Deodorant dust suppressant and preparation method

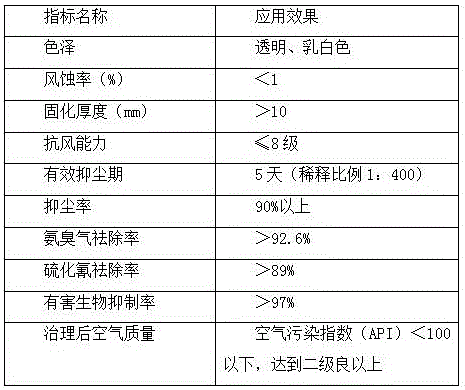

A dust suppressant and deodorizing type technology, which is applied in the field of deodorizing dust suppressant and its preparation, can solve problems such as peculiar smell, and achieve the effect of suppressing flying dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A deodorizing dust suppressant, which is prepared according to the following parts by weight: 50 parts of urea, 5 parts of polymer water-absorbing resin, 5 parts of dispersible latex powder, 5 parts of polyacrylamide, 5 parts of gypsum and deodorant. Among them, the deodorant is mainly composed of the following components in proportion by weight, 8 parts of zinc oxide, 10 parts of sodium dodecylsulfonate, 11 parts of sodium sulfate, 13 parts of sodium tripolyphosphate, 0.5 parts of carboxymethyl cellulose The deodorant is mixed with the mixture of urea, polymer water-absorbing resin, and dispersible latex powder in a ratio of 5:95.

[0014] When preparing, first add tap water in the reaction kettle, heat up to 45 °, the pH value of tap water is 6-8, then add urea, polymer water-absorbing resin, dispersible latex powder and deodorant, and stir until Completely dissolve and mix evenly, keep warm for 40 minutes, then pack out of the kettle.

Embodiment 2

[0016] A deodorizing dust suppressant, which is prepared according to the following parts by weight: 60 parts of urea, 10 parts of polymer water-absorbing resin, 10 parts of dispersible latex powder, 10 parts of polyacrylamide, 10 parts of gypsum and deodorant. Among them, the deodorant is mainly composed of the following components in proportion by weight, 10 parts of zinc oxide, 12 parts of sodium dodecylsulfonate, 13 parts of sodium sulfate, 16 parts of sodium tripolyphosphate, 1 part of carboxymethyl cellulose The deodorant is mixed with the mixture of urea, polymer water-absorbing resin, and dispersible latex powder in a ratio of 5:95.

[0017] When preparing, first add tap water in the reaction kettle, heat up to 45 °, the pH value of tap water is 6-8, then add urea, polymer water-absorbing resin, dispersible latex powder and deodorant, and stir until Completely dissolve and mix evenly, keep warm for 40 minutes, then pack out of the kettle.

Embodiment 3

[0019] A deodorizing dust suppressant, proportioned according to the following parts by weight: 70 parts of urea, 15 parts of polymer water-absorbing resin, 15 parts of dispersible latex powder, 15 parts of polyacrylamide, 15 parts of gypsum and deodorant. Among them, the deodorant is mainly composed of the following components in proportion by weight, 12 parts of zinc oxide, 15 parts of sodium dodecylsulfonate, 16 parts of sodium sulfate, 20 parts of sodium tripolyphosphate, 1.5 parts of carboxymethyl cellulose The deodorant is mixed with the mixture of urea, polymer water-absorbing resin, and dispersible latex powder in a ratio of 5:95.

[0020] When preparing, first add tap water in the reaction kettle, heat up to 45 °, the pH value of tap water is 6-8, then add urea, polymer water-absorbing resin, dispersible latex powder and deodorant, and stir until Completely dissolve and mix evenly, keep warm for 40 minutes, then pack out of the kettle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com