Multistage pressure screening filter drum machine for sanitary towel primary pulp

A technology for sanitary napkins and filter cartridges is applied in the field of multistage pressure screening filter cartridge machines for sanitary napkin puree, which can solve the problems of clogging in the screen slits, reducing the effect of fluff puree, and poor effect, so as to ensure the effect of continuous screening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] as attached figure 1 to attach Figure 6 Shown:

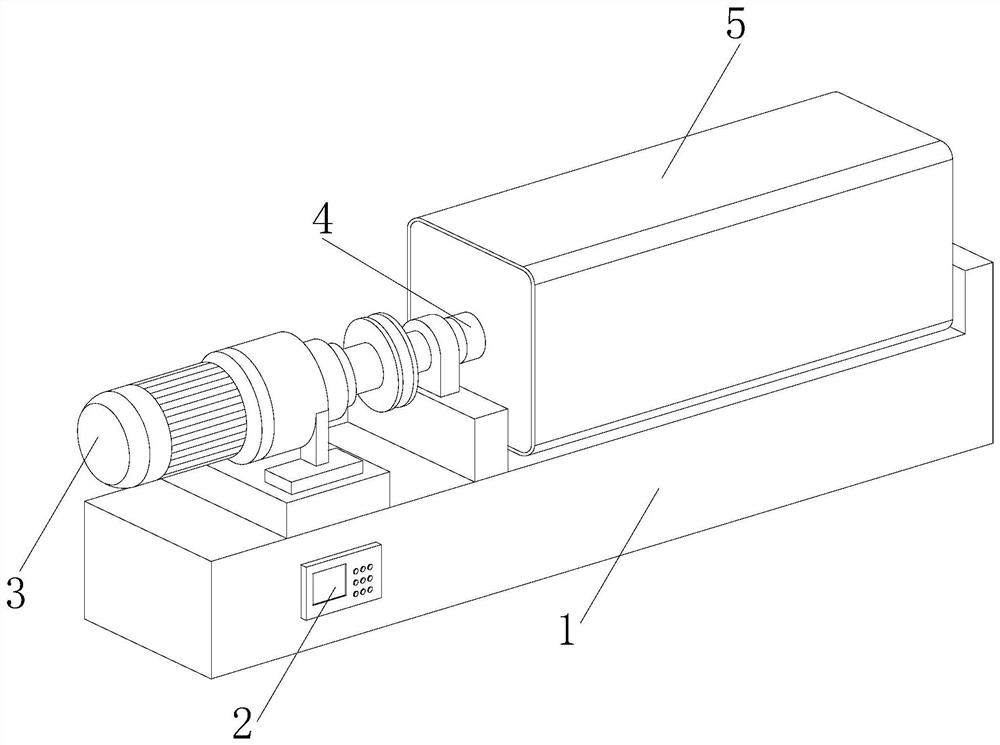

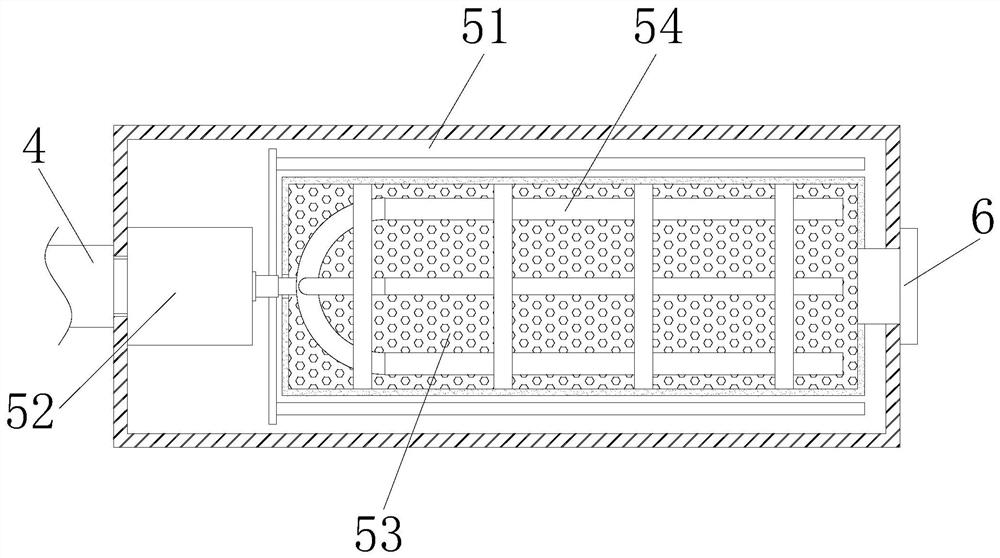

[0025] The present invention is a sanitary napkin raw pulp multi-stage pressure screening filter cartridge machine, the structure of which includes a fixed base 1, a control panel 2, a motor 3, a transmission shaft 4, a screening device 5, and a material inlet 6. The front surface of the fixed base 1 is Embedded with a control panel 2, the lower end of the motor 3 is fixedly mounted on the upper surface of the left end of the fixed base 1, and the output end of the motor 3 rotates synchronously with the transmission shaft 4, and the transmission shaft 4 is mounted on the left side of the screening device 5 with clearance fit. And the lower end of the screening device 5 is fixedly installed on the upper surface of the fixed base 1, and the inlet 6 is embedded in the right side of the screening device 5 and communicates with each other. The screening device 5 includes a screening outer box 51, a driving device 52, and a f...

Embodiment 2

[0033] as attached Figure 7 to attach Figure 8 Shown:

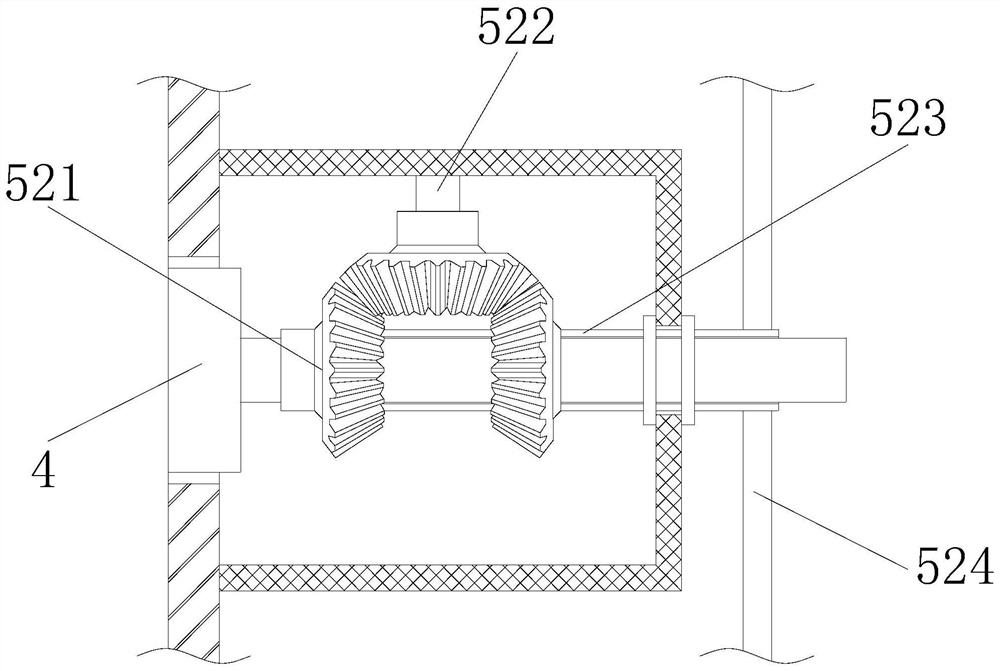

[0034] Wherein, the graded air pressure mechanism 54 includes an agitator 541, an extruded film 542, and an air injection mechanism 543. The head end of the agitator 541 is welded to the right end of the first bevel gear shaft 521, and an air injection mechanism 543 is arranged on the outside of the agitator 541. The inner surface of the air injection mechanism 543 is embedded with an extruding film 542, which is connected to each other. The extruding film 542 is made of rubber and has a certain resilience, which is beneficial to elastic reset after being rotated and extruded by the agitator 541, and at the same time, the air pressure Squeeze to the inside of the air injection mechanism 543, and there are four air injection mechanisms 543, which are equidistantly distributed on the outside of the agitator 541, forming multi-stage pressure, and performing multi-stage screening on the raw fluff pulp.

[0035] Wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com