Odor evaluation method for automobile part material by threshold method

A technology of auto parts and evaluation methods, applied in the field of auto parts, can solve problems such as inability to switch between different states, large errors, and evaluation interference, and achieve the effects of improving reliability, increasing screening, and increasing credibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: The dilution factor of a single substance is determined, select nonanone, a common compound in car seat leather, use a micro-sampling needle to take 1ul of nonanone and inject it into an odorless sampling bag filled with 10L high-purity nitrogen, and heat up to Heat in a high-temperature oven at 40°C for 60 minutes. Nonanone purity density: 0.82g / ml, the initial concentration in the air bag is 82mg / m 3 .

[0030] Connect the prepared odor bag to the dynamic odor olfactometer, set the dilution program, and four odor evaluators evaluate the gas samples at different dilution ratios, and use high-purity air as the dilution gas.

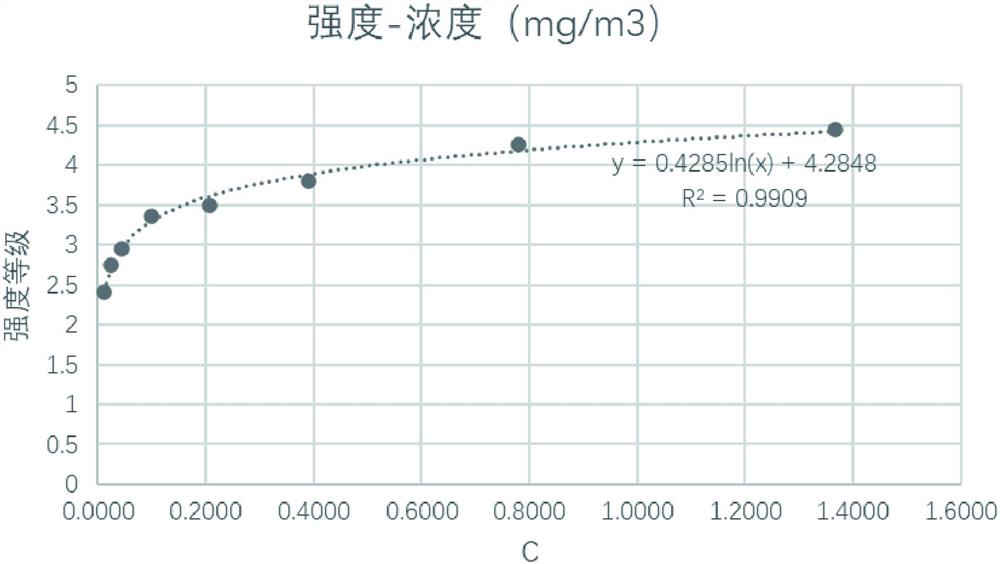

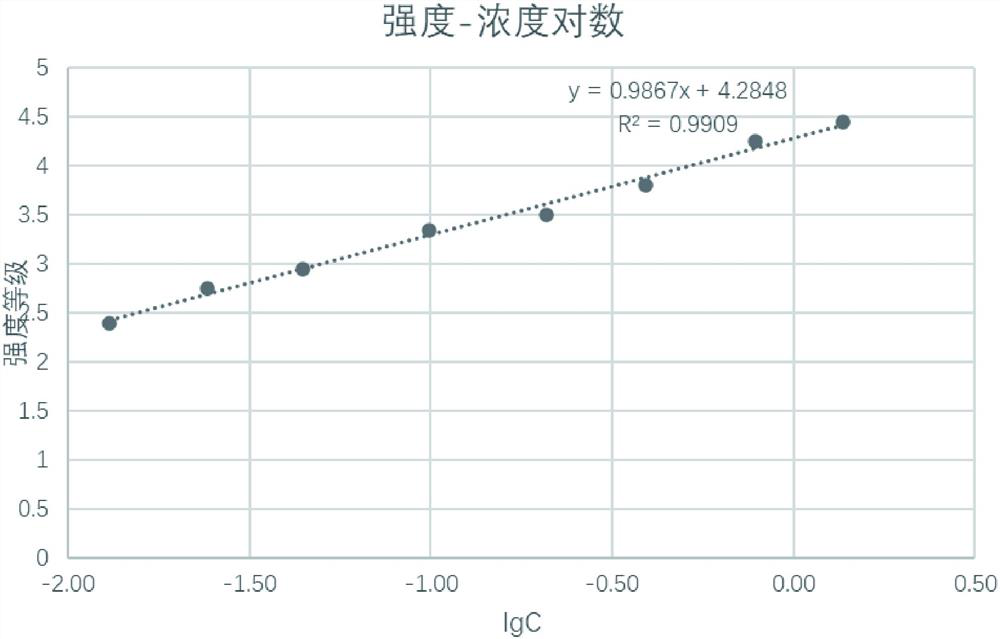

[0031] The concentration of each sample was calculated from the content of nonanone added and each dilution factor. The data statistics of different dilution multiples, concentrations, and average odor intensity are as follows:

[0032] Table 3, compound nonanone odor intensity concentration data table

[0033] serial nu...

Embodiment 2

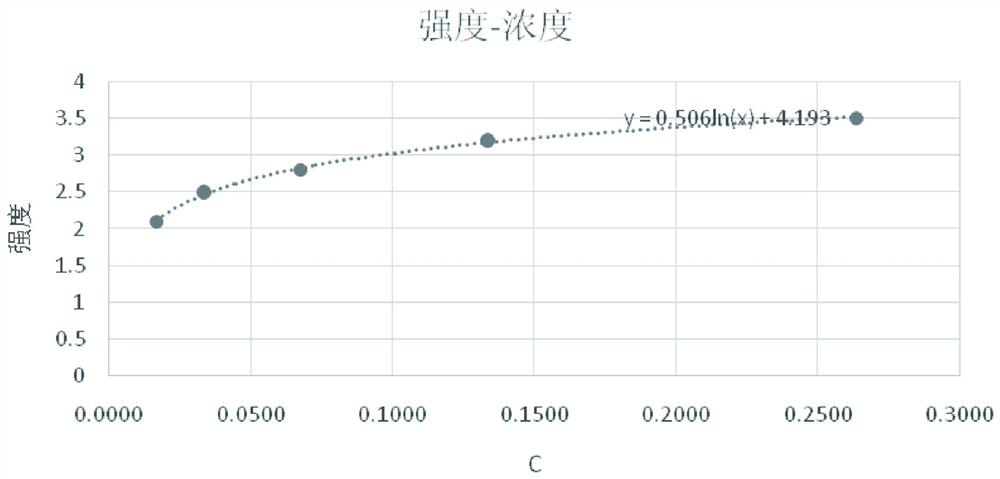

[0040] The determination of the dilution factor of embodiment 2 leather fabrics:

[0041] Put the leather fabric sample into an odorless sampling bag filled with 10L of high-purity nitrogen gas in a size of 10cm*20cm, and let it stand in an incubator at 40°C for 16 hours. After taking it out, cool it for 10 minutes. The initial concentration in the air bag is C 0 .

[0042] Connect the prepared odor bag to the dynamic odor olfactory apparatus, set the dilution program, and 4 odor evaluators evaluate the gas samples at different dilution ratios (the dilution gas uses high-purity air).

[0043] C 0 is a constant in the calculation and has no reflection in the final calculation, let C 0 =1mg / m 3 , by C 0 and each dilution factor to calculate the concentration of each sample. The data statistics of different dilution multiples, concentrations, and average odor intensity are as follows:

[0044] Table 5. Leather fabric odor intensity-relative concentration table

[0045] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com