Substrate binding device and method

A technology for bonding devices and substrates, applied in non-electric welding equipment, instruments, static indicators, etc., can solve problems such as inability to remove dust and dust, reduce yield, disturb airflow, etc., to suppress dust and dust flying, and ease sharp The effect of vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

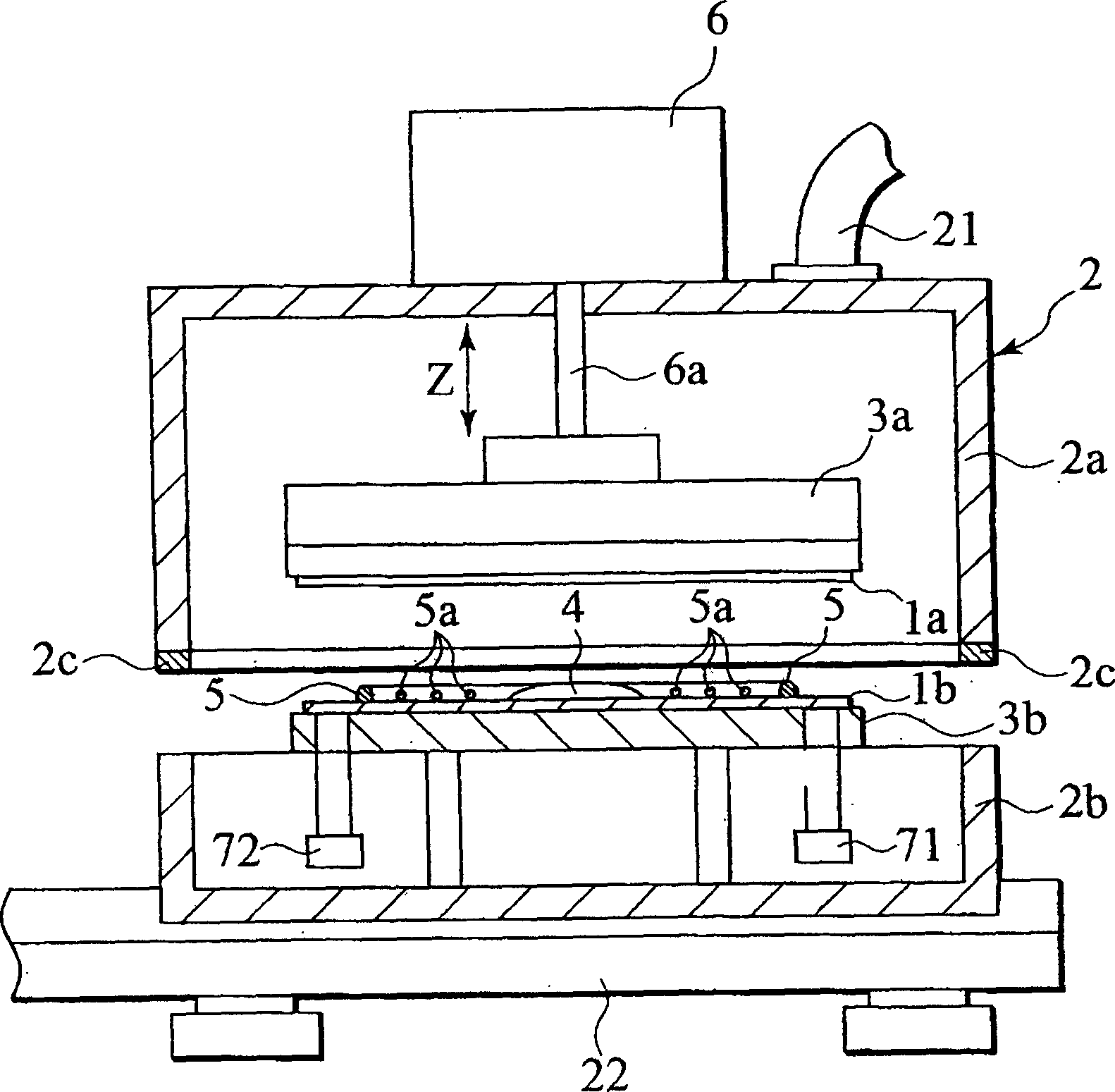

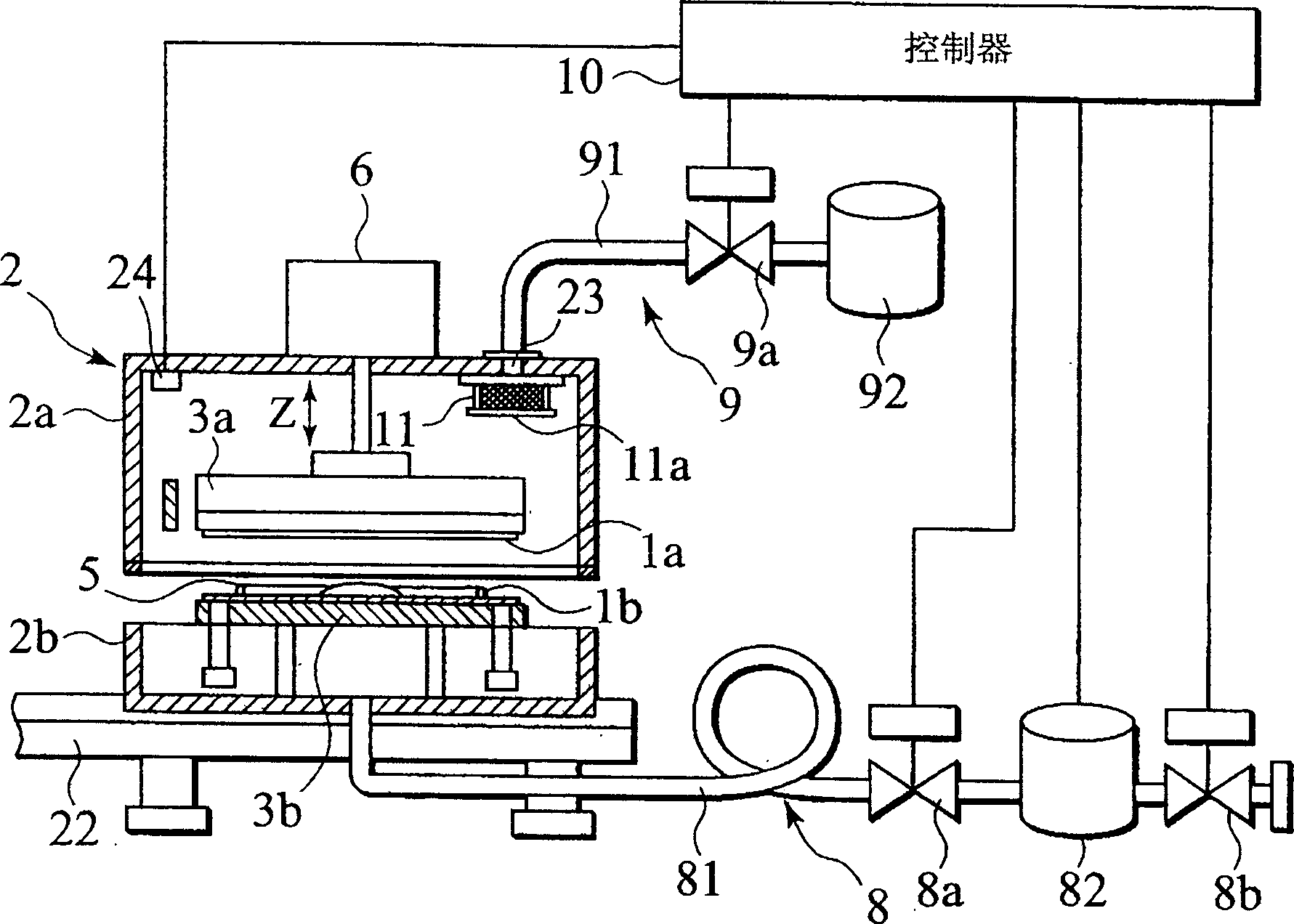

[0062] Refer to the following Figure 3 to Figure 13 , the embodiment of the substrate bonding device and the substrate bonding method according to the present invention will be described in detail. In these figures, with figure 1 with figure 2 The structures that are the same as the existing structures shown are assigned the same symbols, and detailed description thereof will be omitted.

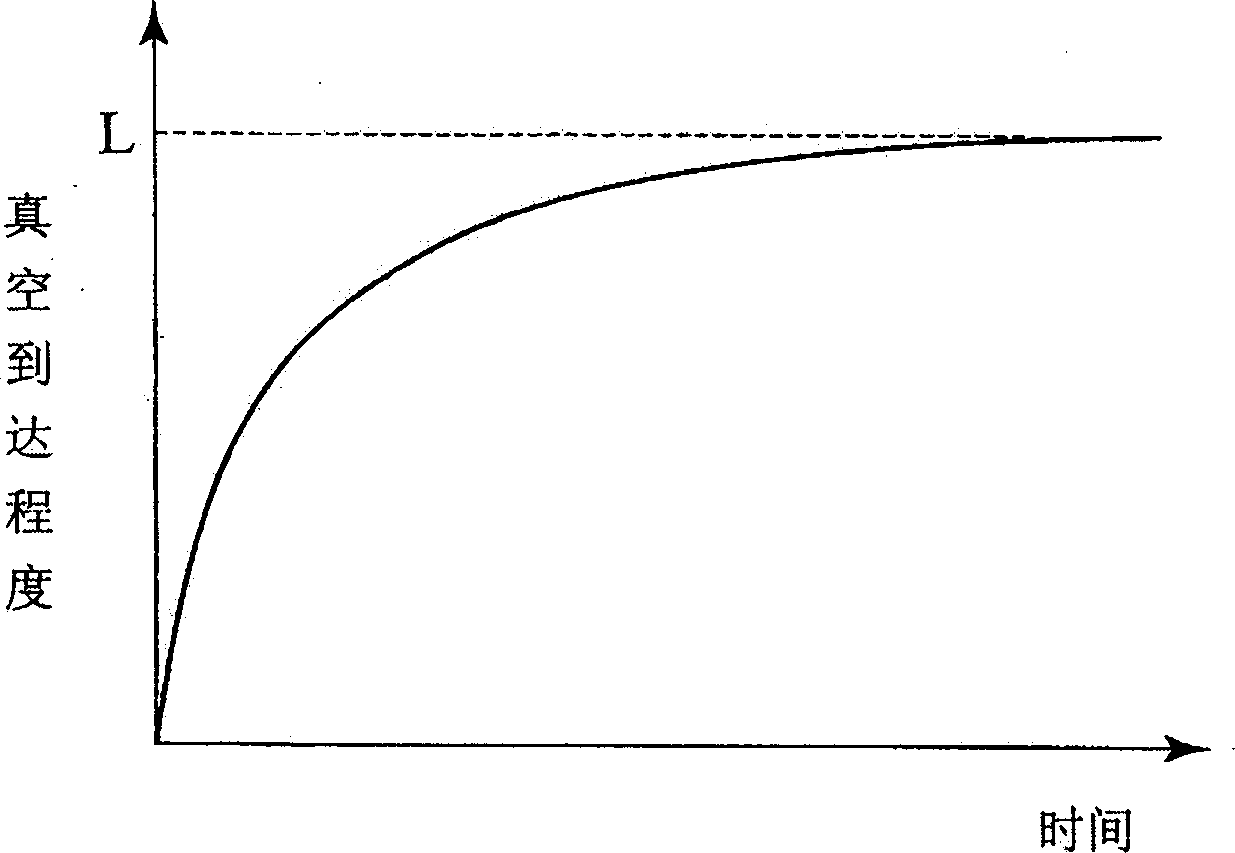

[0063] image 3 It is a sectional view showing the main part of the first embodiment of the substrate bonding device of the present invention used in the manufacture of drop-type liquid crystal display panels; Figure 4 yes means image 3 In the shown device, when the valve is controlled by the controller, the characteristic curve of the attainment degree of the vacuum degree in the chamber changes.

[0064] Such as image 3 As shown, a pair of upper and lower rectangular peeling substrates 1a, 1b are held on the bottom of the upper chuck 3a and the upper surface of the lower chuck 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com