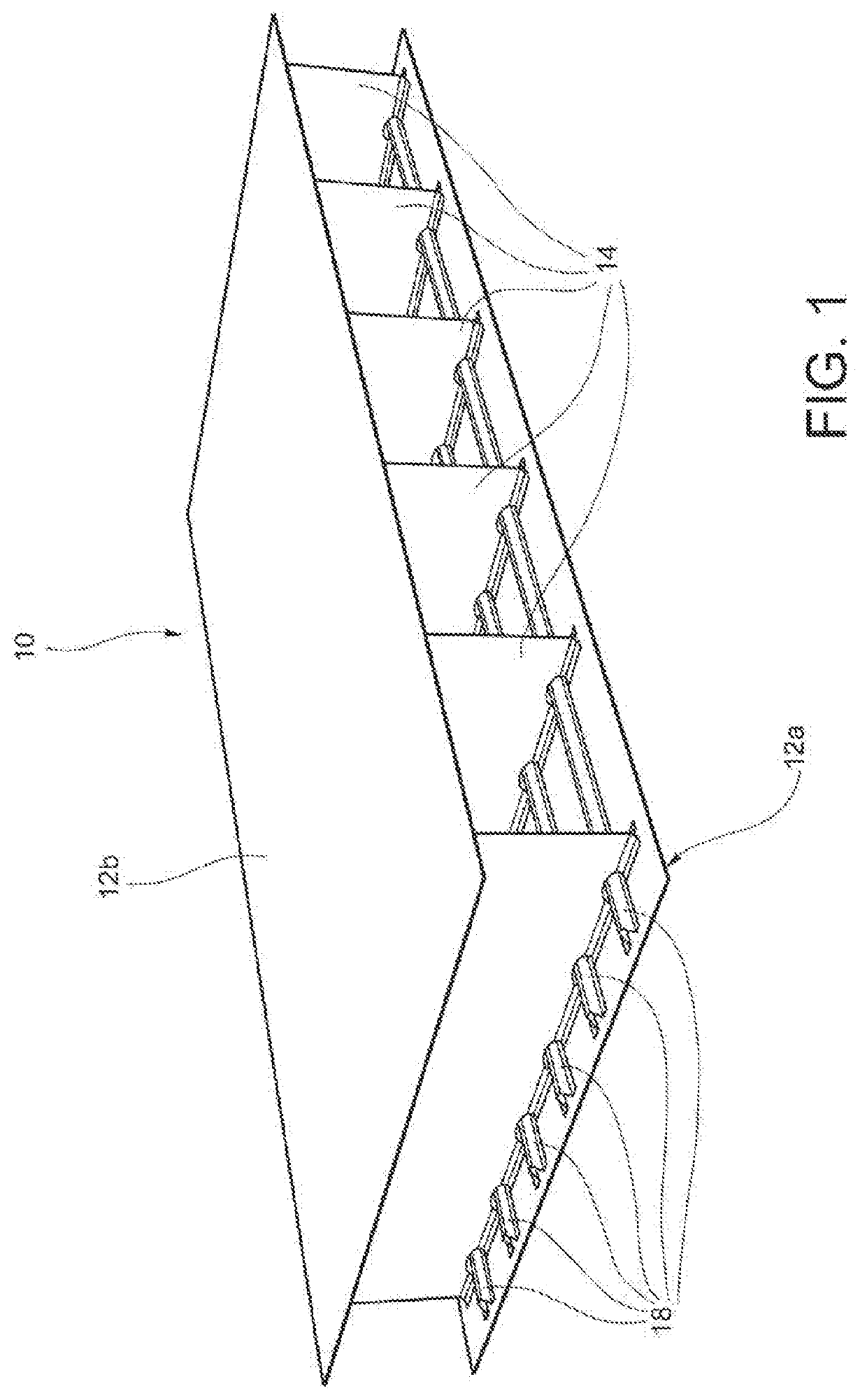

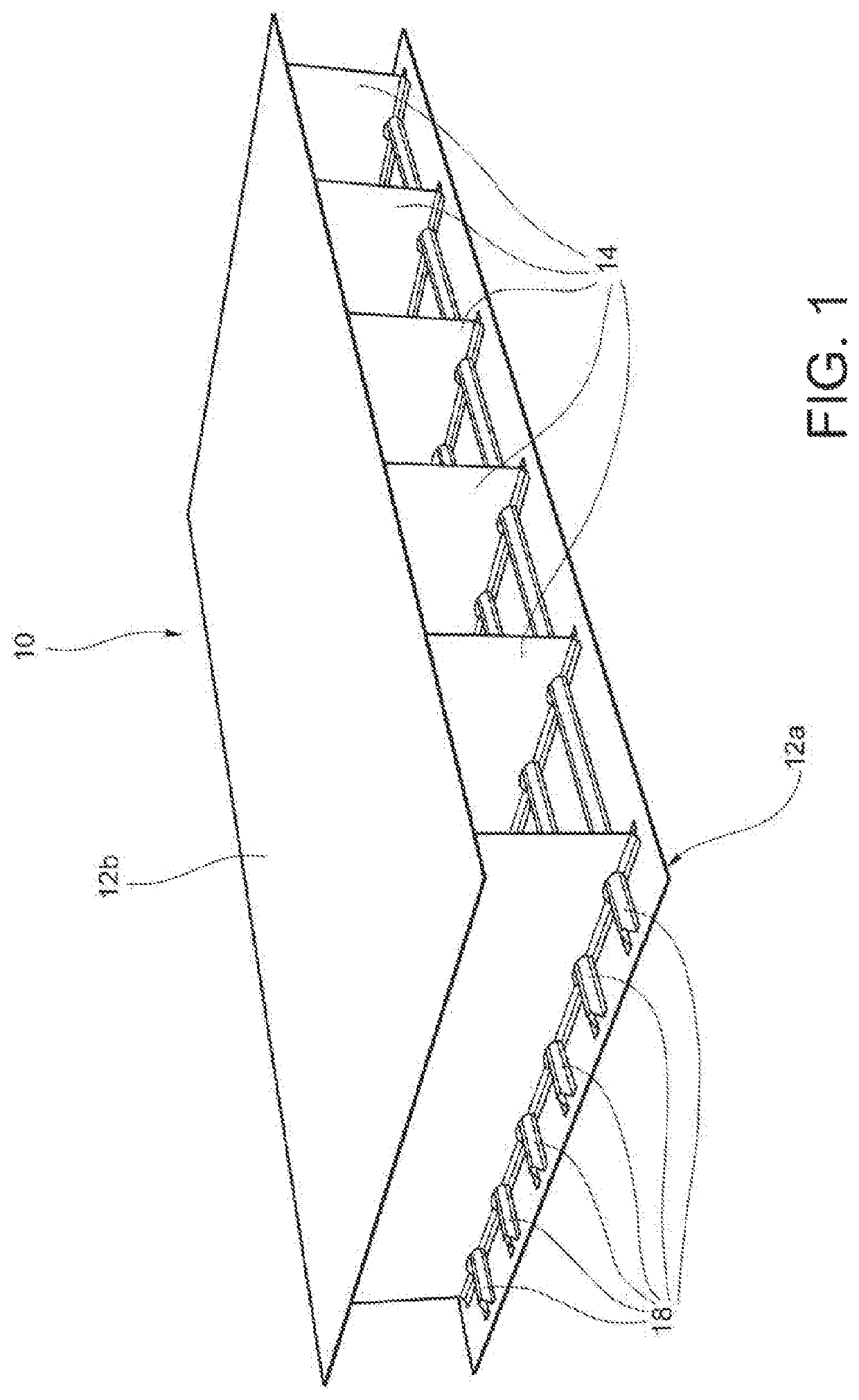

Method for manufacturing a multi-ribbed wing box of composite material with integrated stiffened panels

ActiveUS20200148328A1Complex configurationIncreased torsional strengthSpars/stringersWeight reductionMechanical engineeringAutoclave

A method for manufacturing a wing box for aircraft comprises the steps of arranging, on a curing surface, a first panel of composite material, alternately arranging, on the first panel, along a transverse direction, a rib of non-polymerized composite material and a tool comprising a central part, a bottom part and a top part, wherein the central part of each tool is interposed between said bottom part and the top part and may be extracted in a transverse direction, arranging a second panel of composite material by putting said second panel in contact with the flanges of each rib, pulling out the central part of each tool along the transverse direction and removing the top part and the bottom part of each tool, and subjecting the first panel, the second panel, and each rib to a curing process in autoclave with vacuum bag.

Owner:LEONARDO SPA

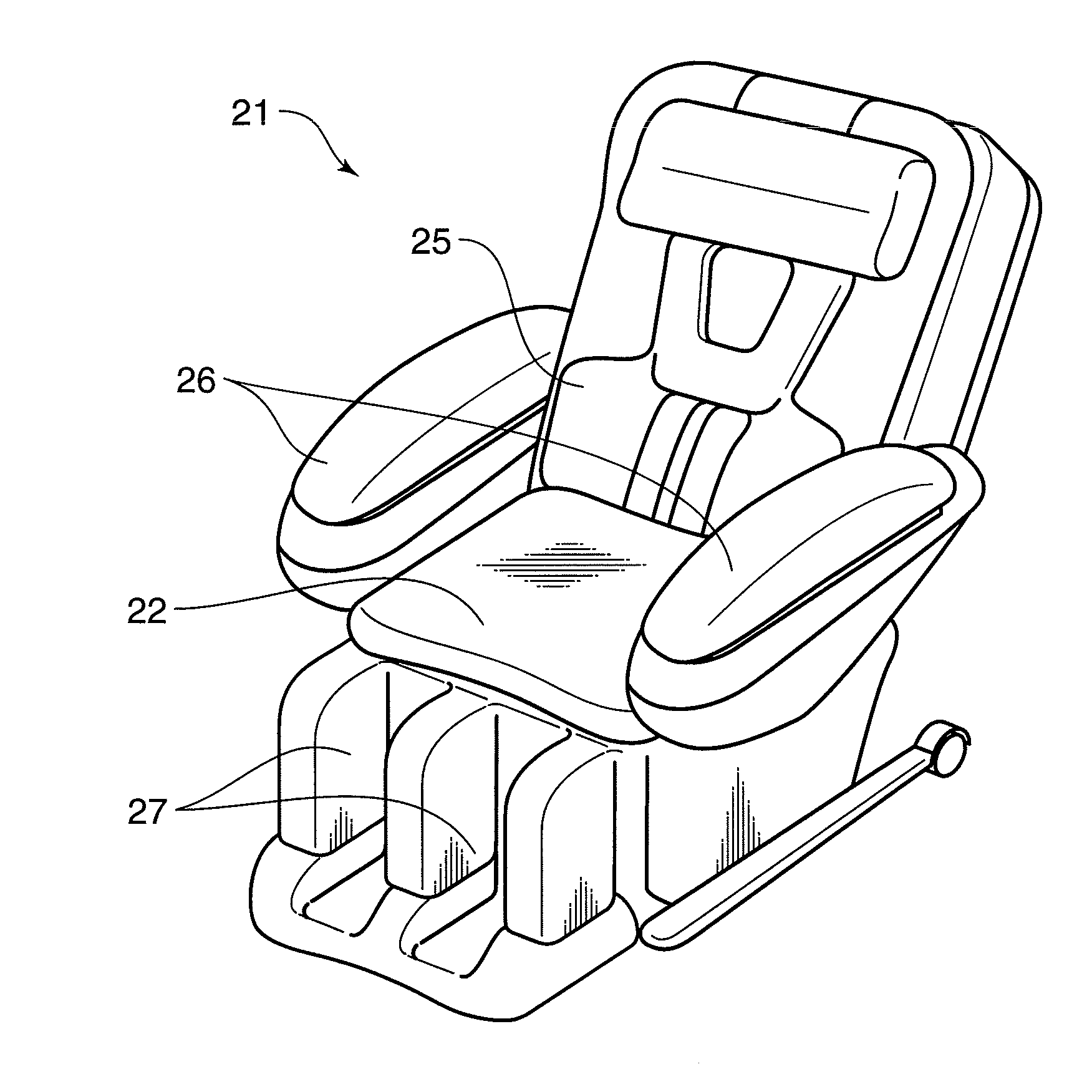

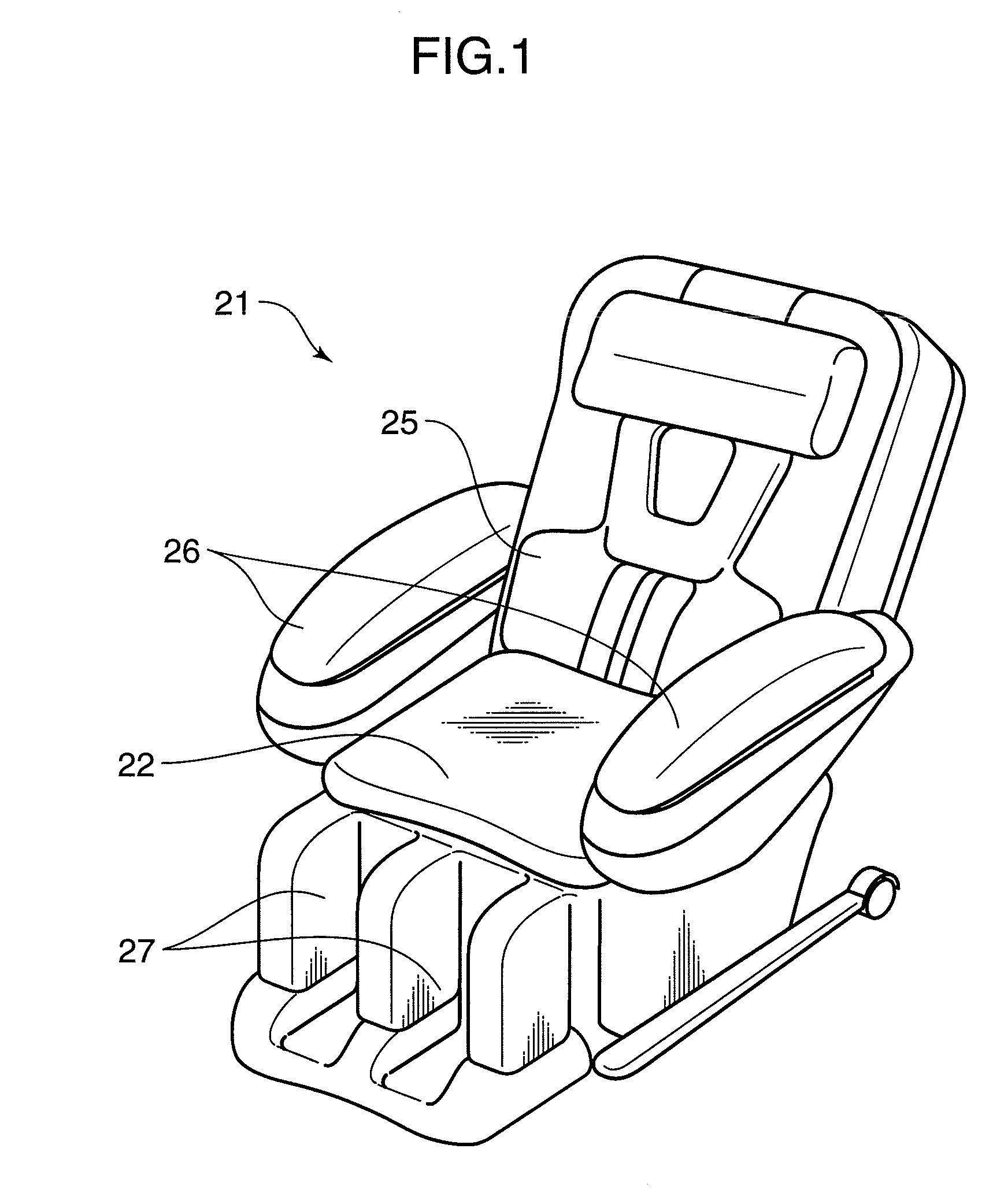

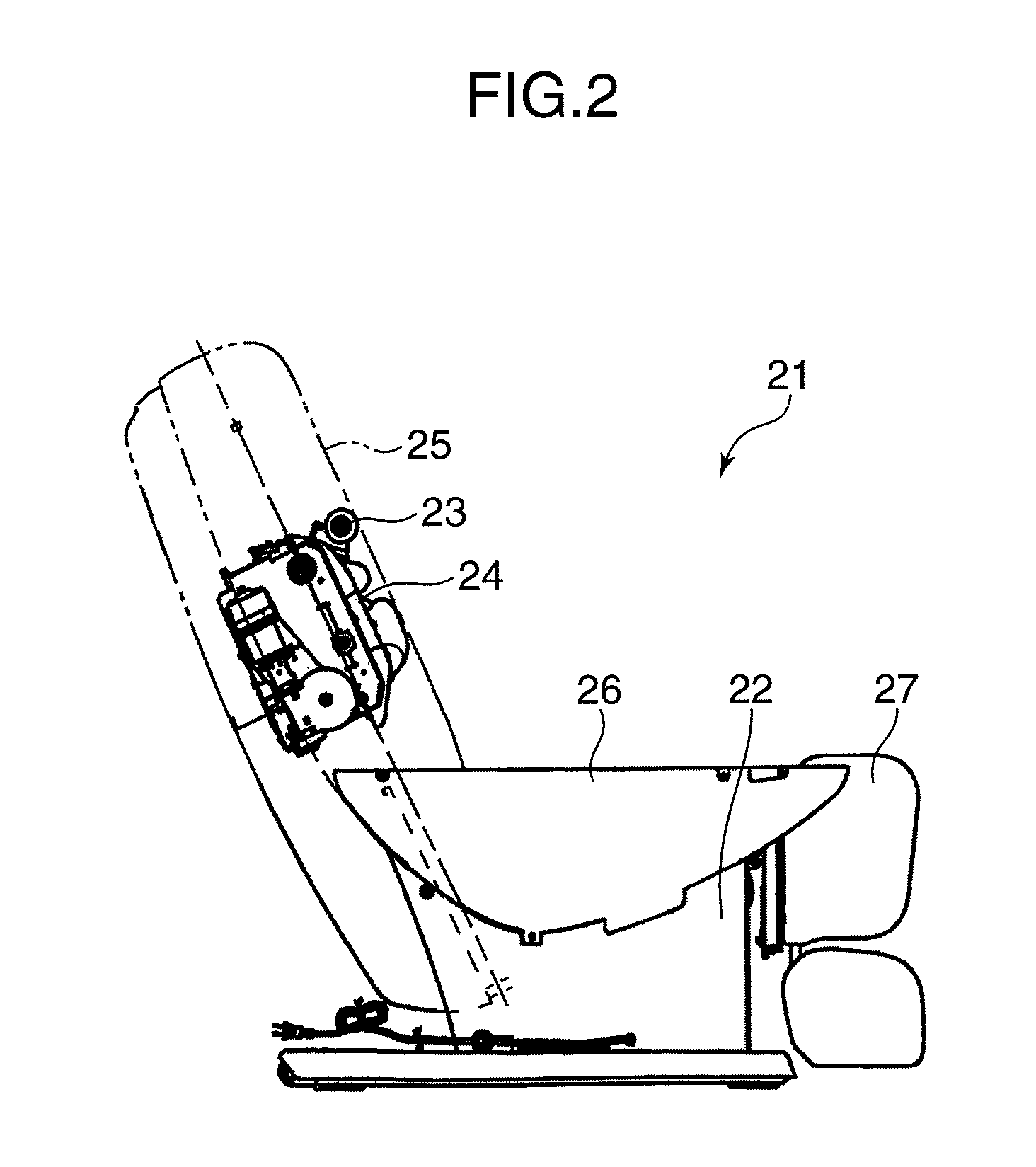

Chair-type massage machine

InactiveUS20110009781A1Reliable preventionComplex configurationVibration massageRoller massagePush outTreatment Arm

A chair-type massage machine has a seat, a backrest part, and a treatment mechanism that is provided in the backrest part so as to able to move up and down, and the treatment mechanism comprises: a treatment arm having a treatment element at substantially a tip end thereof; a massage power selection mechanism for adjusting massage strength by displacing the treatment arm between a weak state in which the treatment arm is substantially parallel to a backrest face of the backrest part and a strong state in which the treatment arm is erected substantially perpendicular to the backrest face; and a push-out member that is provided closer to a base end side than the treatment element of the treatment arm and is positioned below the treatment element when the treatment arm is in the strong state.

Owner:PANASONIC CORP

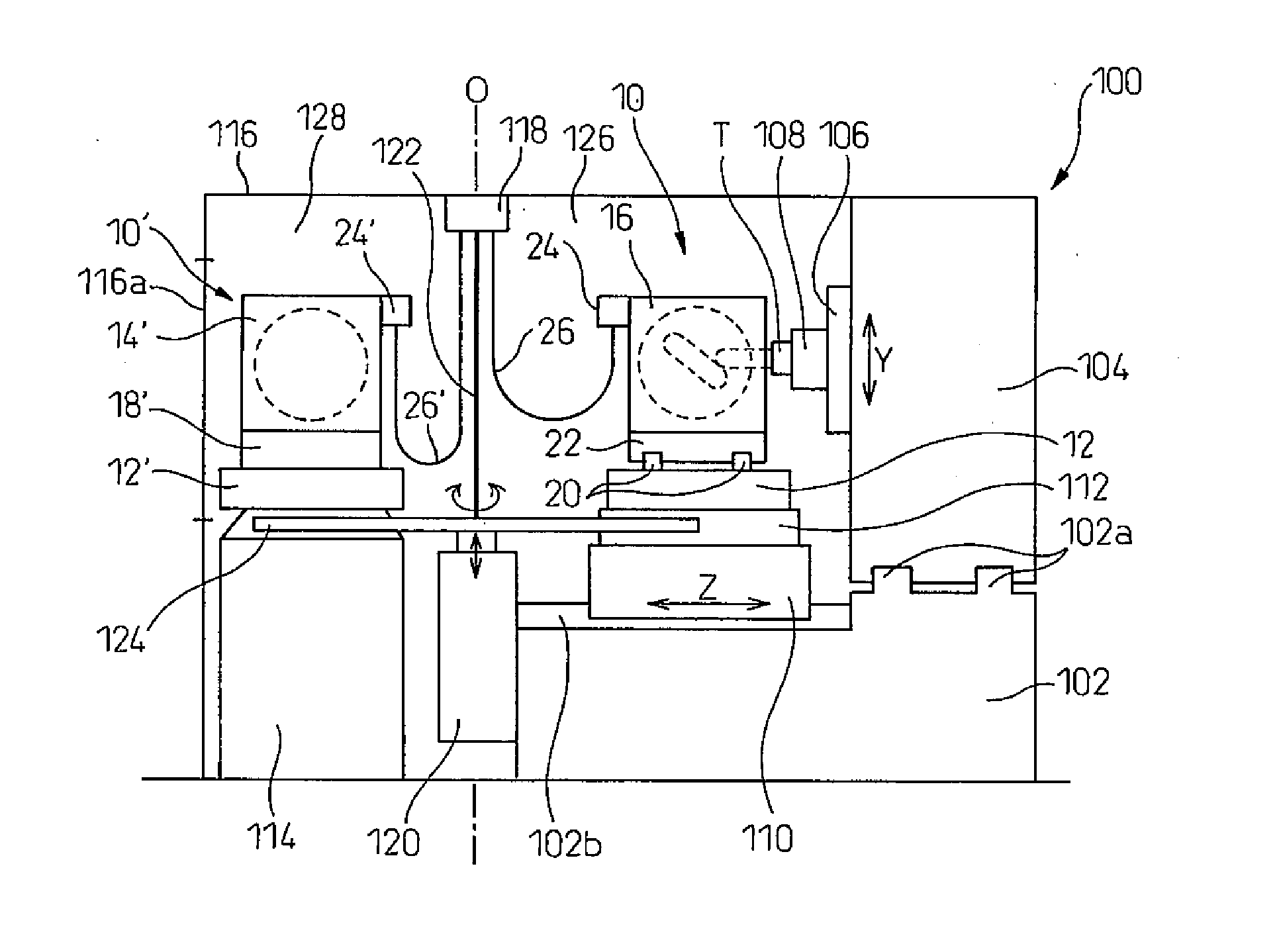

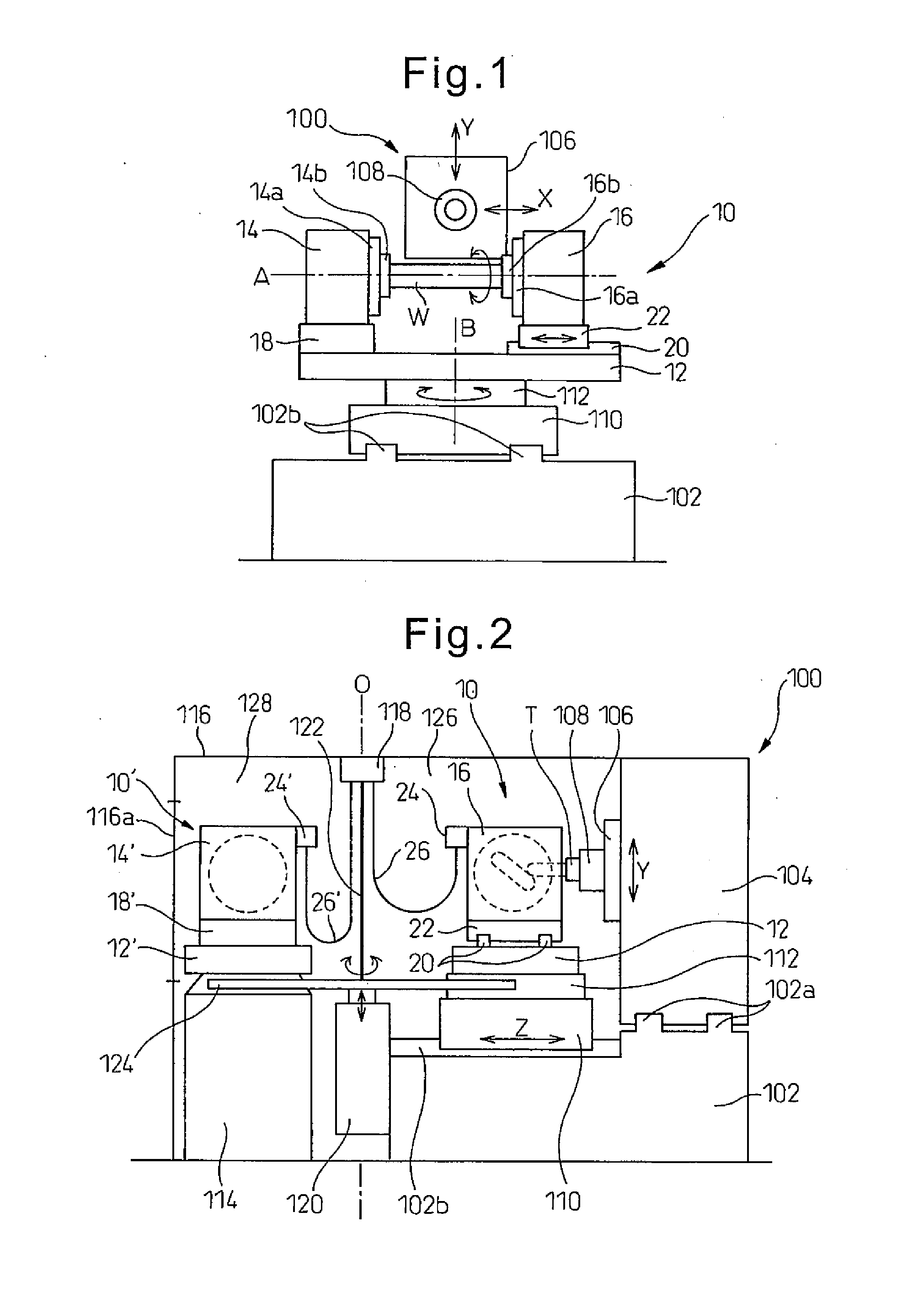

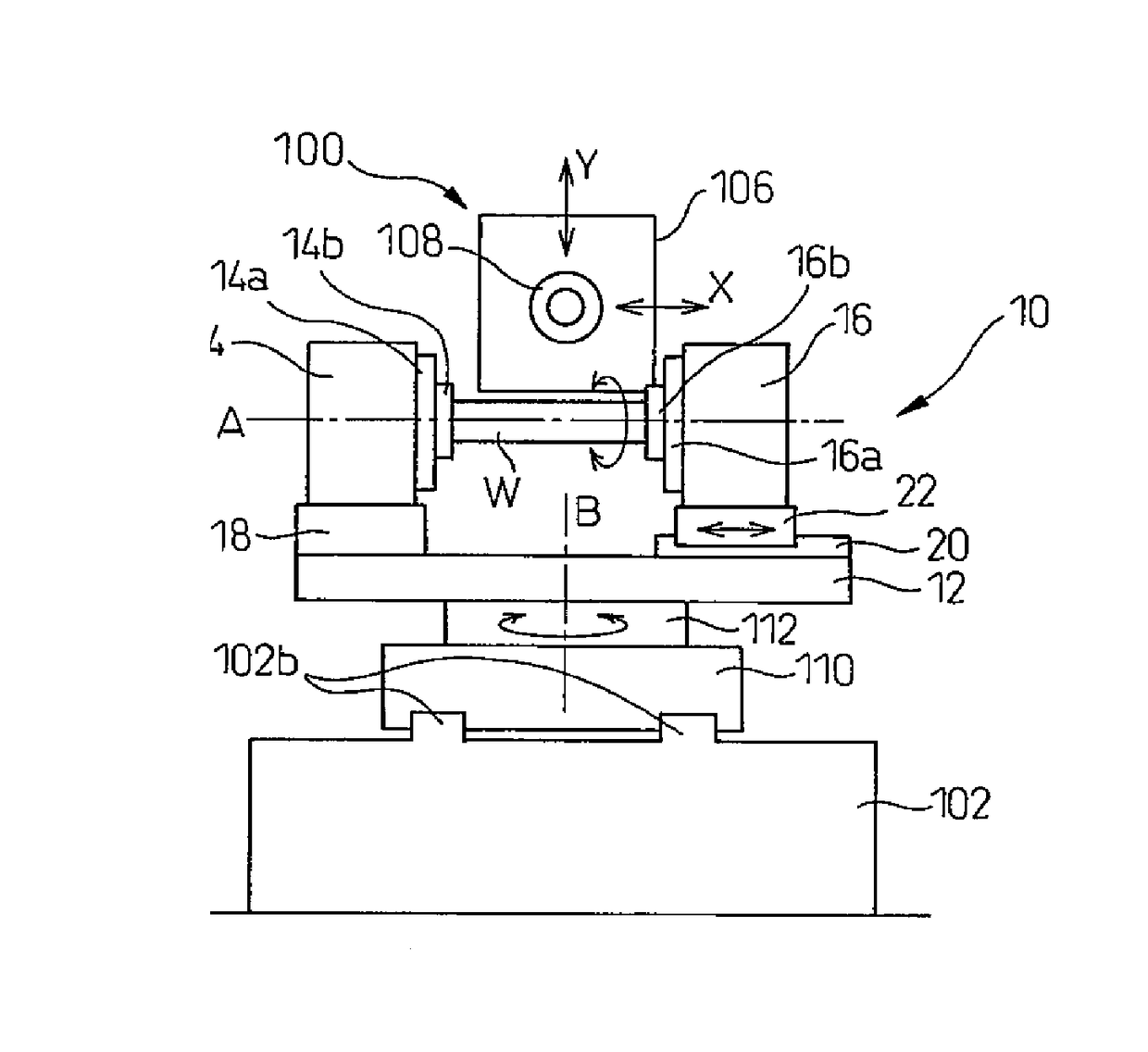

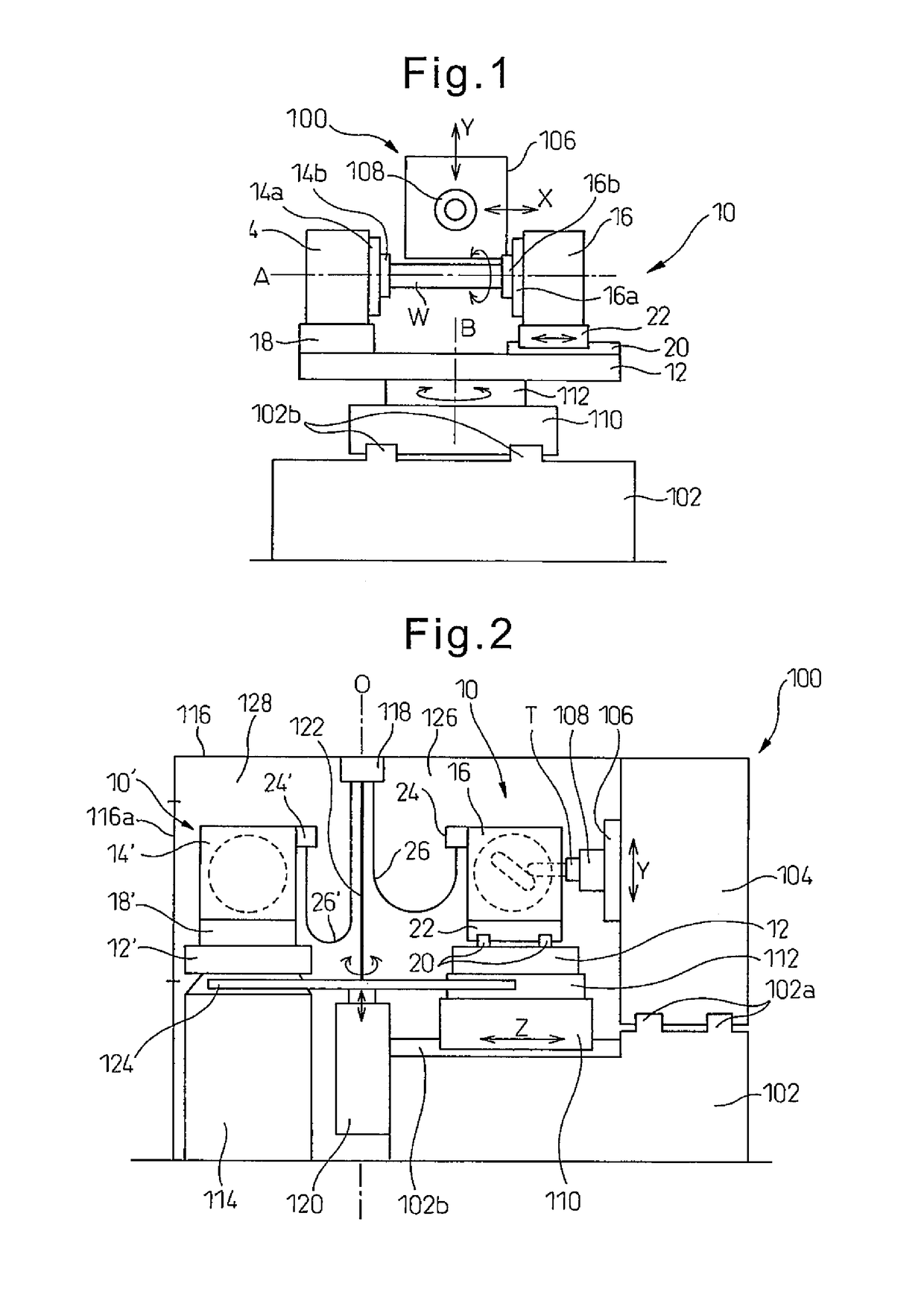

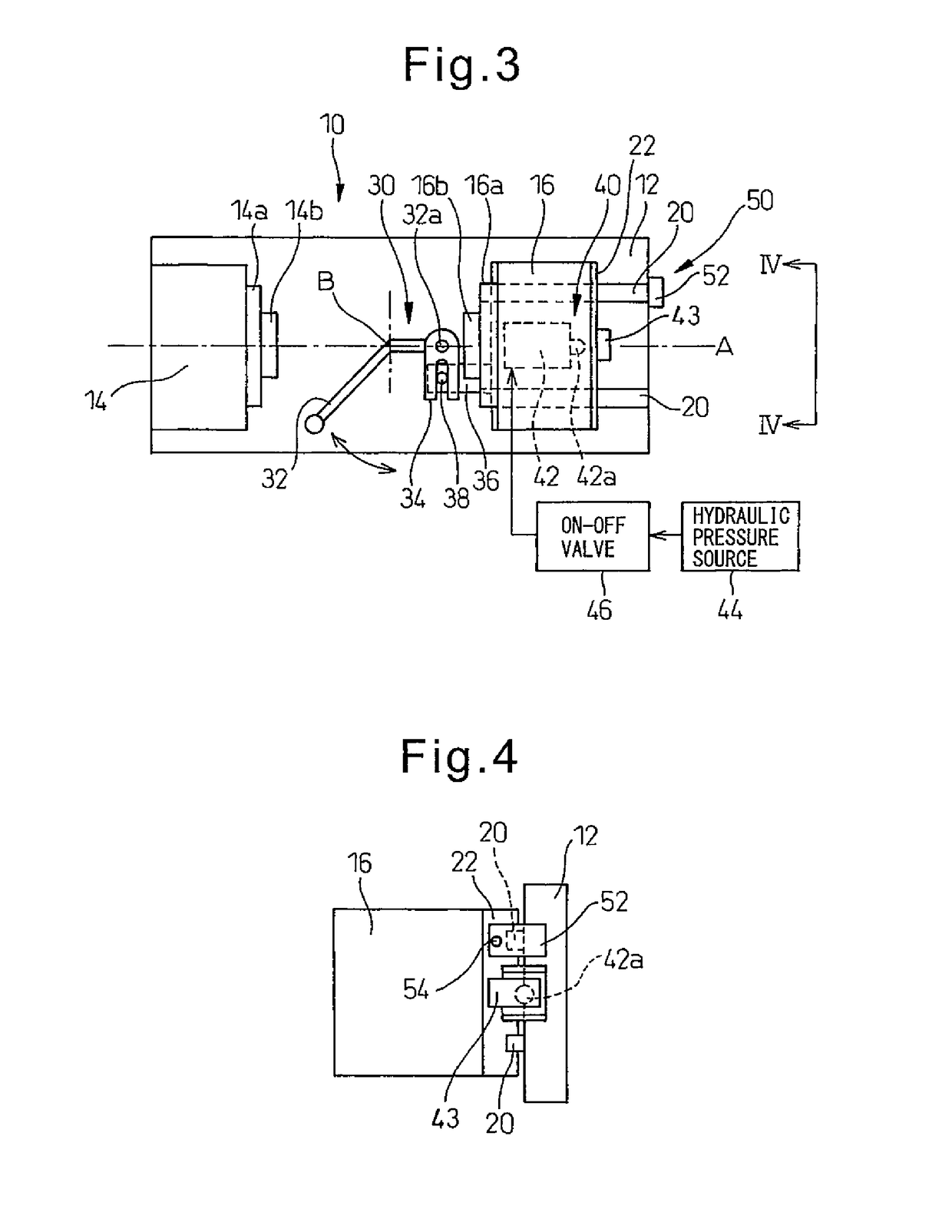

Rotary workhead device

The rotary workhead device, which is loaded on the table of a machine tool and onto which a workpiece to be machined is rotatably mounted, is equipped with: a base plate that is attached to the table of the machine tool; two rotary workheads that are provided on the base plate and disposed so that the axes of rotation coincide and the workpiece-fixing parts face each other; a guide means that is provided so as to be capable of moving at least one of the rotary workheads back and forth in the direction of the rotation axes; and an impelling means for impelling the one rotary workhead in a direction that separates or brings together the two rotary workheads. The rotary workhead device applies a tensile force or a compressive force on a workpiece, the respective ends of which are fixed between the two rotary workheads.

Owner:MAKINO MILLING MASCH CO LTD

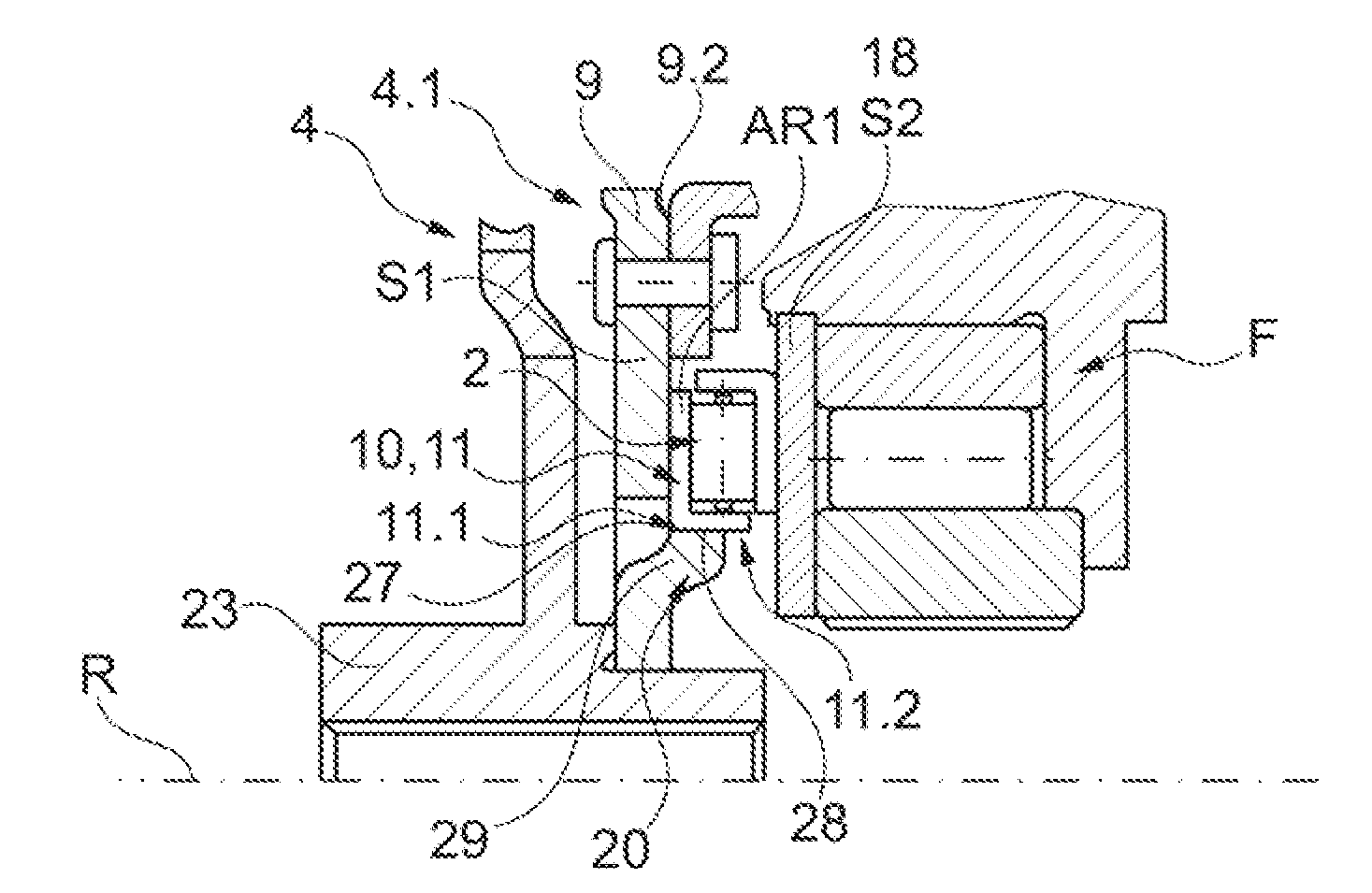

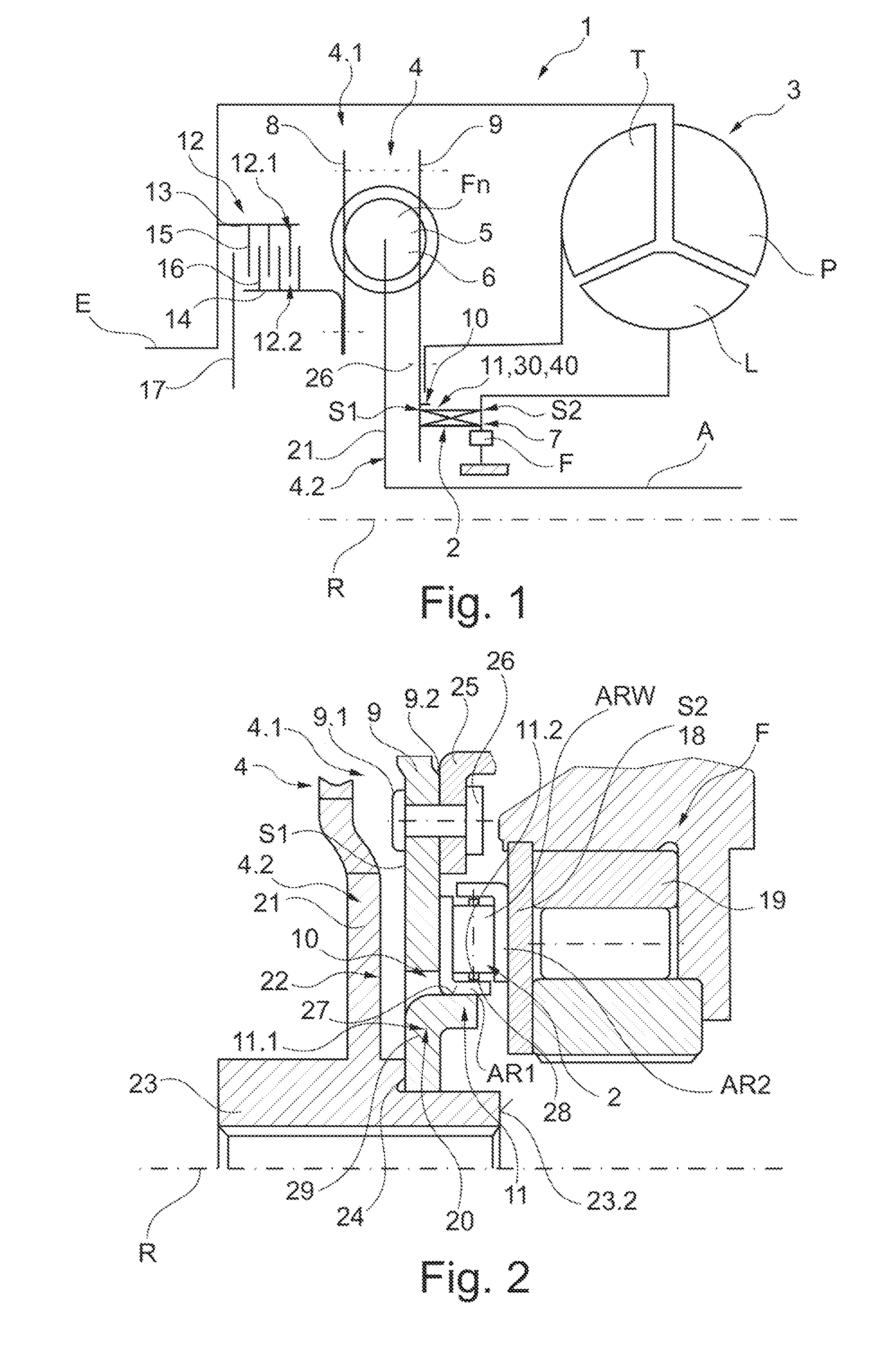

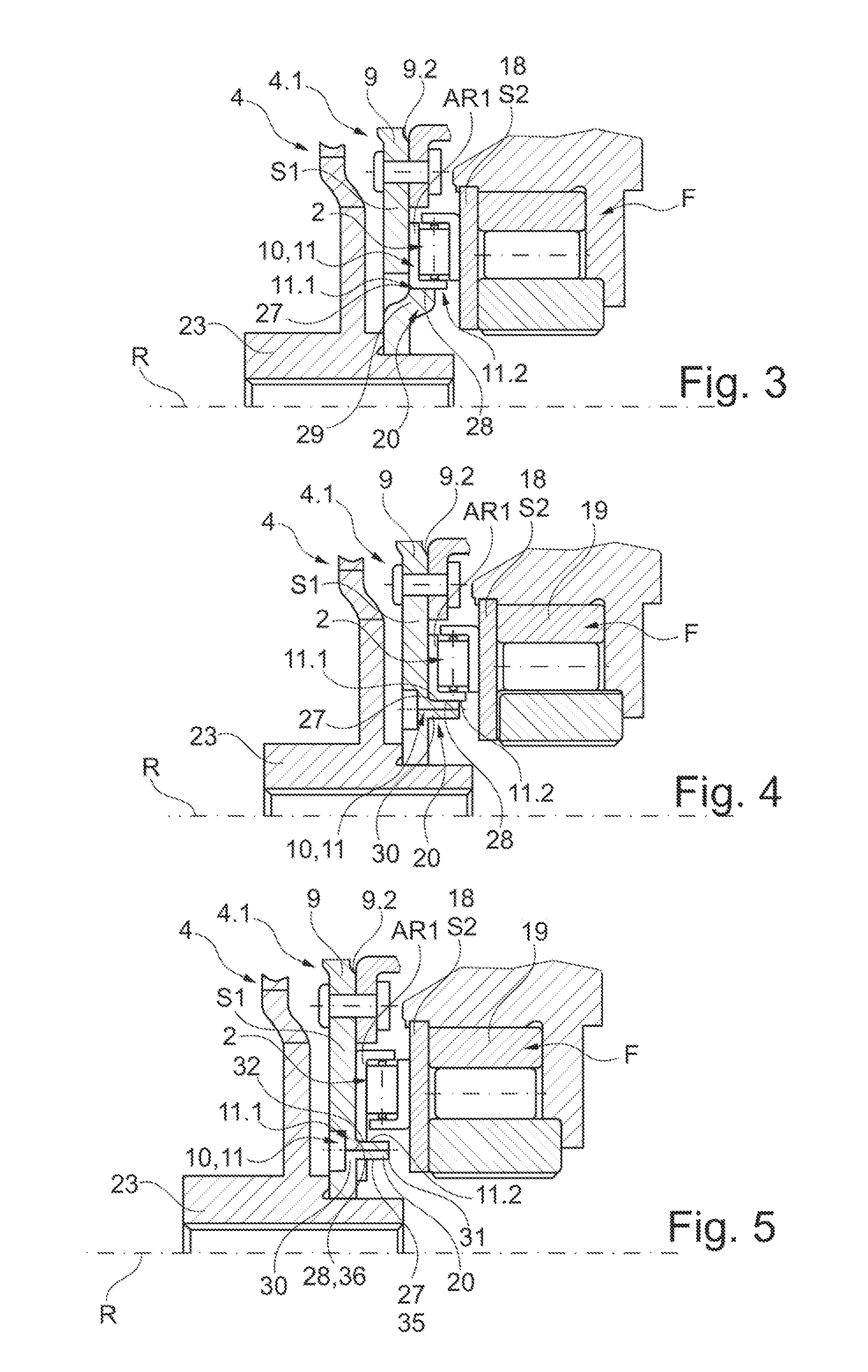

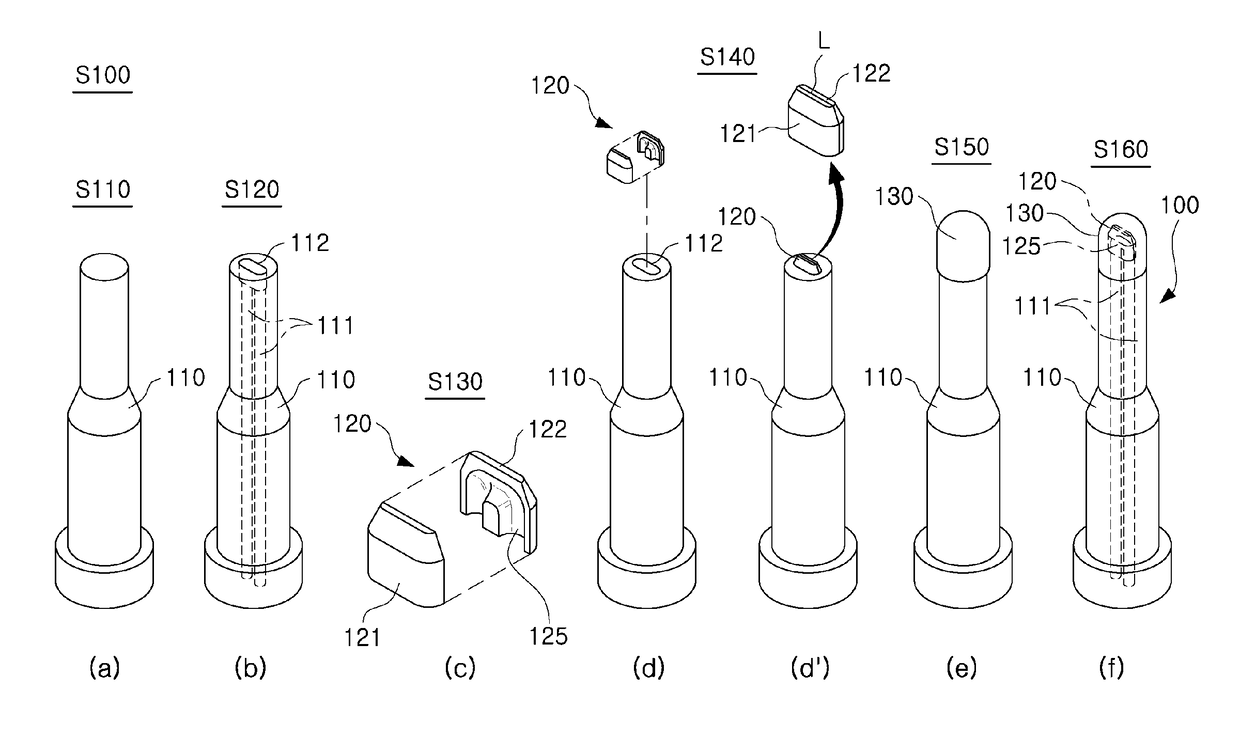

Hydrodynamic torque converter with torsion vibration damper

InactiveUS8813483B2Arrangement is limitedEasy to manufactureRotary clutchesFluid gearingsClassical mechanicsEngineering

The invention relates to a hydrodynamic torque converter, comprising: a torsion vibration damper and an axial bearing disposed between a damper component of the torsion vibration damper or a turbine shell of the hydrodynamic torque converter, the turbine shell connected with the damper component, and an adjacent connecting component; and devices for centering the axial bearing in a radial direction. The invention is characterized in that the axial bearing is disposed between two disc shaped components and the centering devices are disposed at least at one of the two disc shaped components.

Owner:SCHAEFFLER TECH AG & CO KG

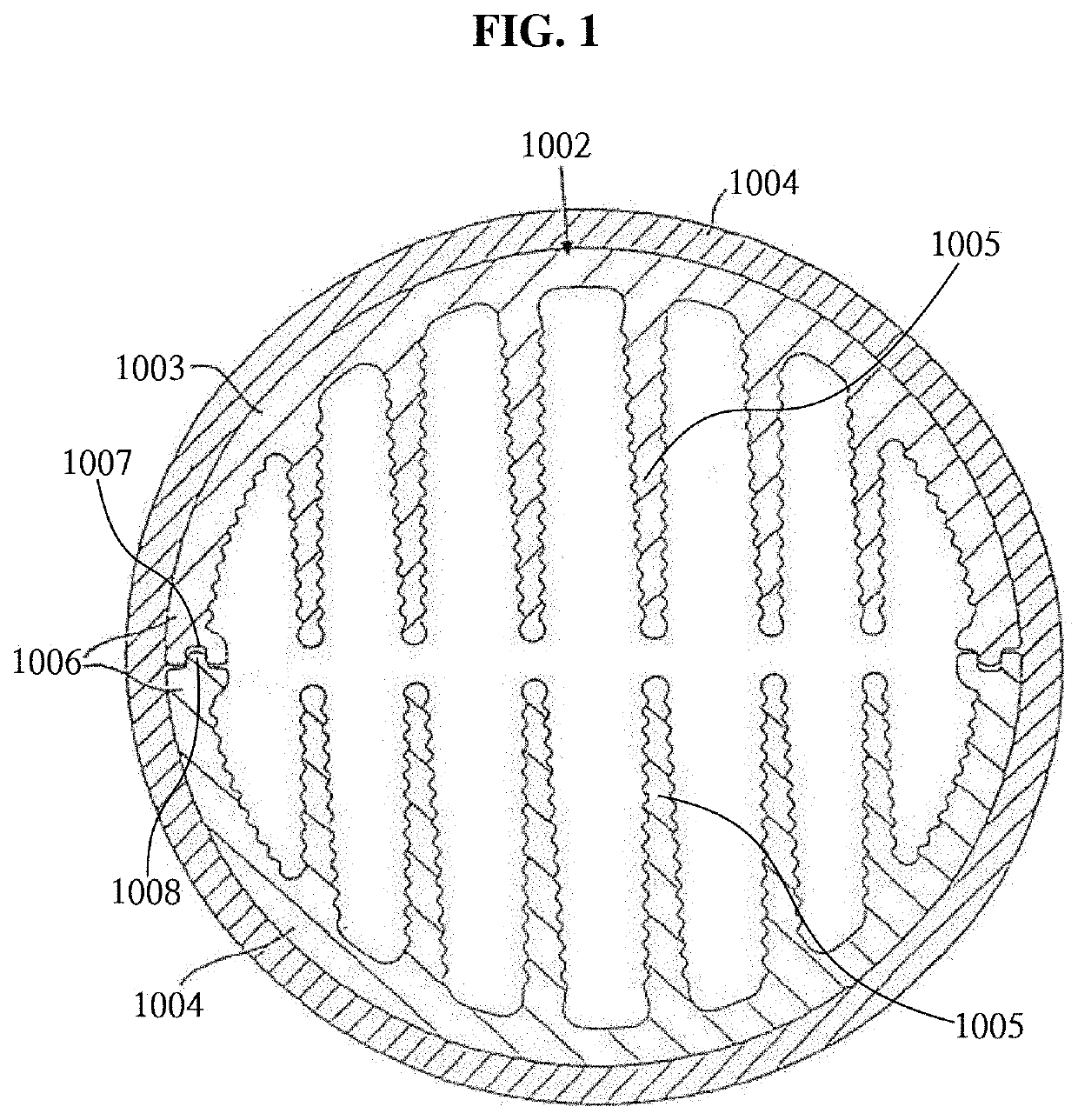

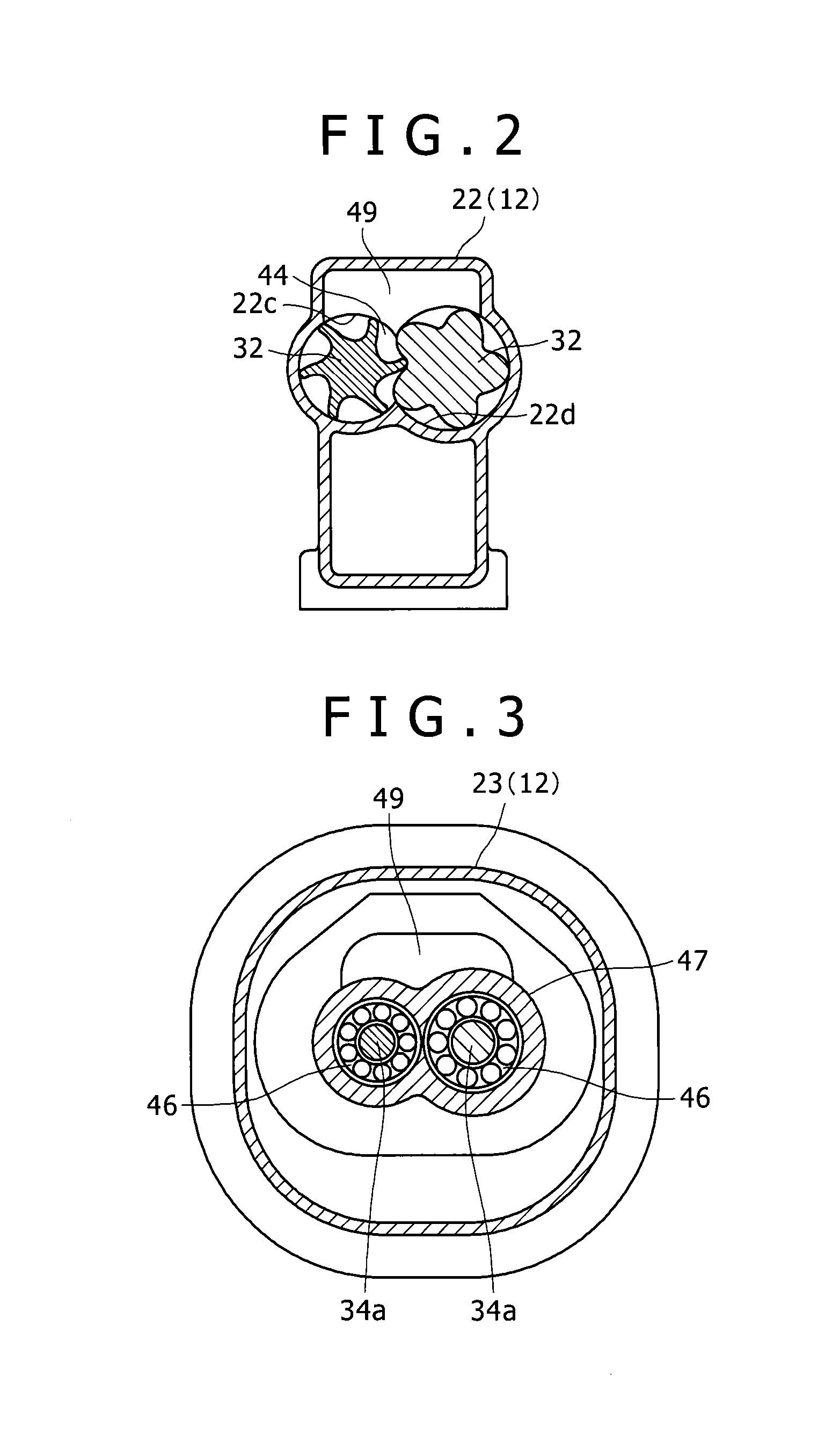

Heat exchanger pipe, method of manufacturing heat exchanger pipe, heat exchanger fin, elliptical heat exchanger pipe, and hot water storage type heat exchanger having elliptical heat exchanger pipe

PendingUS20200318855A1Prevent leakageSealing is reliableHeat exhanger finsStationary tubular conduit assembliesWater storageEngineering

The present invention relates to a heat exchanger pipe enabling heat exchange between fluid flowing through the pipe and fluid existing outside the pipe, and a method of manufacturing the heat exchanger pipe. In particular, the present invention relates to a heat exchanger pipe that improves a heat exchange rate by making flow of fluid through the pipe more active and increasing a contact amount, that has an improved contact characteristic and a sealing characteristic between an outer pipe and an insert inserted in the outer pipe in the process of manufacturing, and that is easily manufactured; and a method of manufacturing the heat exchanger pipe.

Owner:CHOI OK

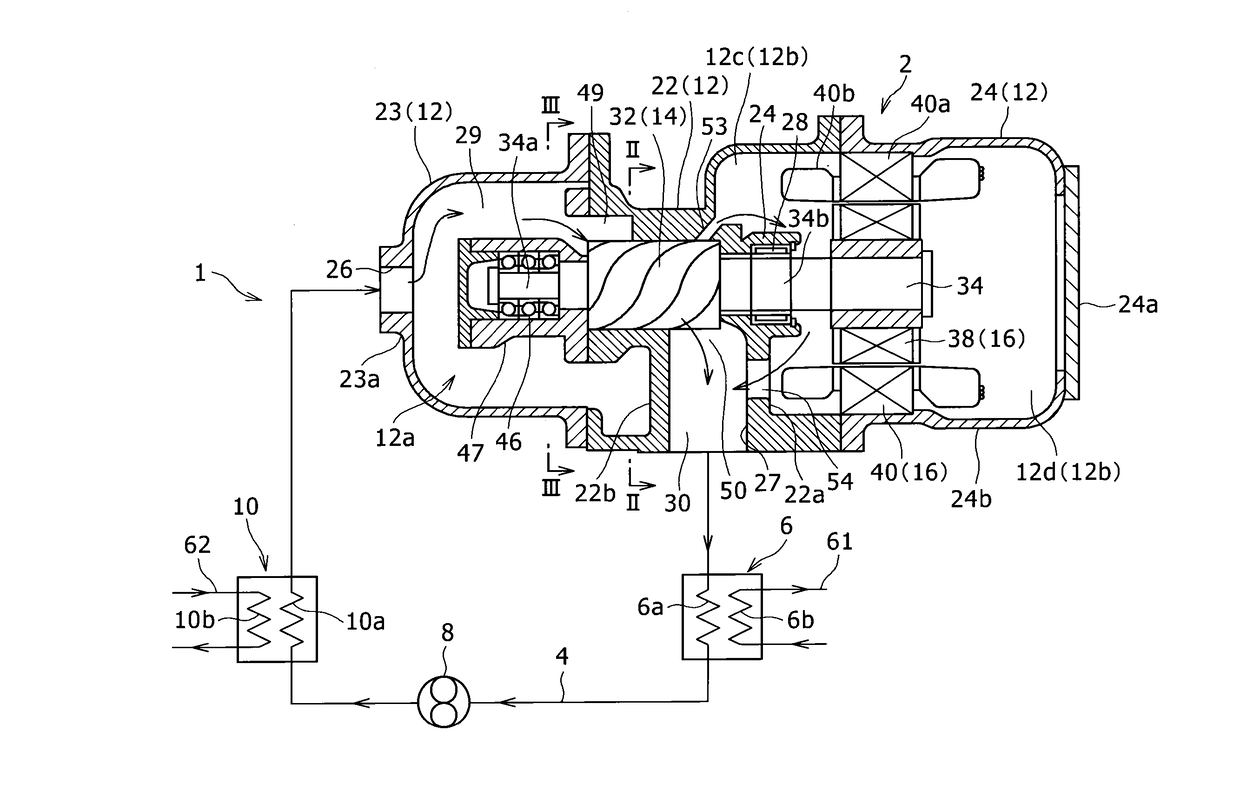

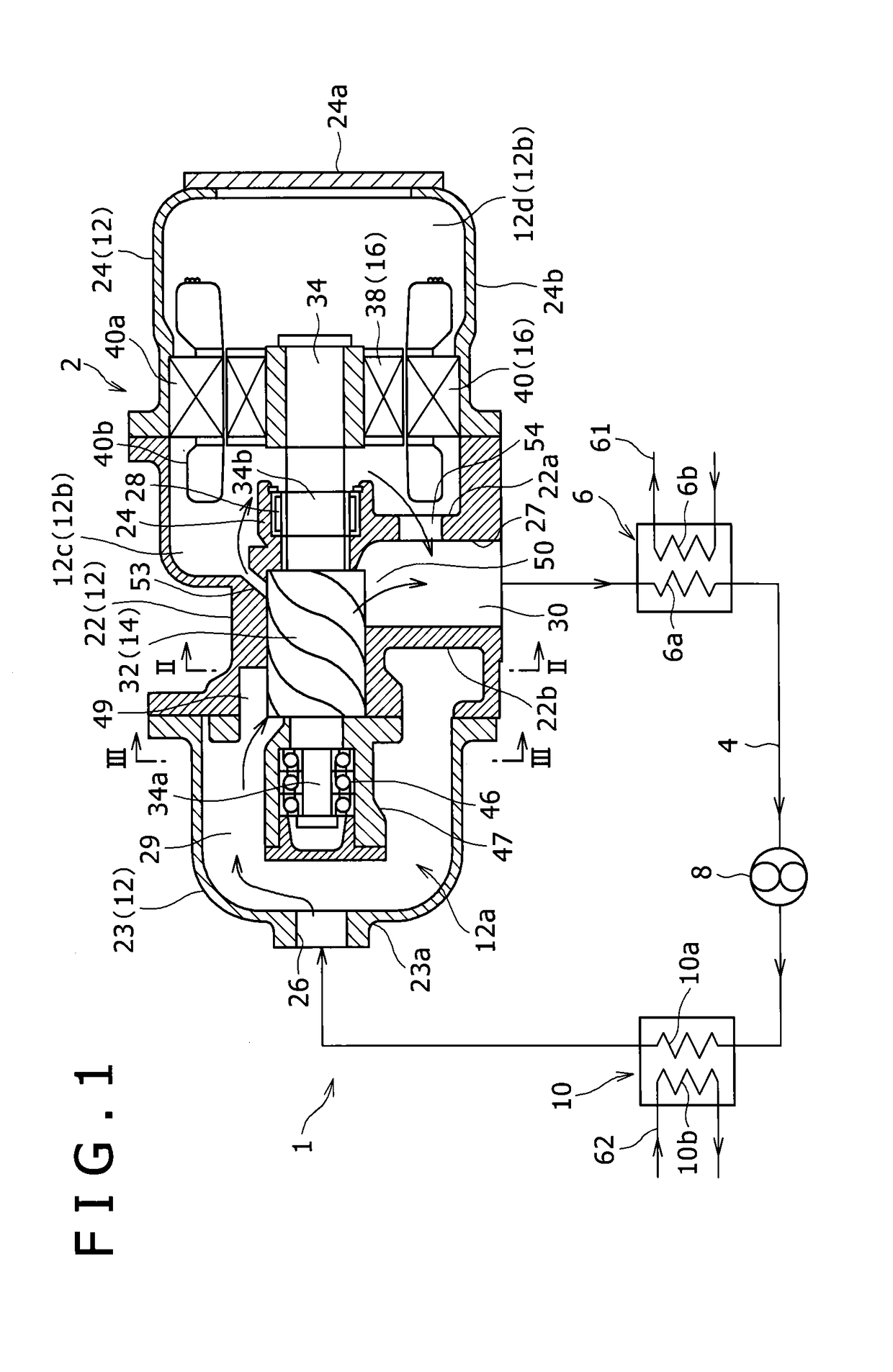

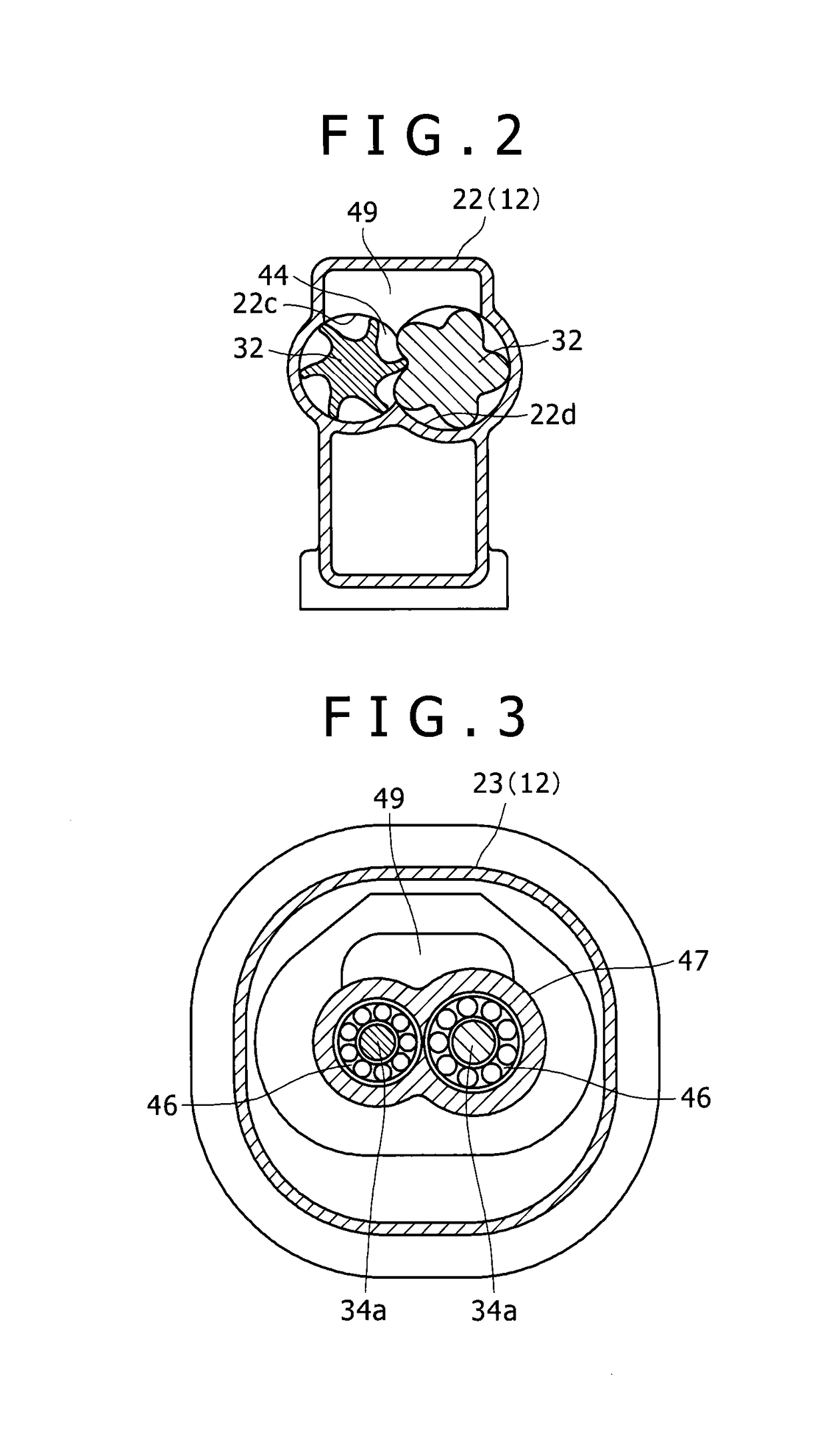

Power generation apparatus and power generation system

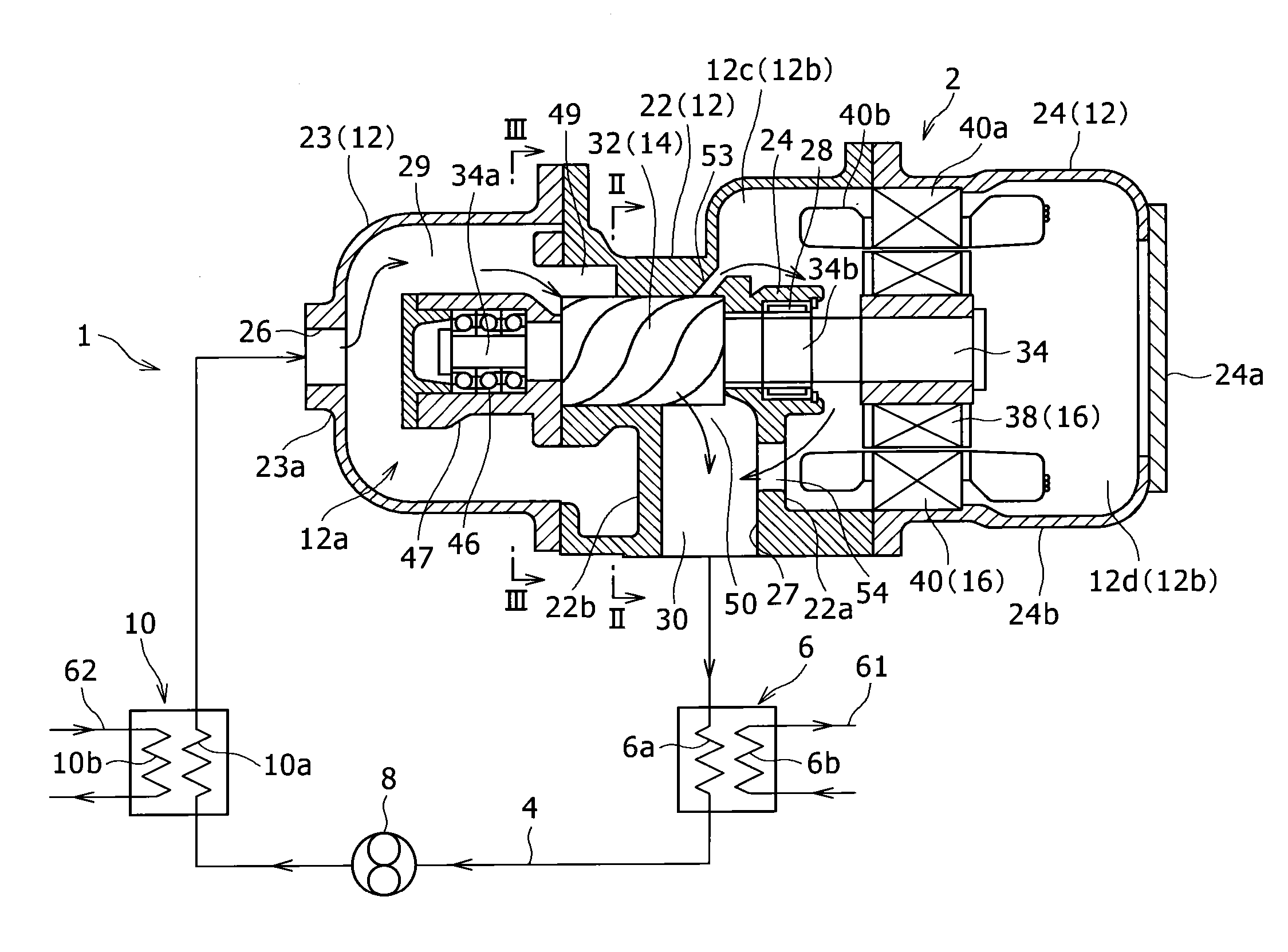

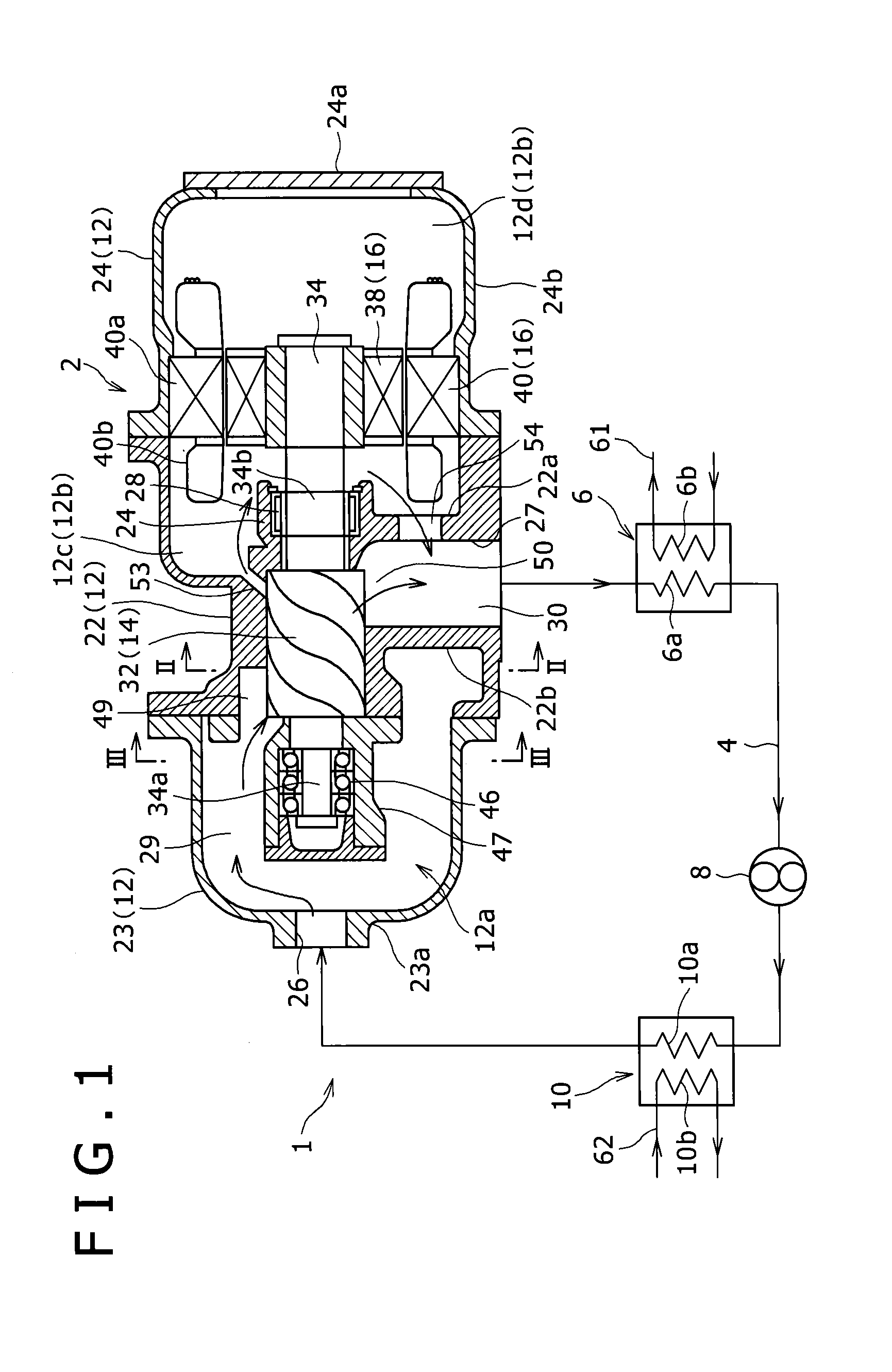

ActiveUS20140284931A1Suppress working medium circulation resistanceSimple configurationEngine of intermeshing engagement typeFluid-pressure actuatorsNuclear engineeringExpansion chamber

A power generation apparatus according to the present invention includes: an expander; a generator that includes a generator rotor driven by the expander and a stator disposed outside the generator rotor in the radial direction; and a casing that includes an expander chamber accommodating the expander and a generator chamber accommodating the generator. The casing includes a first communication portion that causes an expansion chamber which gradually expands a working medium by the expander in the expander chamber to communicate with a front generator portion which is located nearer the expansion chamber than the generator in the generator chamber and a second communication portion that causes a portion which is a downstream portion from the expansion chamber and is located near the expansion chamber with respect to the generator to communicate with the front generator portion.

Owner:KOBE STEEL LTD

Rotary workhead device

ActiveUS9919393B2Complex configurationIncrease production costLathesWorkpiecesPull forceMachine tool

The rotary workhead device, which is loaded on the table of a machine tool and onto which a workpiece to be machined is rotatably mounted, is equipped with: a base plate that is attached to the table of the machine tool; two rotary workheads that are provided on the base plate and disposed so that the axes of rotation coincide and the workpiece-fixing parts face each other; a guide means that is provided so as to be capable of moving at least one of the rotary workheads back and forth in the direction of the rotation axes; and an impelling means for impelling the one rotary workhead in a direction that separates or brings together the two rotary workheads. The rotary workhead device applies a tensile force or a compressive force on a workpiece, the respective ends of which are fixed between the two rotary workheads.

Owner:MAKINO MILLING MASCH CO LTD

Fluid regulating microvalve assembly for fluid consuming cells

InactiveUS7378168B2Low costInexpensive and straightforward to produceFuel and primary cellsReactant parameters controlElectrochemical cellBiomedical engineering

A fluid regulating microvalve assembly for use to control fluid flow to a fluid consuming electrode, such as an oxygen reduction electrode, in an electrochemical cell. The microvalve assembly includes a stationary valve body having an aperture and a microactuator movable from a first position where the microvalve body aperture is closed to fluid flow to at least a second position where fluid is able to pass through the microvalve body aperture. The fluid regulating microvalve assembly can utilize cell potential or a separate source to open and close the microvalve. The fluid regulating microvalve assembly can be located outside the cell housing or inside the cell housing, for example between one or more fluid inlet apertures and the fluid consuming electrode. The invention includes a method of making a multilayer microvalve assembly, particularly one for use in a fluid depolarized battery, using a printing process to deposit at least one of the layers.

Owner:SCHUMM BROOKE JR +3

Apparatus for heat treatment of structural body parts in the automobile industry

InactiveUS7235209B2Easy to bendComplex configurationFurnace typesIncreasing energy efficiencySheet steelHorizontal axis

Owner:BENTELER AKTIENGES

Metal product having internal space formed therein and method of manufacturing thereof

ActiveUS9636790B2Low costShorten the timeShaping toolsAdditive manufacturing apparatusCooling channelCooling efficiency

There are provided a metal product having an internal space formed therein, allowing for improvements in the flow of a coolant in the internal space, such as a cooling channel and an increase in cooling efficiency, and a method of manufacturing thereof. The metal product includes a body part having a first space formed therein; a space formation member having a second space formed therein, mounted on the body part to be communicated with the first space; and a finishing part forming an exterior by covering the space formation member in a state in which the space formation member is mounted on the body part.

Owner:INSSTEK

Fluid regulating microvalve assembly for fluid consuming cells with spring-like shape-retaining aperture cover

ActiveUS9252467B2Inexpensive and straightforward to produceLow costFuel and primary cellsValve arrangementsEngineeringElectrochemical cell

A fluid regulating microvalve assembly for use to control fluid flow to a fluid consuming electrode, such as an oxygen reduction electrode, in an electrochemical cell is proposed. The microvalve assembly includes a stationary valve body having an aperture and microactuators movable from a first closed aperture position to at least a second position where fluid is able to pass through the microvalve body aperture. These microactuators control the movement of spring-like shape-retaining interior aperture covers, which covers can be belleville springs or flat springs. The fluid regulating microvalve assembly can utilize cell potential or a separate source. The latter assembly can be located outside or inside the cell housing, for example between a fluid inlet aperture and the fluid consuming electrode. Using a printing process to deposit at least one of the layers is proposed for making the multilayer microvalve assembly for a fluid depolarized battery.

Owner:SCHUMM JR BROOKE

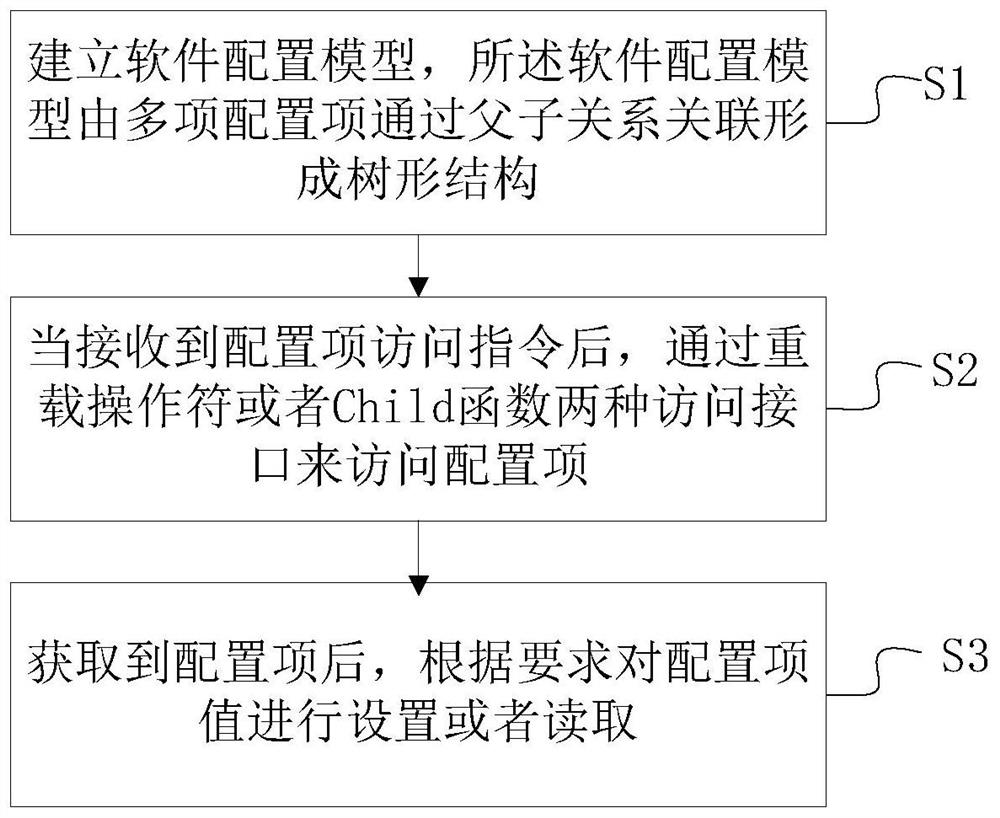

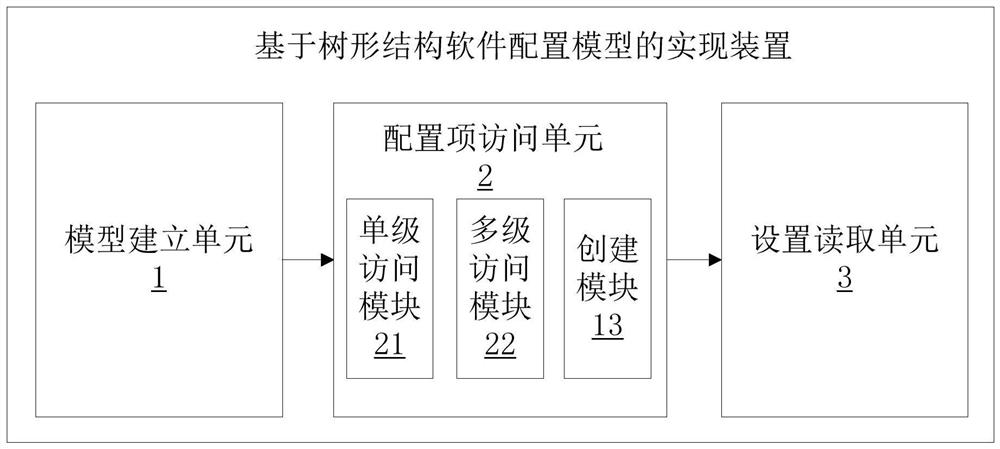

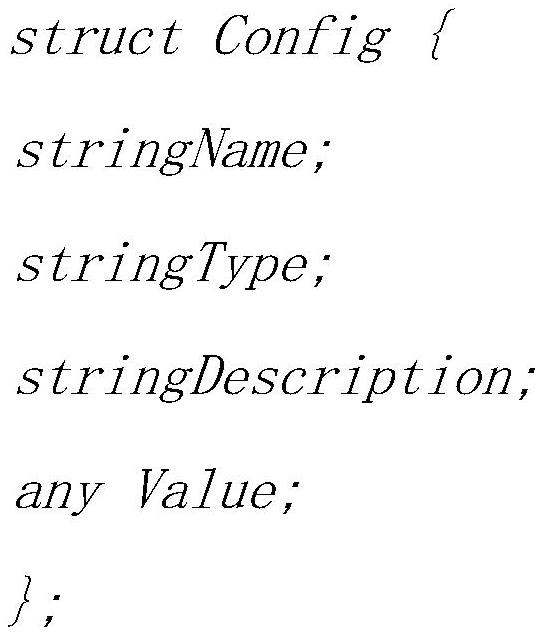

A method and device for realizing software configuration model based on tree structure

ActiveCN109976799BComplex configurationAdapt to configuration requirementsVersion controlSemi-structured data indexingFault toleranceConfiguration item

The present invention is applicable to the technical field of computer software, and provides an implementation method and device based on a tree-structured software configuration model. The method includes: establishing a software configuration model; Child function has two access interfaces to access configuration items; set or read the value of configuration items as required. The present invention forms a tree-shaped configuration by associating a parent-child relationship, and can compose a large number of configuration items into configurations of arbitrary complexity; in addition, various types of configuration data are described by defining a unified configuration item data structure, and two access interfaces are designed to To realize the acquisition of configuration items, the two access interfaces have other designs when specifically accessing configuration items, thus greatly improving the user experience of using configuration. Finally, in any case, a default value of the corresponding type needs to be passed in to obtain the configuration value. The design of the default value can greatly improve the fault tolerance of the configuration system.

Owner:吉奥时空信息技术股份有限公司

Power generation apparatus and power generation system

ActiveUS9618020B2Simple configurationSuppressing a working medium circulation resistanceEngine of intermeshing engagement typeFluid-pressure actuatorsNuclear engineeringExpansion chamber

A power generation apparatus according to the present invention includes: an expander; a generator that includes a generator rotor driven by the expander and a stator disposed outside the generator rotor in the radial direction; and a casing that includes an expander chamber accommodating the expander and a generator chamber accommodating the generator. The casing includes a first communication portion that causes an expansion chamber which gradually expands a working medium by the expander in the expander chamber to communicate with a front generator portion which is located nearer the expansion chamber than the generator in the generator chamber and a second communication portion that causes a portion which is a downstream portion from the expansion chamber and is located near the expansion chamber with respect to the generator to communicate with the front generator portion.

Owner:KOBE STEEL LTD

Method for manufacturing a multi-ribbed wing box of composite material with integrated stiffened panels

ActiveUS11292577B2Precise positioningComplex configurationSpars/stringersWeight reductionMechanical engineeringMaterials science

A method for manufacturing a wing box for aircraft comprises the steps of arranging, on a curing surface, a first panel of composite material, alternately arranging, on the first panel, along a transverse direction, a rib of non-polymerized composite material and a tool comprising a central part, a bottom part and a top part, wherein the central part of each tool is interposed between said bottom part and the top part and may be extracted in a transverse direction, arranging a second panel of composite material by putting said second panel in contact with the flanges of each rib, pulling out the central part of each tool along the transverse direction and removing the top part and the bottom part of each tool, and subjecting the first panel, the second panel, and each rib to a curing process in autoclave with vacuum bag.

Owner:LEONARDO SPA

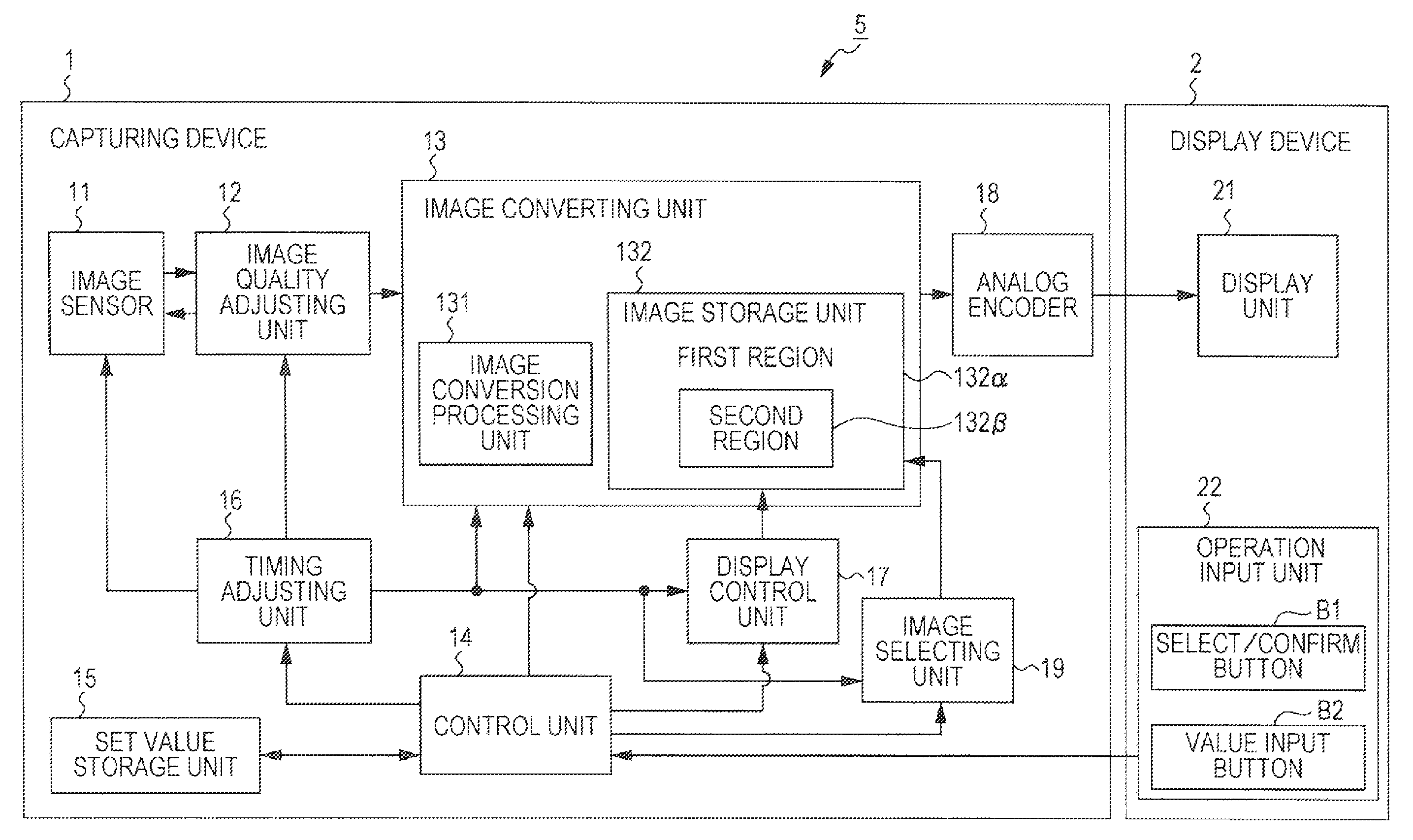

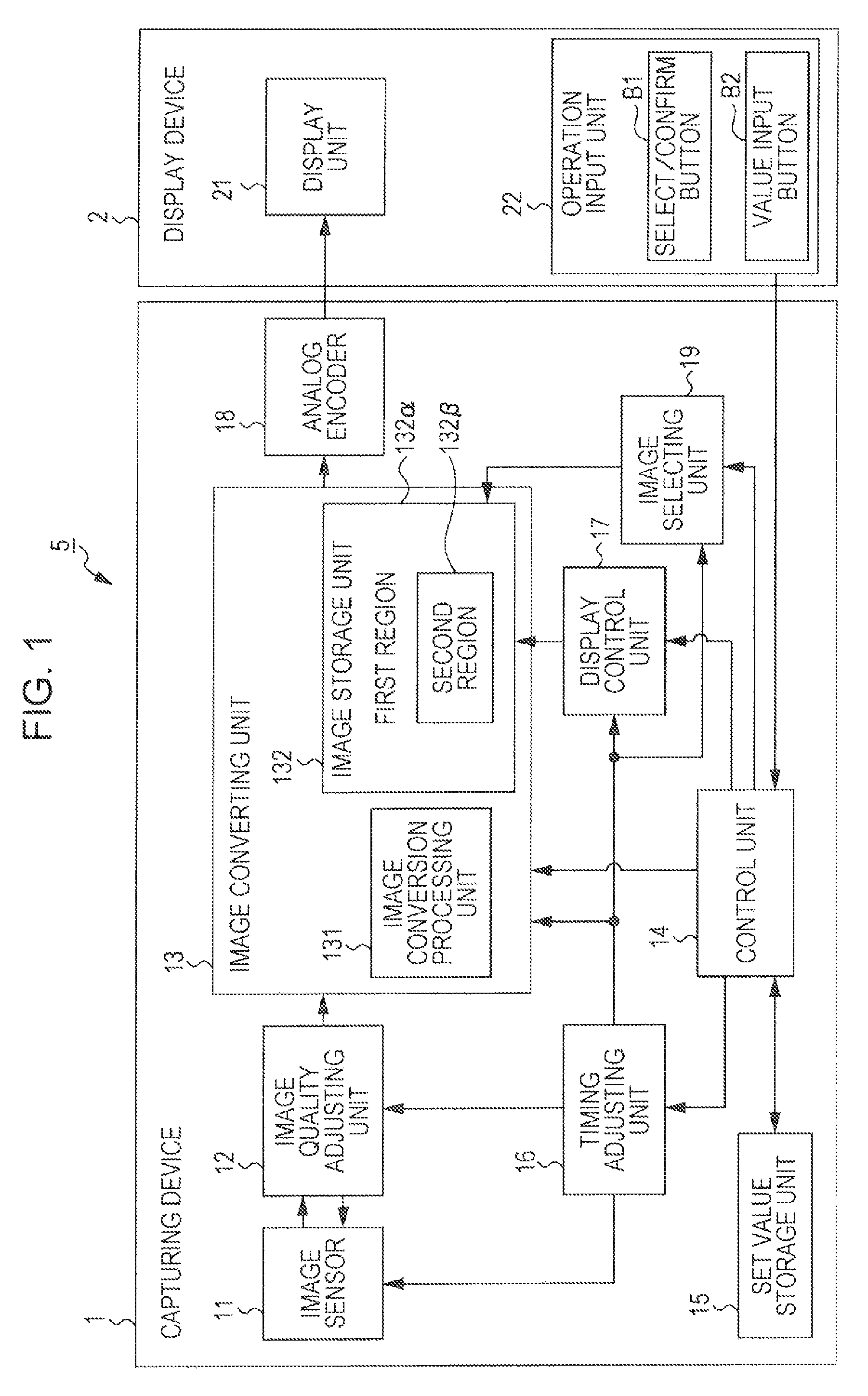

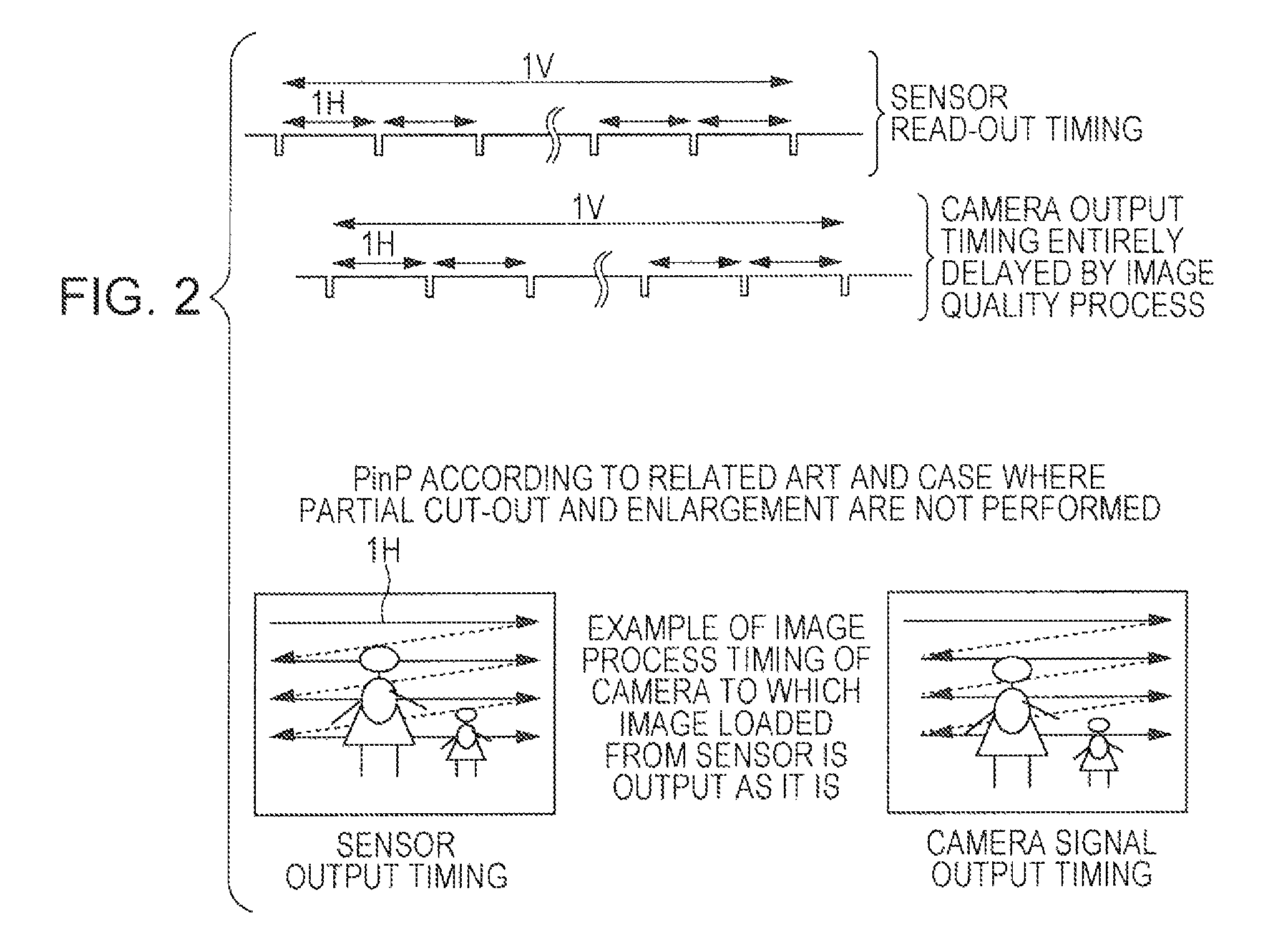

Capturing device, capturing system, and capturing method

InactiveUS8970735B2Complex configurationIncrease the number ofTelevision system detailsColor television detailsComputer hardwareImage conversion

A capturing device includes: an image sensor generating an image signal; a storage unit setting a second region in a first region; a timing adjusting unit adjusting a timing at which the image signal is read out to write the image signal in the storage unit, and a timing at which the image signal is read out from the storage unit; an image conversion processing unit performing a predetermined process on the image, alternately writing a first image signal corresponding to a full image or a second image signal corresponding to a partial image in the first region in a different frame period, and writing an image signal that is different from the image signal written in the first region in the second region; and an output unit converting and outputting the first and second image signals into an image signal in a predetermined format.

Owner:SONY CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com