Energy-saving and environment-friendly factory production device

A production device, energy saving and environmental protection technology, applied in chemical instruments and methods, solid separation, smoke and dust removal, etc., can solve problems such as inconvenient cleaning, environmental pollution in the workshop, increase labor burden of workers, etc., and achieve the effect of speeding up the screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

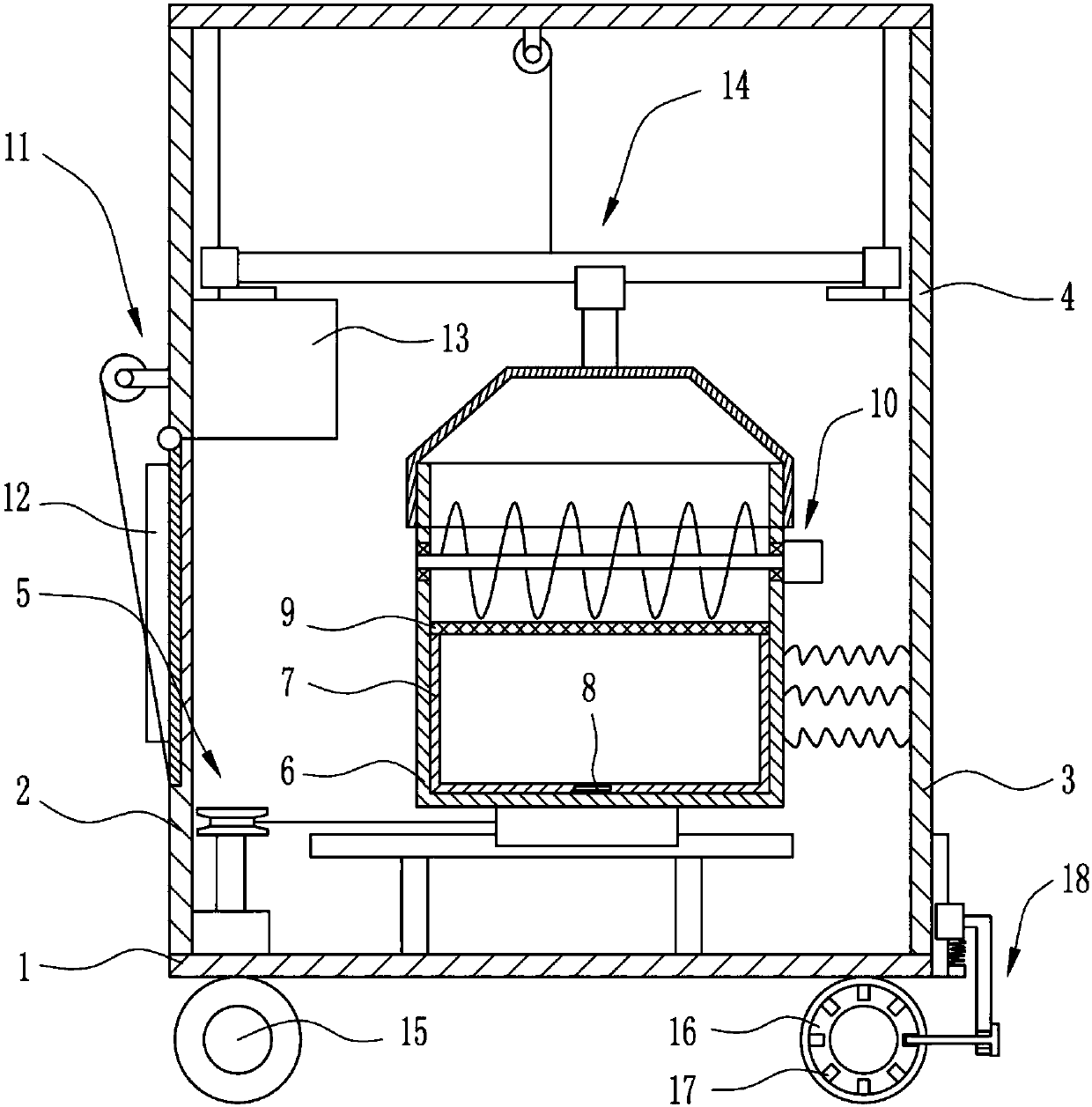

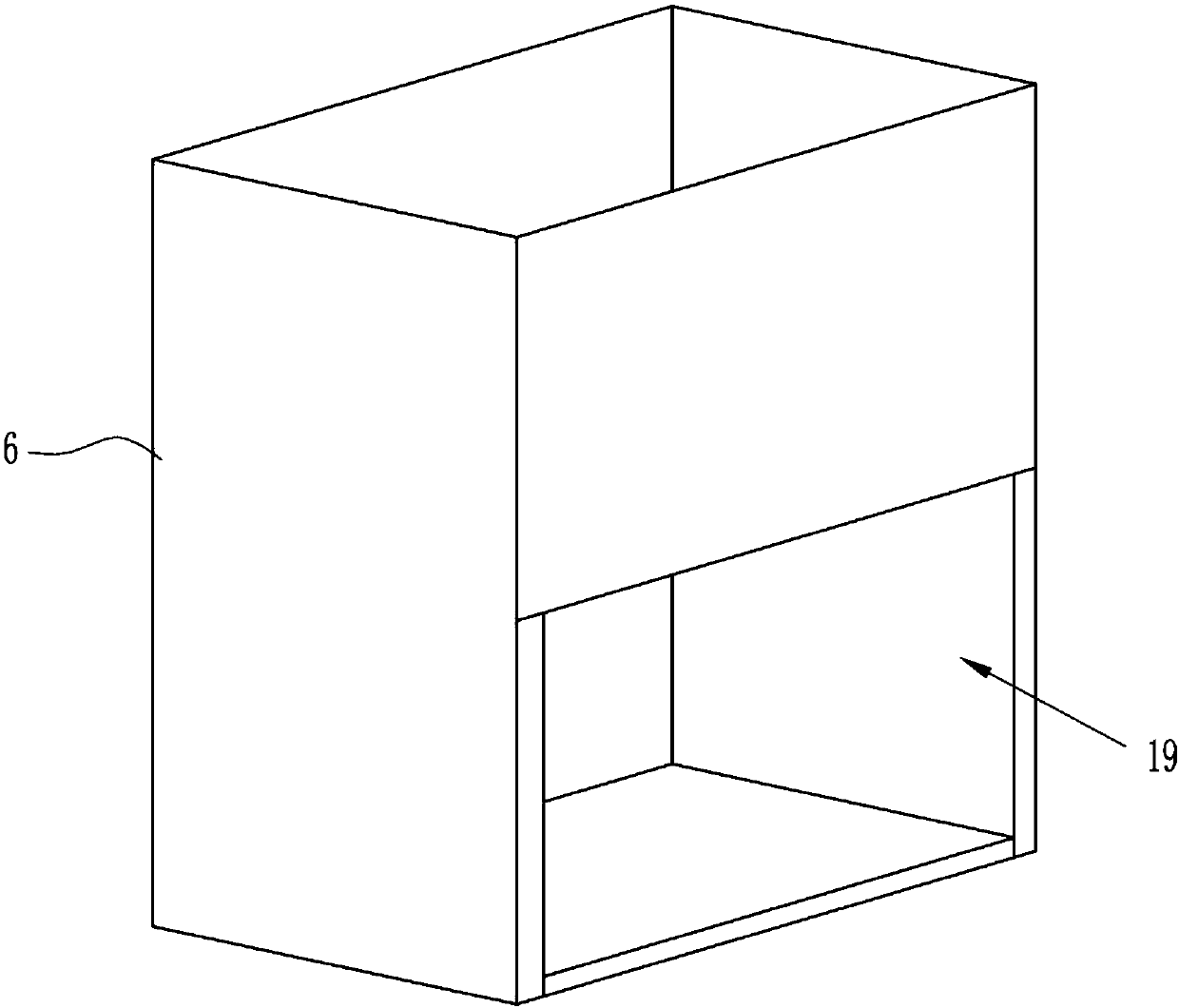

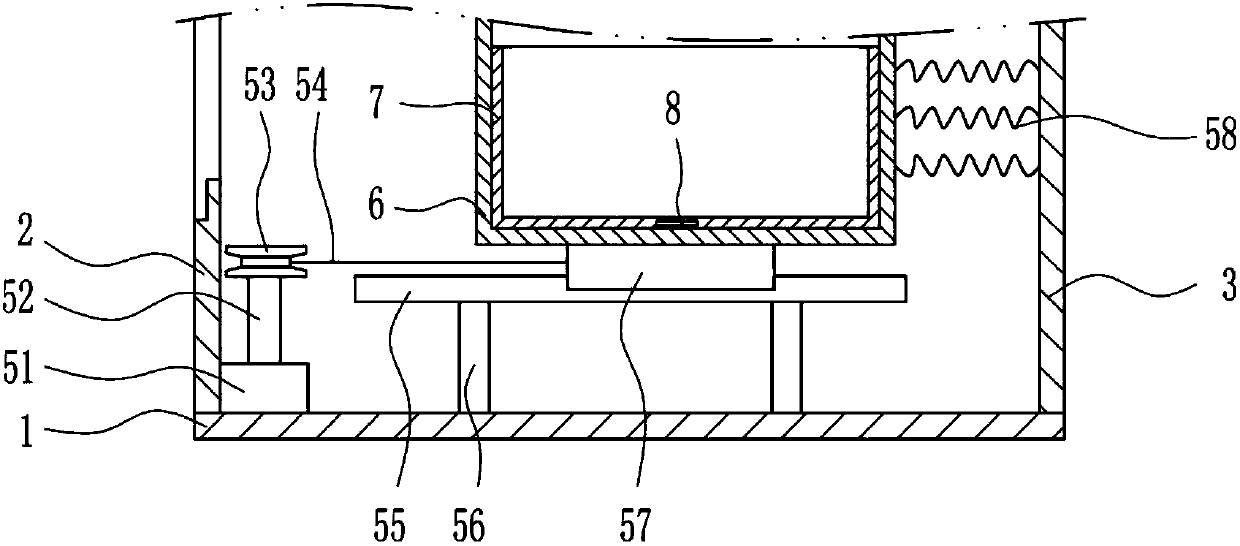

[0037] An energy-saving and environment-friendly chemical plant production device, such as figure 1 As shown, it includes a first mounting plate 1, a second mounting plate 2, a third mounting plate 3, a fourth mounting plate 4, an oscillation mechanism 5, a placement frame 6, a collection frame 7, a handle 8, a sieve plate 9, a punching Crushing mechanism 10, auxiliary mechanism 11, solar panel 12, battery 13, dustproof mechanism 14, wheels 15, circular mounting plate 16 and fixing mechanism 18; the second mounting plate 2 is fixedly connected to the top end of the first mounting plate 1, and the second The third mounting plate 3 is affixed to the other end of the top of the first mounting plate 1; the fourth mounting plate 4 is fixed to the top of the second mounting plate 2 and the third mounting plate 3, and the wheels 15 are installed on the bottom of the first mounting plate 1, round The mounting plate 16 is affixed to the side of the wheel 15, and the circular mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com