Efficient smashing device for pesticide production

A high-efficiency crushing and pesticide technology, applied in application, solid separation, filtration and screening, etc., can solve the problems of increased production cost, low screening efficiency, and insufficient crushing, and achieve the effects of increased screening speed, compact structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

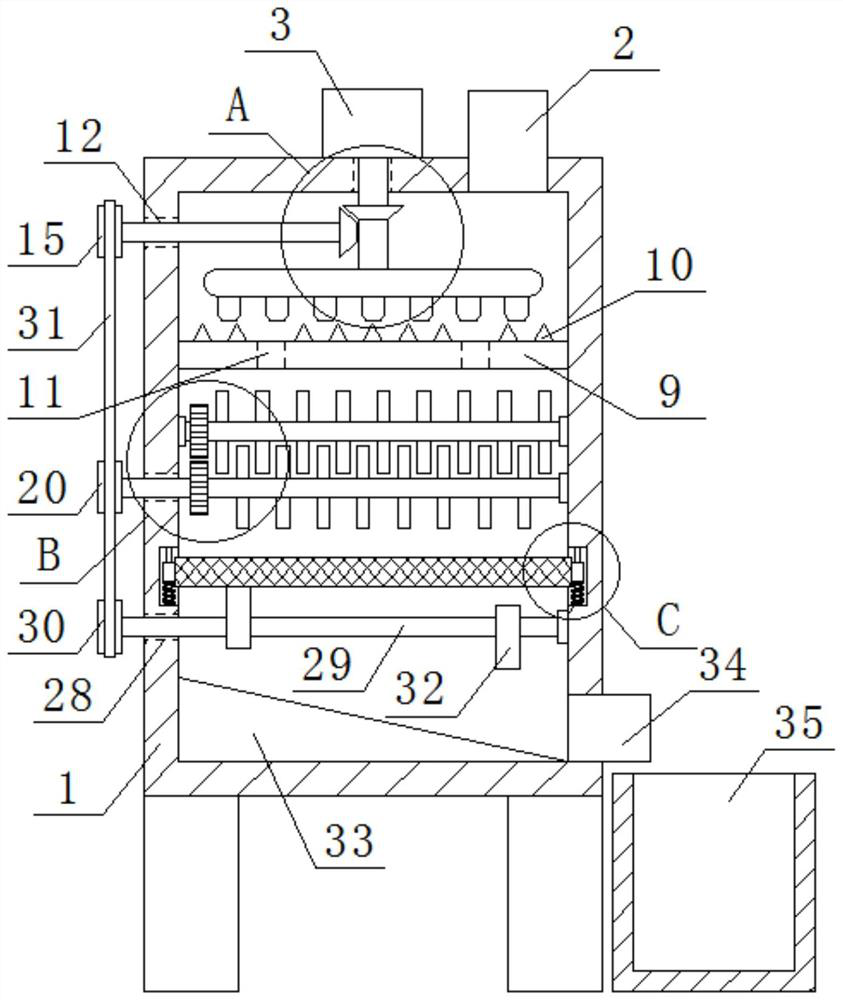

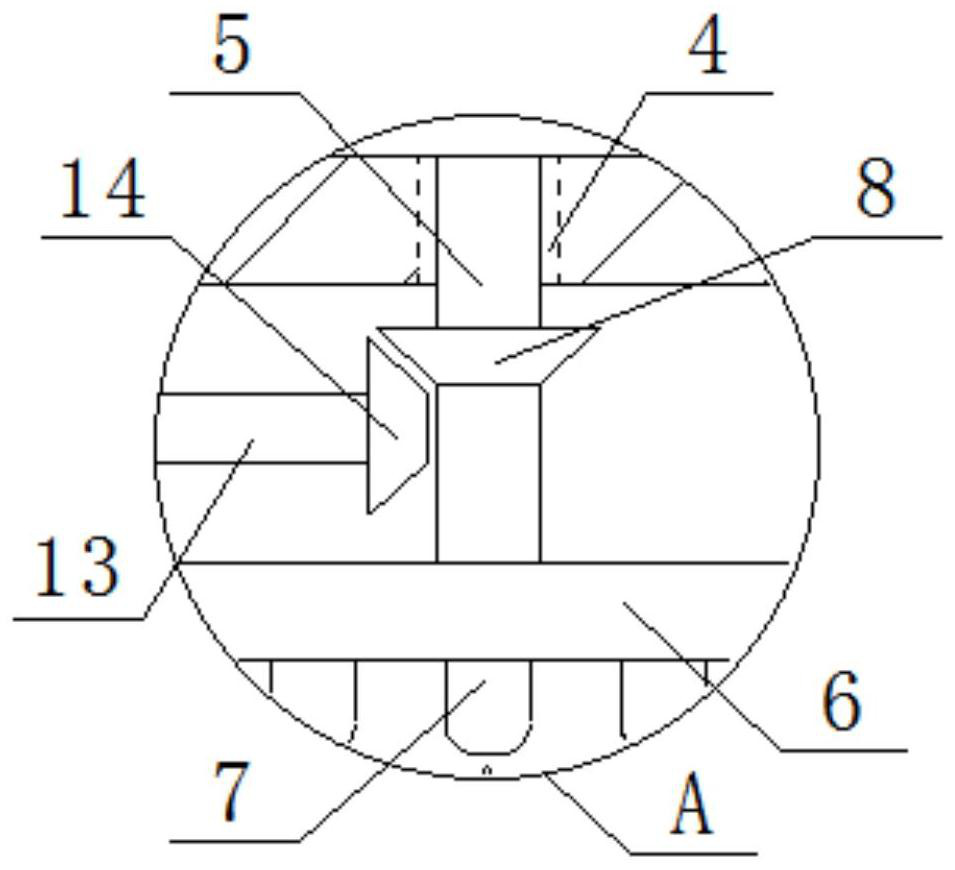

[0024] refer to Figure 1-5, a high-efficiency crushing device for pesticide production, comprising a crushing box 1, a feeding pipe 2 is fixedly installed on one side of the top of the crushing box 1, and the feeding pipe 2 communicates with the crushing box 1, and the top center of the crushing box 1 A motor 3 is installed in a fixed position, and a first through hole 4 is provided at the center of the top of the crushing box 1, and a rotating rod 5 is installed in the first through hole 4, and the top of the rotating rod 5 extends to the top of the crushing box 1, and is fixed Installed on the output shaft of the motor 3, the bottom end of the rotating rod 5 extends into the crushing box 1, and is fixedly sleeved with a turntable 6, and the bottom of the turntable 6 is equidistantly and evenly fixed with a plurality of grinding teeth 7, on the rotating rod 5 The first bevel teeth 8 located above the turntable 6 are fixedly sleeved, and a fixed plate 9 is fixedly installed i...

Embodiment 2

[0026] In the present invention, the first bevel teeth 8 and the second bevel teeth 14 are vertically arranged, and the first bevel teeth 8 are meshed with the second bevel teeth 14 , the rotation of the first bevel teeth 8 can drive the rotation of the second bevel teeth 14 .

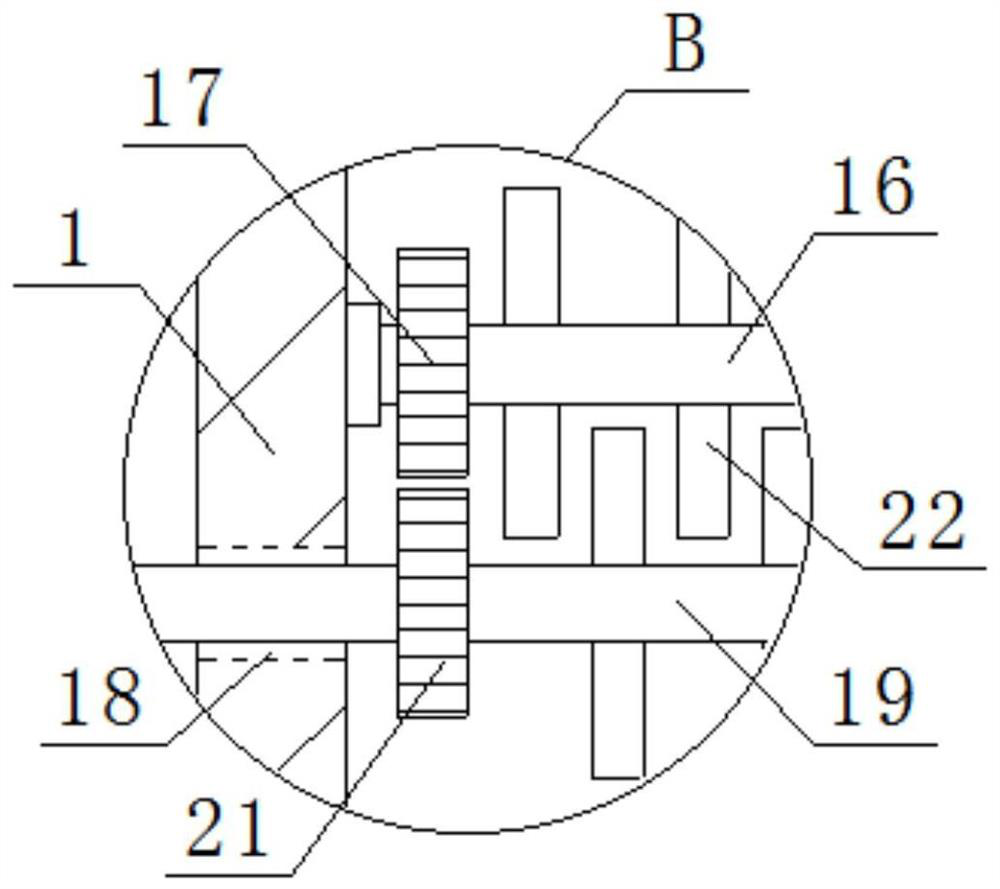

[0027] In the present invention, the second crushing rod 19 is fixedly sleeved with the driving gear 21 located in the crushing box 1, and the driving gear 21 is meshed with the driven gear 17, and the rotation of the driving gear 21 can drive the driven gear 17 to rotate in the opposite direction.

[0028] In the present invention, the top and bottom of the second crushing rod 19 and the first crushing rod 16 are uniformly fixed with a plurality of crushing blades 22, and the crushing blades 22 on the first crushing rod 16 and the blades on the second crushing rod 19 The crushing blades 22 are staggered, and the staggered crushing blades 22 can perform deep crushing processing on the raw material.

[...

Embodiment 3

[0034] refer to Figure 1-5 , a high-efficiency crushing device for pesticide production, comprising a crushing box 1, a feeding pipe 2 is fixedly installed on one side of the top of the crushing box 1, and the feeding pipe 2 communicates with the crushing box 1, and the top center of the crushing box 1 A motor 3 is installed in a fixed position, and a first through hole 4 is provided at the center of the top of the crushing box 1, and a rotating rod 5 is installed in the first through hole 4, and the top of the rotating rod 5 extends to the top of the crushing box 1, and is fixed Installed on the output shaft of the motor 3, the bottom end of the rotating rod 5 extends into the crushing box 1, and is fixedly sleeved with a turntable 6, and the bottom of the turntable 6 is equidistantly and evenly fixed with a plurality of grinding teeth 7, on the rotating rod 5 The first bevel teeth 8 located above the turntable 6 are fixedly sleeved, and a fixed plate 9 is fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com